Ternary distortion-type groove end surface mechanical sealing structure

An end-face mechanical seal and mechanical seal technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of insufficient fluid film rigidity, large fluid film rigidity, large seal leakage, etc., and achieve strong diversion effect. , low leakage rate, enhanced compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

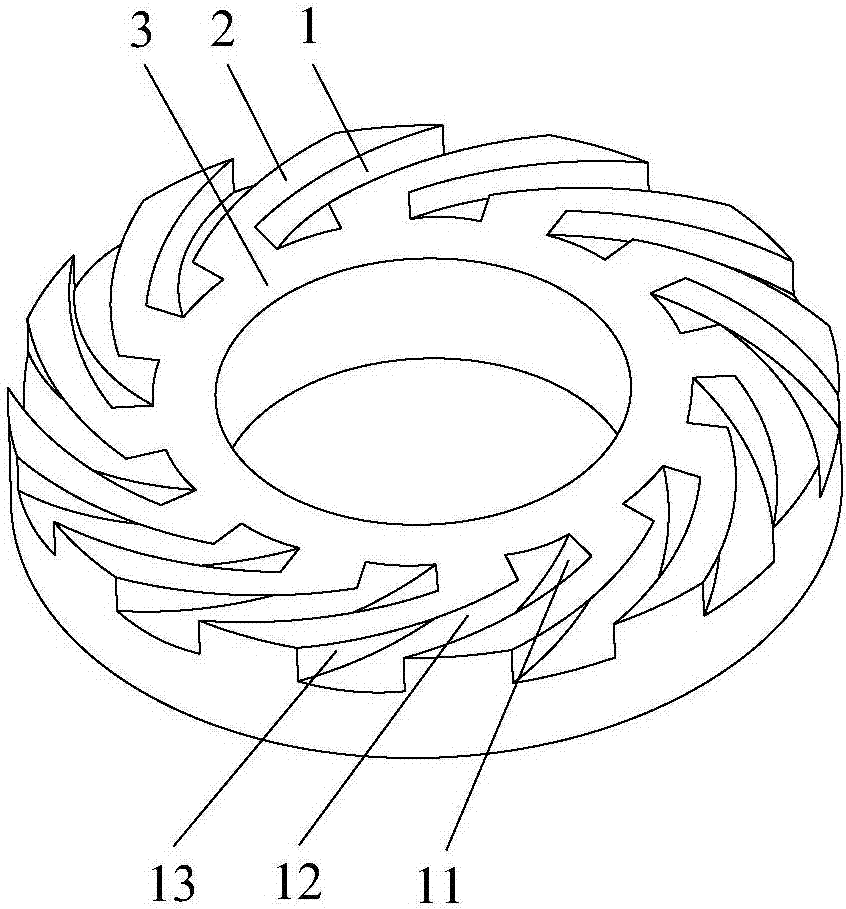

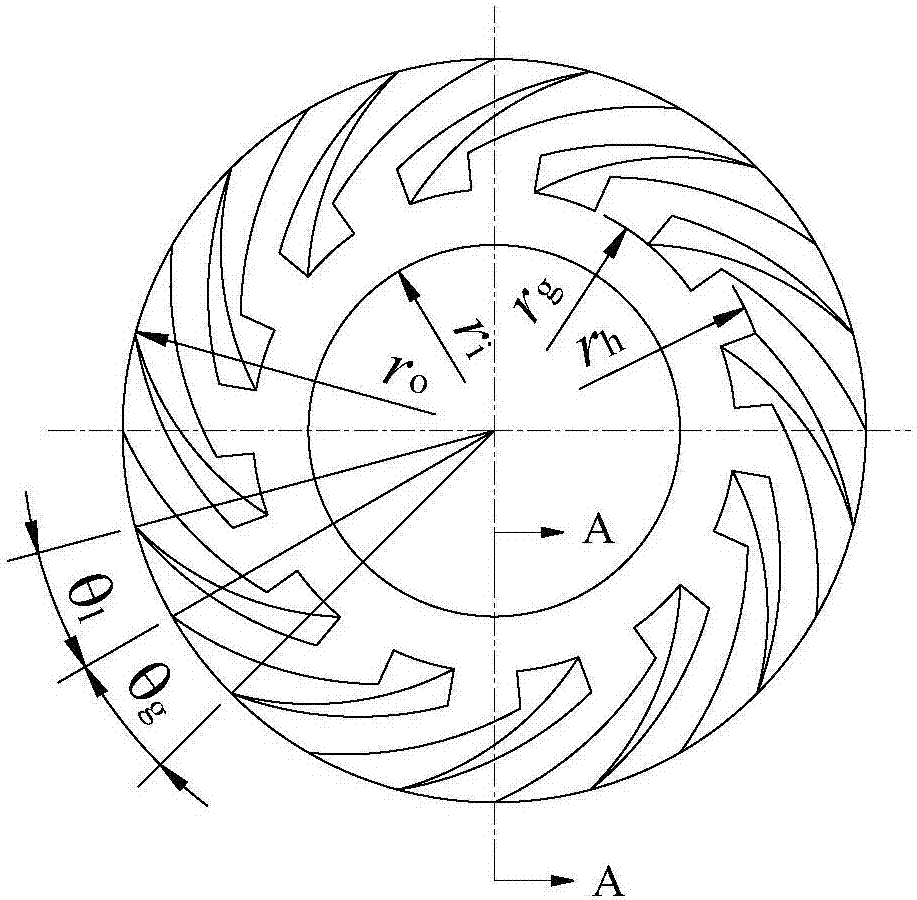

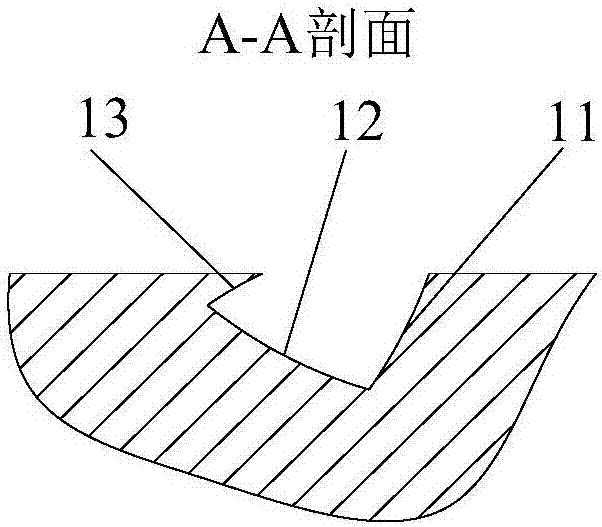

[0025] see figure 1 , 2 , 3 and 4, a three-element twisted groove end face mechanical seal structure, including a moving ring and a static ring of a mechanical seal, at least one of the sealing rings in the moving ring and the static ring is processed with seals evenly distributed along the circumference Three-dimensional twisted groove 1, the three-dimensional twisted groove 1 is composed of a three-dimensional twisted wall surface 11 on the windward side, a three-dimensional twisted wall surface 13 on the leeward side, and a three-dimensional twisted deep groove bottom surface 12; the side wall of the three-dimensional twisted groove 1 Including the three-dimensional twisted wall surface 11 on the windward side and the three-dimensional twisted wall surface 13 on the leeward side, the bottom surface 12 of the three-dimensional twisted deepening groove gradually becomes shallower in a twisted shape from the outer peripheral side wall of the sealing ring to the center of the s...

Embodiment 2

[0032] see figure 1 , 2 , 3 and 4, the difference between this embodiment and Embodiment 1 is: the intersecting line of the medium inlet side in the intersection line between the side wall of the three-dimensional twisted groove 1 and the sealing end surface, that is, the three-dimensional twisted wall surface 11 on the windward side and the sealing end surface The intersection line 113 on the leakage port side and the intersection line 133 between the ternary twisted wall surface 13 on the leeward side and the medium inlet side of the sealing end surface are logarithmic helical lines. At the same time, the projection line of the intersection line 112 of the three-dimensional twisted wall surface 11 on the windward side and the bottom surface 12 of the three-dimensional twisted deep groove on the sealing end surface, and the intersection line 132 of the three-dimensional twisted wall surface 13 on the leeward side and the bottom surface 12 of the three-dimensional twisted deep...

Embodiment 3

[0036] refer to Figure 5 , 6 The difference between this embodiment and Embodiment 1 is that the projection line of the intersection line 112 of the three-dimensional twisted wall surface 11 on the leeward side and the bottom surface 12 of the three-dimensional twisted deep groove on the sealing end surface is a straight line, and the three-dimensional twisted wall surface on the windward side The projection line of the intersection line 132 of the element twisted wall surface 13 and the three-dimensional twisted deep groove wall surface 12 on the sealing end surface is a straight line; the intersection line 113 of the three-dimensional twisted wall surface 11 on the leeward side and the medium inlet side of the sealing end surface is a straight line, and the The intersection line 133 between the three-dimensional twisted wall surface 13 on the windward side and the medium inlet side of the sealing end surface is a straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com