Auxiliary opening mechanism for flue check valve

A technology of check valve and flue, which is applied in the direction of lift valve, valve device, mechanical equipment, etc. It can solve the problems that the windshield cannot be opened and the windshield is bonded to the shell, so as to achieve the concentration of force and the smoothness of the valve plate. Enhanced opening force and convenient opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

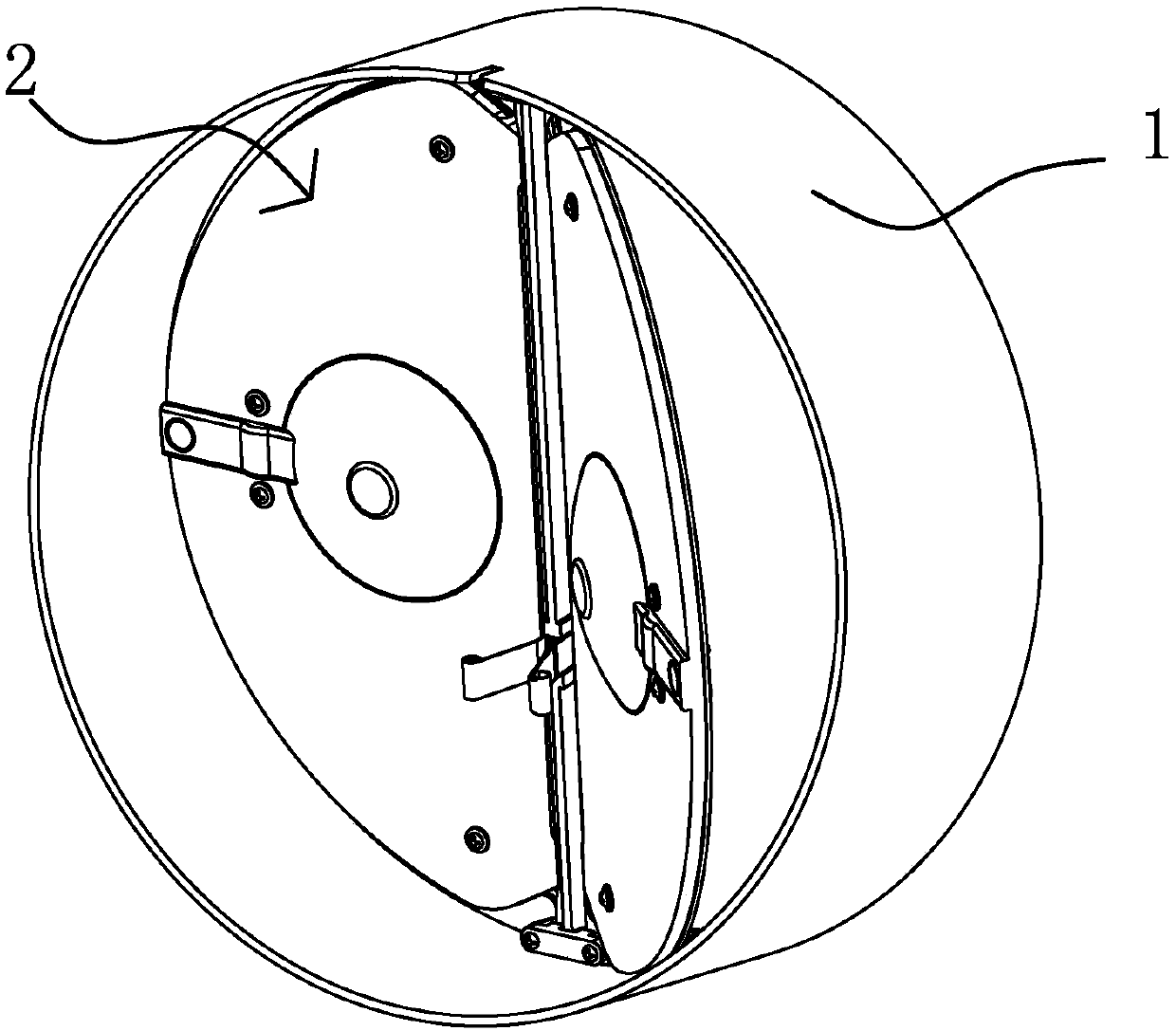

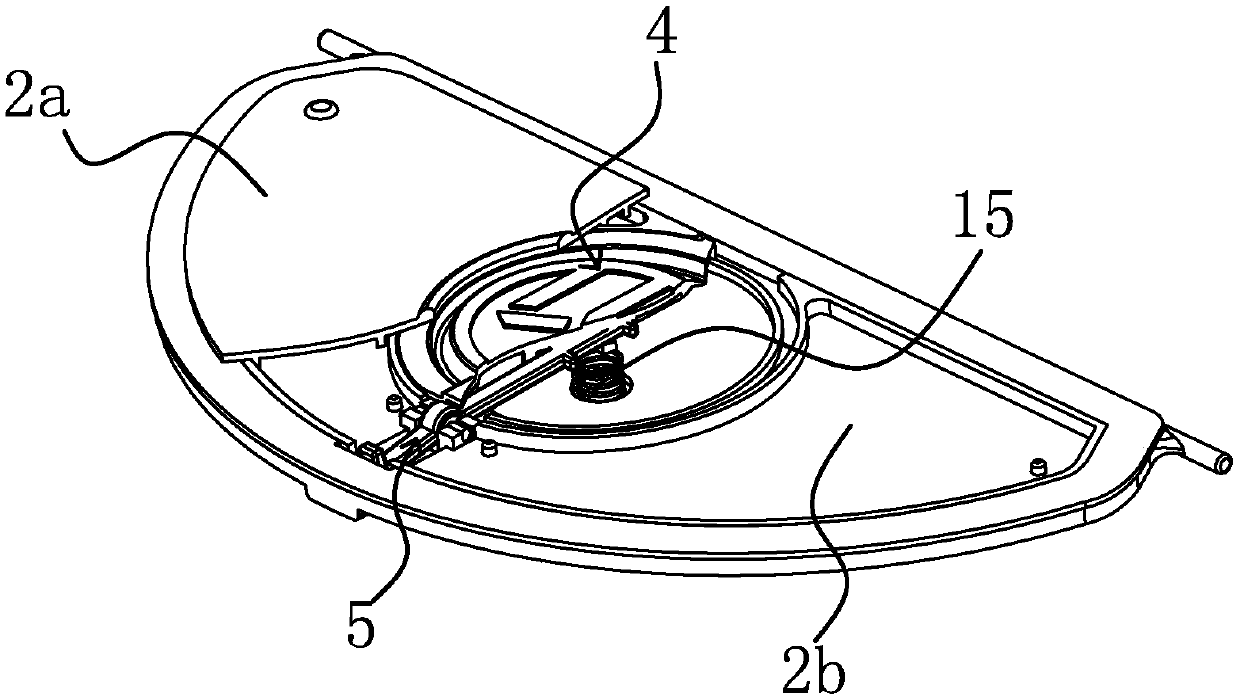

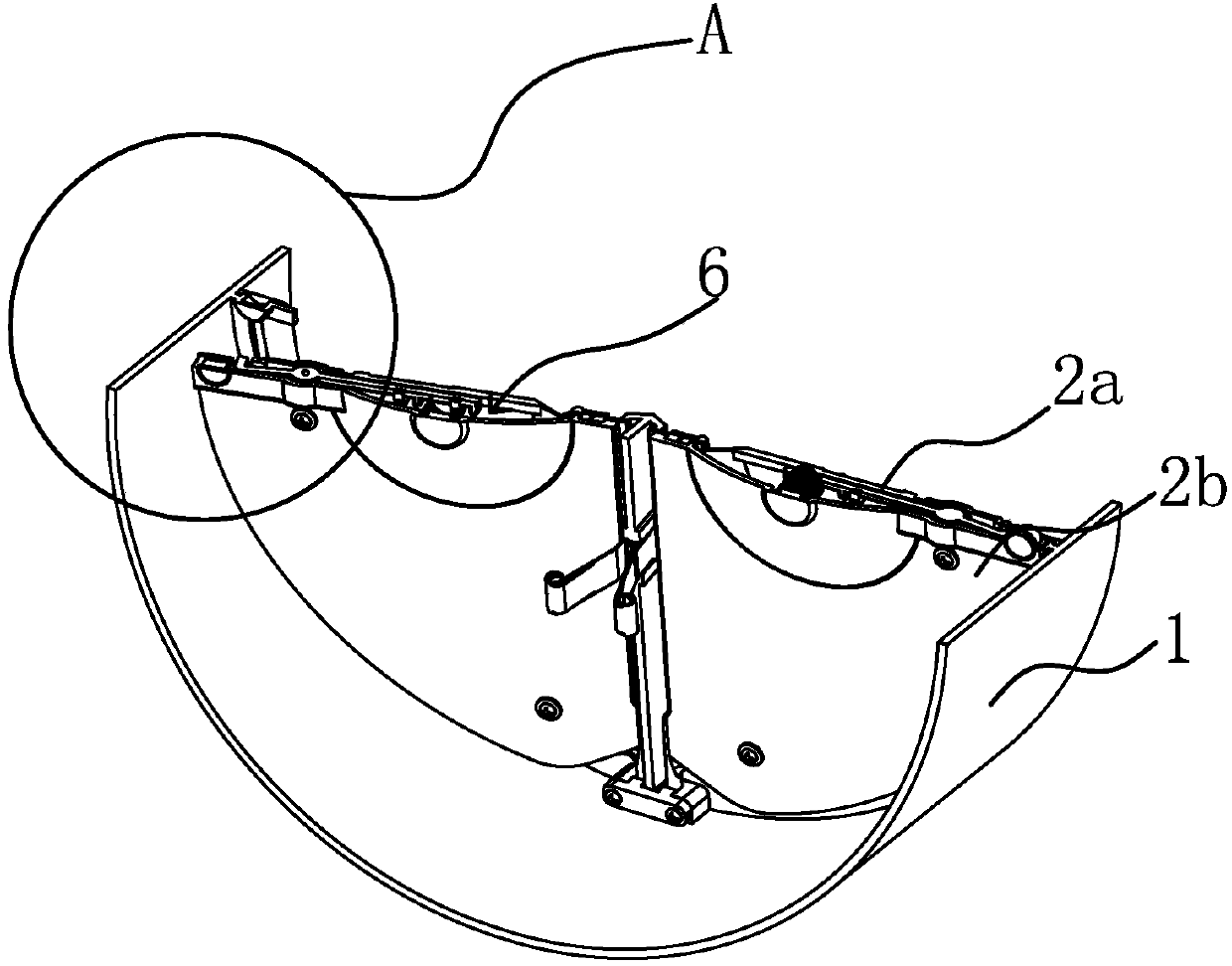

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6Shown is an auxiliary opening mechanism for a flue check valve. The flue check valve includes a casing 1 and two valve pieces 2. The casing 1 has an annular sealing edge 3, and the valve piece 2 is hinged on the casing 1. Inside, the edge of the valve plate 2 can be attached to or separated from the annular sealing edge 3. The housing 1 has an air inlet end and an air outlet end. The auxiliary opening mechanism includes a swing rod 5. The valve plate 2 includes an upper body 2a and a lower body. The plate body 2b, the upper plate body 2a and the lower plate body 2b are fixed, the upper plate body 2a is close to the air inlet end, the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com