Waxing device for production of sofa leather

A leather and sofa technology, which is applied in the field of waxing devices for sofa leather production, can solve the problems that the liquid wax of the spraying tube cannot be automatically cleaned, the leather of different thicknesses cannot be automatically applied, and the spraying tube is easy to be blocked, so as to prevent the spraying tube from being blocked, The effect of ensuring stability and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

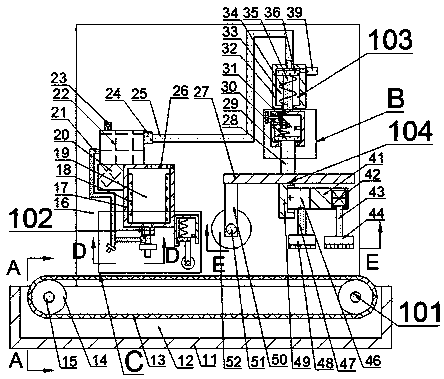

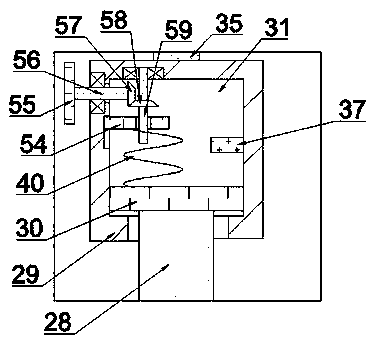

[0018] Combine below Figure 1 to Figure 6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] The present invention relates to a kind of waxing device that is used for sofa leather production, is mainly used in the waxing of sofa leather, the present invention will be further described below in conjunction with accompanying drawing of the present invention:

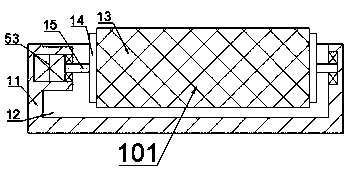

[0020] A waxing device for sofa leather production according to the present invention includes a feed box 11, and a feed chamber 12 with an opening facing upward is provided in the feed chamber 11, and a feed chamber 12 is provided in the feed chamber 12. In the feeding device 101 for conveying leather, the upper end surface of the rear side of the feeding chamber 12 is fixedly connected with a fixed plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com