Industrial welding and cutting gas modified additive as well as preparation method and application thereof

An industrial gas and additive technology, applied in the petroleum industry, welding equipment, metal processing equipment, etc., can solve the problems of insufficient acetylene gas cutting effect, low flame temperature, slow preheating, etc., to shorten the cutting preheating time, The effect of high product temperature and long flame front

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the industrial welding and cutting gas modified additive comprises the following steps:

[0040] S1, mix part of the solvent and polymerization inhibitor evenly to prepare A solution;

[0041] S2. First mix the smoke suppressant and the remaining amount of solvent evenly, then add the stabilizer and catalyst in turn, and mix well to obtain the B solution;

[0042] S3, mixing A solution and B solution evenly to prepare C solution;

[0043] S4. Compound the C solution and the oxygen generator in proportion, and stir evenly to obtain the modified additive.

[0044]Wherein, the amount of solvent used to prepare solution A is 30% to 50% of the total amount of solvents, and the amount of solvent used to prepare solution B is 50% to 70% of the total amount of solvents.

[0045] The preparation process is carried out under normal temperature and pressure, and the reactor used in the preparation process is a corrosion-resistant reactor.

[0046] The ...

Embodiment 1

[0055] A modified additive for industrial welding and cutting gas, comprising the following components:

[0056] components category Dosage (parts by weight) Methanol: acetone = 1:1 solvent 26 toluene Polymerization inhibitor 9 Xylene Polymerization inhibitor 9 Ferrocene smoke suppressant 25 Ether smoke suppressant 25 fuse catalyst 1.8 Aluminum powder stabilizer 0.3 Di-tert-butyl peroxide stabilizer 0.3 hydrogen peroxide Oxygen generator 55

[0057] The preparation method of the industrial welding and cutting gas modified additive comprises the following steps:

[0058] S1, put 50% of the mixed solvent into the reactor, then add toluene and xylene in proportion to the mixed solvent, stir evenly, and prepare A solution;

[0059] S2, firstly mix ether, ferrocene and remaining mixed solvent in another reactor uniformly, then add aluminum powder, di-tert-butyl peroxide and fuse in sequence, st...

Embodiment 2

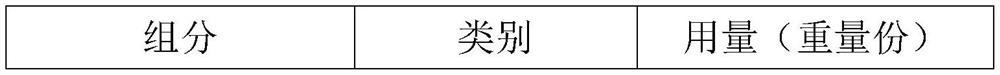

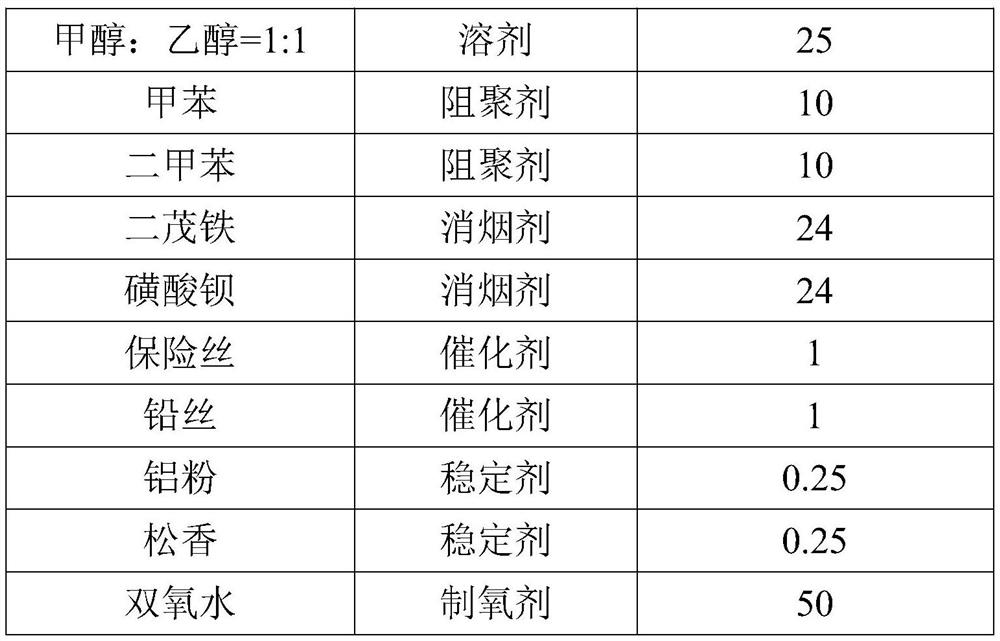

[0064] A modified additive for industrial welding and cutting gas, comprising the following components:

[0065]

[0066]

[0067] The preparation method of the industrial welding and cutting gas modified additive comprises the following steps:

[0068] S1, put 30% of the mixed solvent into the reactor, then add toluene and xylene in proportion to the mixed solvent, stir evenly, and prepare A solution;

[0069] S2, first mix ferrocene, barium sulfonate and remaining mixed solvent in another reactor, then add aluminum powder, rosin, lead wire and fuse in turn, stir and mix evenly, and prepare B solution;

[0070] S3, mixing A solution and B solution evenly to prepare C solution;

[0071] S4. Compound C solution and oxygen generator in proportion, and stir evenly to obtain modified additive 2#.

[0072] The modified combustion-supporting additive 2# is added into a container filled with liquefied petroleum gas at 2.5 wt%, and the modified industrial welding and cutting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com