Orderly-positioned weakening matrix self-forming ultra-thin gear-shaped diamond saw blade and manufacturing process thereof

A diamond saw blade and manufacturing process technology, applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve problems such as unfavorable energy saving, large cutting resistance, waste of resources, etc., to save resources and energy, reduce contact Area, the effect of improving sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

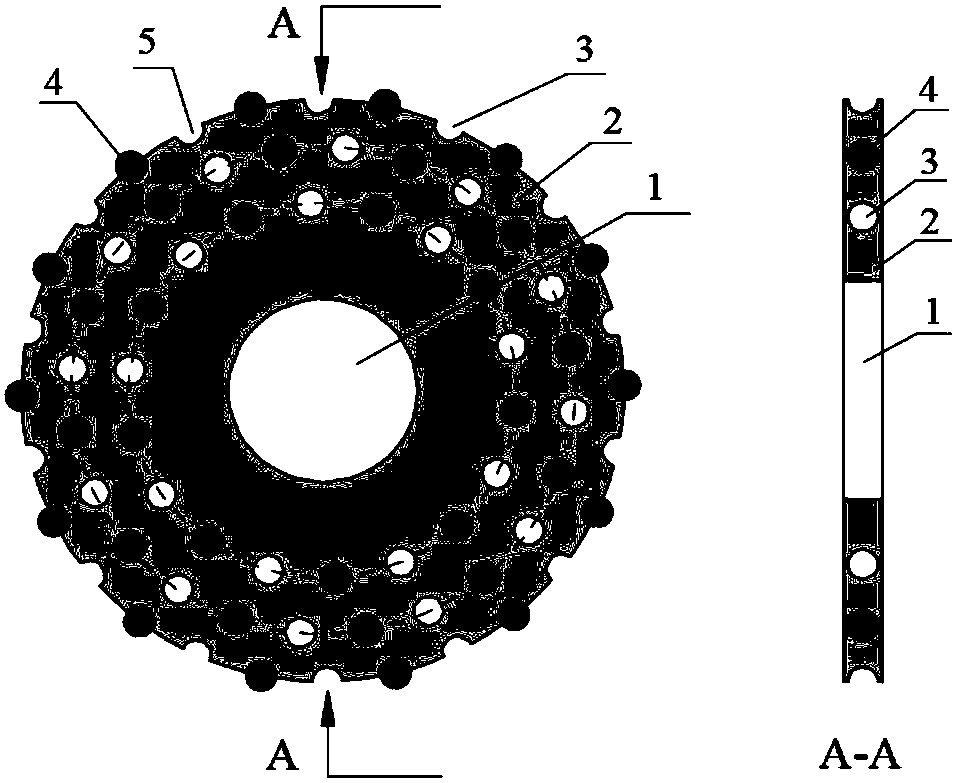

[0015] refer to figure 1 , orderly positioning the weakened carcass to form an ultra-thin gear-shaped diamond saw blade, including the installation hole 1 and the carcass working layer 2. Diamond particles 4 and weakened carcass particles 3 arranged in order are distributed all over the carcass working layer 2 . The saw blade after cutting and working, the diamond particles 4 protrude from the blade, the weakened carcass particles fall off and appear pits 5, automatically forming a gear-shaped working surface. Saw blade diameter Φ30mm, thickness 0.3mm, installation hole Φ10mm, carcass working layer formula (mass ratio): cobalt powder 40%, nickel powder 10%, iron powder 10%, chromium powder 5%, copper powder 30%, tin powder 5%, the powder particle size is less than 45 microns; the diamond volume concentration is 2%, and the particle size is 150-178 microns; Arranged radially and orderly.

[0016] The weakened carcass is positioned in an orderly manner to form an ultra-thin g...

Embodiment 2

[0026] refer to figure 1 , orderly positioning the weakened carcass to form an ultra-thin gear-shaped diamond saw blade, including the installation hole 1 and the carcass working layer 2. Diamond particles 4 and weakened carcass particles 3 arranged in order are distributed all over the carcass working layer 2 . The saw blade after cutting and working, the diamond particles 4 protrude from the blade, the weakened carcass particles fall off and appear pits 5, automatically forming a gear-shaped working surface. Saw blade diameter Φ100mm, thickness 0.6mm, installation hole Φ40mm, carcass working layer formula (mass ratio): cobalt powder 40%, nickel powder 5%, iron powder 10%, chromium powder 5%, copper powder 32%, tin powder 8%, the powder particle size is finer than 45 microns; the diamond volume concentration is 5%, and the particle size is 180-380 microns; the weakened matrix particles 3 use rounded graphite particles, the volume concentration is 10%, and the graphite partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com