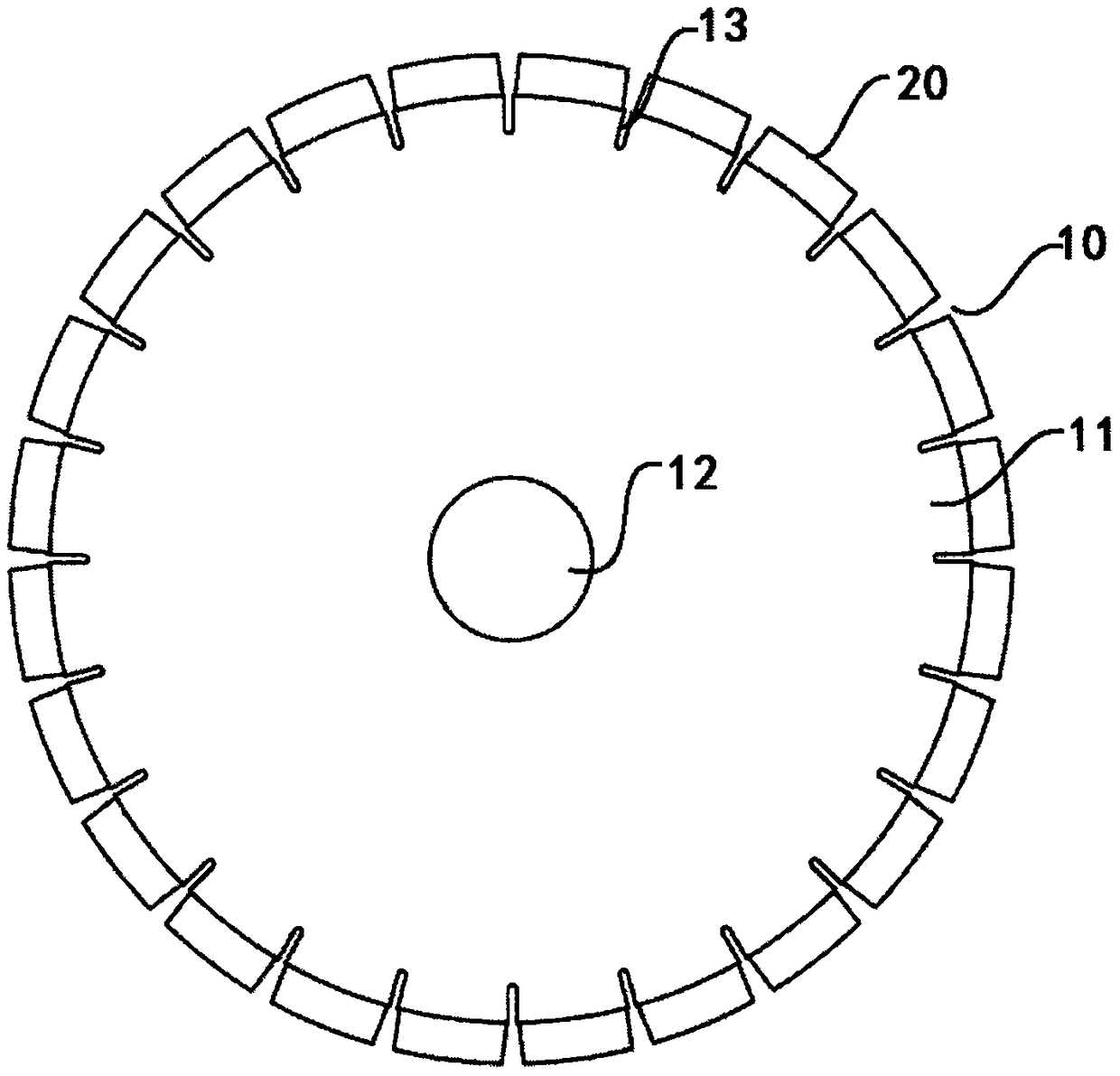

Energy-saving efficient diamond sawblade and manufacturing method thereof

A diamond saw blade and diamond cutting technology, which is applied in the direction of stone processing equipment, manufacturing tools, stone processing tools, etc., can solve the problems of unbalanced force on the diamond layer, occupying more costs, etc., and achieve fast cutting speed and low tool cost. The effect of stable cost and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

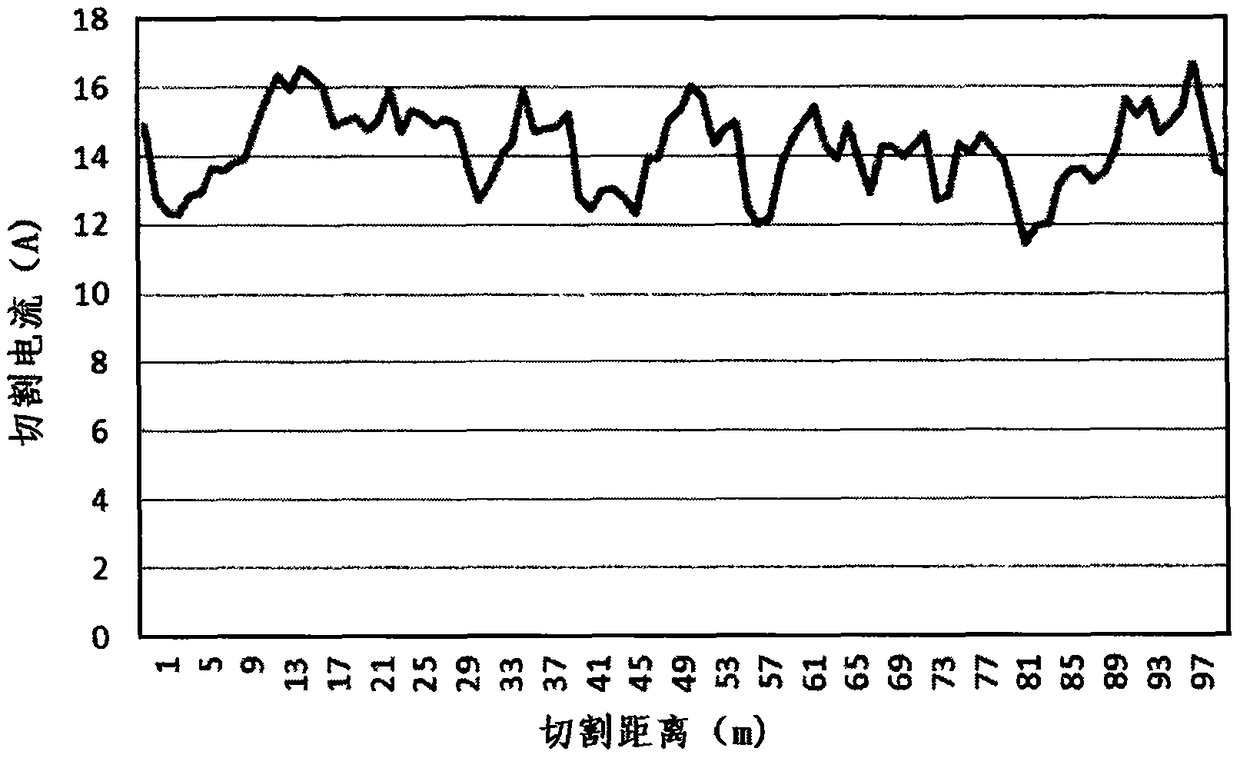

Examples

preparation example Construction

[0029] The preparation method of the energy-saving and high-efficiency diamond saw blade of the present invention is as follows:

[0030] 1. According to the requirements of the drawings, the steel plate is quenched and heat treated, tempered, laser cut into shape, tempered, plane ground, inner hole ground, outer circle ground, and deburred to make a circular steel substrate.

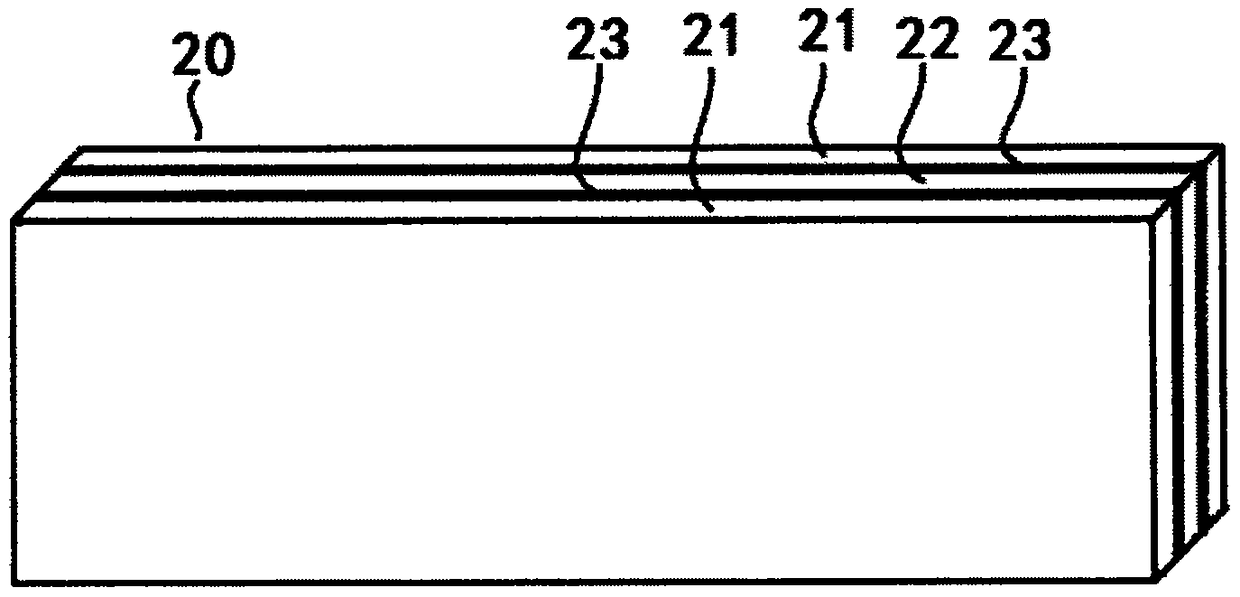

[0031] 2. Mix the carcass powder and diamond particles uniformly and cold-press to form and cold-press into a diamond blank in the middle and diamond blanks on both sides, and combine the diamond blank in the middle and the diamond blanks on both sides with the The metal blank layer forms a laminated structure according to the order and is hot-pressed and sintered, and the grinding wheel and abrasive belt are ground to make a composite multi-layer diamond cutter head. The temperature of hot-pressing sintering is 725-800 °C, and the pressure is 250-300kg / cm 2 , The holding time is 150-250 seconds.

[00...

Embodiment 1

[0039] Put 3.0kg of bronze powder, 0.3kg of tin powder, 0.01kg of graphite powder and 6.64kg of pre-alloyed powder into the mixing tank and mix for 30 minutes, then add 0.05kg of liquid paraffin and 0.35kg of diamond particles, continue After 3 hours of mixing, the powder is poured into the mold and cold-pressed to obtain the diamond blank layer in the middle;

[0040] Take 1.0kg of bronze powder, 0.3kg of tin powder and 8.65kg of pre-alloyed powder and mix them in the mixing tank for 30 minutes, then add 0.05kg of liquid paraffin and 0.30kg of diamond particles, and continue mixing for 3 hours. The powder is poured into the mold and cold-pressed to obtain the diamond blank layer on both sides;

[0041] Pour the bronze powder into the mold and cold press to form the metal blank layer;

[0042] The above-mentioned diamond blank layer and the metal binder blank layer are arranged at intervals to form a laminated structure (3 layers of diamond blank layers and 2 layers of metal ...

Embodiment 2

[0045] Put 4.0kg of bronze powder, 0.4kg of tin powder, 0.01kg of graphite powder and 5.55kg of pre-alloyed powder into the mixing tank and mix for 30 minutes, then add 0.04kg of liquid paraffin and 0.30kg of diamond particles, continue After 3 hours of mixing, the powder is poured into the mold and cold-pressed to obtain the diamond blank layer in the middle;

[0046] Put 1.5kg of bronze powder, 0.5kg of tin powder and 7.95kg of pre-alloyed powder into the mixing tank and mix for 30 minutes, then add 0.05kg of liquid paraffin and 0.30kg of diamond particles, and continue mixing for 3 hours. The powder is poured into the mold and cold-pressed to obtain the diamond blank layer on both sides;

[0047] Pour the bronze powder into the mold and cold press to form the metal blank layer;

[0048] The above-mentioned diamond green layer and the metal binder green layer are arranged at intervals to form a laminated structure (3 layers of diamond green layers and 2 layers of metal bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com