Cutting line vibrating ultrasonic sawing machine tool

A cutting line and ultrasonic technology, applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems that it is difficult to give full play to the superior performance of diamond abrasive grains, and the cutting speed is low, so as to achieve low noise, material saving and cost saving low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

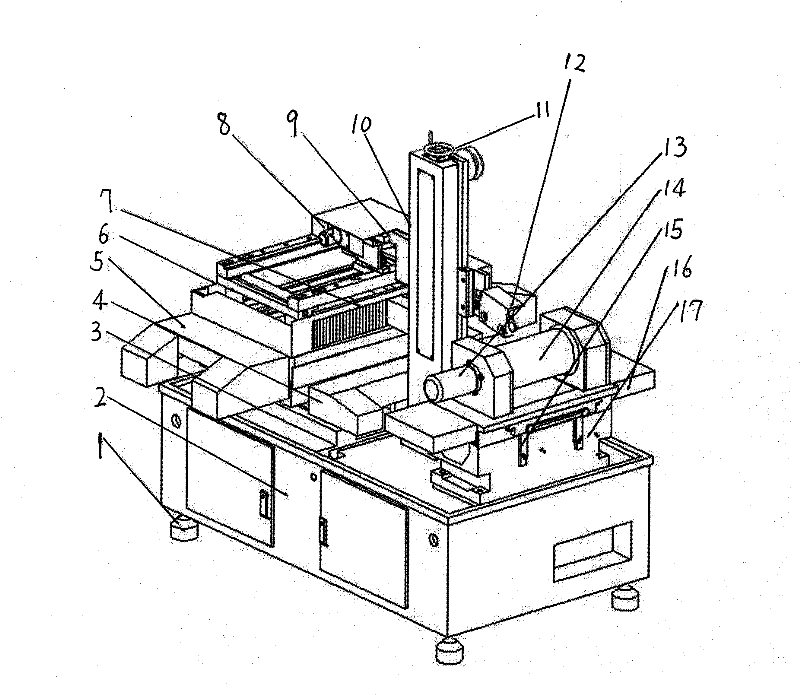

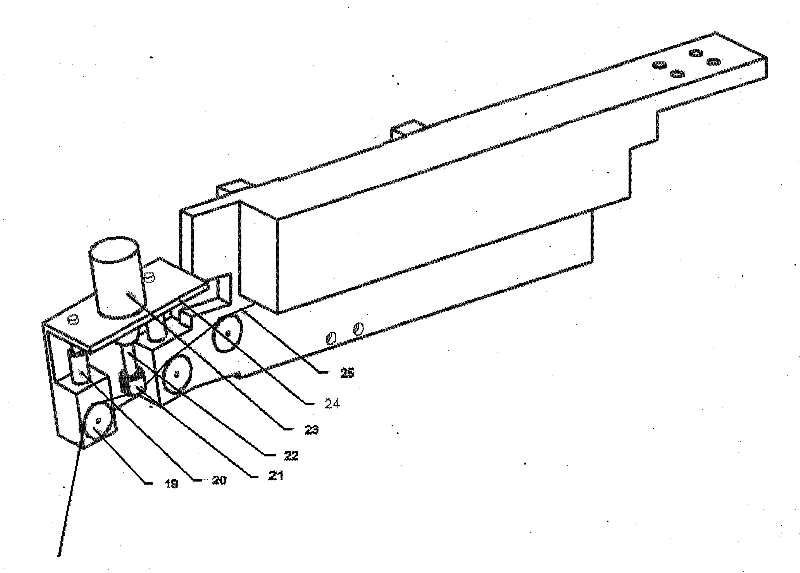

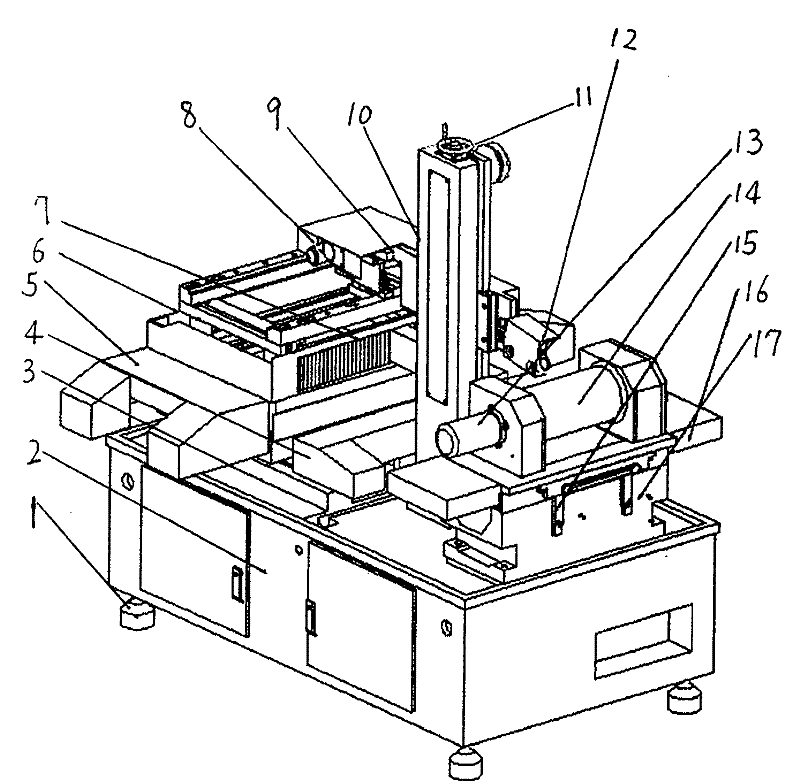

[0010] The saw includes bed 2, guide rail 3, X-direction slide table 4, Y-direction slide table 5, workbench 6, lower wire guide frame 7, wire guide wheel 8, upper wire guide frame 9, column 10, lead screw and hand Wheel 11, ultrasonic vibration drive mechanism 12, wire drum drive motor 13, wire storage drum 14, photoelectric switch 15, wire storage drum slide table 16, base 17, electric control cabinet 18, wire guide wheel 19, cylinder 20, vibration head 21 , Horn 22, transducer 23, support frame 24, cutting line 25 and auxiliary water cooling circulation system, protective cover and so on.

[0011] The bottom of the bed 2 is equipped with 4 adjustable casters 1. The bed 2 is respectively connected with the guide rail 3, the column 10, and the wire drum base 17 through positioning pins and bolts; The X-direction sliding table is driven by the screw nut to move linearly. The X-direction sliding table 4 is equipped with a guide rail, which cooperates with the Y-direction slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com