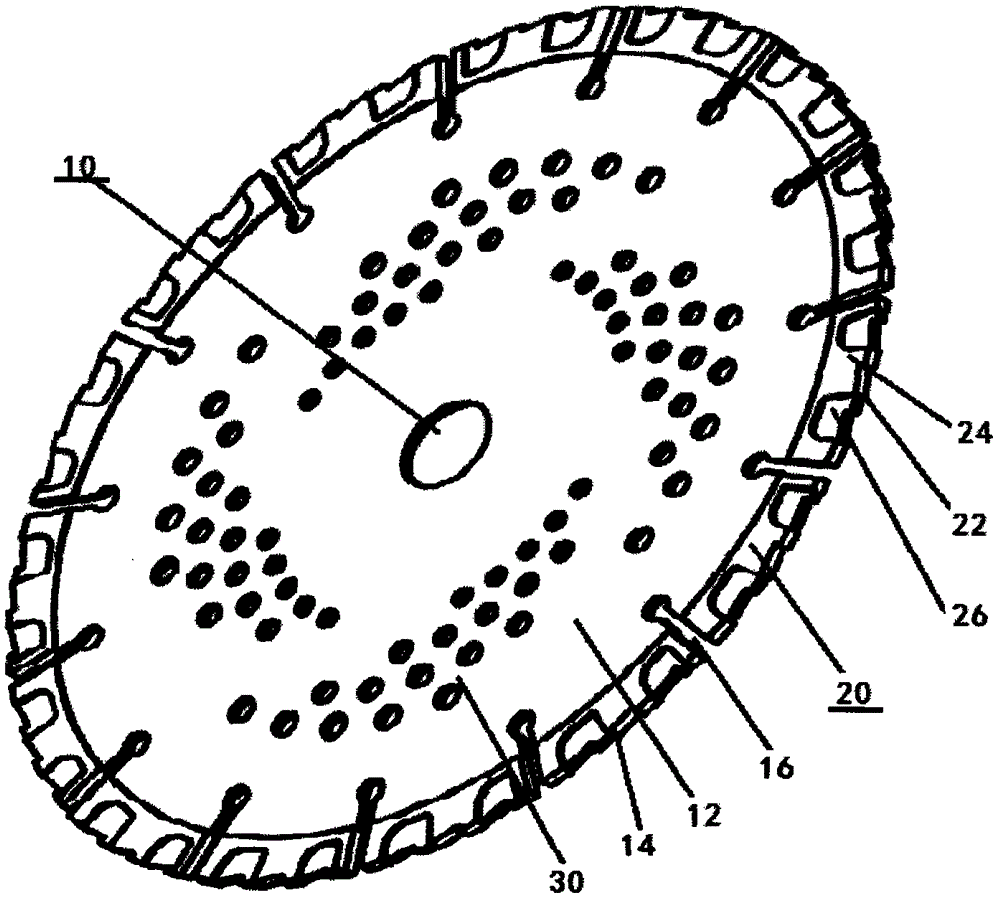

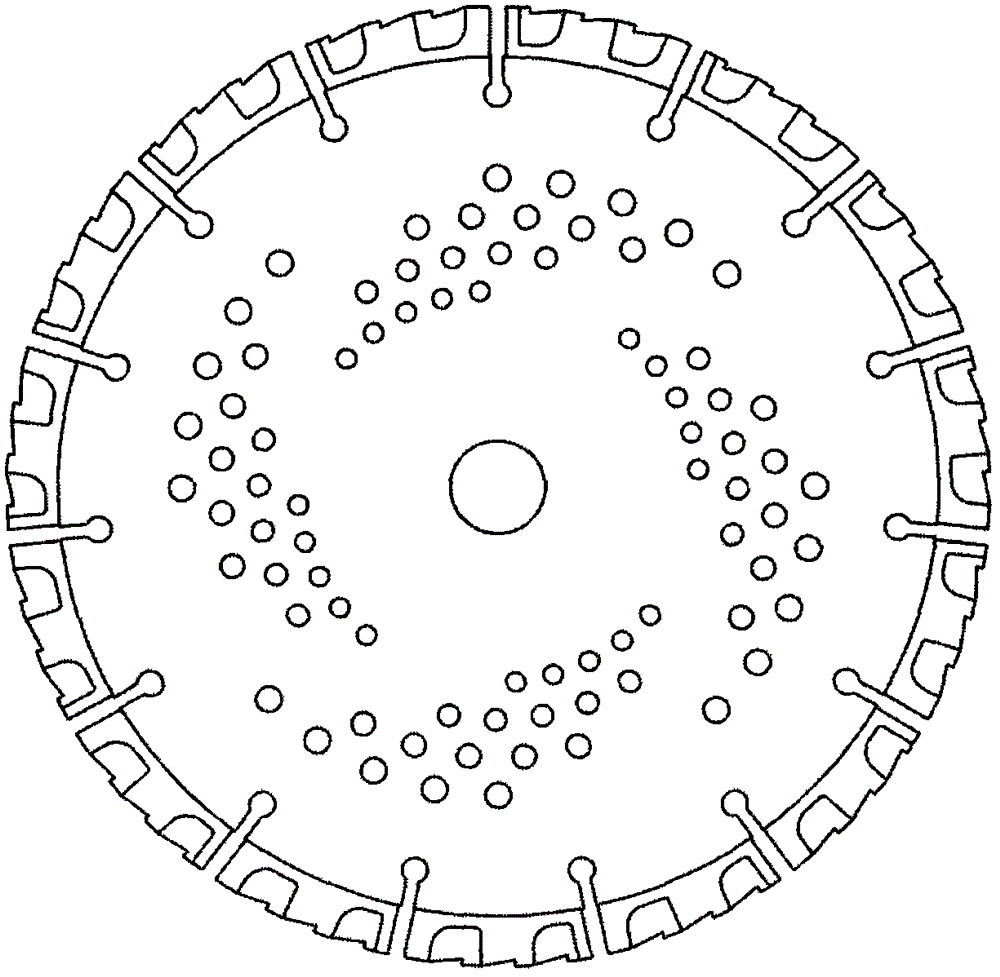

Saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method

A laser welding, sharp-edged technology, applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced load bearing capacity, loss of cutting ability, and decreased rigidity of the substrate, achieving small cutting deflection, Good cutting sharpness and narrow kerf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Concrete preparation process is as follows:

[0030] 1) Batching and granulation: According to the ratio, take atomized alloy powder, FCP alloy powder, copper powder, and nickel powder, add diamond, pre-mix to form a molding material, use a three-dimensional mixer to mix the material, and then use a manufacturing The molding material is obtained by granulating with a granulator, and the particle size is 50-200 μm.

[0031] 2) Cold pressing: adjust the tooling mold, put in the molding material and assemble it into the cold pressing forming steel mold for press molding to obtain the cutting sheet blank.

[0032] 3) Hot-press sintering: put the cut pieces into graphite molds, and carry out pressure sintering in a hot-press sintering press with a vacuum environment. The hot-press sintering temperature is about 800°C, and the unit pressure is 250-300kgf / cm 2 .

[0033] 4) The hot-pressed and sintered cutter head is deburred and arc-ground; together with the substrate, lase...

Embodiment 1

[0037] In this embodiment, the laser welding cutting sheet is prepared by the method of the present invention. Specifically, the cutting sheet of this embodiment is made of metal bond and diamond under vacuum conditions, sintered by hot pressing, and sintered The temperature is 800°C and the pressure is 280kgf / cm2 . Wherein, the metal bonding agent is composed of 18wt% FCP alloy powder, 30wt% copper powder, 6wt% nickel powder, and the rest atomized alloy powder. The concentration of diamond is 1.1ct / cm 3 , wherein the volume of 35 / 40 is 30%, the volume of 40 / 45 is 40%, and the volume of 50 / 60 is 30%. The FCP alloy powder contains the following components by weight: 20wt% of Ni, 8wt% of W, 10wt% of Co, 1.0wt% of C, 1.0wt% of WC, and the rest of Fe; And the above components are obtained by performing mechanical alloying treatment in a ball mill for 180-200 hours, and the particle size is 20-50nm. The atomized alloy powder contains by weight: 20wt% tungsten carbide, 10wt% coba...

Embodiment 2

[0039] In this embodiment, the laser welding cutting sheet is prepared by the method of the present invention. Specifically, the cutting sheet of this embodiment is made of metal bond and diamond under vacuum conditions, sintered by hot pressing, and sintered The temperature is 800°C and the pressure is 280kgf / cm 2 . Wherein, the metal bonding agent is composed of 20wt% FCP alloy powder, 25wt% copper powder, 8wt% nickel powder, and the rest atomized alloy powder. The concentration of diamond is 1.1ct / cm 3 , wherein the volume of 35 / 40 is 30%, the volume of 40 / 45 is 40%, and the volume of 50 / 60 is 30%. The FCP alloy powder contains the following components by weight: 20wt% of Ni, 8wt% of W, 10wt% of Co, 1.0wt% of C, 1.0wt% of WC, and the rest of Fe; And the above components are obtained by performing mechanical alloying treatment in a ball mill for 180-200 hours, and the particle size is 20-50nm. The atomized alloy powder contains by weight: 20wt% tungsten carbide, 10wt% co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com