An ultra-high temperature, high pressure and large flow rapid response solenoid valve

A fast-response, high-flow technology, applied in the field of solenoid valves, it can solve the problems of unsuitable high temperature and high pressure environment, long opening and closing response time, etc., and achieve the effect of clear movement direction, enhanced opening speed, and strong opening force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

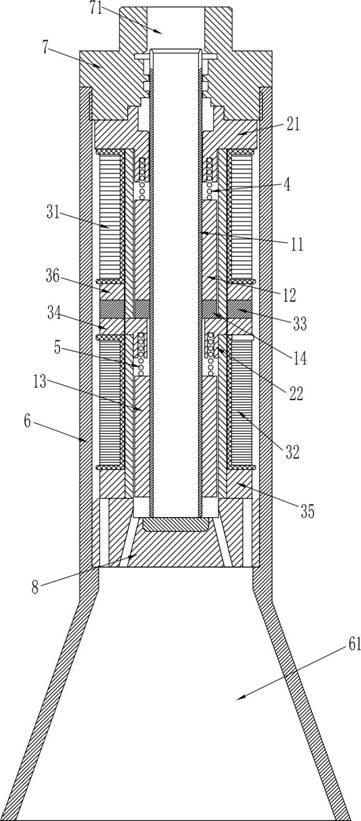

[0047] see Figure 1 to Figure 12 , The present invention provides an ultra-high temperature, high pressure and large flow rapid response solenoid valve, including a slidable movable valve core assembly, a magnetic isolation tube assembly, a coil assembly, a casing 6 and a valve body 7 .

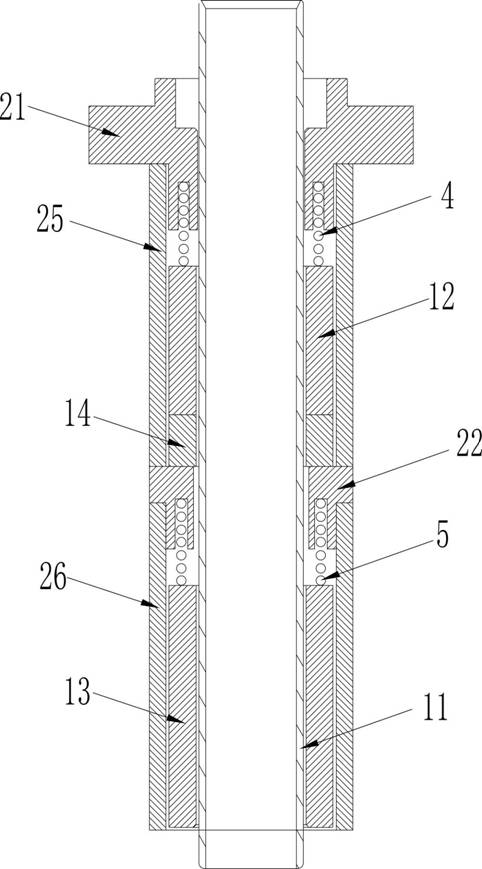

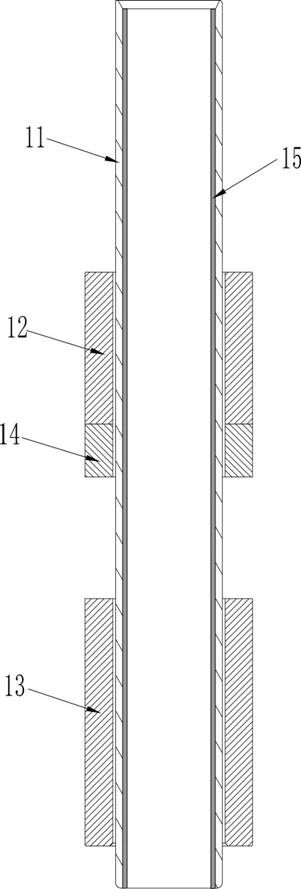

[0048] see figure 2 and image 3 , the movable valve core assembly includes a slidable central tube 11 and an upper movable iron core 12 and a lower movable iron core 13 arranged on the outer wall of the central tube 11 at intervals along the axial direction, between the upper movable iron core 12 and the lower movable iron core 13 A magnetic isolation ring 14 is installed. A heat insulating layer 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com