Dry gas seal device

A dry gas sealing and sealing support technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high rigidity of the gas film, deformation, easy collision between the compensation ring and the active ring, etc. High membrane stiffness, low leakage, enhanced effect of hydrodynamic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

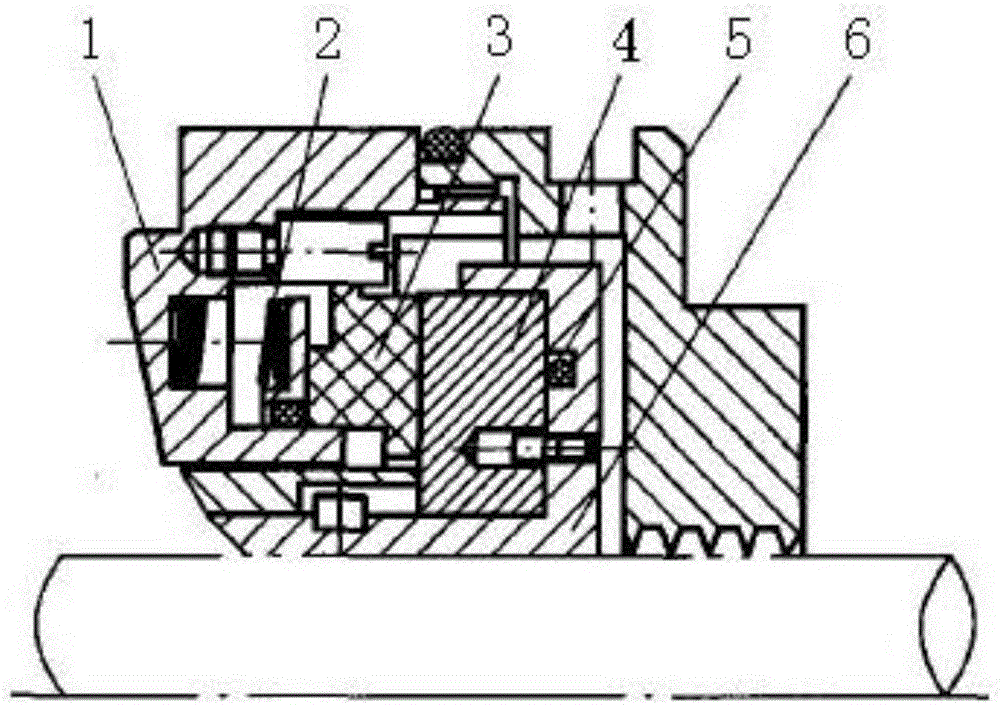

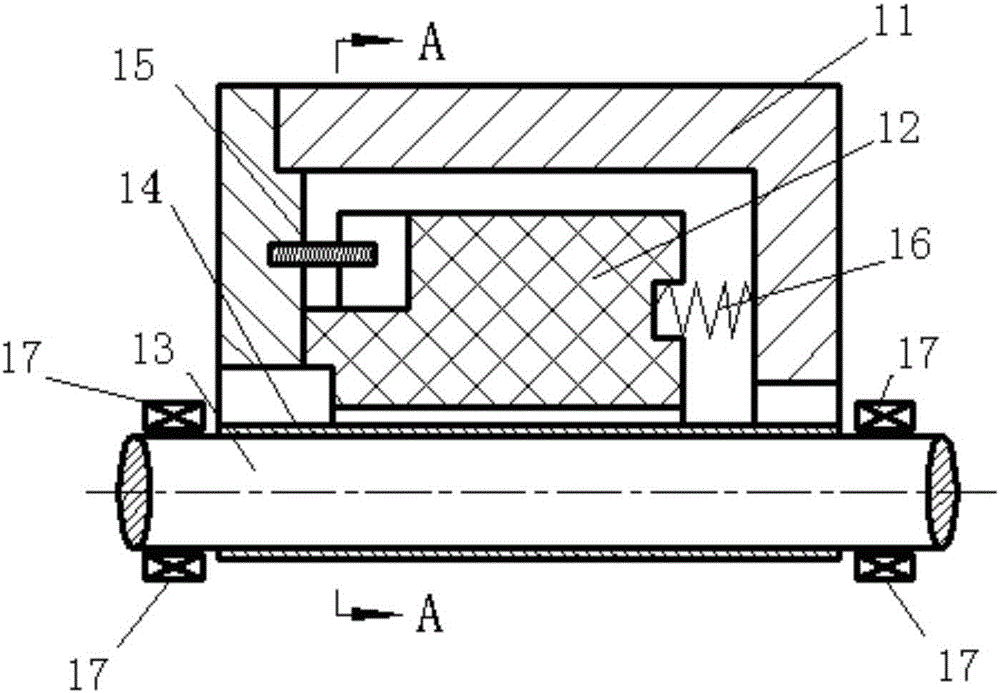

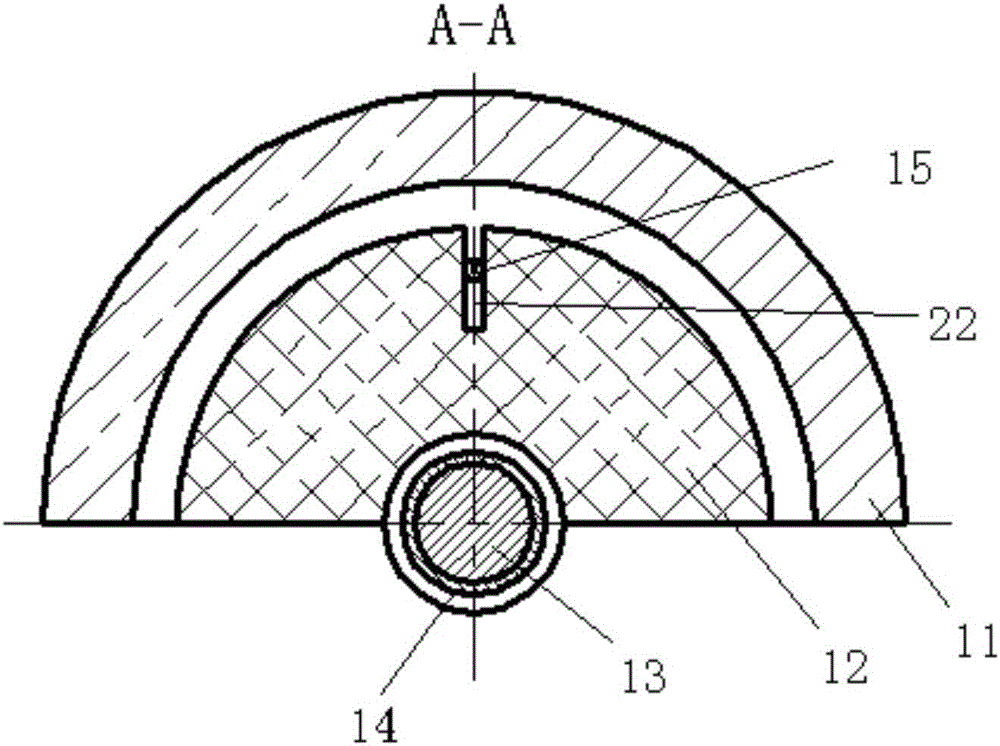

[0024] The technical scheme of the present invention will be introduced below in conjunction with the accompanying drawings.

[0025] like figure 2 and image 3 As shown, the dry gas sealing device of the present invention includes a sealing support 11 , a compression spring 16 , a floating ring 12 , a rotating shaft 13 , a shaft sleeve 14 , and a positioning pin 15 . The sealing support 11 is an annular structure, the middle part of the sealing support 11 is provided with a bearing 17, and the rotating shaft 13 is assembled on the bearing 17, so that the rotating shaft 13 is fixedly connected with the sealing support 11. The axle sleeve 14 is interference fit on the rotating shaft 13, and the axle sleeve 14 rotates with the rotating shaft 13, as Figure 4 As shown, the outer wall of the shaft sleeve 14 is provided with a helical groove 18, a platform 19 and a dam 20, wherein the platform 19 refers to the surface between the two helical grooves 18, and the dam 20 refers to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com