Valve assembly for controlling gas pressure, fuel system comprising valve assembly for controlling gas pressure

A fuel system and gas pressure technology, applied in the charging system, engine components, combustion engines, etc., can solve the problems of crack formation, irreparable and damaged sealing components, and achieve the effect of damping and reliable medium separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

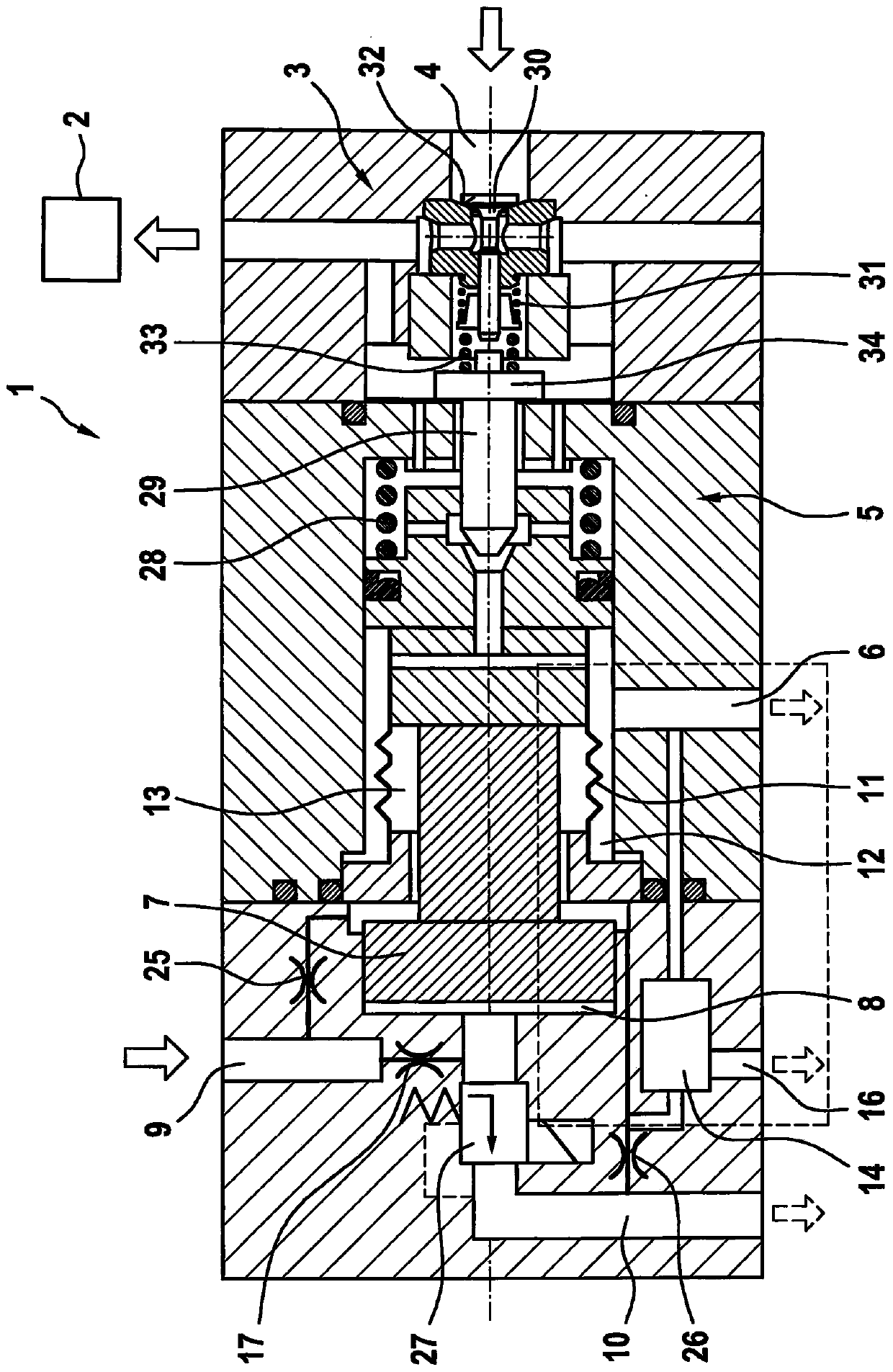

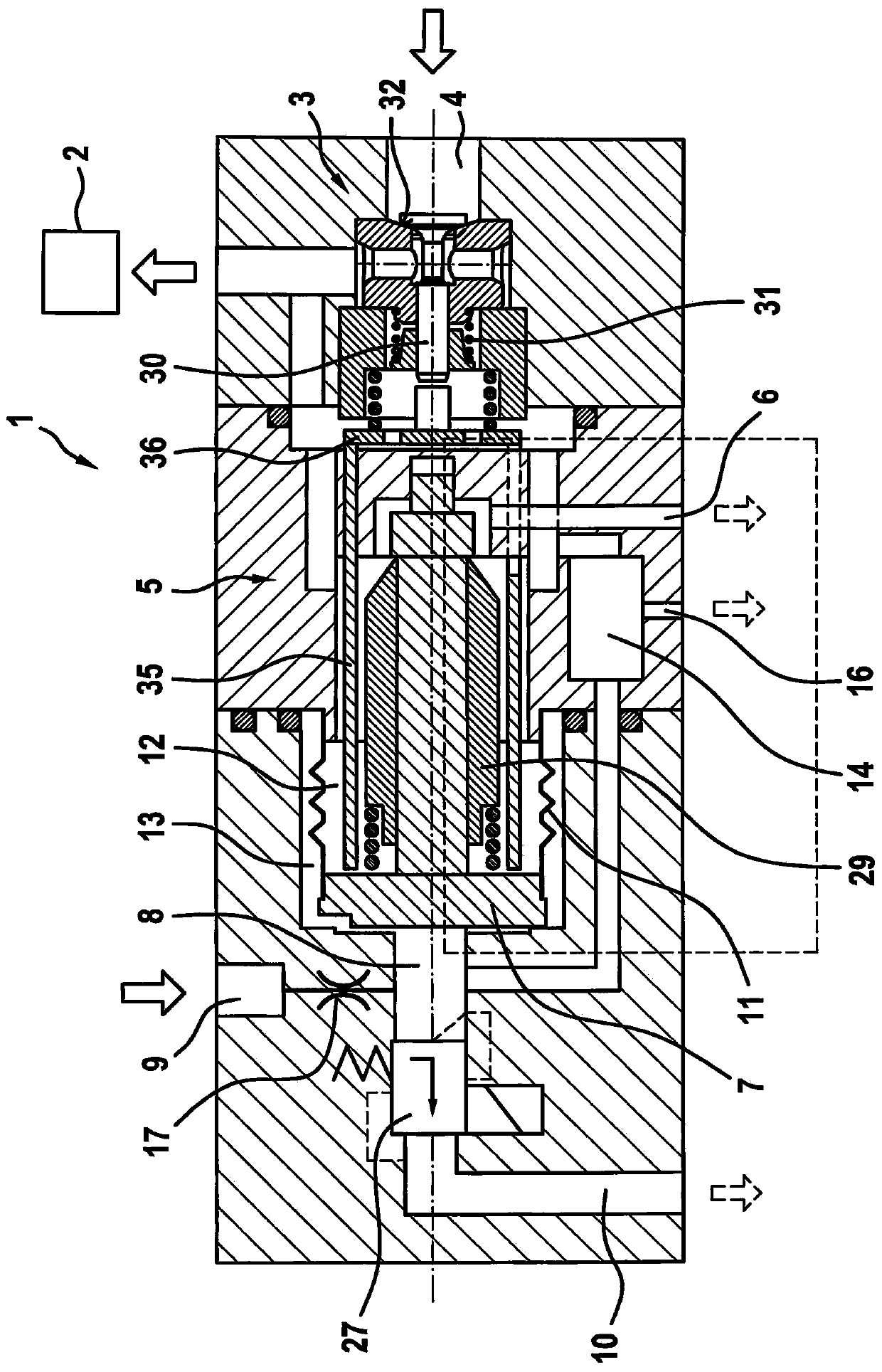

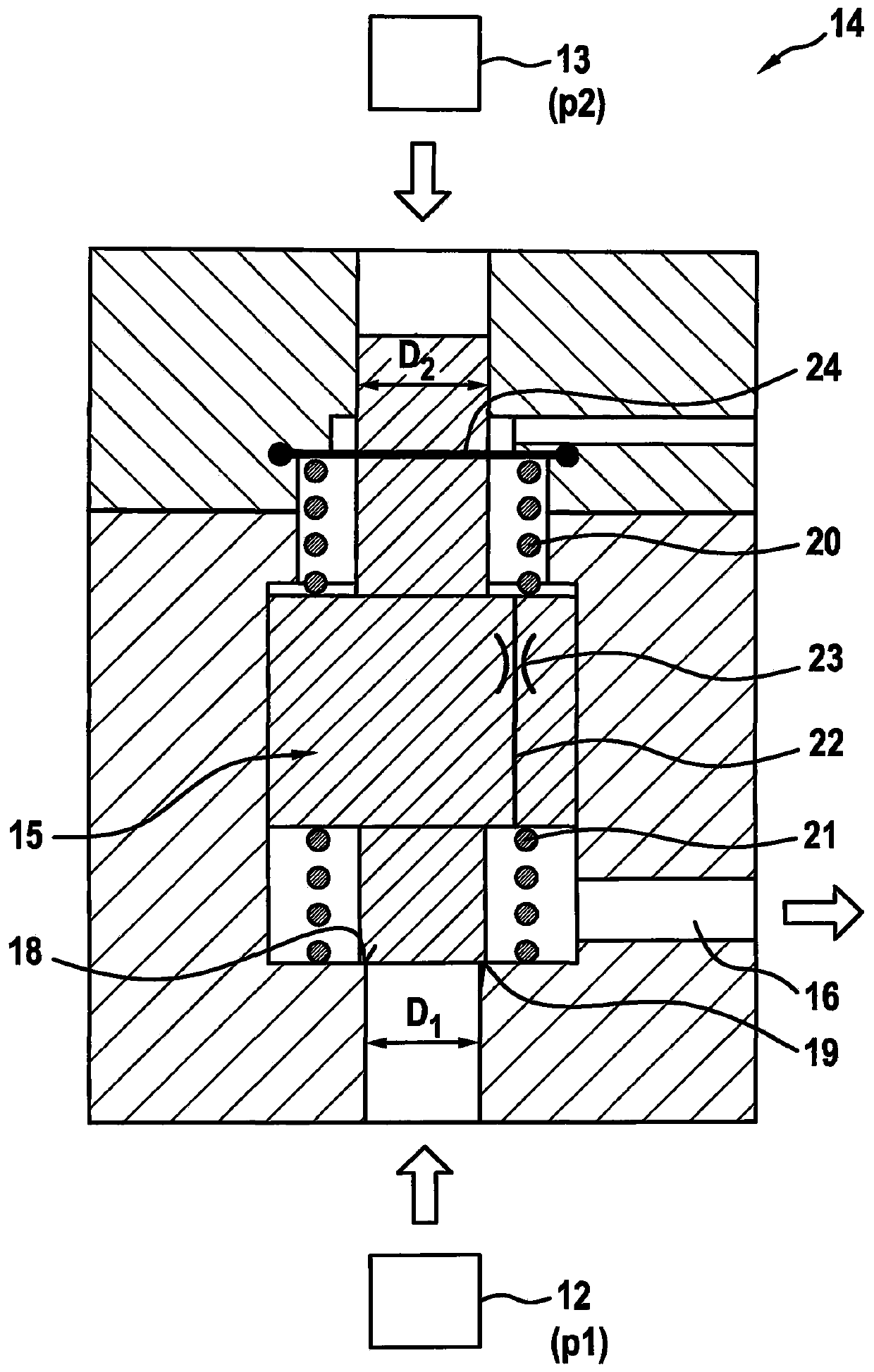

[0027] from figure 1A valve assembly 1 for regulating the gas pressure in a gas rail 2 of a fuel system for supplying an internal combustion engine with gaseous fuel is known from . The gaseous fuel may especially be natural gas. For this purpose, the valve assembly 1 shown has a first valve 3 via which the gas rail 2 can be connected to the gas inflow 4 and a second valve 5 for connecting the gas rail 2 to the gas return 6 connect. By selectively opening and closing the valves 3, 5, the gas pressure in the gas rail 2 can be increased or decreased. The two valves 3 , 5 are arranged coaxially and are actuated by a control piston 7 which is likewise arranged coaxially. The control piston 7 delimits a control chamber 8 , which can be supplied with hydraulic pressure medium, for example diesel fuel, via a pressure medium inflow 9 with an integrated inlet restriction 17 . The control chamber 8 can be connected to the pressure medium outflow 10 via a pressure medium overflow val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com