A portable wire cutting saw

A wire cutting saw, portable technology, applied in the field of portable wire cutting saw, can solve the problem of inconvenient wire cutting, etc., and achieve the effect of small size, stable discharge, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

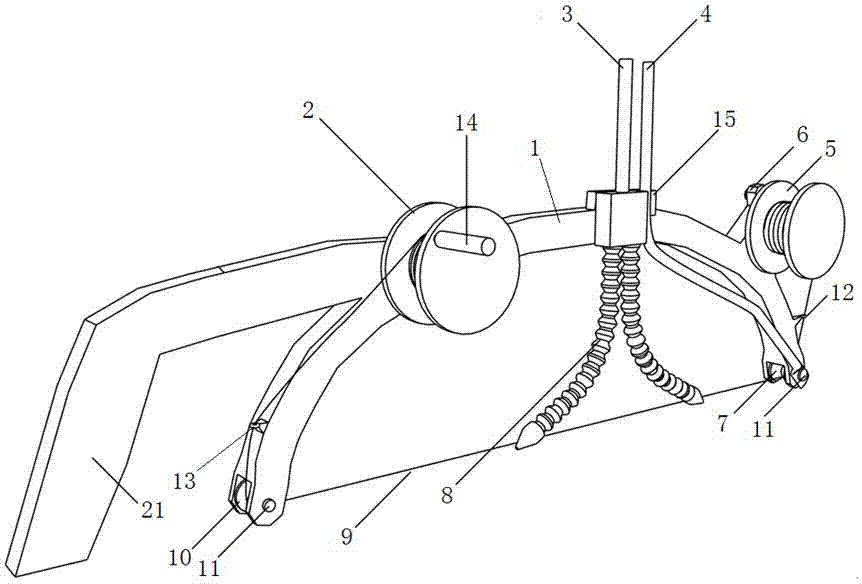

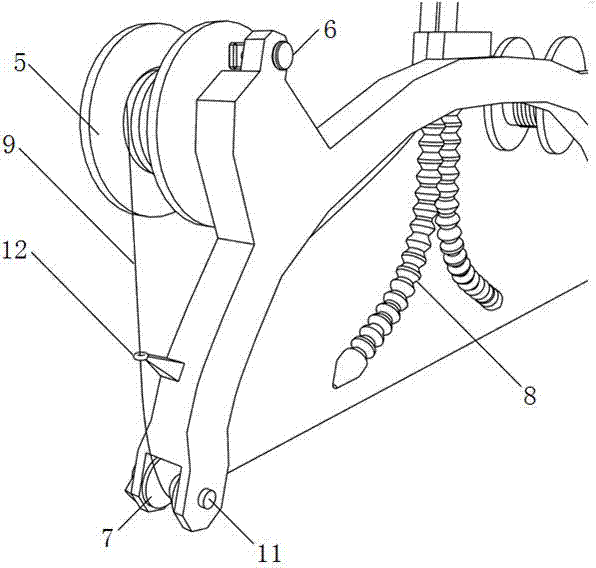

[0036] In conjunction with the accompanying drawings, a portable wire saw of the present embodiment (such as figure 1shown), including saw body 1, handle 21, water inlet pipe 3, electrode wire 4, universal water spray pipe 8 and electrode wire 9, and also includes front winding mechanism, front wire guiding mechanism, rear guiding wire mechanism and rear winding wire Mechanism; the saw body 1 is fixedly connected with the handle 21, and the saw body 1 is a bow-shaped structure. In this embodiment, the saw body 1 adopts nylon 6 engineering plastics produced by Baling Branch of China Petroleum and Chemical Corporation. Plastic has good comprehensive properties, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication, and has a low coefficient of friction, has certain flame retardancy, and is easy to process. The end of the saw body 1 away from the handle 21 is provided with a front wire guide mechanism, and the end of the saw b...

Embodiment 2

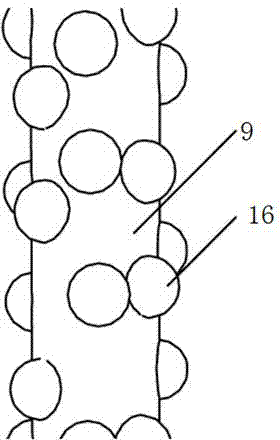

[0052] A portable wire cutting saw of this embodiment has the same basic structure as that of Embodiment 1, except that the front guide wheel 7, the rear guide wheel 10 and the guide wheel pin 11 of this embodiment are made of brass, in order to ease the operation The labor intensity of personnel, improve the stability of the movement of electrode wire 9, the rear wire winding wheel 2 is driven by a DC motor, the particle diameter of the insulating resin particles 16 is 100 μm, and the distance between two adjacent insulating resin particles 16 is 2 times particle size, the roughness of the groove surface is Rz100μm.

[0053] A kind of using method of portable wire cutting saw of this embodiment, its basic steps are the same as embodiment 1, the difference is:

[0054] In step 1, use high-pressure gas atomization to spray atomized liquid insulating resin on the surface of the wire electrode 9 for wire cutting, the particle size of the insulating resin particles 16 is 100 μm, a...

Embodiment 3

[0059] A portable wire cutting saw of this embodiment has the same basic structure as that of Embodiment 1, except that the front guide wheel 7, rear guide wheel 10 and guide wheel pin 11 of this embodiment are made of brass, and insulating resin particles The particle size of 16 is 200 μm, the distance between two adjacent insulating resin particles 16 is 0.5 times the particle size, and the roughness of the groove surface is Rz150 μm.

[0060] A kind of using method of portable wire cutting saw of this embodiment, its basic steps are the same as embodiment 1, the difference is:

[0061] In step 1, use high-pressure gas atomization to spray atomized liquid insulating resin on the surface of the wire electrode 9 for wire cutting. The particle size of the insulating resin particles 16 is 200 μm, and the distance between two adjacent insulating resin particles 16 is 0.5 times particle size.

[0062] In step 3, adjust the tension of the electrode wire 9 to 5N.

[0063] In step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com