Automatic casting system for casting machine

An automatic pouring and pouring machine technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of affecting the pouring appearance, casting quality, uneven wear of the end of the stopper rod, and inconvenient adjustment of the stopper rod, etc. , to achieve the effects of avoiding uneven wear, precise distance adjustment, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

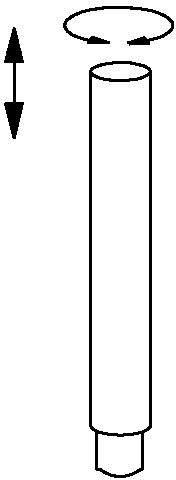

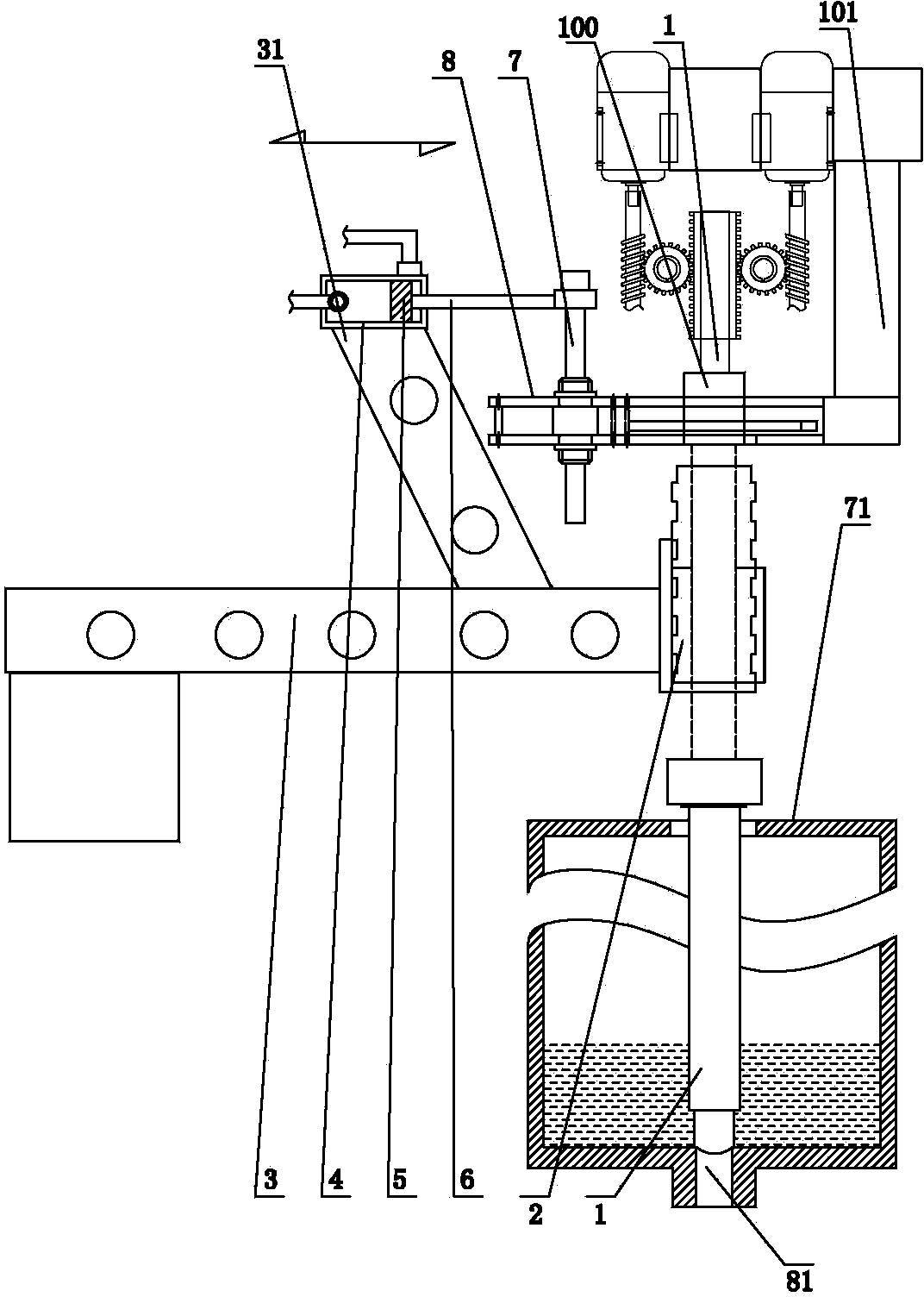

[0016] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It can be seen from the figure that the anti-drip stopper mechanism of the pouring machine includes a stopper rod 1, a stopper rod rotating device 8, etc., and a heat insulation layer can be sleeved outside the stopper rod.

[0017] One end of the cantilever 3 is fixed, the other end of the cantilever 3 is connected to the connecting ring 2, the middle part of the stopper rod 1 is sleeved in the holding ring 2, and the lower part of the stopper rod 1 extends into the pouring ladle 71. The top of the cantilever 3 is provided with a cylinder 4 through a bracket 31, and a piston 5 is arranged in the cylinder 4, and the piston 5 is connected with a piston push rod 6.

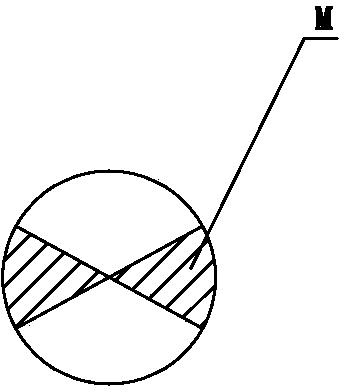

[0018] The stopper rod clamping sleeve 100 is arranged on the two arc splints 9, and the head of the splint 9 is wider than the end. The connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com