Dry gas sealing device for technical screw compressor and application system thereof

A screw compressor, dry gas sealing technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as unfavorable lubricating oil system safe operation, large heat generation on the sealing end face, pollution of lubricating oil, etc., to achieve low friction coefficient, operational safety, and the effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

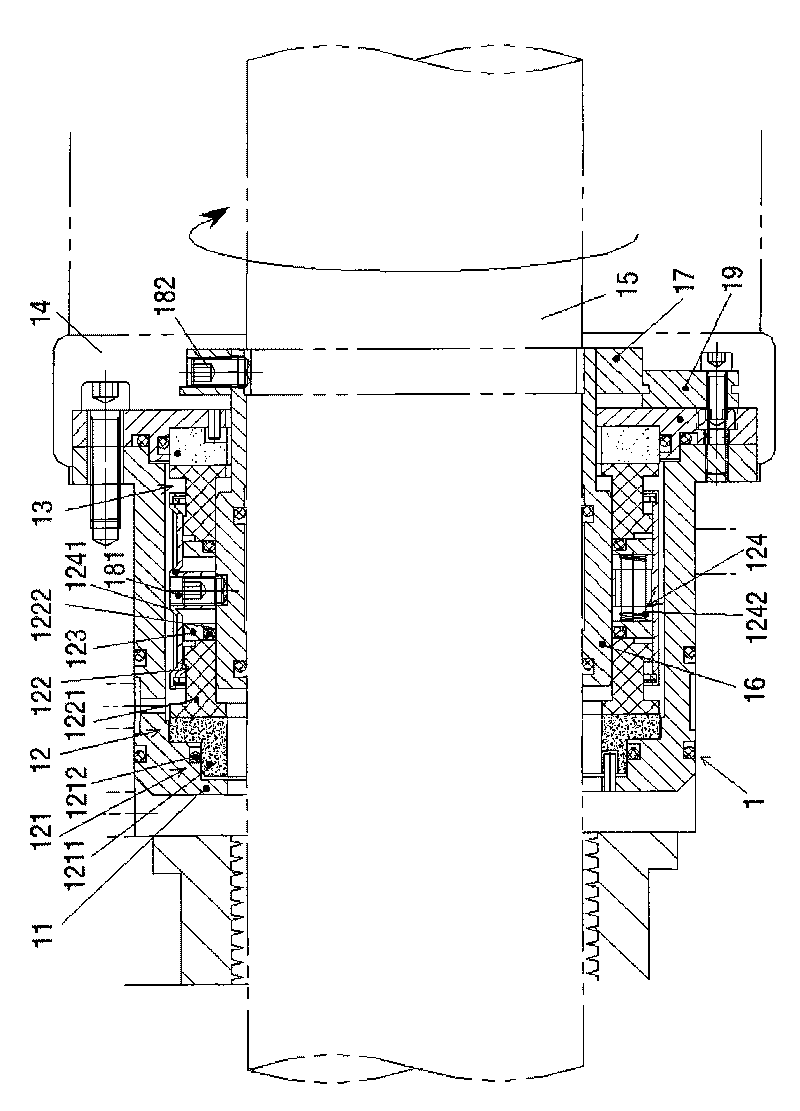

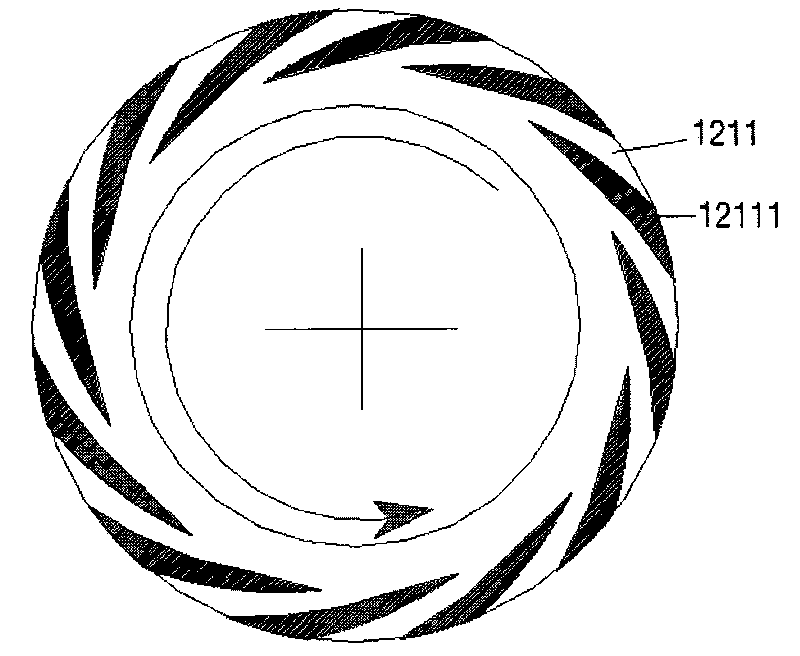

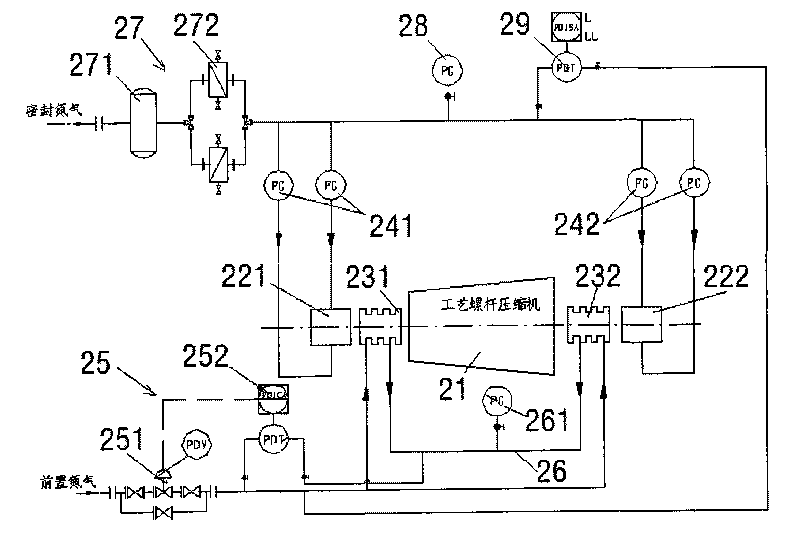

[0027] see figure 1 , figure 1 It is a structural schematic diagram of the dry gas sealing device used in the process screw compressor of the present invention. The present invention is a dry gas sealing device 1 for process screw compressors, comprising a gland 11 and two sets of single sealing mechanisms 12 and 13 with the same structure relatively arranged in the gland, the glands are filled with Gases including nitrogen. Since the two sets of single-sealing mechanisms have the same structure, the single-sealing mechanism 12 is taken as an example for detailed description. The single seal 12 includes a stationary ring assembly 121 , a moving ring assembly 122 , a push ring 123 , and a spring assembly 124 arranged in sequence. The static ring assembly 121 includes a static ring and 1211 a static ring sealing ring 1212, the moving ring assembly 122 includes a moving ring 1221 and a moving ring sealing ring 1222, and the spring assembly includes a spring seat 1241 and A sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com