Double-wire annular diamond fretsaw horizontal cutting method and numerical control jade fretsaw machine

A technology of diamond wire saw and wire saw machine, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

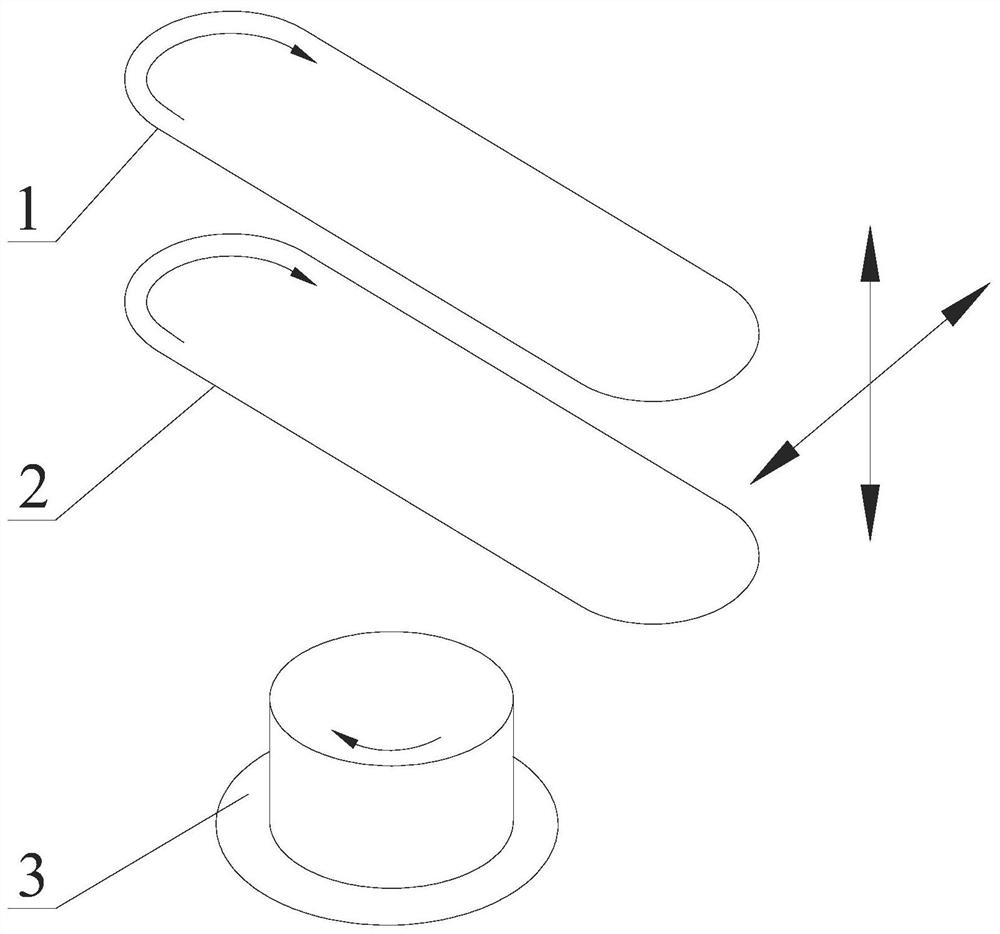

[0036] see figure 1 Shown, a kind of two-wire annular diamond wire saw flat cutting method, comprises the following steps:

[0037] S1, fixing the workpiece to be cut;

[0038] S2. Adjusting the vertical parallel distance between the first cutting loop line 1 and the second cutting loop line 2;

[0039] S3. After the spacing is adjusted, control the first cutting loop 1 and the second cutting loop 2 to feed the workpiece to be cut at the same time. The vertical parallel distance between the first cutting loop line 1 and the second cutting loop line 2 is 8-1000 mm. In the step S1, the workpiece to be cut is fixed on the rotating platform 3, and the rotating platform 3 is provided with a rotating support seat and a servo motor driving the rotating platform 3 to rotate.

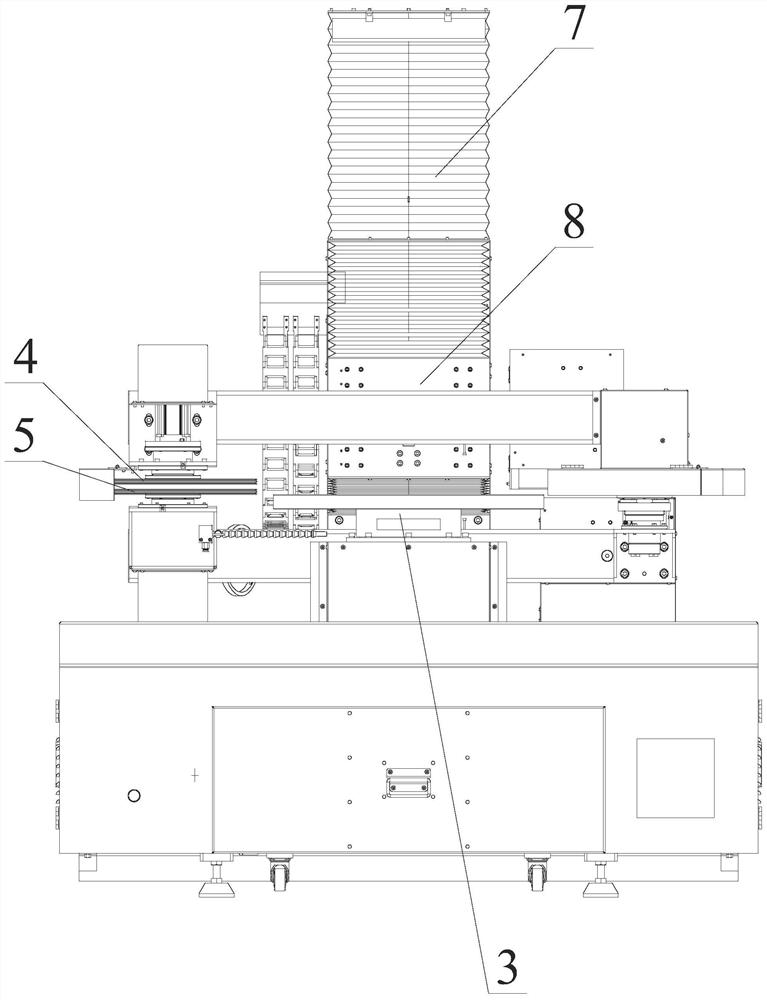

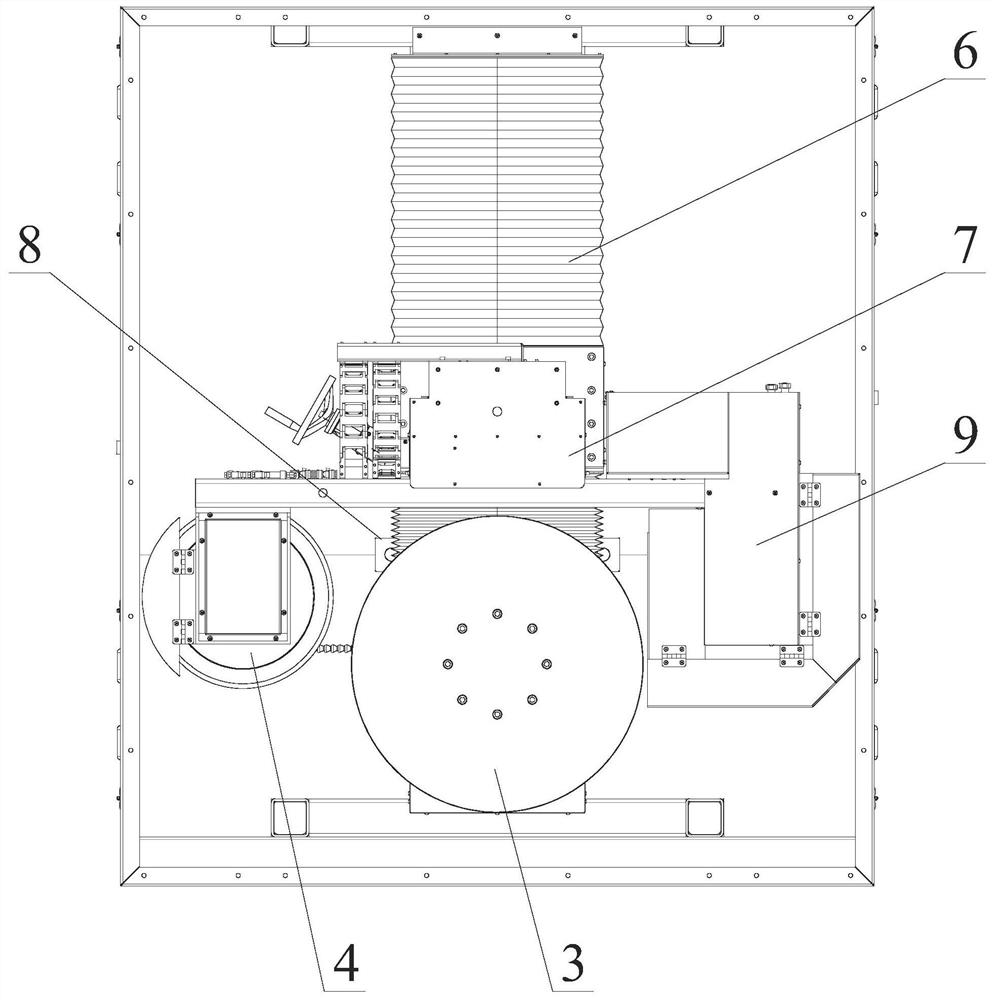

[0040] see Figure 2-8 As shown, the CNC jade wire saw machine according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com