High-strength saw blade production technology

A production process, high-strength technology, applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems affecting the durability of saw blades, etc., to achieve high material utilization, narrow cutting seam, high welding seam hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

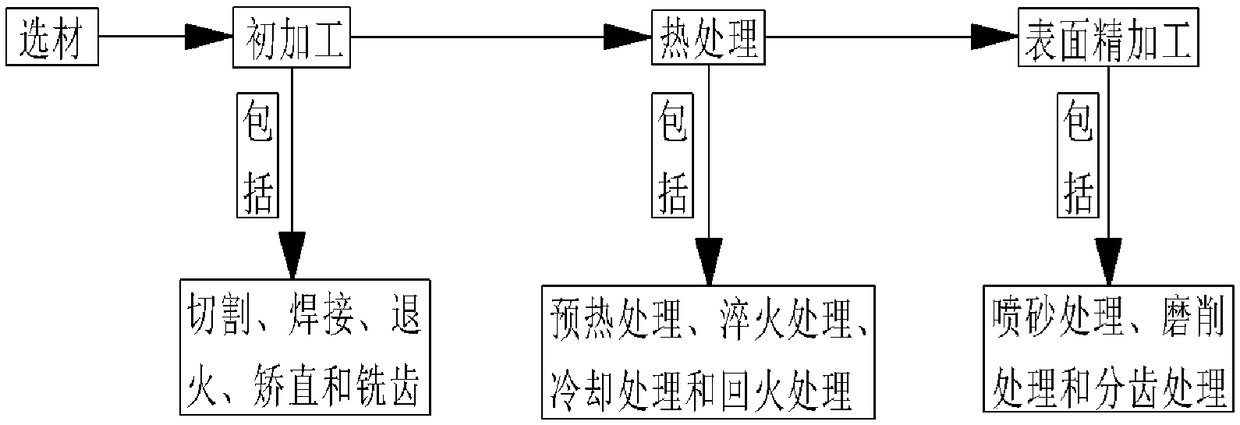

[0025] Example one, please refer to figure 1 In this embodiment, a high-strength saw blade production process includes the following steps:

[0026] S1. Material selection: M42 high-speed steel is selected for sawtooth material, and X32 spring steel is selected for saw back material;

[0027] S2. Preliminary processing: The processing steps are cutting, welding, annealing, straightening and milling. According to the size of the saw blade produced, when cutting M42 high-speed steel and X32 spring steel, the cutting is carried out by a wire cutting machine. When the material is not deformed by force, and under the control of CNC commands, the machining accuracy is high, the cutting seam is narrow, and the material utilization rate is high; then the cut M42 high-speed steel and X32 spring steel are welded together, and the welding is high-frequency induction brazing Technology for welding, which uses the principle of induction heating to heat M42 high-speed steel and X32 spring steel...

Embodiment 2

[0030] Example two, please refer to figure 1 In this embodiment, a high-strength saw blade production process includes the following steps:

[0031] S1. Material selection: M42 high-speed steel is selected for sawtooth material, and X32 spring steel is selected for saw back material;

[0032] S2. Preliminary processing: The processing steps are cutting, welding, annealing, straightening and milling. According to the size of the saw blade produced, when cutting M42 high-speed steel and X32 spring steel, the cutting is carried out by a wire cutting machine. When the material is not deformed by force, and under the control of CNC commands, the machining accuracy is high, the cutting seam is narrow, and the material utilization rate is high; then the cut M42 high-speed steel and X32 spring steel are welded together, and the welding is high-frequency induction brazing Technology for welding, which uses the principle of induction heating to heat M42 high-speed steel and X32 spring steel...

Embodiment 3

[0035] Example three, please refer to figure 1 In this embodiment, a high-strength saw blade production process includes the following steps:

[0036] S1. Material selection: M42 high-speed steel is selected for sawtooth material, and X32 spring steel is selected for saw back material;

[0037] S2. Preliminary processing: The processing steps are cutting, welding, annealing, straightening and milling. According to the size of the saw blade produced, when cutting M42 high-speed steel and X32 spring steel, the cutting is carried out by a wire cutting machine. When the material is not deformed by force, and under the control of CNC commands, the machining accuracy is high, the cutting seam is narrow, and the material utilization rate is high; then the cut M42 high-speed steel and X32 spring steel are welded together, and the welding is high-frequency induction brazing Technology for welding, which uses the principle of induction heating to heat M42 high-speed steel and X32 spring ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com