Supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure

A centrifugal compressor, carbon dioxide technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve the problems of complex system, high motor manufacturing requirements, and increased cost, and achieve large enthalpy drop, compact structure, and cost-saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

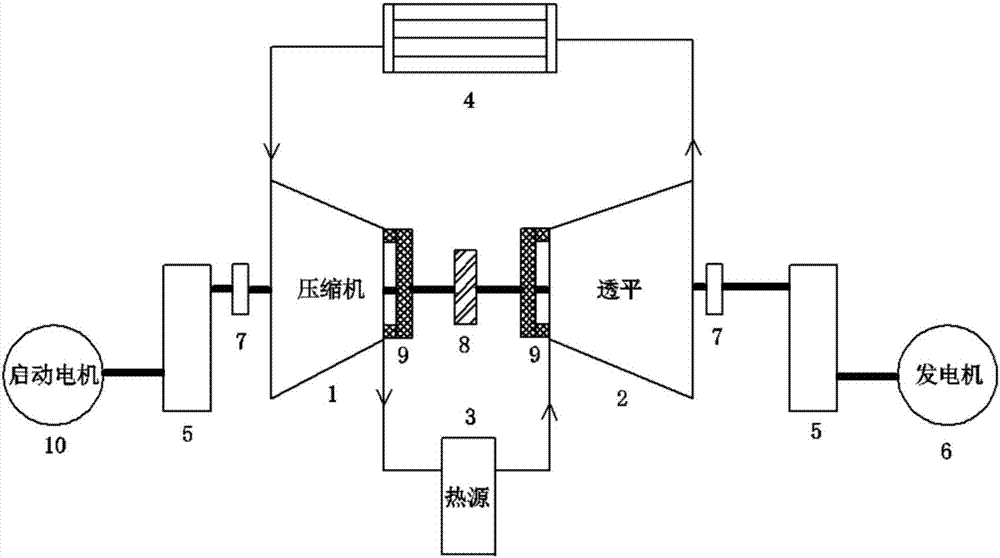

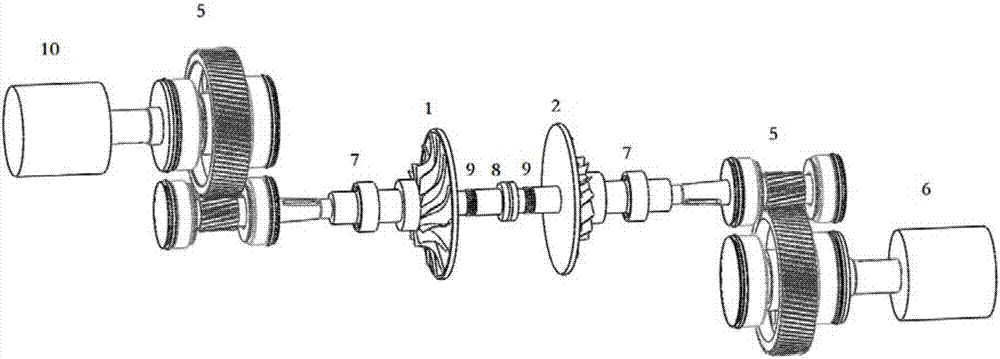

[0029] refer to figure 1 , a supercritical carbon dioxide centrifugal compressor and centripetal turbine coaxial structure of the present invention, including centrifugal compressor 1, centripetal turbine 2, heat source 3, cooler 4, gearbox 5, generator 6, radial bearing 7. Thrust bearing 8, supercritical carbon dioxide dry gas seal 9 and starter motor 10; wherein, the centrifugal compressor 1 with supercritical carbon dioxide as the working fluid and the radial turbine 2 form a coaxial structure, and the starter motor 10 passes through the gearbox 5 drives the coaxial structure to start working, and the power provided by the centripetal turbine 2 can not only drive the centrifugal compressor 1, but also output power to the generator 6 through the gearbox 5.

[0030] The supercritical carbon dioxide working medium first flows through the centrifugal compressor 1 to reach a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com