Water and sand separation and measurement device in water and sand uprush test system

A test system and metering device technology, applied to the measuring device, by removing certain components to weigh, weigh, etc., can solve the problem of insufficient water head pressure, inability to measure water and sand surges separately, and inconvenient tests, etc. problem, to achieve the effect of preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

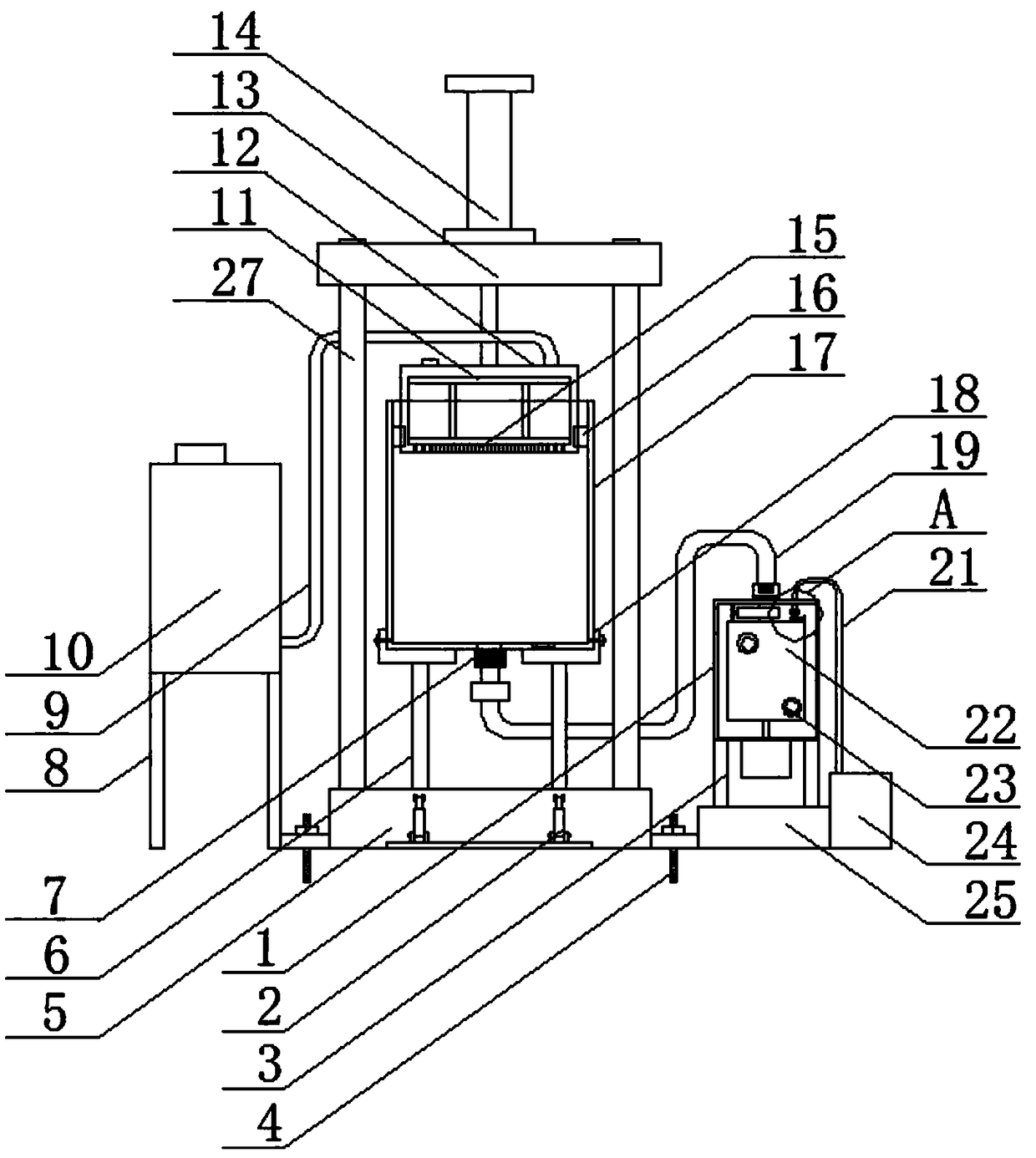

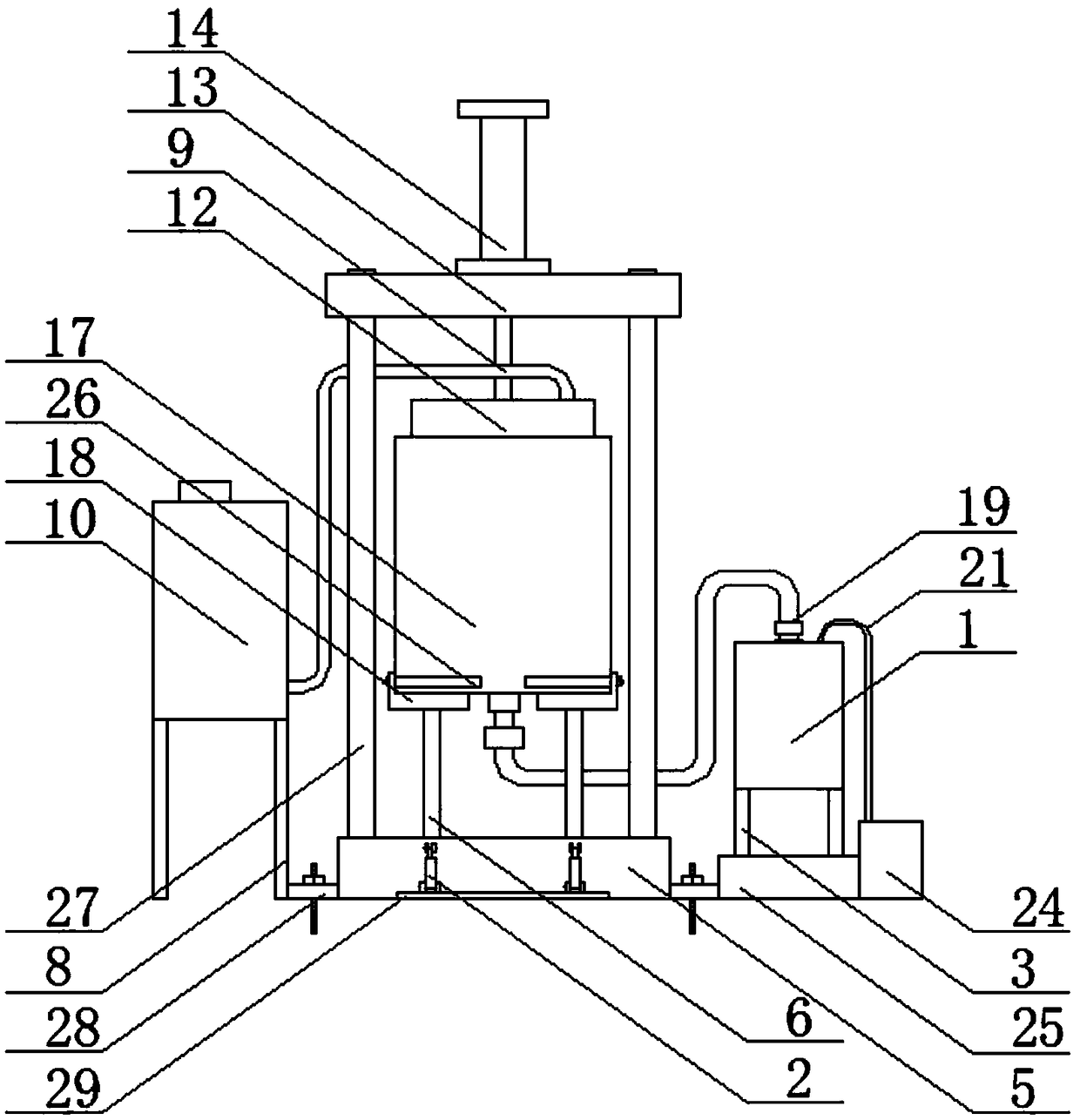

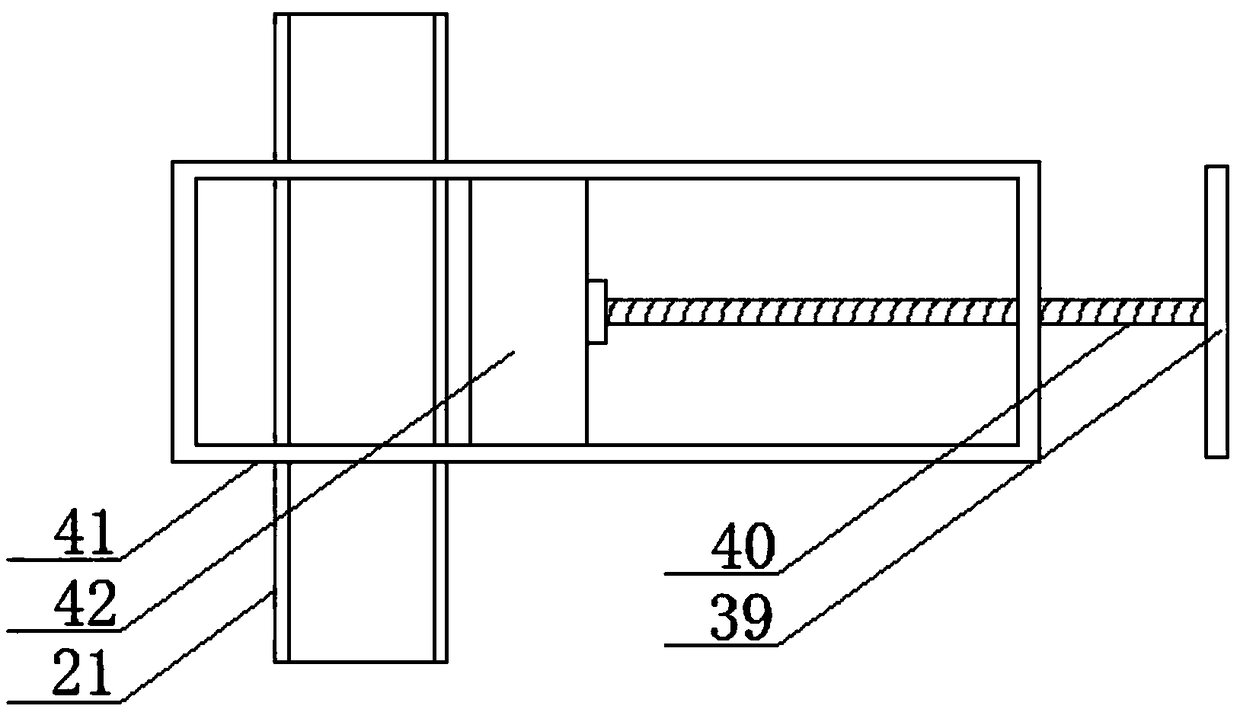

[0030] refer to Figure 1-7 , a water-sand inrush separation and metering device in a water-sand inrush test system, including an operating platform 5, conveniently supports the test chamber 17, prevents the test chamber 17 from being disassembled during each test, and avoids causing damage to the test chamber 17. wear and tear, the upper end of the console 5 is fixed with four fixed rods 27, the upper ends of the four fixed rods 27 are jointly fixed with a beam 13, the upper end of the beam 13 is fixed with an oil cylinder 14, and the piston rod of the oil cylinder 14 runs through the side wall of the beam 13 and extends To the lower end of the crossbeam 13, four be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com