High pressure fuel pump for fuel injection system

A fuel injection system and fuel injection technology, which are applied to fuel injection pumps, fuel injection devices, charging systems, etc., can solve problems such as rapid stop of internal combustion engines, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

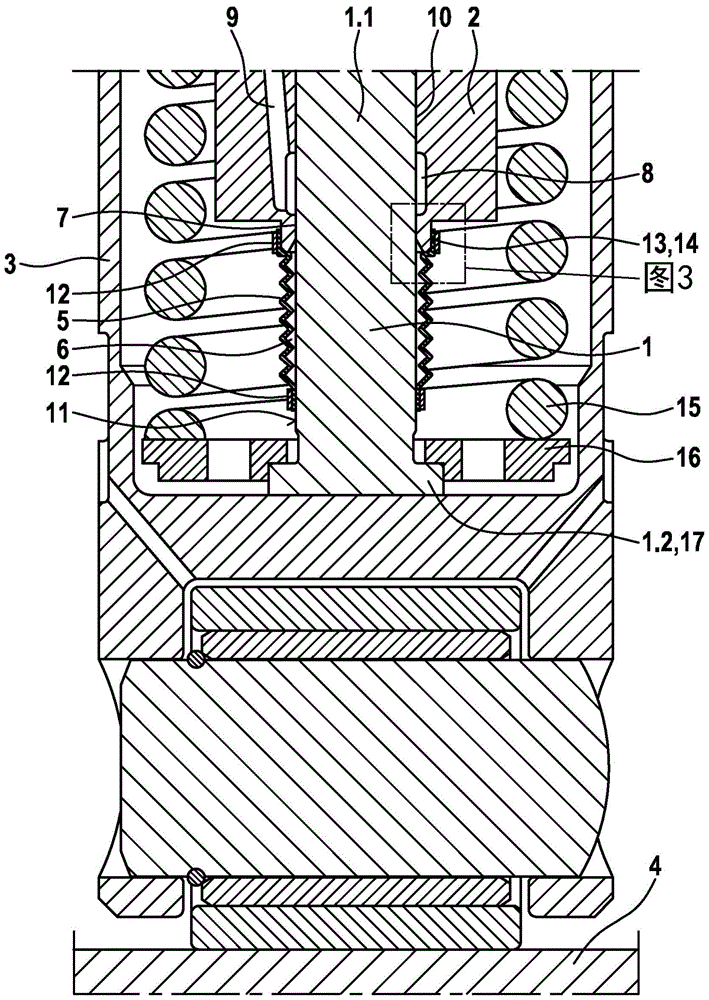

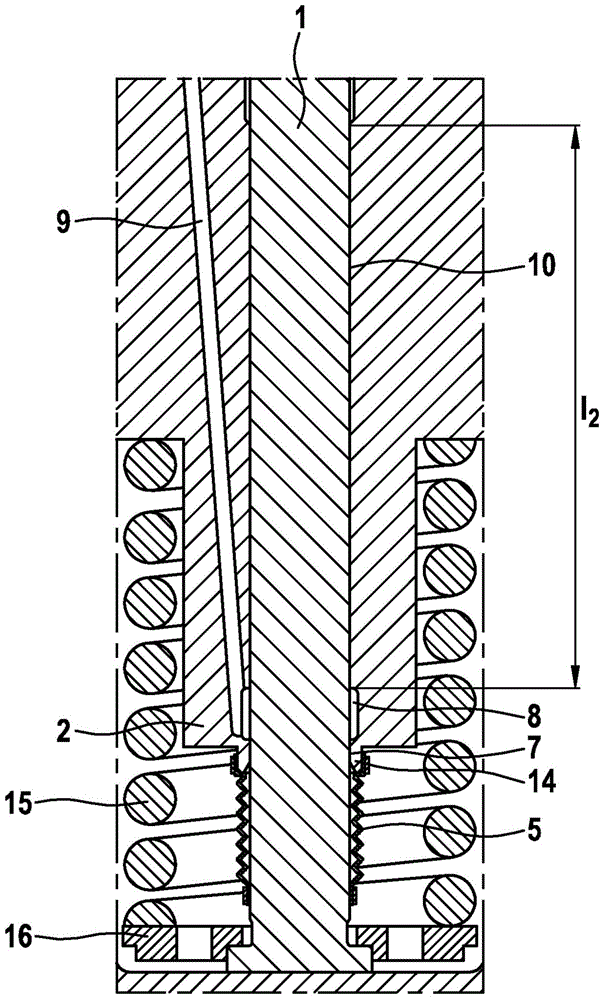

[0018] figure 1 The shown cartridge pump comprises a pump piston 1 whose first end 1.1 is housed in a hollow cylinder 2 of the cylinder head and whose second end 1.2 is indirectly supported on a camshaft 4 via a cup-shaped part 3 superior. The second end 1 . 2 forms a piston bottom 17 on which a spring seat 16 is located, wherein the spring seat 16 serves to accommodate the spring 15 . The spring force of the spring 15 keeps the cup part 3 and the pump piston 1 in contact with the camshaft 4 . The hollow cylinder 2 is surrounded by the spring 15 and the cup-shaped part 3 .

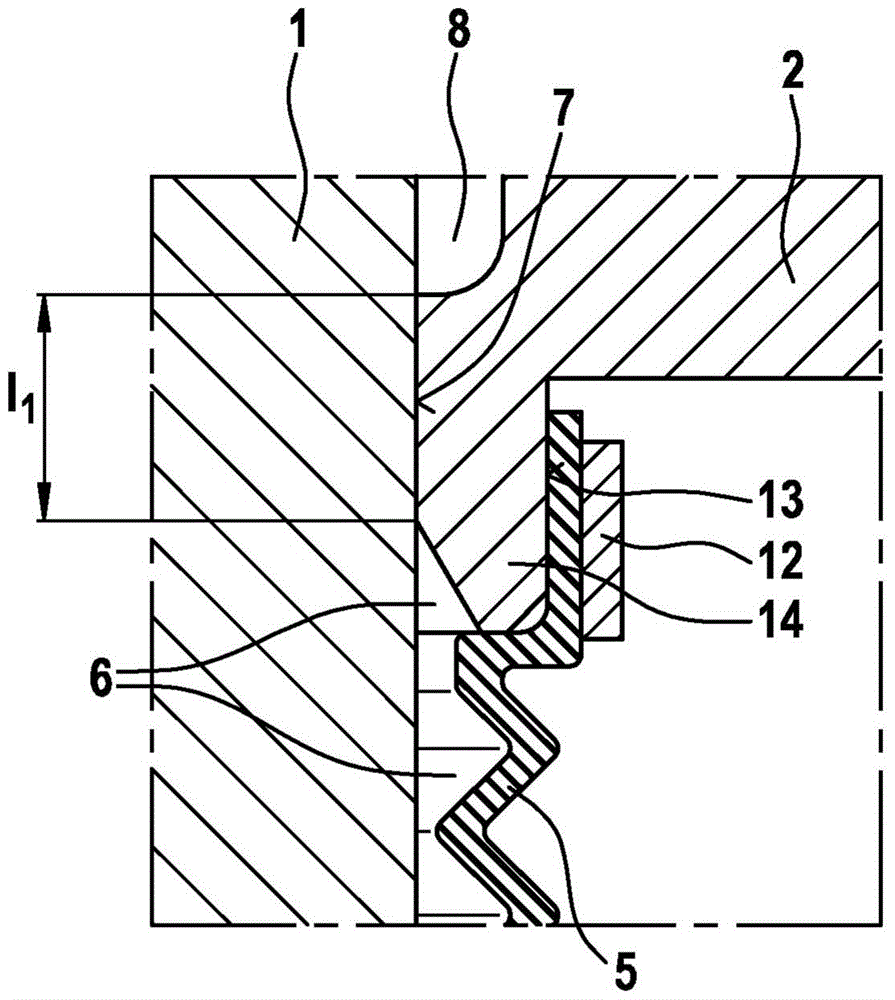

[0019] To seal the guide gaps 7 , 10 , the pump piston 1 and the hollow cylinder 2 are connected via a seal 5 designed as a bellows. The seal 5 is fastened on one side to the outer peripheral surface 11 of the pump piston 1 and on the other side to the outer peripheral surface 13 of a neck ring 14 which rests on the hollow cylinder 2 . These fastenings are carried out by means of a crimped ring 12 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com