Phosphoric acid axial-flow pump dry gas sealing device

A dry gas seal, axial flow pump technology, which is applied to the components of the pumping device for elastic fluid, the seal of the engine, the pump, etc. Stability and other issues, to achieve the effect of less power consumption, low operating cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

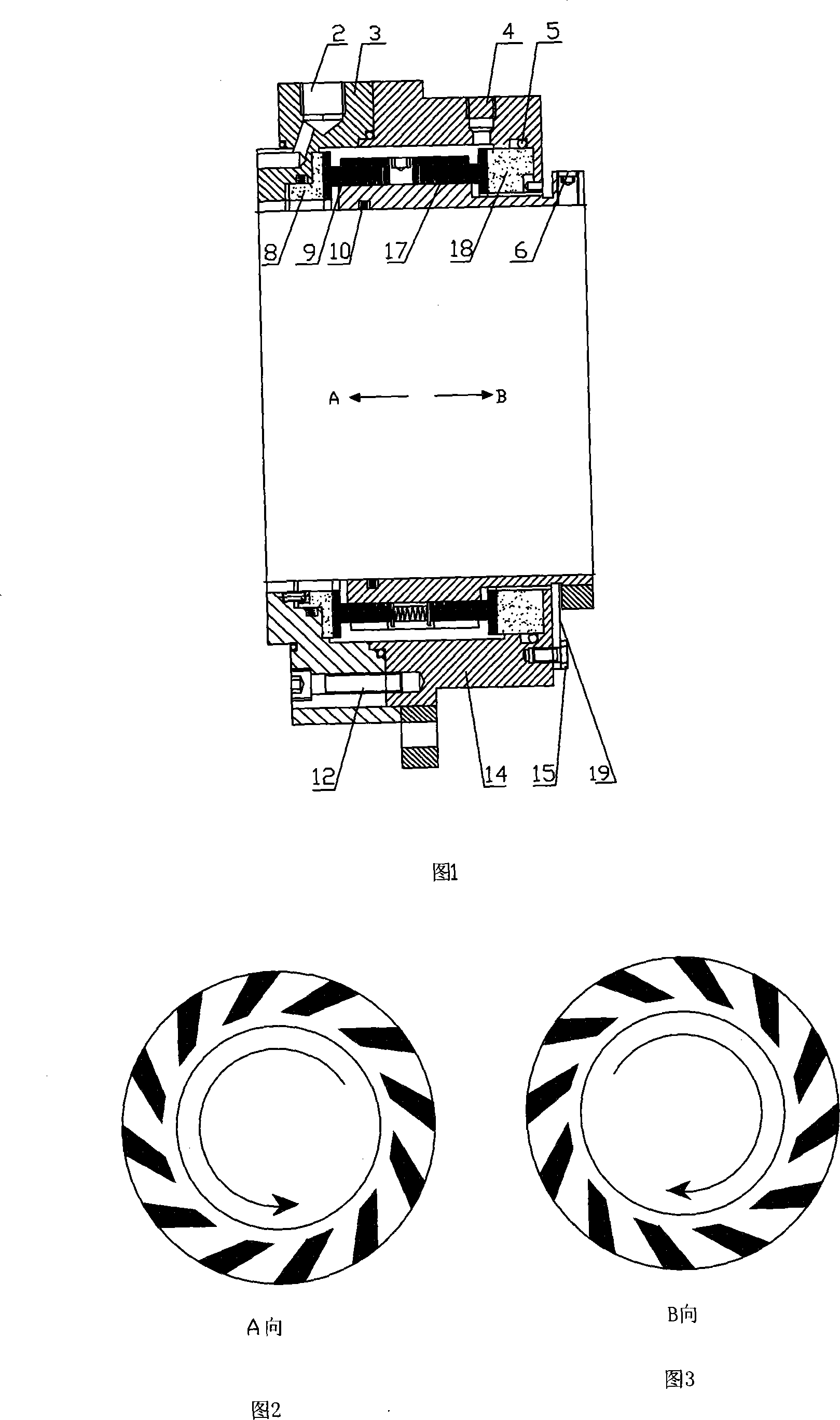

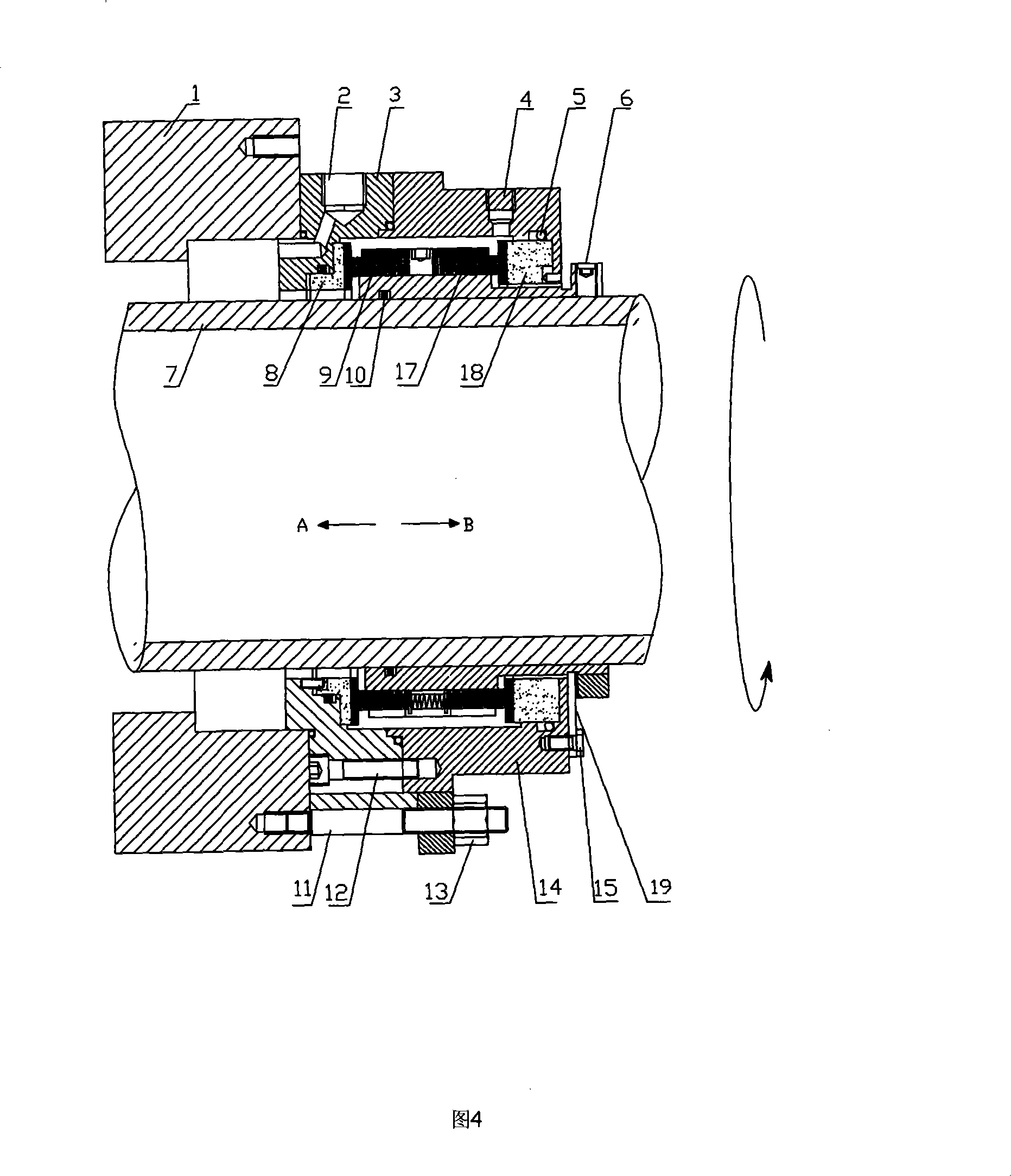

[0015] Phosphoric acid axial flow pump dry gas seal device, including double-end seal friction pair, spring 16, pressure plate assembly 14, connecting bolts, wherein: air seal groove 19 is engraved on the static ring, and the direction of rotation of the slot 20 is consistent with the rotation of the pump. To ensure that the air film is formed, the air seal can work normally.

[0016] The double-end seal friction pair is composed of the driving ring 3, the moving ring A9, the static ring A8, the moving ring B17, and the static ring B18. The static ring A8 is fixed on the driving ring 3, and there is a O-ring 5, the pressure plate assembly 14 are connected by connecting bolts A12 and B15, the two ends of the spring 16 are connected with the moving ring A9 and the moving ring B17, the exhaust port 2 and the air inlet 4 are opened on the pressure plate assembly 14 .

[0017] When in use: the static ring A8, the static ring B18 and the pressure plate assembly 14 are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com