Nozzle assembly for fuel injection valve, and fuel injection valve

A fuel injection valve and component technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as poor preparation of gaseous fuel, high calorific value, etc., achieve reliable medium separation, improve service life, wear and tear reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

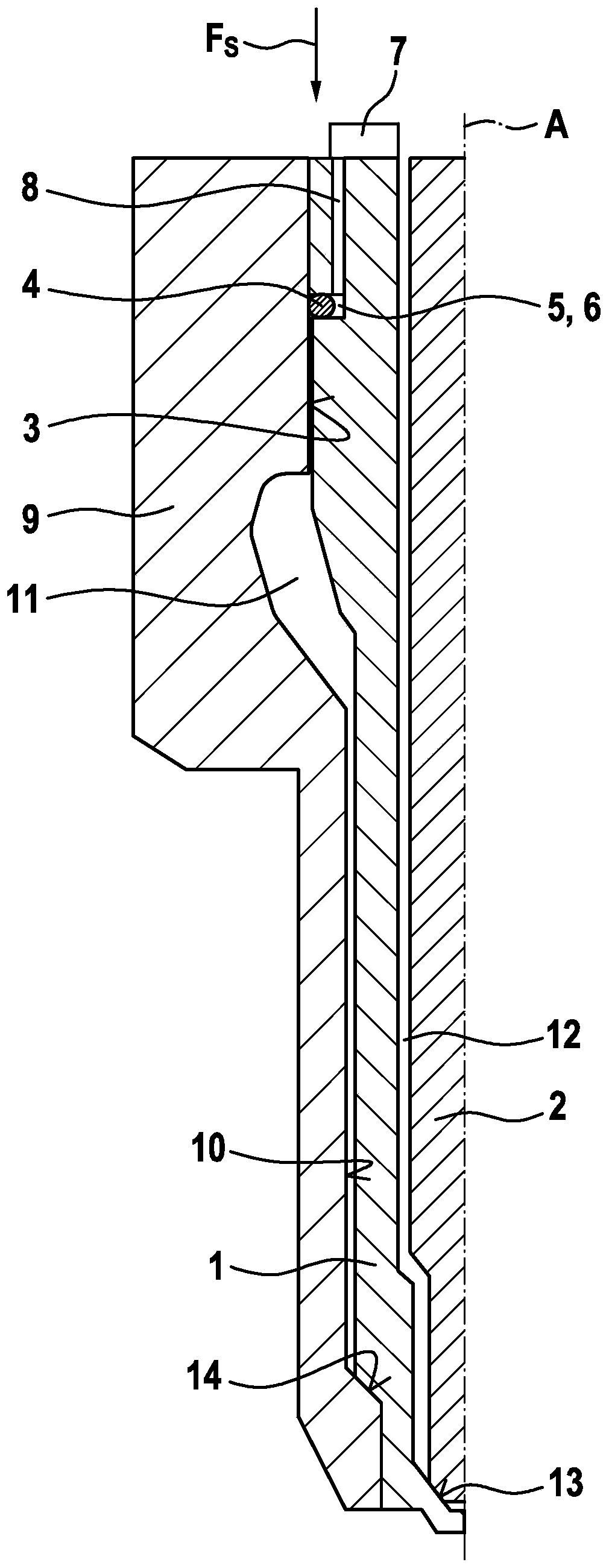

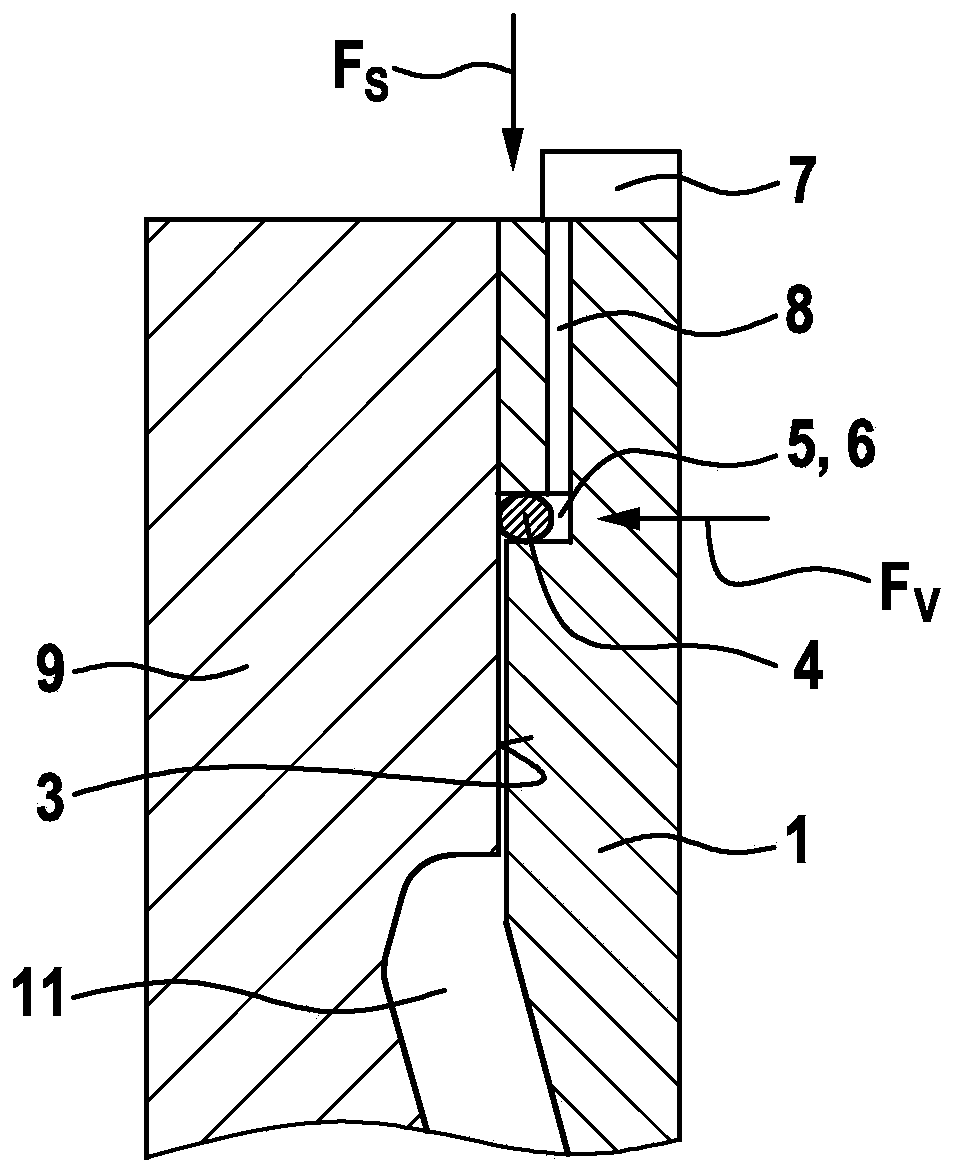

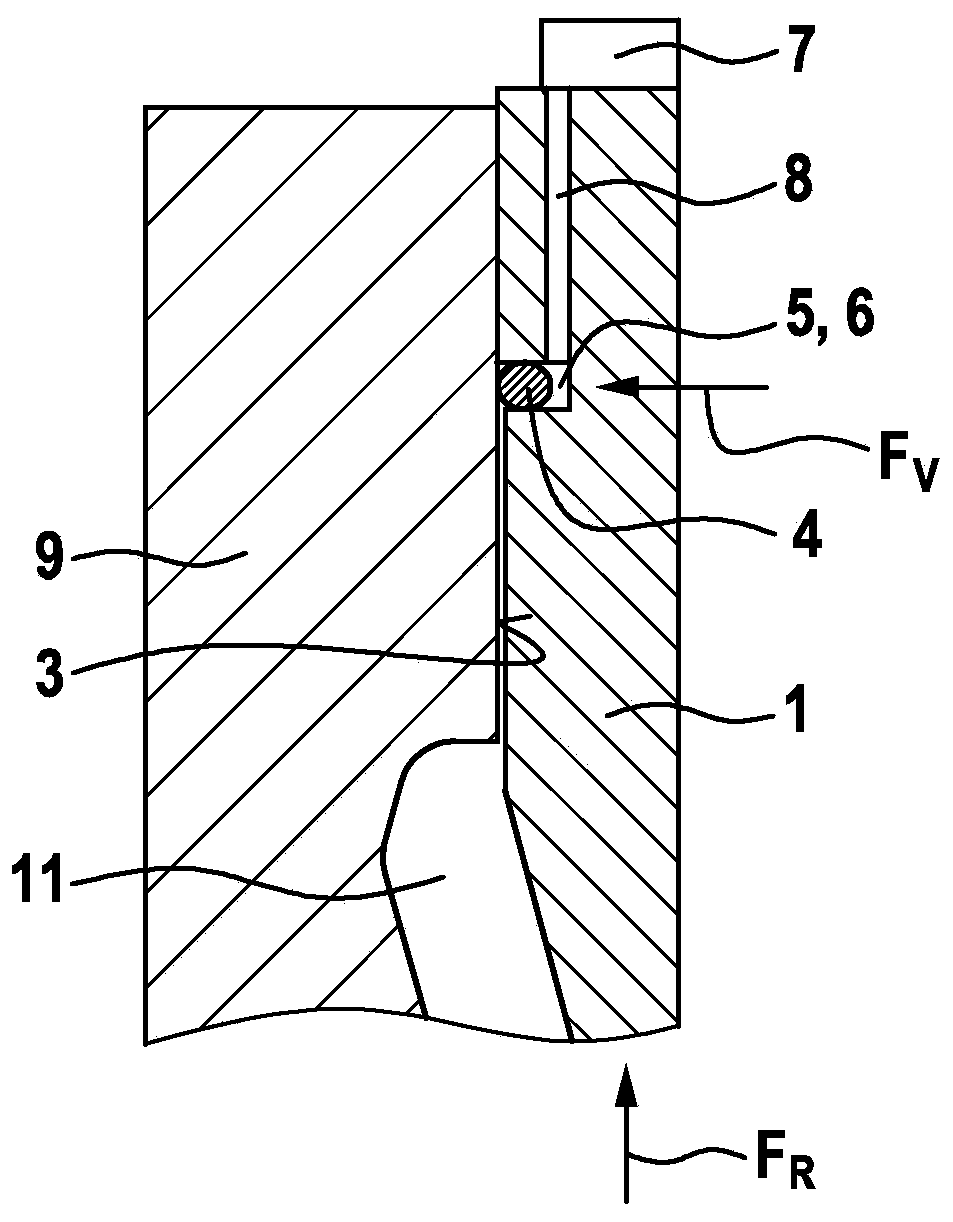

[0025] Depend on figure 1 The nozzle assembly of the present invention is available for fuel injection valves, especially for dual fuel injectors. The nozzle assembly comprises two coaxially arranged nozzle needles 1 , 2 guided within one another, which are accommodated at least in sections in a nozzle body 9 . For this purpose, the nozzle body 9 has a central bore 10 . The outer nozzle needle 1 delimits within the bore 10 a gas region 11 which can be impinged with gaseous fuel. The inner nozzle needle 2 and the outer nozzle needle 1 together delimit a liquid fuel region 12 . In this case, the outer nozzle needle 1 forms the sealing seat 13 of the inner nozzle needle 2 , and the nozzle body 9 forms the sealing seat 14 of the outer nozzle needle 1 .

[0026] The two nozzle needles 1 , 2 are controlled hydraulically, liquid fuel, preferably diesel fuel, being used as control medium.

[0027] In order to control the lift movement of the outer nozzle needle 1 , a control chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com