Device and process for separating C4 fractions by adopting binary mixed solvent

A binary mixing, carbon four fraction technology, applied in distillation purification/separation, hydrocarbon purification/separation, chemical industry, etc. The problem of large feed ratio, etc., can improve the solvent selectivity, reduce the temperature of the tower and kettle, and achieve the effect of small solvent ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

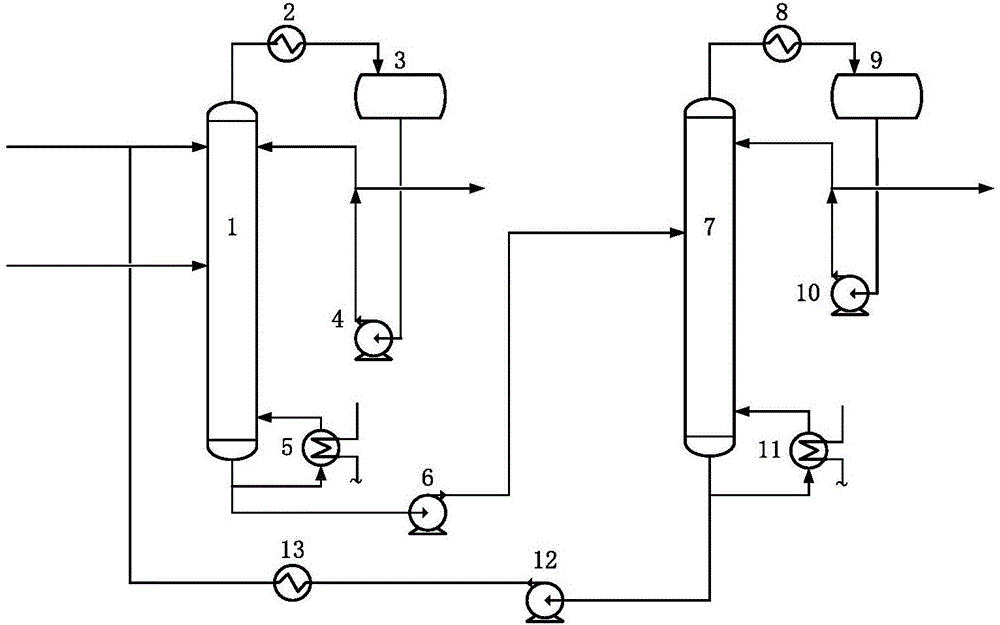

Image

Examples

Embodiment

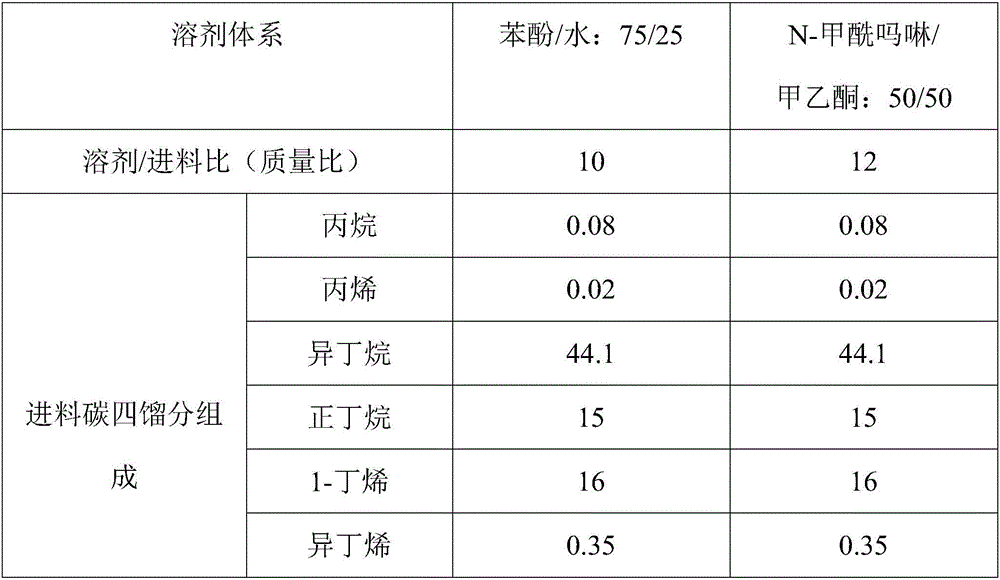

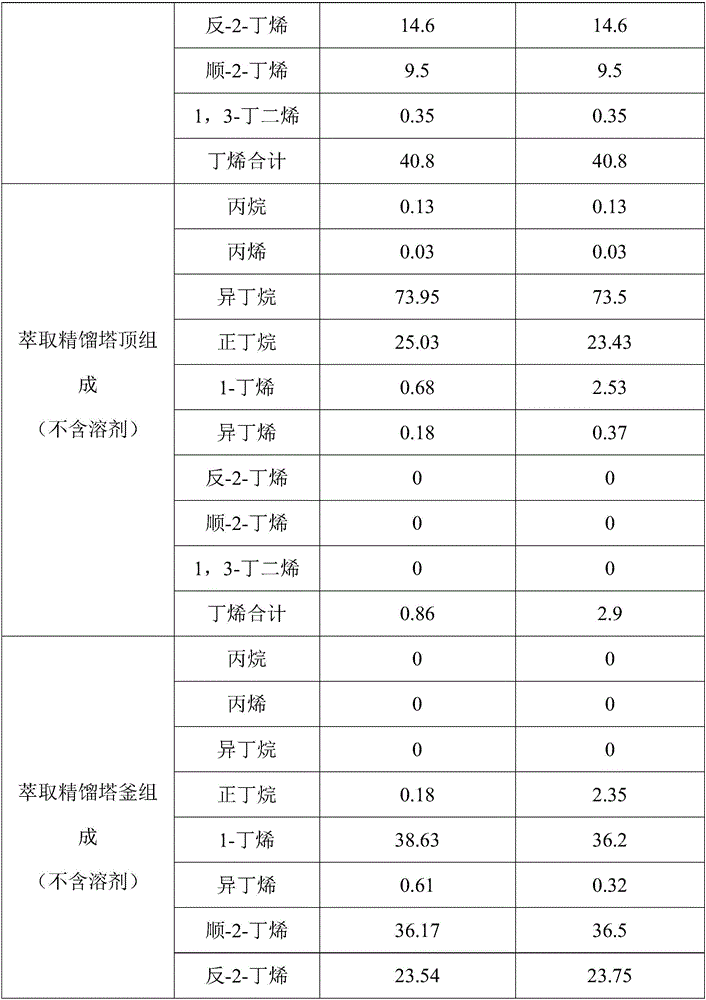

[0023] Taking a C4 separation process as an example, the process described in the present invention is adopted. The feed amount of C4 fraction is 10t / h, feed composition: propane 0.08%, propylene 0.02%, isobutane 44.1%, n-butane 15%, 1-butene 16%, isobutene 0.35%, trans-2- Butene 14.6%, cis-2-butene 9.5%, 1,3-butadiene 0.35%; solvent / feed ratio is 10 (mass ratio), mixed solvent amount is 100t / h, solvent composition is phenol 75% , water 25%. The theoretical plate number of the extractive distillation column is 165, the feeding position of the C4 fraction is the 84th plate, the mixed solvent feeding position is the 12th plate, the operating pressure is 0.5MPag, and the output of the extractive distillation column is 6t / h, the butane content in the mined product is controlled above 98.2%. The theoretical plate number of the stripper is 45, the feed position of butene-containing solvent is the 25th plate, the operating pressure is 0.4MPag, the output of the stripper top is 3.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com