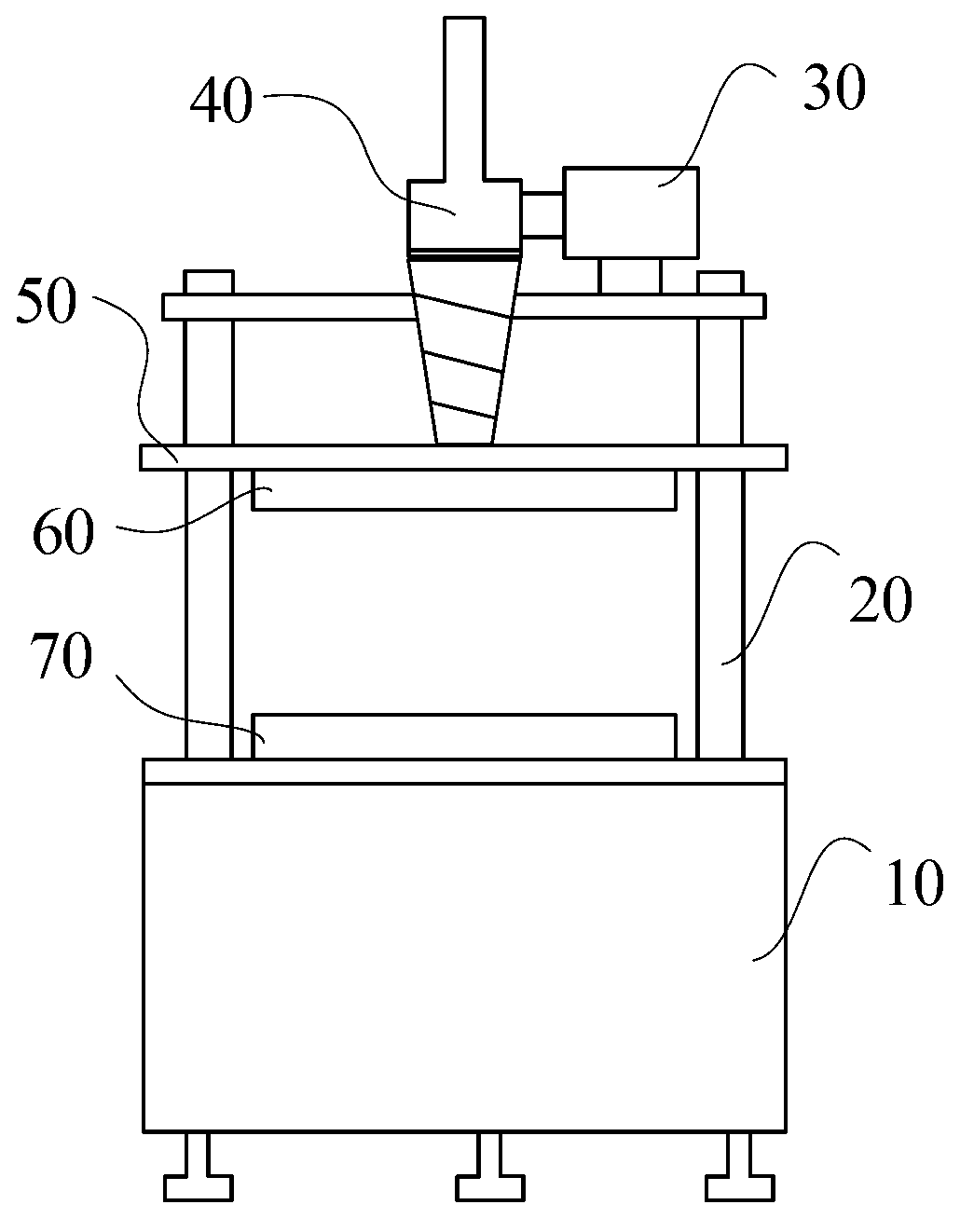

Pressure device

A technology of pressurizing equipment and static pressure plate, applied in the directions of presses, punching machines, optics, etc., can solve the problems of uneven pressure of liquid crystal panels, high pressure, affecting the qualification rate of liquid crystal panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

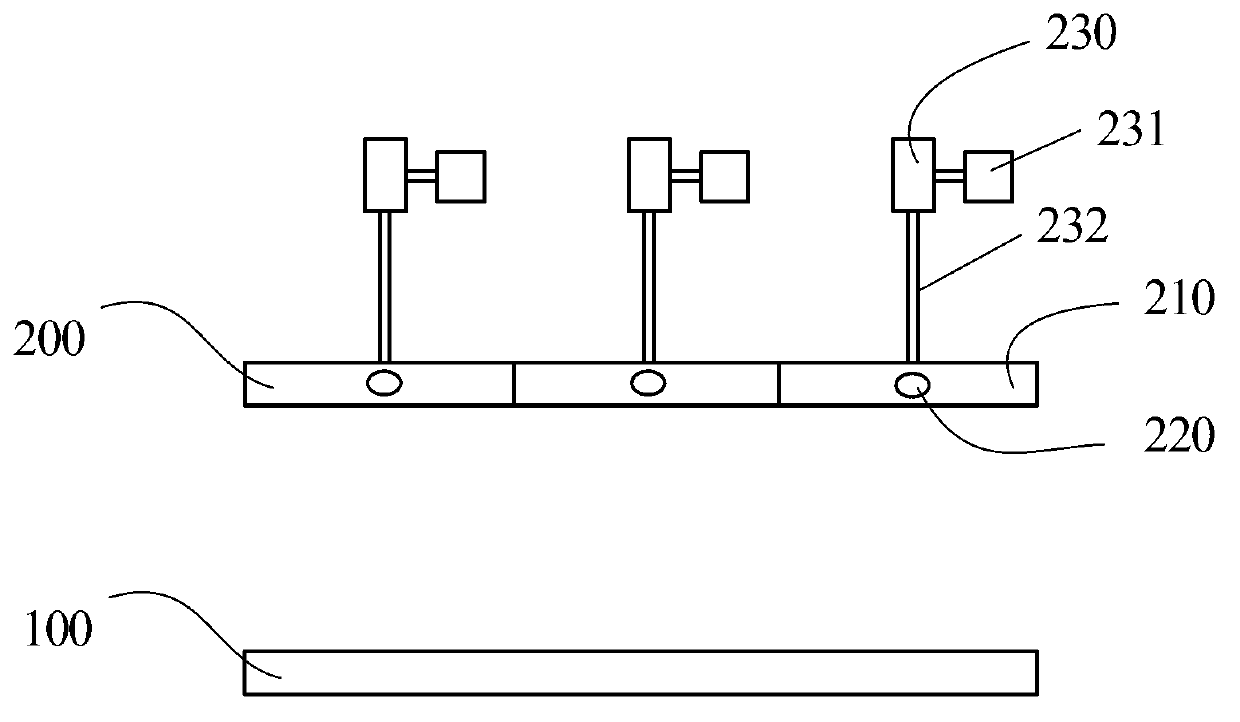

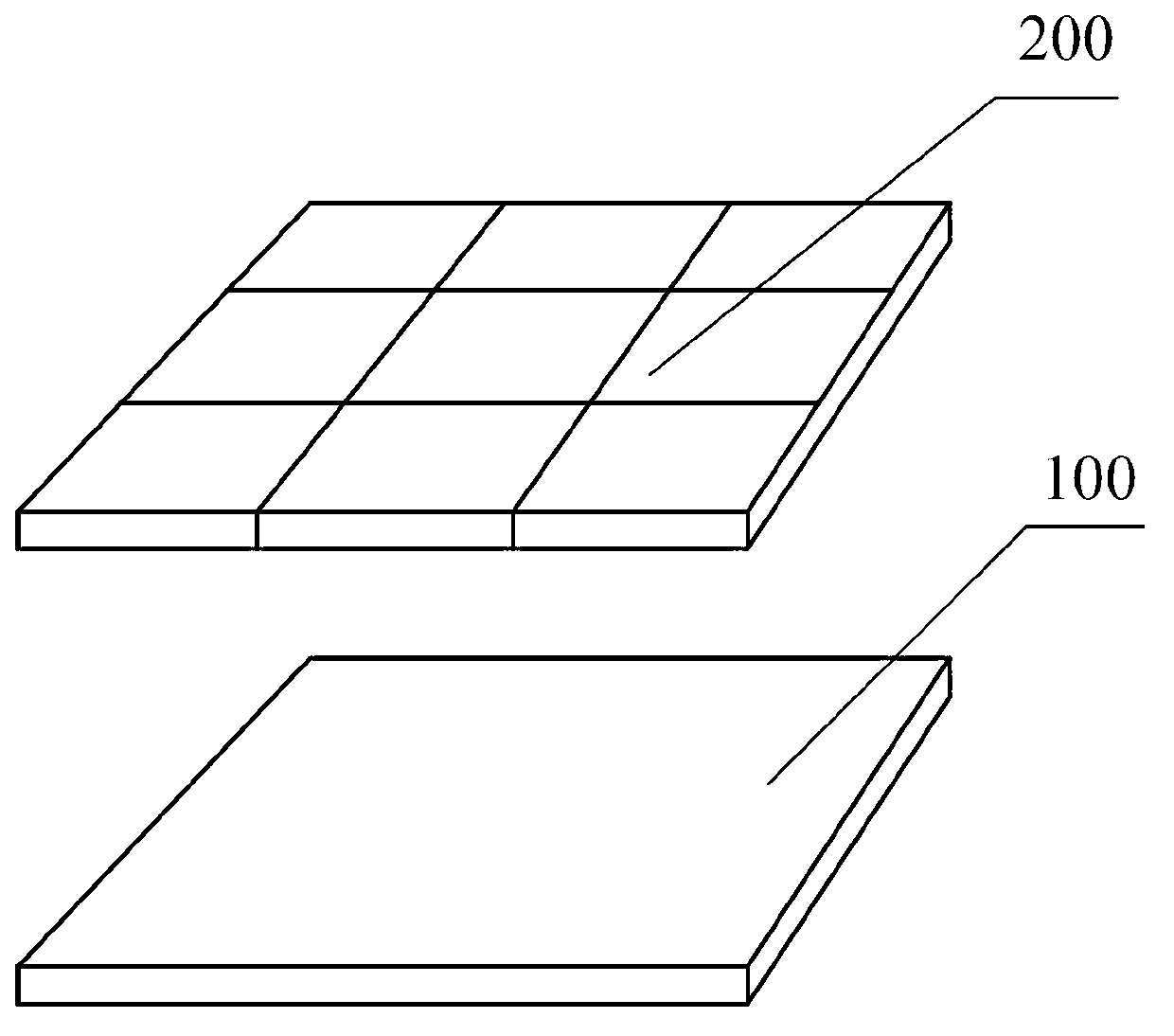

[0027] The invention provides a pressurizing device, which divides the dynamic pressure plate of the overall structure into a plurality of movable pressing blocks, and adjusts the pressure exerted on the liquid crystal panel by each movable pressing block through a control device, that is, appropriately increases the pressure of the area where the pressure is insufficient. For the area with excessive pressure, the pressure on the area is appropriately reduced, so that the pressure on each area of the LCD panel is the same, thereby reducing the probability of defects such as uneven thickness of the sealing glue line and uneven thickness of the box, thereby improving The qualified rate of LCD panels in the lamination process.

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com