Lead-acid storage battery negative electrode lead paste and preparation method thereof

A technology of lead-acid battery and negative electrode paste, applied in the direction of lead-acid battery, battery electrode, circuit, etc., can solve the problems of reduced battery life, poor uniformity, complex chemical reaction, etc., to improve battery performance and service life, avoid The effect of non-uniform active substance content and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

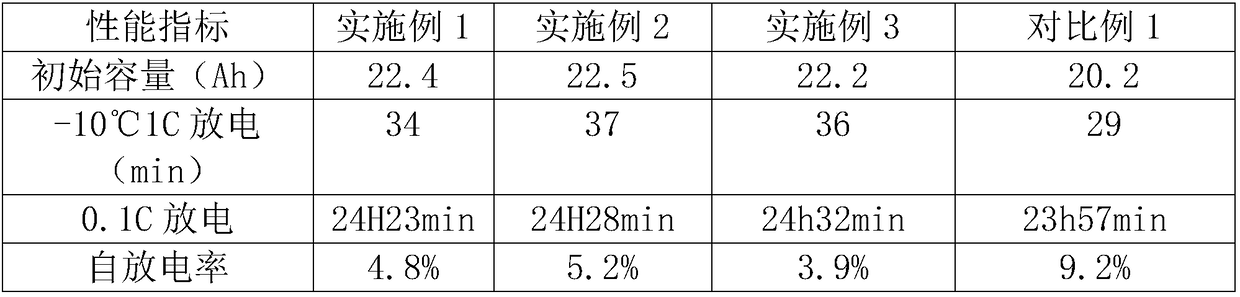

Embodiment 1

[0031] A kind of lead-acid accumulator negative pole lead paste, takes the raw material of following weight:

[0032] Tribasic lead sulfate (3BS) 50, lead powder 50; deionized water 15, acetylene black 0.5, sodium sulfate 0.2, conductive fiber 0.15, lignin 0.2, humic acid 0.2, barium sulfate 0.5.

[0033] Among them, the specific surface area of acetylene black is 50m 2 / g, the length of conductive fiber is 1mm, the particle size of 3BS is 1-3 microns, and the particle size of lead powder is 1-3 microns.

[0034] The above raw materials are mixed and stirred evenly to prepare lead-acid battery negative electrode paste.

Embodiment 2

[0036] A kind of lead-acid accumulator negative pole lead paste, takes the raw material of following weight:

[0037] Tribasic lead sulfate (3BS) 45, lead powder 55; deionized water 18, acetylene black 0.8, sodium sulfate 0.4, conductive fiber 0.3, lignin 0.4, humic acid 0.4, barium sulfate 1.

[0038] Among them, the specific surface area of acetylene black is 100m 2 / g, the length of conductive fiber is 1mm, the particle size of 3BS is 1-3 microns, and the particle size of lead powder is 1-3 microns.

[0039] The above raw materials are mixed and stirred evenly to prepare lead-acid battery negative electrode paste.

Embodiment 3

[0041] A kind of lead-acid accumulator negative pole lead paste, takes the raw material of following weight:

[0042] Tribasic lead sulfate (3BS) 40, lead powder 60; deionized water 20, acetylene black 1, sodium sulfate 0.5, conductive fiber 0.25, lignin 0.5, humic acid 0.5, barium sulfate 1.5.

[0043] Among them, the specific surface area of acetylene black is 100m 2 / g, the length of conductive fiber is 1mm, the particle size of 3BS is 1-3 microns, and the particle size of lead powder is 1-3 microns.

[0044] The above raw materials are mixed and stirred evenly to prepare lead-acid battery negative electrode paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com