Laser cutting method for glass

A laser cutting and glass technology, applied in the field of laser applications, can solve the problem of ineffective laser energy gathering, and achieve the effect of overcoming mechanical cutting, narrow slits and smooth cutting surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe in detail the technical content, structural features, achieved objectives and effects of the invention, the following descriptions are combined with the embodiments.

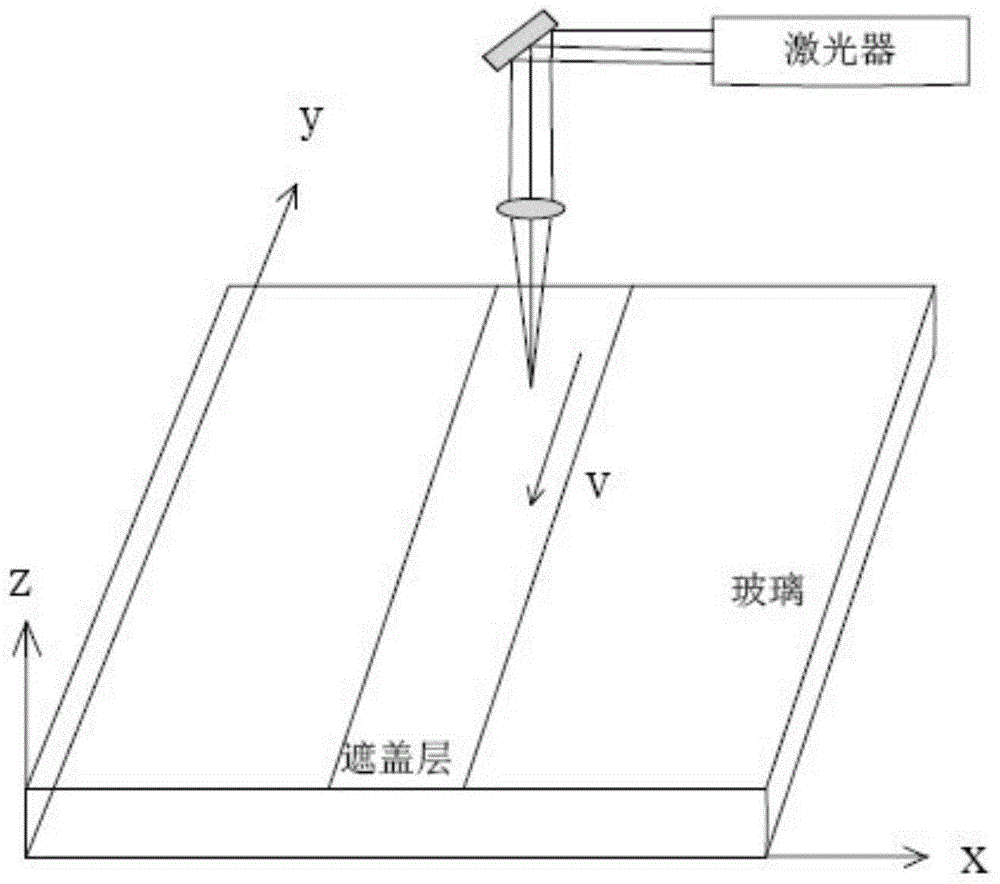

[0017] Such as figure 1 As shown, a method for laser cutting glass first selects the position to be cut of a glass plate with a glass thickness of 0.5-1.5 mm.

[0018] Then apply a layer of titanium dioxide to the part that needs to be cut on the glass plate.

[0019] The light absorption rate of the glass to the wavelength of 10.6μm is very high, which can reach 90%, but as the wavelength becomes smaller and smaller, the light absorption rate of the glass becomes smaller and smaller, from the ultraviolet band to the laser with a wavelength of 1064nm The absorption rate is less than 10%, so it means that a layer of non-volatile light-shielding material is applied, and the covering layer is titanium dioxide, which can make it difficult for the laser to pass through the glass surface, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com