High-sharpness low-cost water drill tool bit and preparation method thereof

A low-cost, cutting-edge technology, applied in the direction of manufacturing tools, stone processing equipment, stone processing tools, etc., can solve the problems of unguaranteed product delivery, increase in the price of gang saw products, and the impact of verification on the supply market. Deterioration tendency, improvement of service life, effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

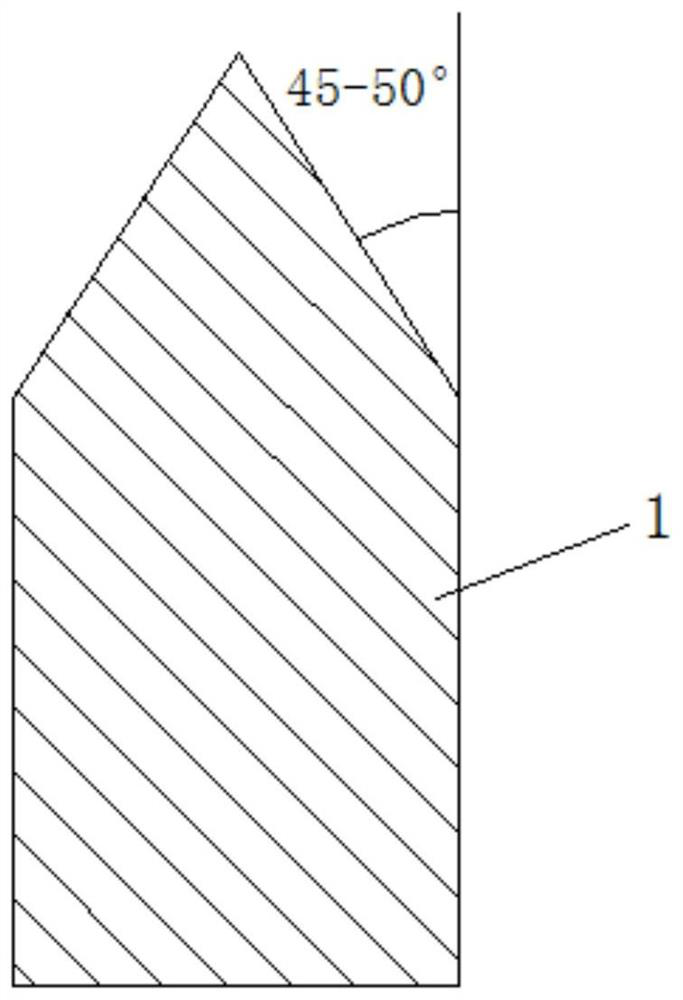

Image

Examples

Embodiment 1

[0039] A high-sharp low-cost rhinestone cutter head, which is sintered by mixing metal powder and diamond. The metal powder includes the following components by weight: 37 kg of iron, 30 kg of copper, 2 kg of tin, and 35 kg of iron-based alloy , 0.6 kg of zinc stearate; the ratio of the volume of diamond to the volume of metal powder is 30%, and the diamond specification is 30 mesh.

[0040] The iron-based alloy consists of 80% by weight of iron, 10% by weight of nickel, 5% by weight of copper and 5% by weight of zinc, and is prepared by an atomization method.

Embodiment 2

[0042] A high-sharp low-cost rhinestone cutter head, which is sintered by mixing metal powder and diamond. The metal powder includes the following components by weight: 47 kg of iron, 20 kg of copper, 5 kg of tin, and 27 kg of iron-based alloy , 0.3 kg of zinc stearate; the ratio of the volume of diamond to the volume of metal powder is 20%, and the diamond specification is 45 mesh.

[0043] The iron-based alloy consists of 80% by weight of iron, 10% by weight of nickel, 2% by weight of copper and 8% by weight of zinc, and is prepared by an atomization method.

Embodiment 3

[0045] A high-sharp low-cost rhinestone cutter head, which is sintered by mixing metal powder and diamond. The metal powder includes the following components by weight: 40 kg of iron, 25 kg of copper, 4 kg of tin, and 30 kg of iron-based alloy , 0.5 kg of zinc stearate; the volume of diamond accounts for 25% of the metal powder volume, and the diamond specification is 40 mesh.

[0046] The iron-based alloy consists of 80% by weight of iron, 10% by weight of nickel, 8% by weight of copper and 2% by weight of zinc, and is prepared by an atomization method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com