A Straw Gas Purification System

A technology of gas purification and straw, which is applied in the field of pyrolysis gas purification process, can solve the problems of large equipment resistance, cumbersome process flow, and inapplicable gas purification, etc., to achieve physical and mental health, short process, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

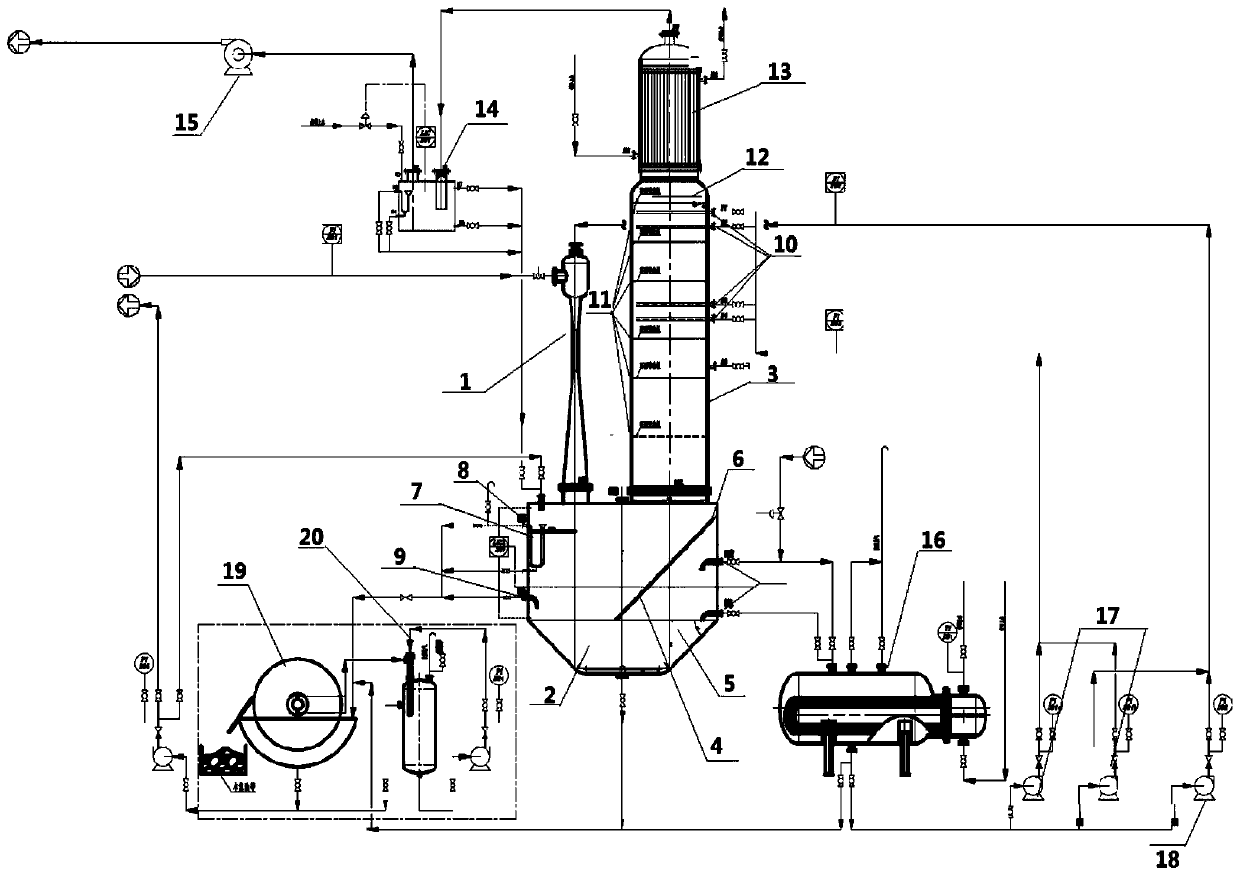

[0044] This embodiment provides a straw gas purification system, such as Figure 1-6 As shown, the straw gas purification system includes:

[0045] The ejector 1 is used to fully mix the high-temperature straw gas with the washing liquid, pressurize it, and then output;

[0046] The sedimentation separation tank 2 is used for gas-liquid separation and output of the straw gas scrubbing liquid mixture output from the ejector 1;

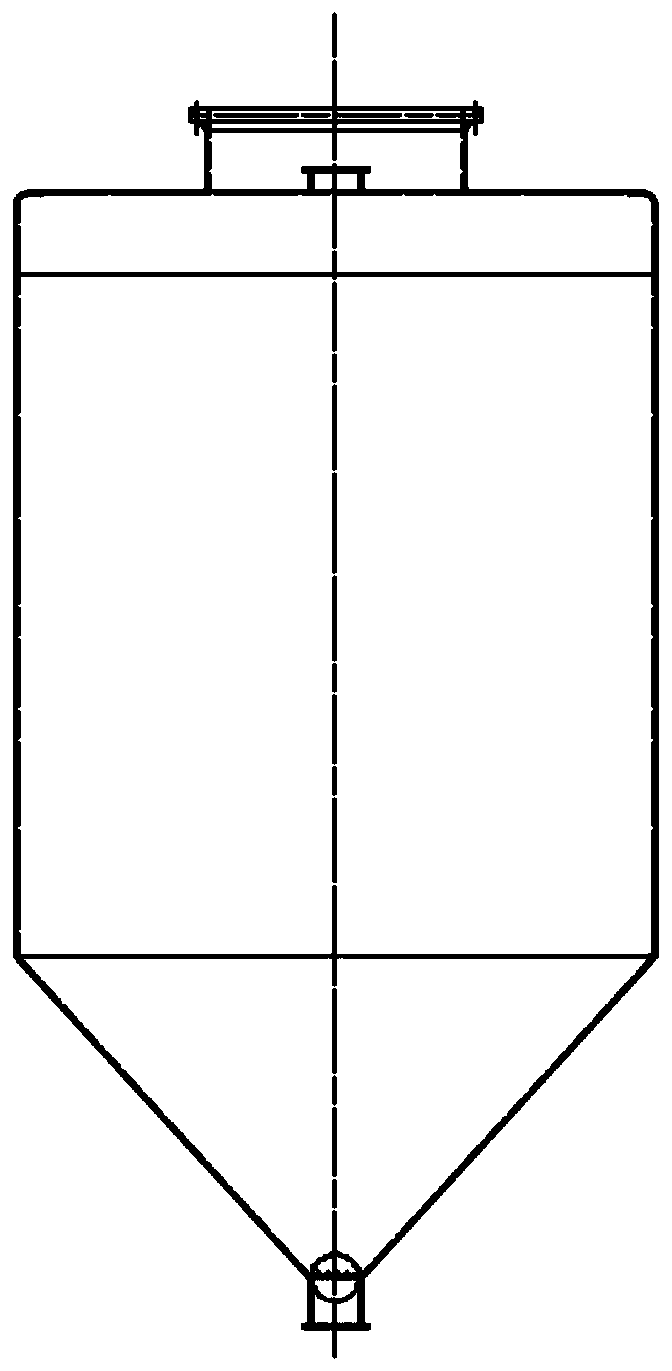

[0047] The spray washing tower 3 is used to purify and wash the gas separated from the settling separation tank 2;

[0048] The settling separation tank 2 is located below the ejector 1 and the spray washing tower 3, and the inlet end and the outlet end of the settling separation tank 2 are respectively connected to the bottom outlet end of the ejector 1 and The bottom inlet end of the spray scrubber 3 is described.

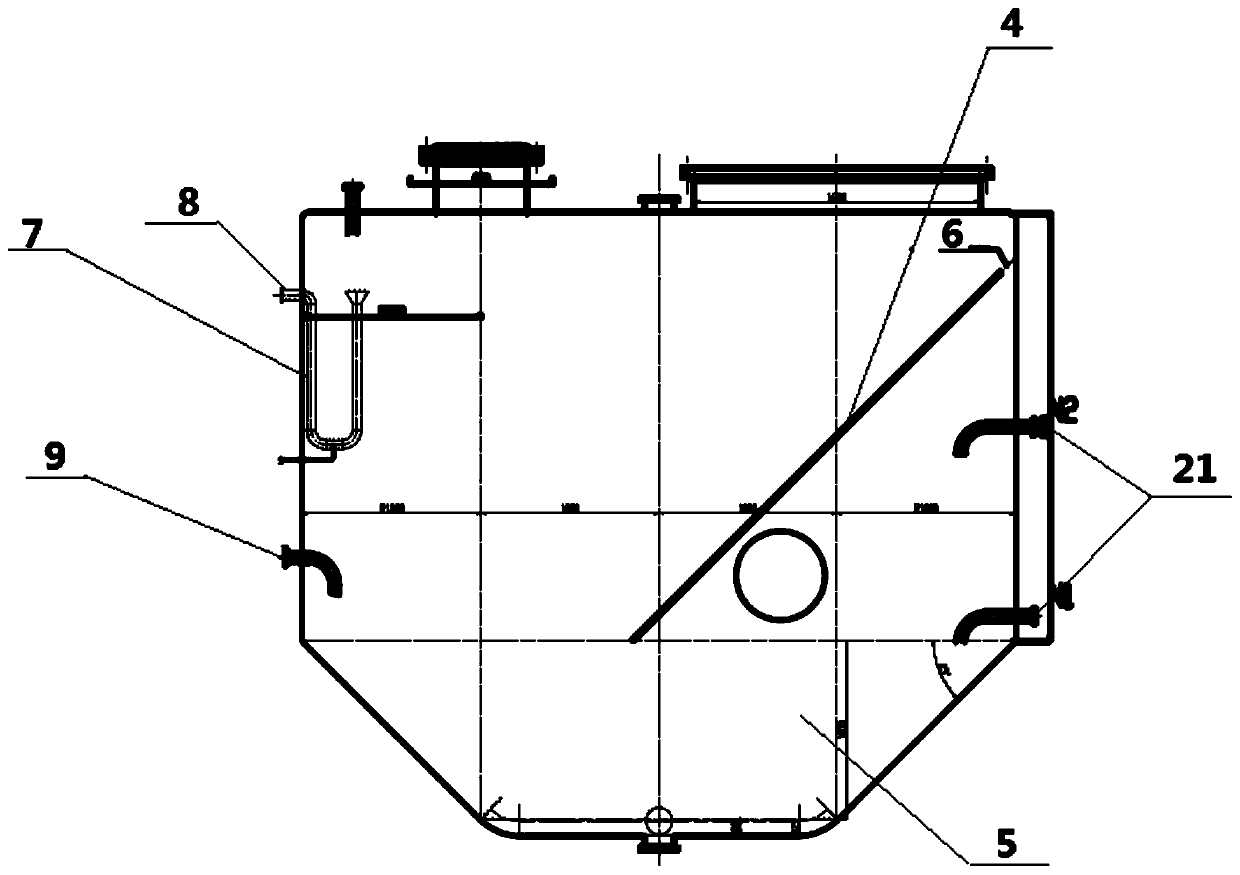

[0049] The sedimentation separation tank 2 is a closed cone-column design, and the sedimentation separation tank 2 is divided into an upper and l...

Embodiment 2

[0062] The high-temperature straw gas from the straw vaporization furnace is fully mixed with the scrubbing liquid under the drive of the ejector and enters the sedimentation separation tank after the temperature is reduced. After the gas-liquid separation, the gas enters the spray scrubber at the bottom, and is condensed at the top of the tower. It is discharged into the liquid sealing tank at the top of the tower, and sent to the straw carbonization furnace as fuel gas through the straw gas induced draft fan;

[0063] The liquid after gas-liquid separation stays in the sedimentation separation tank for about 15 minutes to allow wood tar and entrained dust to settle and layer. The wood vinegar is completely miscible with water, and the floating matter is discharged from the upper part of the liquid layer. It is discharged from the bottom of the tank into the rotary drum vacuum filter, the filter residue after suction filtration, namely the mixture of wood tar and dust, is sent ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com