Double-chamber structure of dry gas seal testing cavity

A technology of dry gas sealing and test chamber, which is applied in the testing of machines/structural components, testing of mechanical components, measuring devices, etc. It can solve problems such as low detection efficiency, low work efficiency, and inability to remove products immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

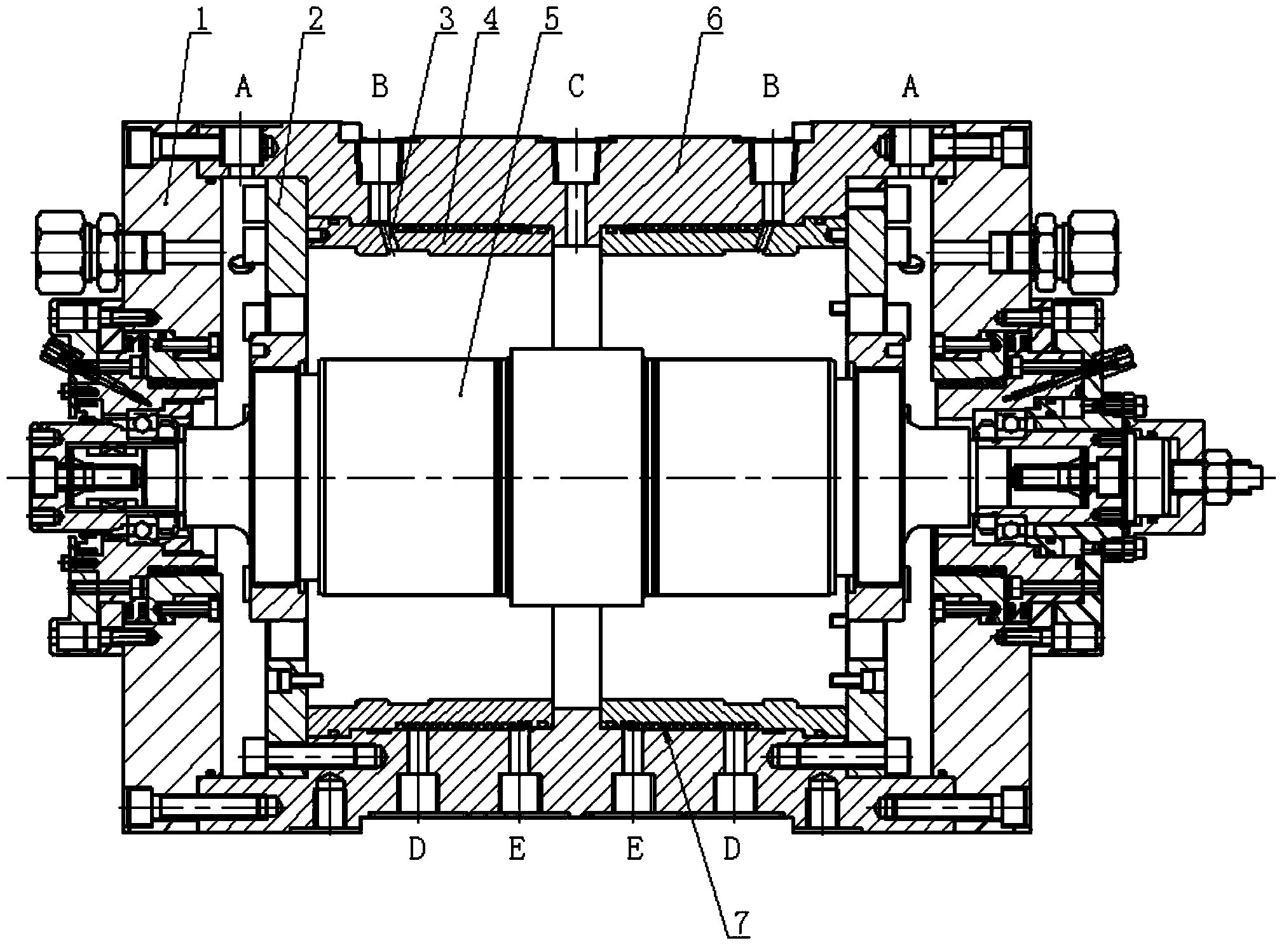

[0012] A double-chamber structure of a dry gas-tight test chamber, such as figure 1 As shown, it includes a chamber 6, a water jacket 4, and a main shaft 5. The chamber is a cylindrical barrel structure. Two water jackets are installed symmetrically on the same axis at both ends of the chamber. The two water jackets pass through the baffle respectively. 2. It is fixed together with the chamber, and a main shaft is coaxially installed in the two water jackets. The two ends of the main shaft are respectively installed together with the two ends of the chamber through the end cover 1. There is a dry gas seal assembly (not shown).

[0013] The outer edge of each water jacket is uniformly formed with a plurality of inclined holes 3 in the radial direction, and the outer edge of the cavity corresponding to each inclined hole is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com