Tacrolimus ointment and preparation method thereof

A technology of tacrolimus and ointment, applied in the field of pharmaceuticals, can solve the problems of low industrialization, need for improvement, uneven ointment content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

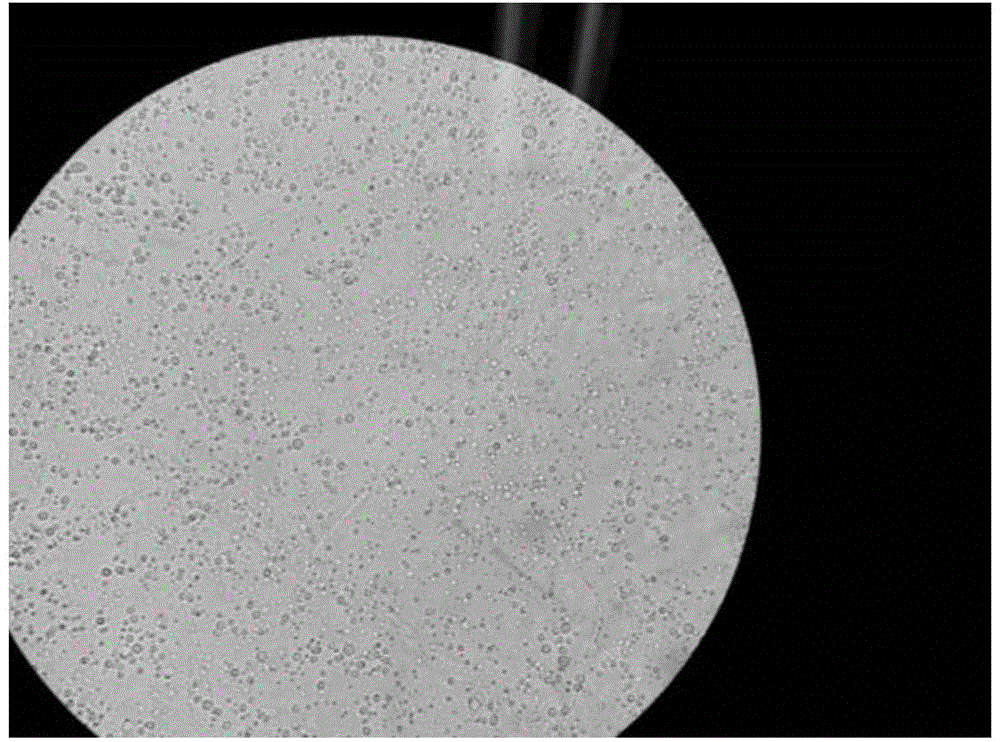

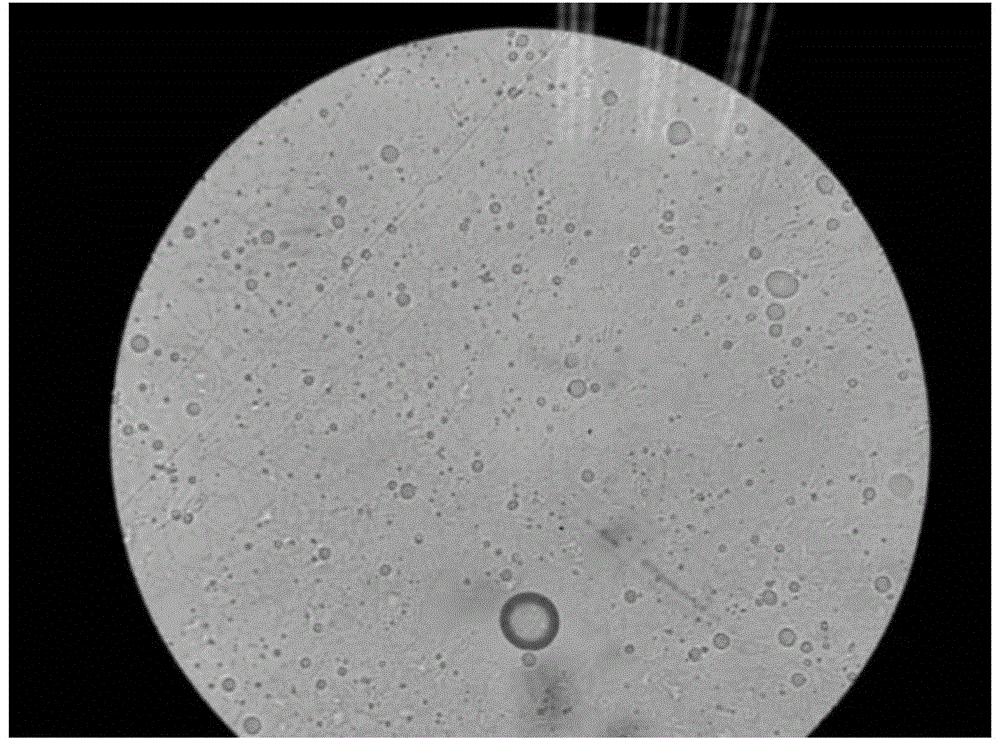

Image

Examples

Embodiment 1

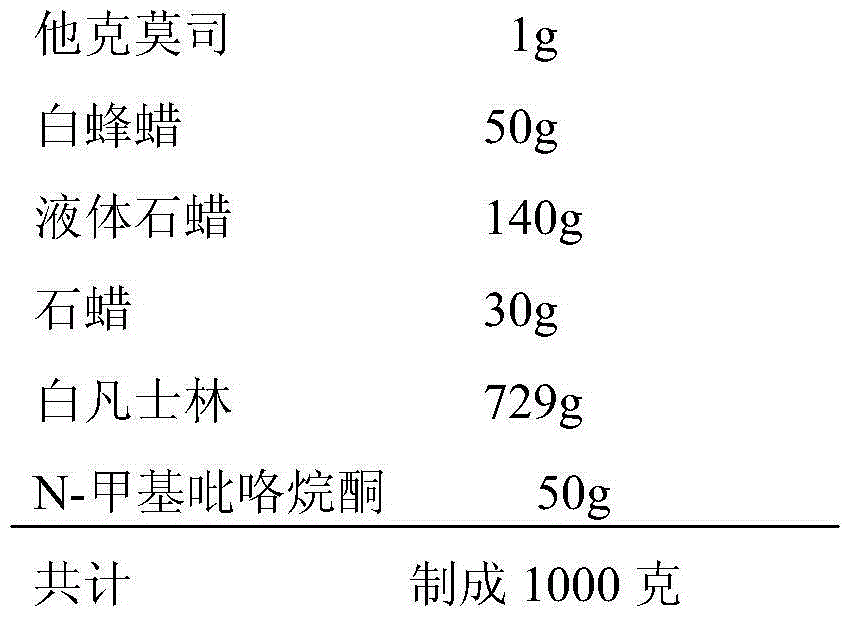

[0186] prescription:

[0187]

[0188] Preparation method:

[0189] (1) Heat and stir 140g of liquid paraffin, 50g of white beeswax and 30g of paraffin to 75°C to melt, keep warm for subsequent use, so as to obtain the first solution;

[0190] (2) heating and stirring 729g of white petrolatum to 75°C to make it melt, keep warm for subsequent use, so as to obtain white petrolatum solution;

[0191] (3) Heat and stir 1 g of tacrolimus and 50 g of N-methylpyrrolidone to 75° C. to dissolve, so as to obtain a second solution;

[0192] (4) Add the first solution into the vacuum homogenization emulsification tank, turn on the vacuum homogenization, and carry out the first vacuum homogenization treatment for 5 minutes under the homogenization speed of 2400 rpm, so as to obtain the first solution of the vacuum homogenization treatment;

[0193] (5) Add the second solution to the first solution that has undergone the first vacuum homogenization treatment, and carry out the second v...

Embodiment 2

[0200] prescription:

[0201]

[0202] Preparation method:

[0203] (1) Heat and stir 140g of liquid paraffin, 50g of white beeswax and 30g of paraffin to 70°C to melt, keep warm for subsequent use, so as to obtain the first solution;

[0204] (2) heating and stirring 730g of white petrolatum to 70° C. to make it melt, keep warm for subsequent use, so as to obtain white petrolatum solution;

[0205] (3) Heat and stir 0.3 g of tacrolimus and 50 g of diethylene glycol monoethyl ether to 70° C. to dissolve, so as to obtain a second solution;

[0206] (4) Add the first solution into the vacuum homogenization emulsification tank, turn on the vacuum homogenization, and perform the first vacuum homogenization treatment for 10 minutes under the homogenization speed of 2400 rpm, so as to obtain the first vacuum homogenization treatment;

[0207] (5) Add the second solution to the first solution that has undergone the first vacuum homogenization treatment, and carry out the second ...

Embodiment 3

[0211] prescription:

[0212]

[0213] Preparation method:

[0214] (1) Heat and stir 140g of liquid paraffin, 50g of white beeswax and 30g of paraffin to 80°C to melt, keep warm for subsequent use, so as to obtain the first solution;

[0215] (2) heating and stirring 729.5 g of white petrolatum to 80° C. to melt it, and keep it warm for subsequent use, so as to obtain a white petrolatum solution;

[0216] (3) Heat and stir 0.5 g of tacrolimus and 50 g of propylene glycol to 80° C. to dissolve, so as to obtain a second solution;

[0217] (4) Add the first solution into the vacuum homogenization emulsification tank, turn on the vacuum homogenization, and perform the first vacuum homogenization treatment for 15 minutes under the homogenization speed of 2400 rpm, so as to obtain the first vacuum homogenization treatment;

[0218] (5) Add the second solution to the first solution that has undergone the first vacuum homogenization treatment, and carry out the second vacuum hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com