Low emission dry gas seal system for compressors

a compressor and low-emission technology, applied in the field of compressors, can solve the problems of toxic or dangerous to the environment and/or to workers in the plant, the overall system is more complex, and the current dry gas seal system is not fault-free, so as to improve the control of potentially hazardous process gas and reduce complexity and maintenance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The following detailed description of the exemplary embodiments refers to the accompanying drawings. The same reference numbers in different drawings identify the same or similar elements. Also, the following detailed description does not limit the invention. Instead, the scope of the invention is defined by the appended claims.

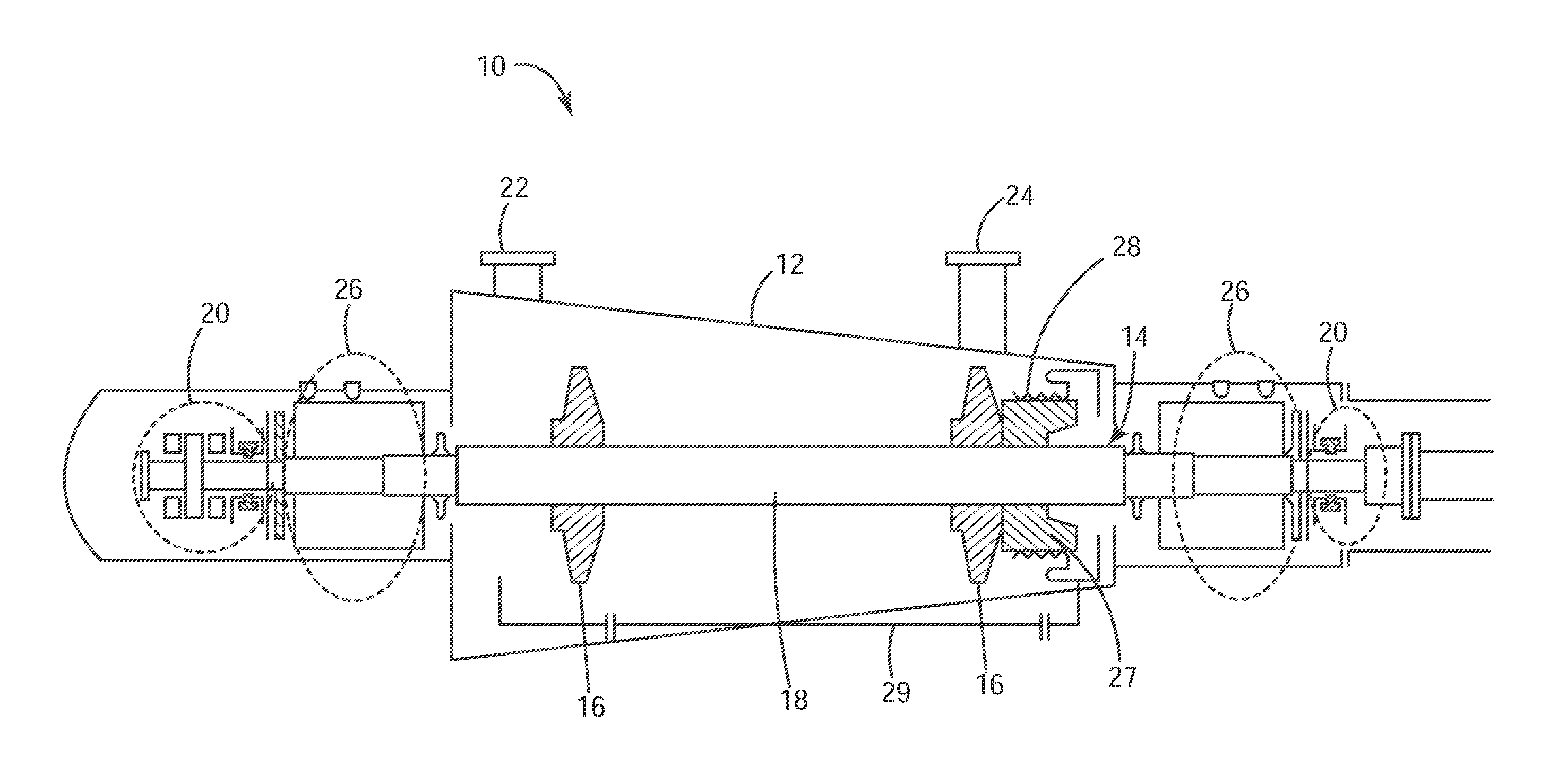

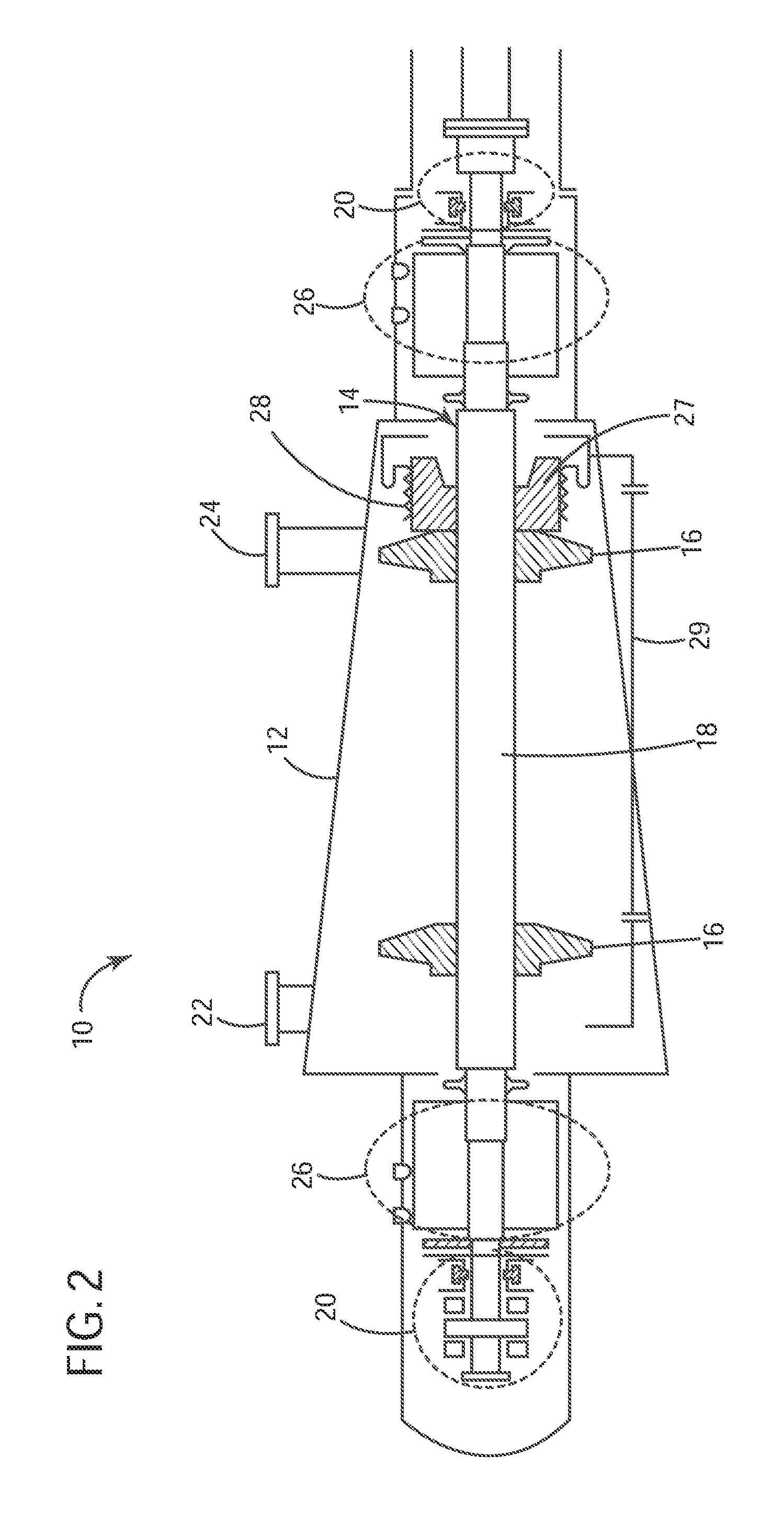

[0022]To provide some context for the subsequent discussion relating to sealing systems according to these exemplary embodiments, FIG. 2 schematically illustrates a multistage, centrifugal compressor 10 in which such sealing systems may be employed. Therein, the compressor 10 includes a box or housing (stator) 12 within which is mounted a rotating compressor shaft 14 that is provided with a plurality of centrifugal impellers 16. The rotor assembly 18 includes the shaft 14 and impellers 16 and is supported radially and axially through bearings 20 which are disposed on either side of the rotor assembly 18.

[0023]The multistage centrifugal compressor operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com