Preparation method of novel high-selectivity positively-charged nanofiltration composite membrane

A high-selectivity, positively charged technology, applied in the field of membrane separation, can solve the problem of low discrimination and achieve the effect of high discrimination, simple operation and large water permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

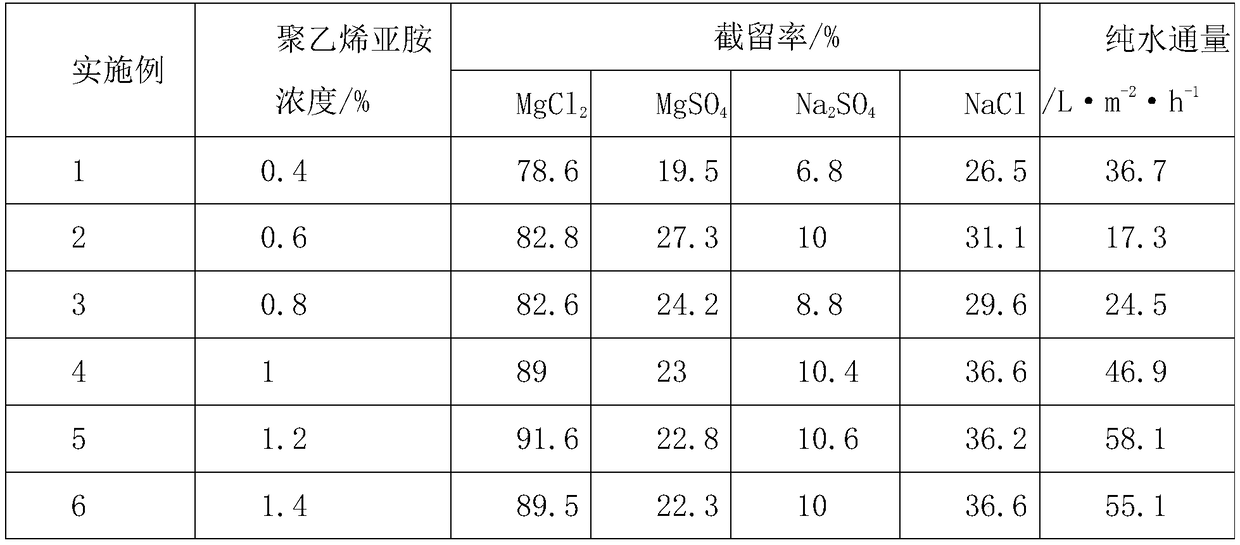

Embodiment 1-6

[0026] Prepare a cross-linking agent containing 0.1% trimesic acid and 0.15% sodium dodecylsulfonate, in which ethanol and water are used as a mixed solvent at a ratio of 1:1. Then the prepared cross-linking agent is uniformly coated on the surface of the polyethersulfone ultrafiltration membrane and fixed with an epoxy polyester frame. After standing for 5 minutes, the excess solution was removed, and placed in an oven at 60-80° C. for 5-10 minutes. The dried film is taken out, and a polyethyleneimine solution with a molecular weight of 10000 of 0.4% to 1.4% is coated on the surface of the film. After standing still for 1-3 minutes, excess solution was removed, and placed in an oven at 90-100° C. for 8-10 minutes. The prepared composite membrane was kept in deionized water.

[0027] In 500ppm salt solution, the operating temperature is 25°C, and the operating pressure is 0.3MPa to test the desalination and water permeability performance.

[0028] The results are shown in t...

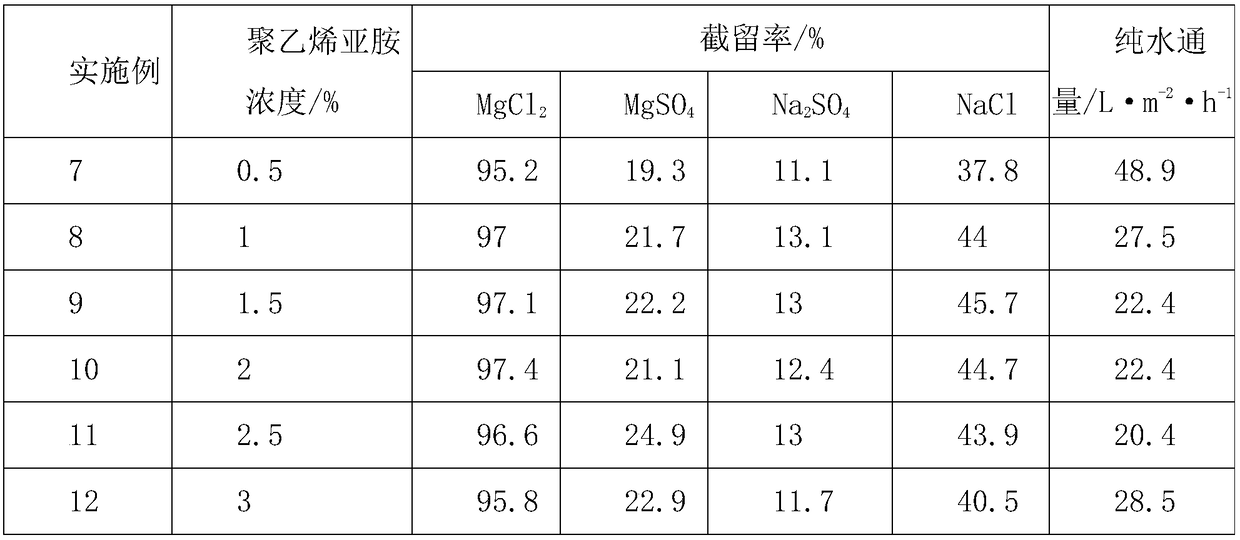

Embodiment 7-12

[0031] As in the above example, mix ethanol and water at a ratio of 1:1, and dissolve the miscible solvent with 0.1% trimesic acid and 0.15% sodium dodecylsulfonate, and apply it on the polyethersulfone ultrafiltration membrane After standing for 3-5 minutes, take it out in an oven at 30-50°C for 6-10 minutes. Then coat with 0.5%-3% 70000 polyethyleneimine aqueous solution, let it stand for 2-3 minutes, take it out after 10 minutes in an oven at 80-90°C, and store it in deionized water.

[0032] In 500ppm salt solution, the operating temperature is 25°C, and the operating pressure is 0.3MPa to test the desalination and water permeability performance.

[0033] The results are shown in the table below

[0034]

Embodiment 13-20

[0036] As described in the above examples, dissolve 0.1 trimesic acid and 0.15% sodium dodecylsulfonate in ethanol and water 1:1 solvent, apply it on the surface of polyethersulfone ultrafiltration membrane, and let it stand for 4 minutes , Remove the excess solution and place it in an oven at 30-40°C, take it out after 9-10 minutes. Apply 1.0% 10000 molecular weight polyethyleneimine aqueous solution on the surface of the membrane, remove the excess solution after standing for 1 to 2 minutes, put it in an oven at 90 to 100°C, take it out after 9 to 10 minutes, and store it in deionized water.

[0037] MgCl at 500ppm 2 solution, the operating temperature is 25°C, and the desalination and water permeability are tested under different operating pressures.

[0038] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com