Cutting torch for cutting ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot

A low-alloy steel and cutting torch technology, which is applied in the field of oxygen cutting devices for super-thick low-carbon steel ingots, can solve the problems of insufficient thickness of low-alloy steel ingots, and achieve the effects of less particle residue, narrow slits, and high-quality cutting surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

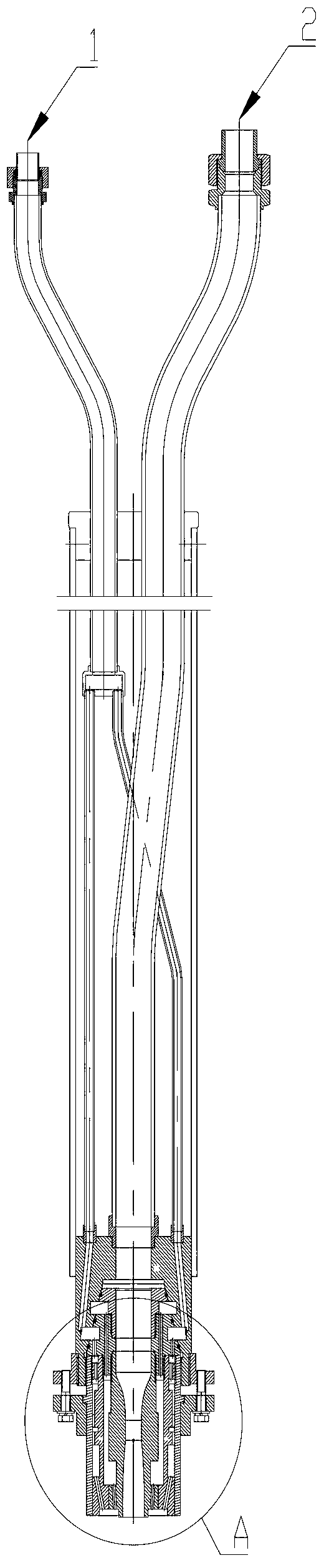

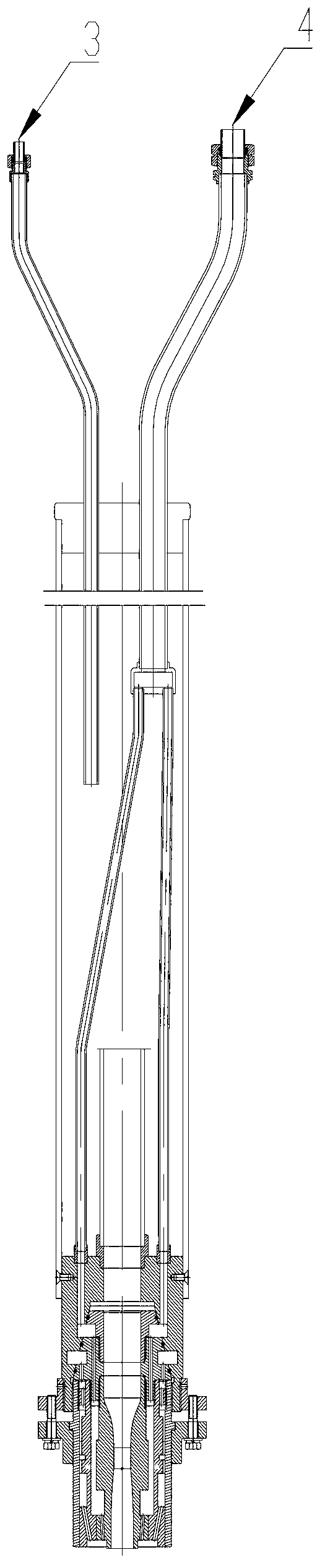

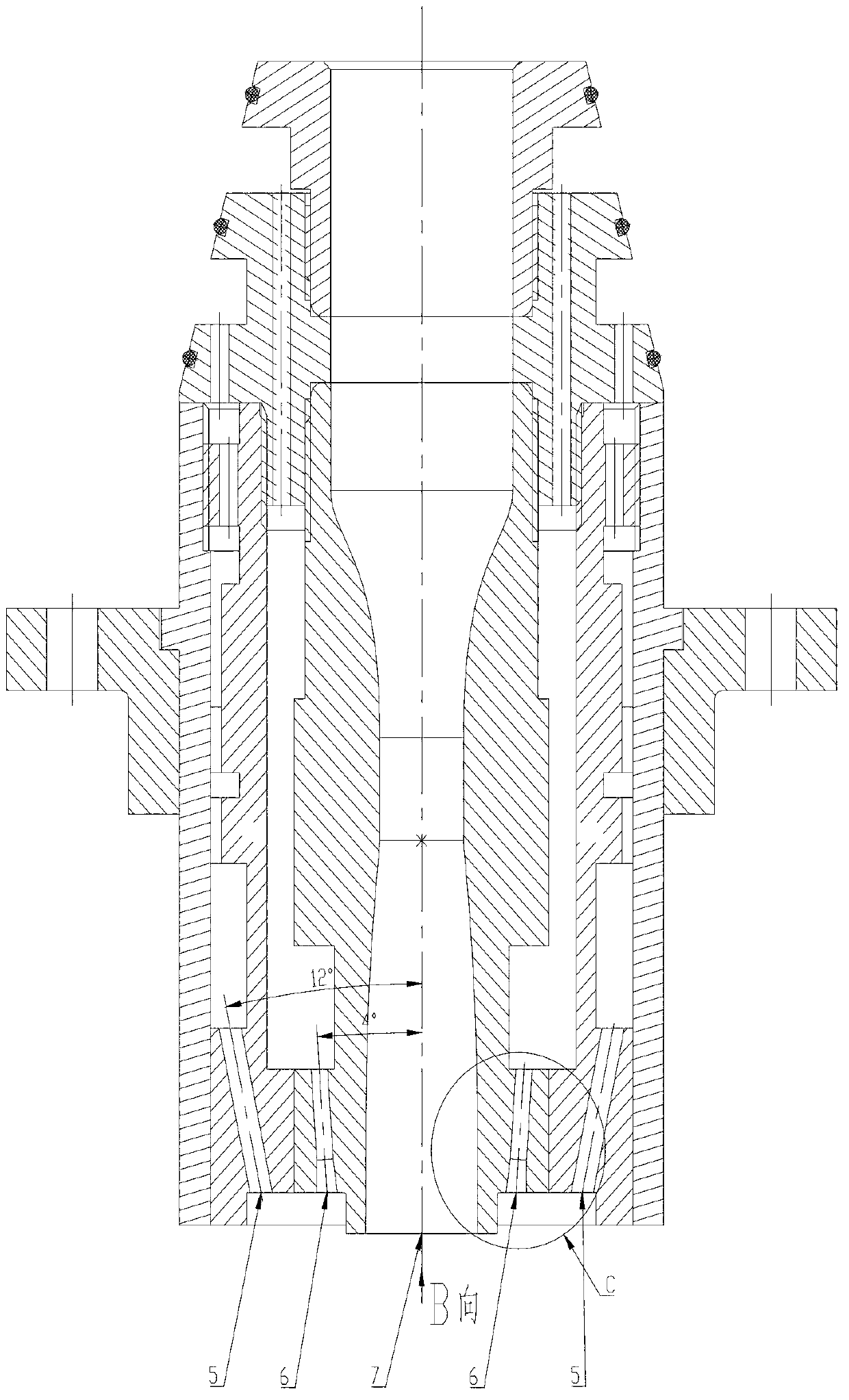

[0037] Article with the present invention such as Figure 1~3 The torch cutting material shown is 25Cr1Mo alloy steel with a thickness of 3100 mm.

[0038] The cutting nozzle 7 in the cutting torch is provided with some annularly distributed preheating oxygen channels 5 and gas channels 6 . Utilize the process specification of cutting torch cutting of the present invention as follows:

[0039] The cutting oxygen inlet pressure that passes into the cutting oxygen input pipe 2 is 1.0MPa,

[0040] The cutting oxygen flow rate flowing out from the cutting nozzle 7 is 1400Nm 3 / h,

[0041] The preheated oxygen pressure input by the preheated oxygen input pipe 1 is 1.0PMPa,

[0042] The preheating oxygen flow rate flowing out from the preheating channel 5 is 420Nm 3 / h,

[0043] The gas pressure input by the gas input pipe 4 is 0.2MPa,

[0044] The gas flow rate flowing out from the gas channel 6 is 140Nm3 / h;

[0045] The cutting speed using the above torch and process speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com