Processing method for processing rectangular photovoltaic cell silicon wafer by using primary single crystal silicon rod

A technology for silicon wafers and monocrystalline silicon rods for photovoltaic cells, which is applied in stone processing equipment, manufacturing tools, fine working devices, etc. Processing time and other issues, to achieve the effect of small loss, high production efficiency, and increase processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

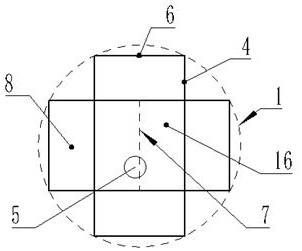

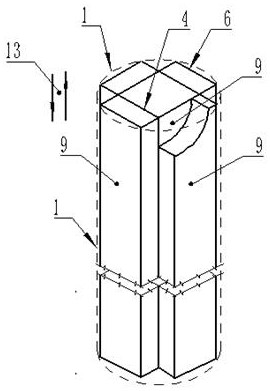

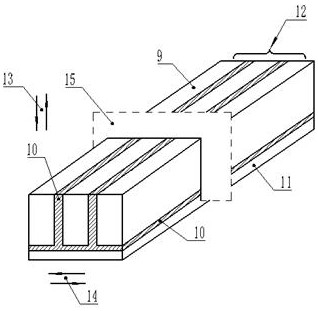

[0083] Reference attached figure 1 , attached figure 2 , attached image 3 , a processing method for processing rectangular photovoltaic cell silicon wafers with primary single crystal silicon rods, taking the processing of 162mm×54mm rectangular silicon wafers as an example, without considering the processing deviation and margin, including the following steps:

[0084] Prepare materials:

[0085] Cutting off the shoulder and the end of the primary monocrystalline silicon rod 1, and truncating the primary monocrystalline silicon rod 1 according to the maximum processing length of the slicing equipment;

[0086] Step (1), determine the vertical tangent line:

[0087] See attached figure 1 , attached figure 2 , draw four straight lines on the cross-sectional plane of the primary single crystal silicon rod 1, and the arrangement of the four straight lines on the plane is a well-shaped line, which is called a well-shaped straight line 4, and the distance between any two pa...

Embodiment 2

[0097] Reference attached figure 1 , attached figure 2 , attached Figure 4 , a processing method for processing rectangular photovoltaic cell silicon wafers with primary single crystal silicon rods, taking the simultaneous processing of two commonly used rectangular silicon wafers of 210mm×105mm and 210mm×210mm as an example, without considering the processing deviation and margin, including the following steps:

[0098] Prepare materials:

[0099] Cutting off the shoulder and the end of the primary monocrystalline silicon rod 1, and truncating the primary monocrystalline silicon rod 1 according to the maximum processing length of the slicing equipment;

[0100] Step (1), determine the vertical tangent line:

[0101] See attached figure 1 , attached figure 2 , make four well-shaped straight lines 4 on the cross-sectional plane of the primary single crystal silicon rod 1, the distance between any two parallel well-shaped straight lines 4 is 210mm, and the central rectan...

Embodiment 3

[0109] Reference attached figure 1 , attached figure 2 , attached Figure 5 , a processing method for processing rectangular photovoltaic cell silicon wafers with primary single crystal silicon rods, taking the processing of 210mm×70mm silicon wafers as an example, without considering the processing deviation and margin, including the following steps:

[0110] Prepare materials:

[0111] Cutting off the shoulder and the end of the primary monocrystalline silicon rod 1, and truncating the primary monocrystalline silicon rod 1 according to the maximum processing length of the slicing equipment;

[0112] Step (1), determine the vertical tangent line:

[0113] See attached figure 1 , attached figure 2 , make four well-shaped straight lines 4 on the cross-sectional plane of the primary single crystal silicon rod 1, the distance between any two parallel well-shaped straight lines 4 is 210mm, and the central rectangle 5 surrounded by the well-shaped straight lines 4 is 210mm×210...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com