Device and method for purifying n-hexane with N,N-dimethylacetamide solvent

A technology of dimethylacetamide and n-hexane, applied in distillation purification/separation, extractive distillation, etc., can solve the problems of high regeneration temperature, high energy consumption, high heat source grade, and achieve a small solvent ratio, low heat source grade, and product quality. high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

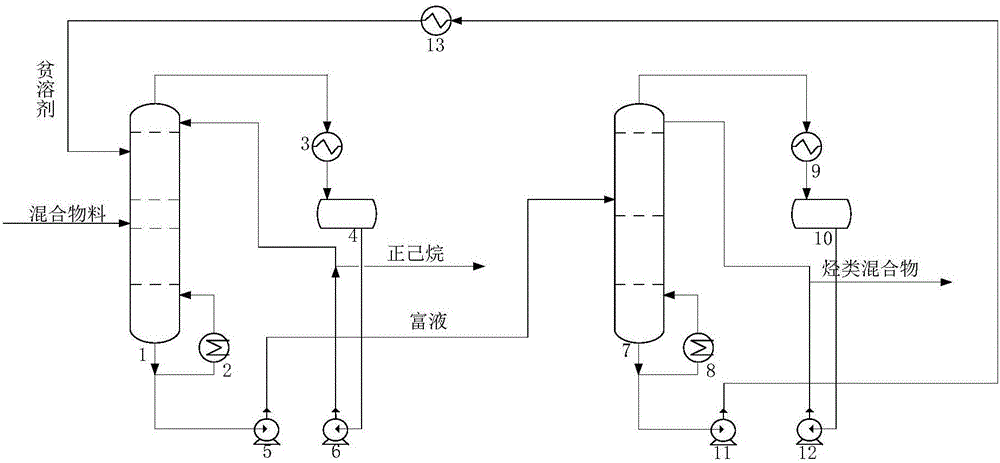

[0022] For a petrochemical company's 8,000-ton / year n-hexane plant, the content of n-hexane in the mixture of alkanes such as n-hexane, methylcyclopentane, 2,3-dimethylbutane, and 2,2-dimethylpentane The content of methylcyclopentane is 12.7%; the content of 2,3-dimethylbutane is 1.3%; the content of 2,2-dimethylpentane is 6.9%; the content of remaining hydrocarbons was 53.5%. After being separated by the device and method of the present invention, the purity of n-hexane reaches 99.1%; wherein, the content of methylcyclopentane is ≤0.8%; 200ppm; the purity of the N,N-dimethylacetamide solvent at the bottom of the solvent regeneration tower is greater than 99.9%.

[0023] Process parameters of the n-hexane tower: the position of the mixed feed plate is 50, the feed temperature is 109°C; the position of the solvent feed plate is 10, the solvent feed temperature is 40°C, the solvent ratio is 8; the operating pressure is 150kPa, and the tower top temperature is 82 °C, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com