A treatment process for copper smelting converter slag containing high-grade matte

A treatment process and converter slag technology, applied in the field of copper smelting converter slag treatment process, can solve problems such as affecting copper recovery, affecting the stability of process operation, and lengthening the flotation process, so as to improve processing capacity, save construction investment, and improve enterprises. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

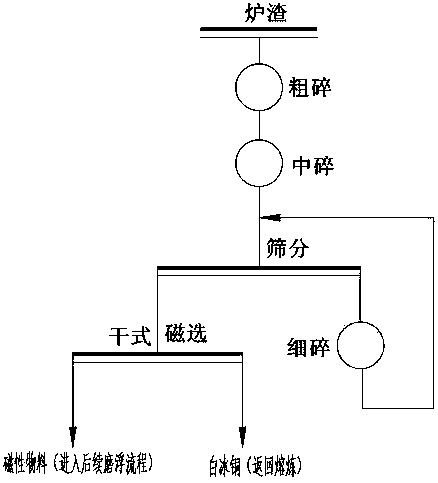

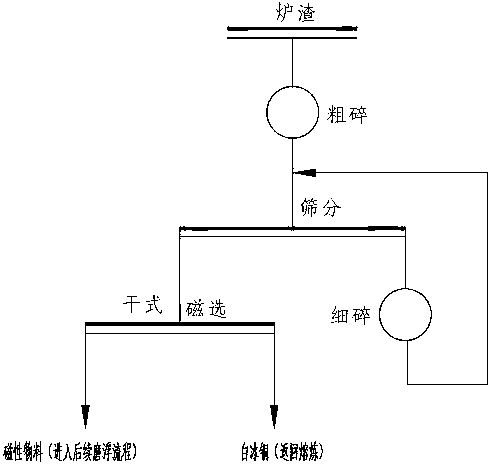

[0014] Now in conjunction with accompanying drawing, the present invention will be further described:

[0015] as attached figure 1 Shown, a kind of copper smelting converter slag treatment process containing high-grade matte is characterized in that:

[0016] S1. Converter slag enters the double-layer vibrating screen for screening after coarse crushing and medium crushing; the mesh size of the upper and lower layers of the double-layer vibrating screen is 40mm×40mm and 9mm×16mm respectively;

[0017] S2. The material on the sieve is finely crushed, and the finely crushed product returns to the double-layer vibrating screen to form a three-stage and one closed-circuit crushing and screening process to obtain a suitable particle size that meets the requirements of the subsequent process. The particle size of the material after crushing and screening is 80%. less than 10mm;

[0018] S3. The material under the vibrating screen enters the drum-shaped dry magnetic separator for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com