Patents

Literature

33results about "Control using interconnected flow control elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

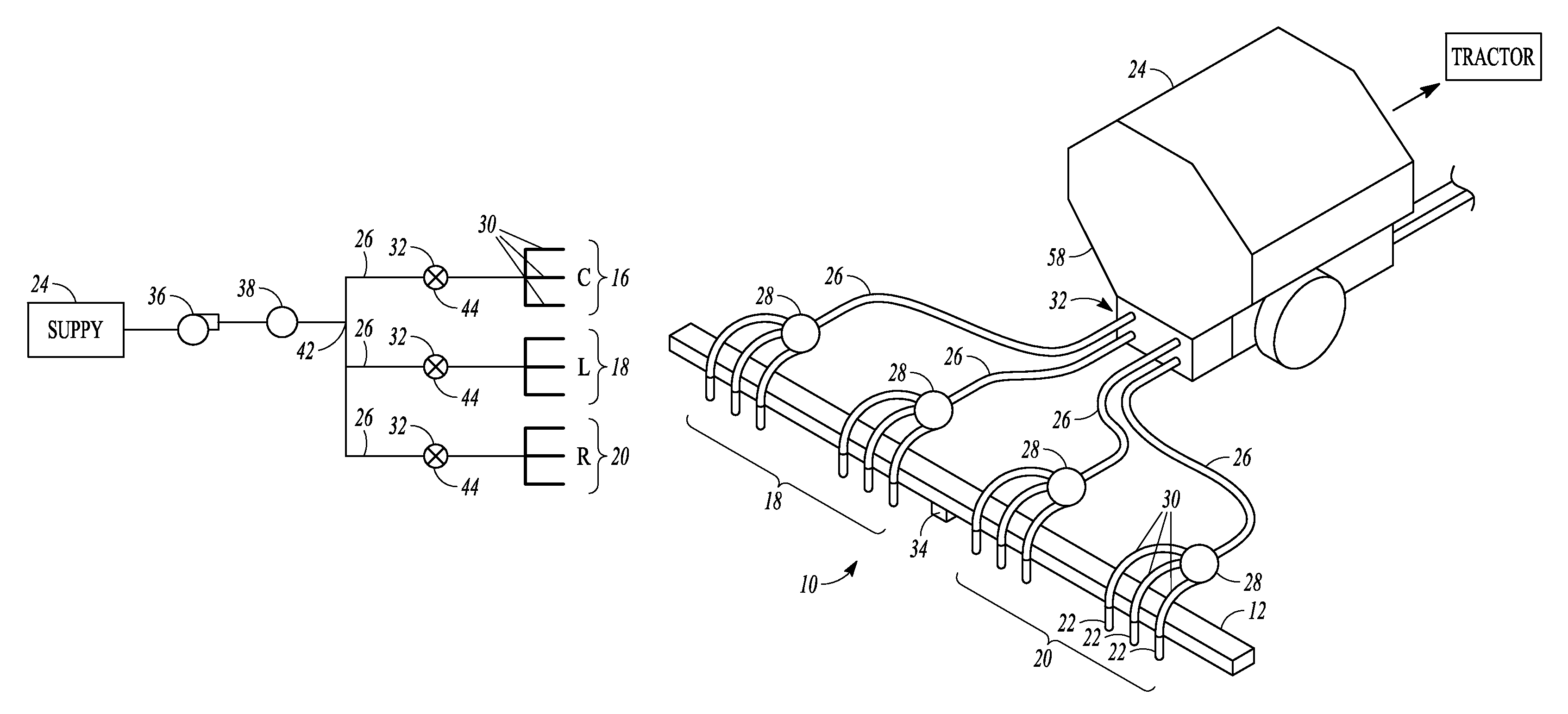

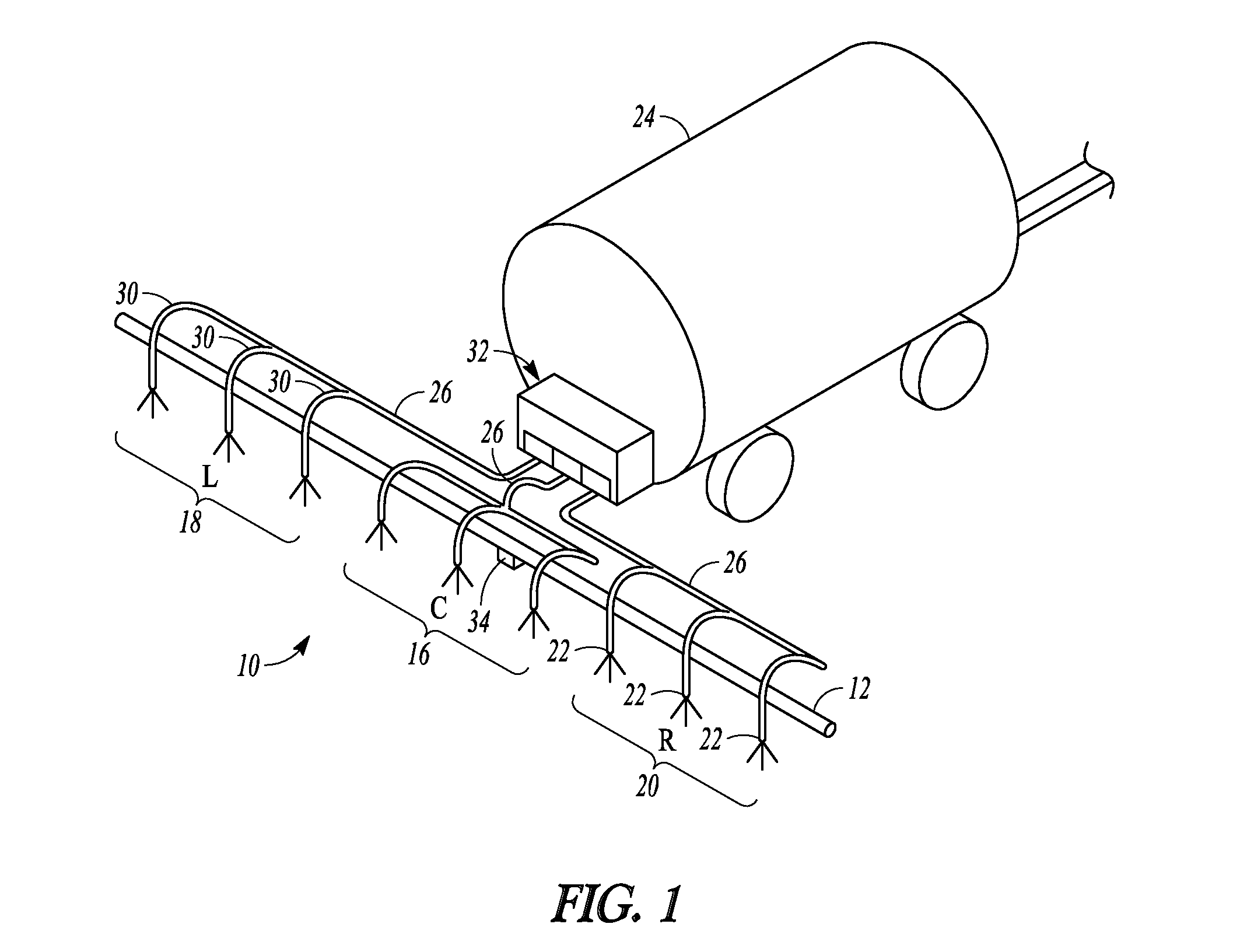

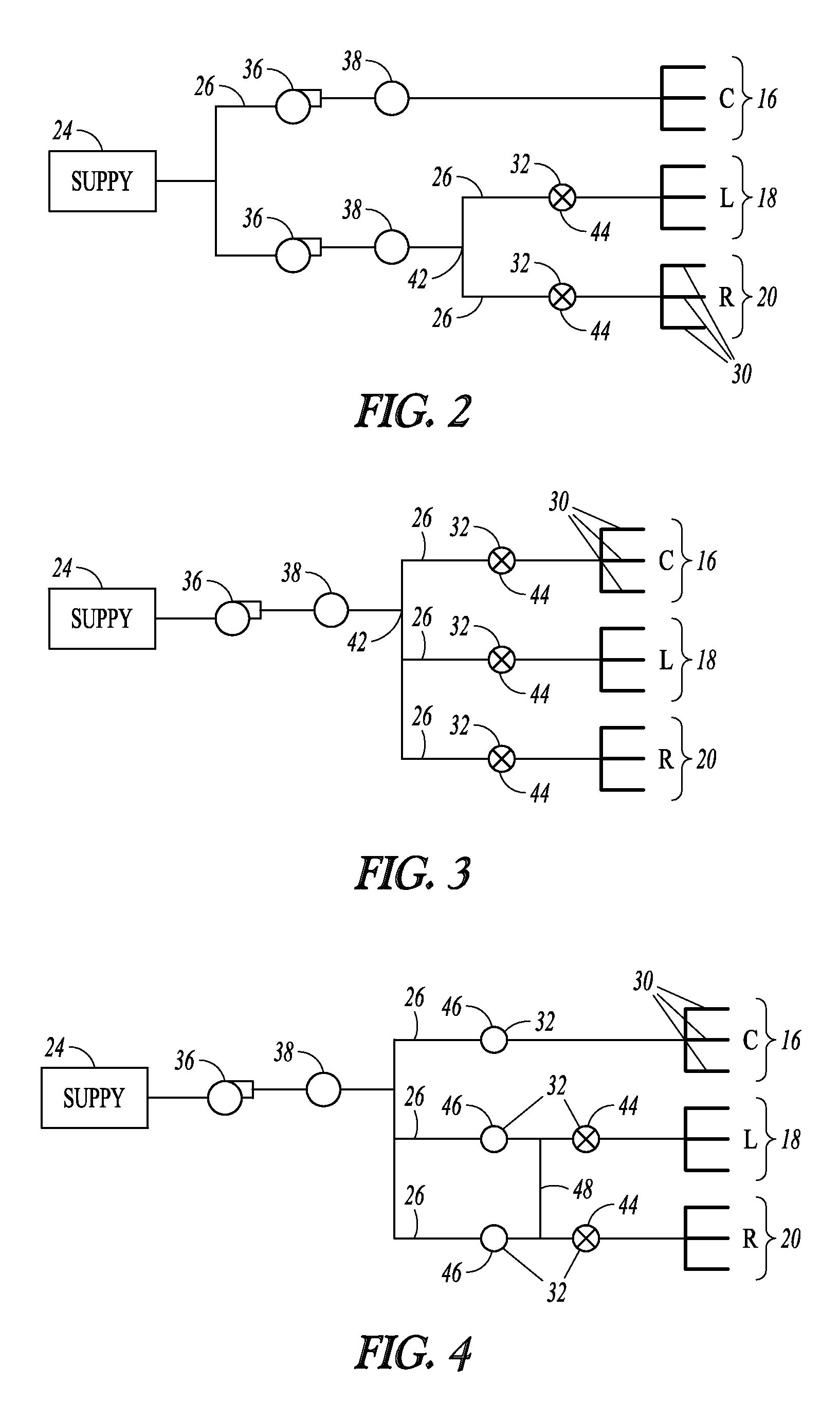

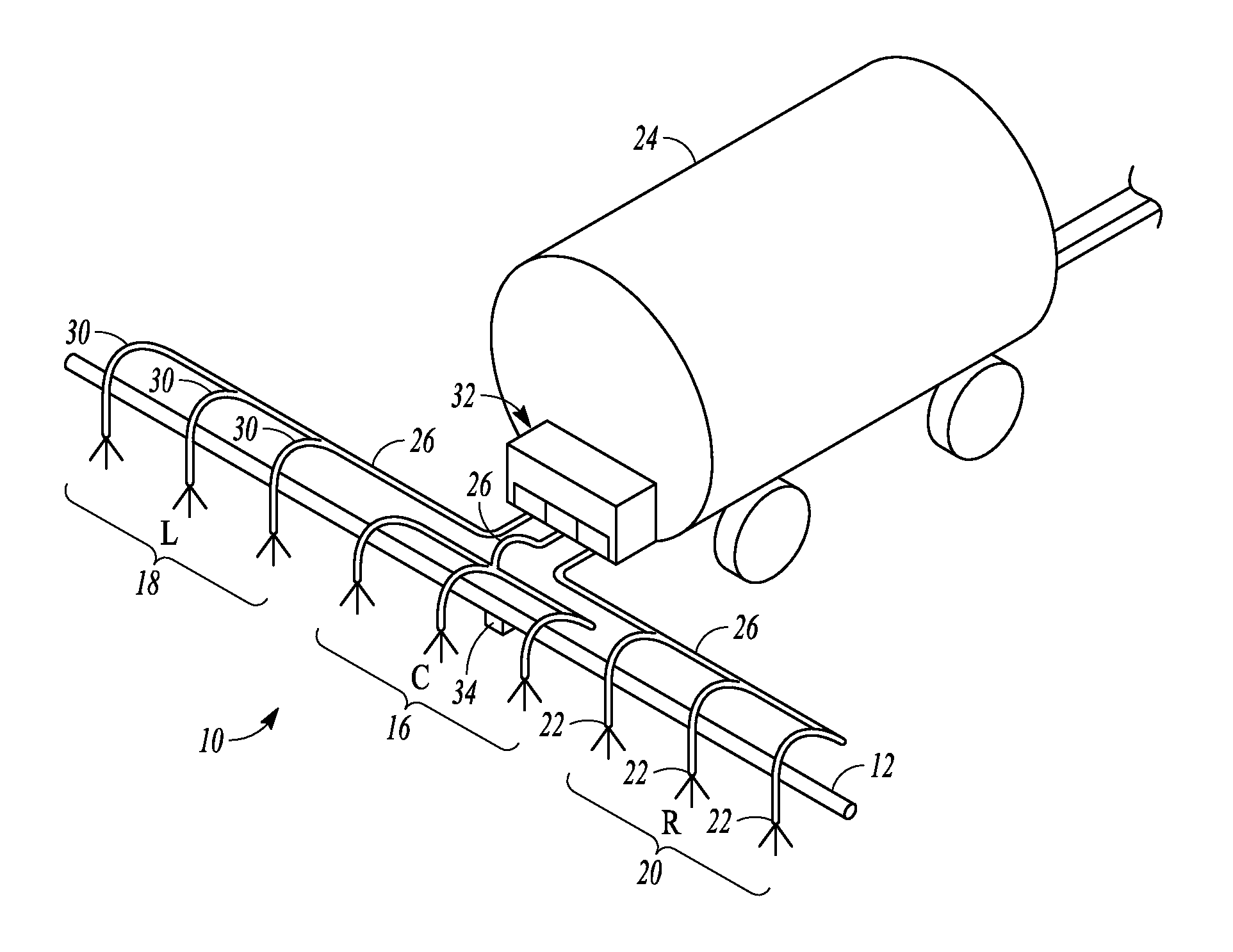

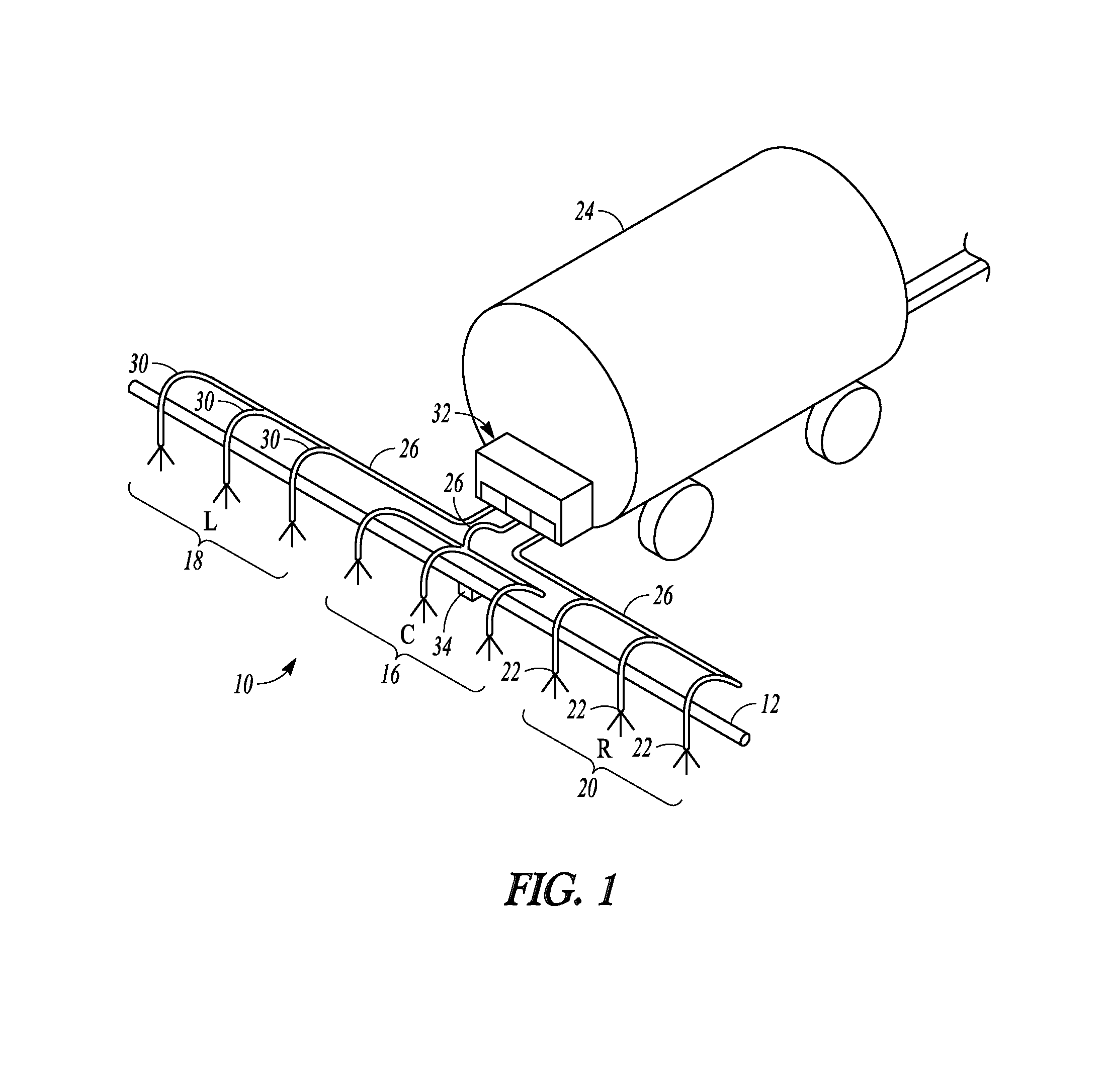

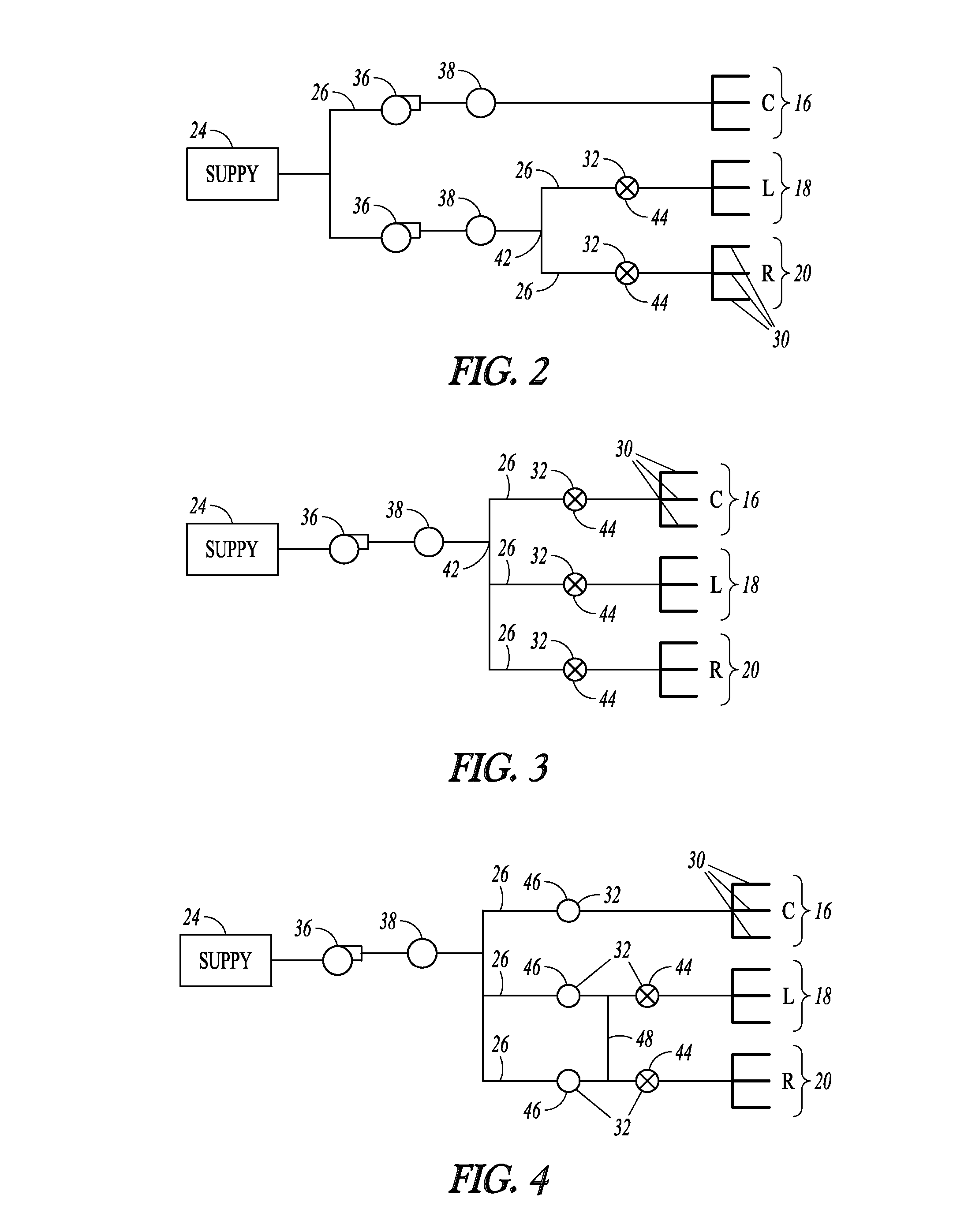

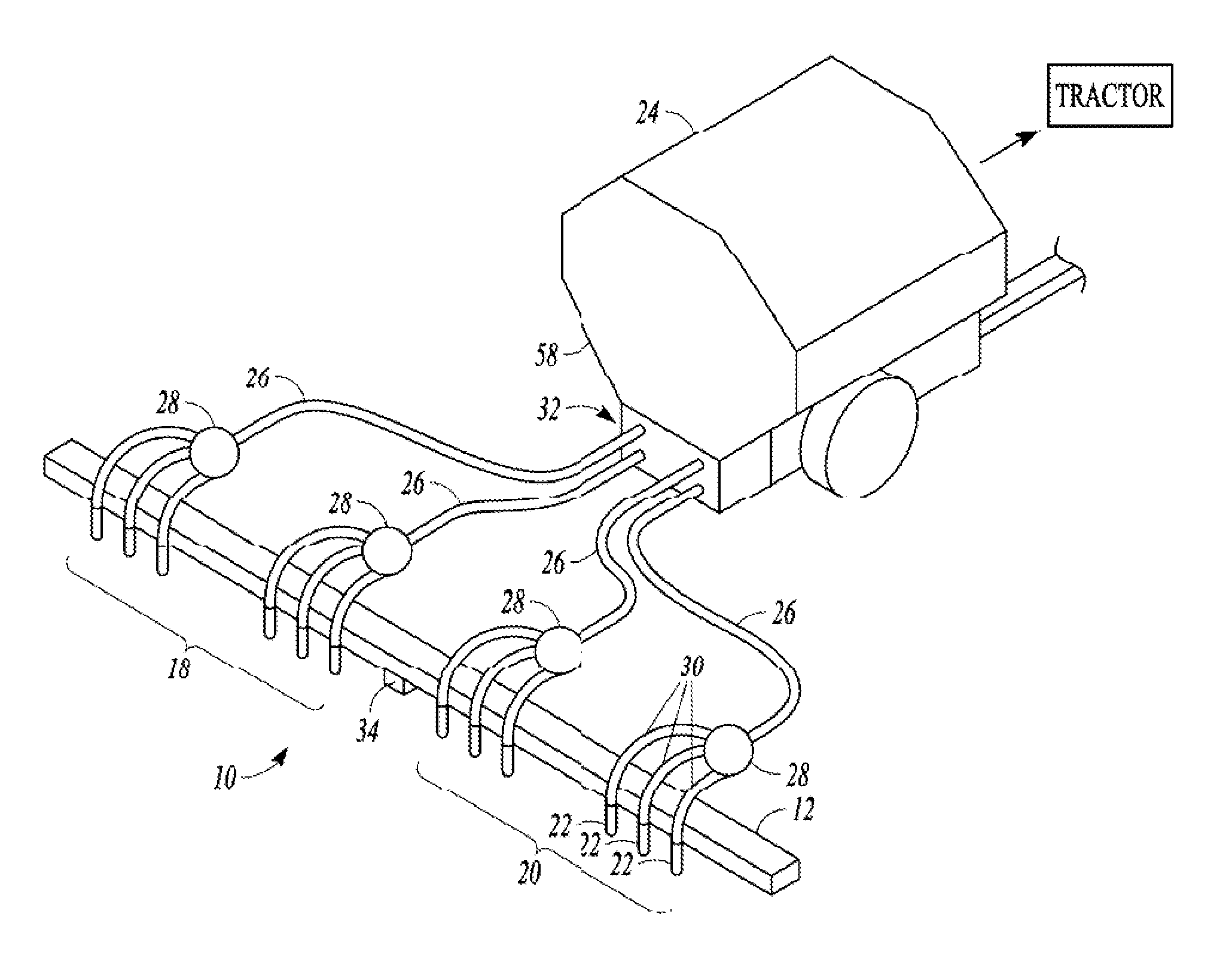

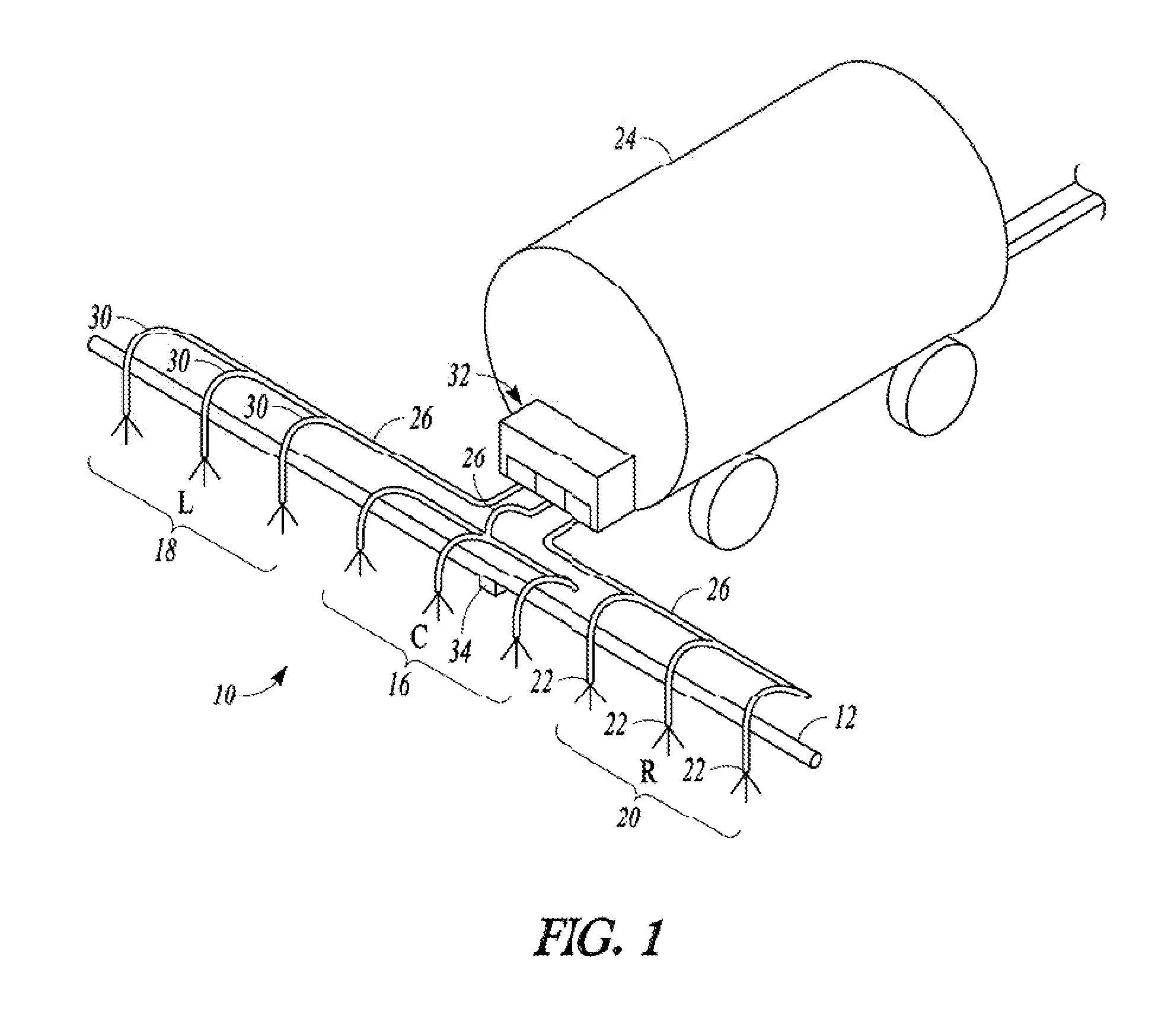

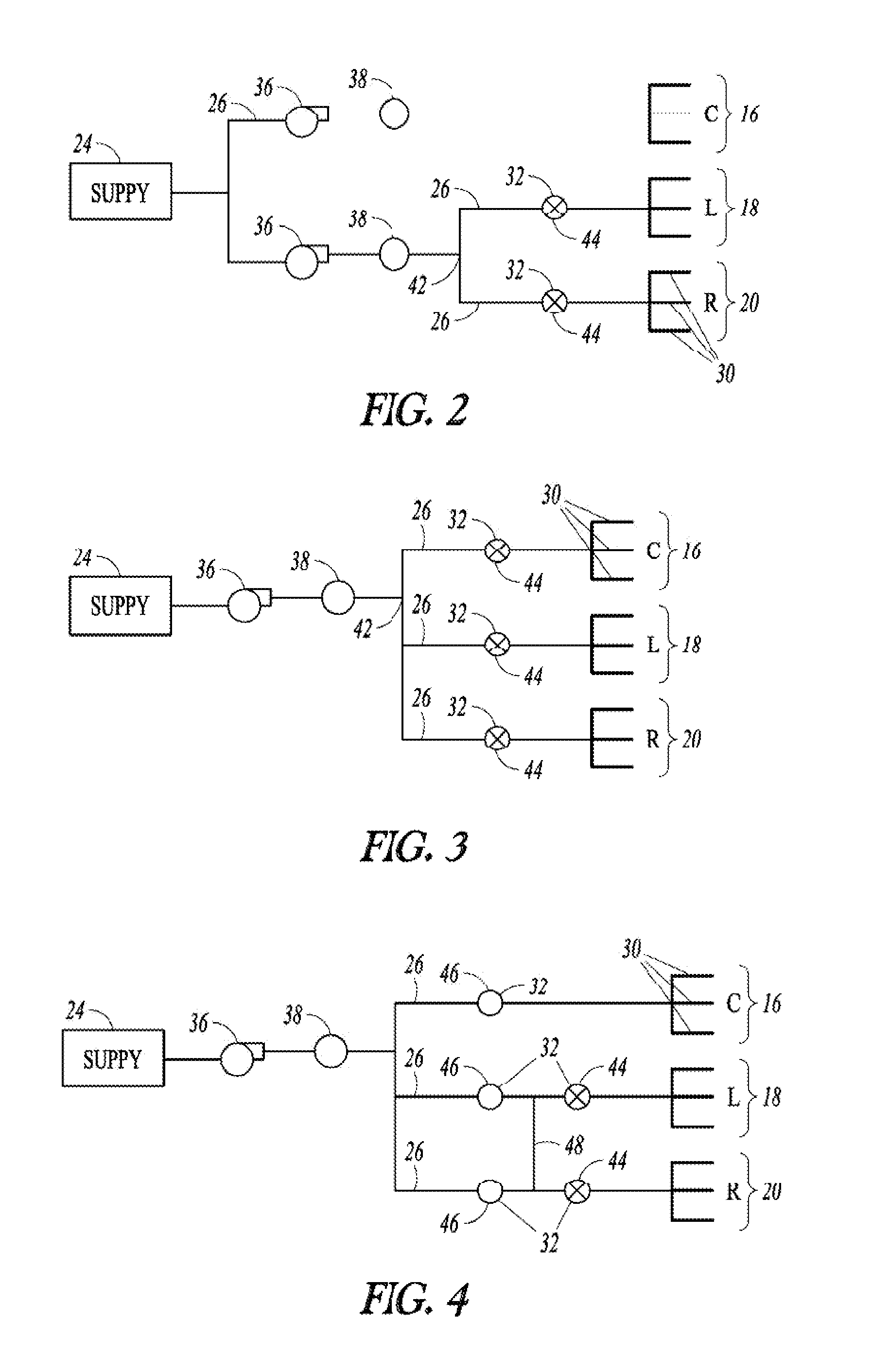

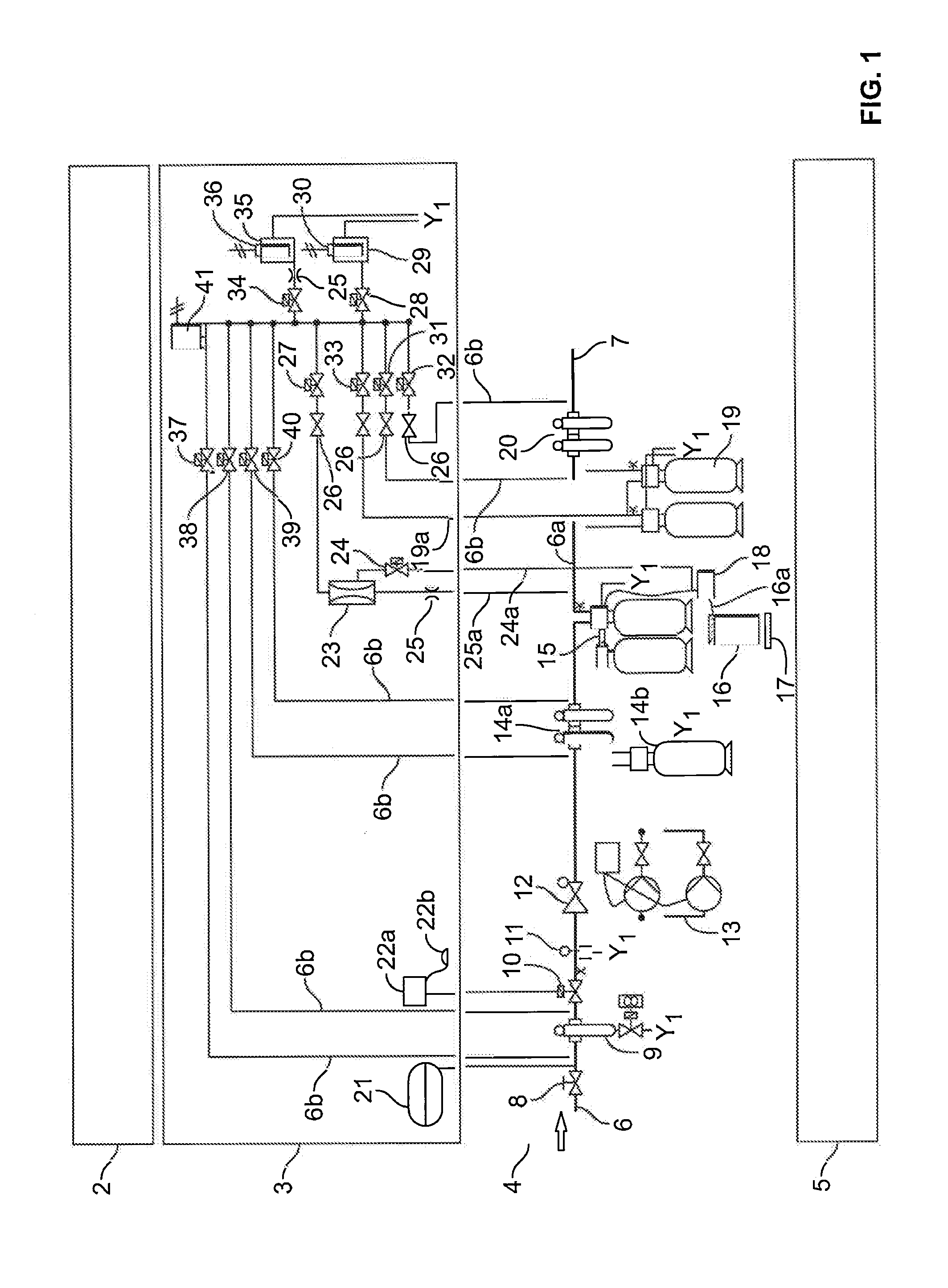

Implement for adjustably metering an agricultural field input according to different frame sections

ActiveUS9113591B2Improve efficiencyLimit wasteControl using interconnected flow control elementsFlow control using electric meansLiquid productEngineering

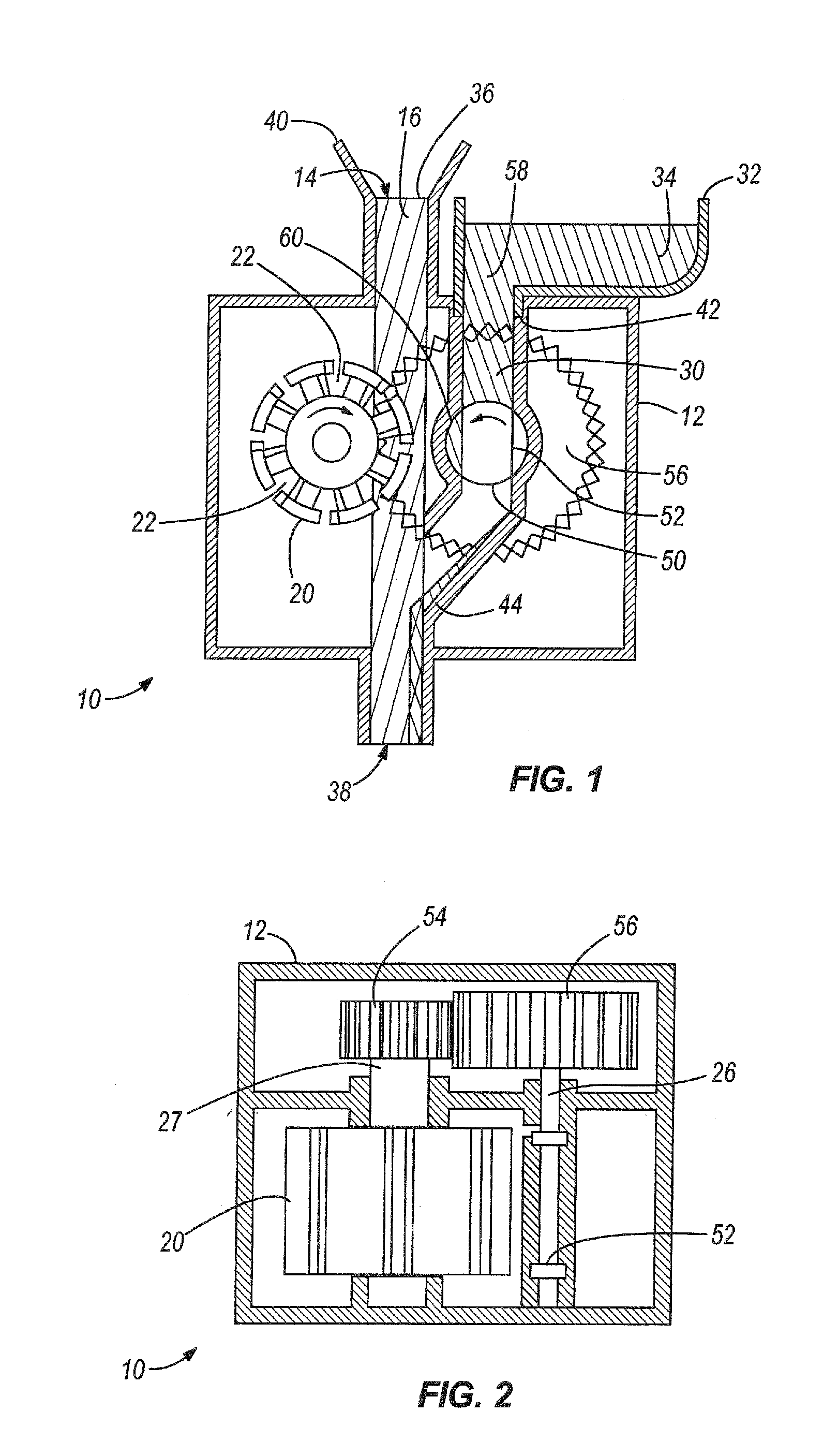

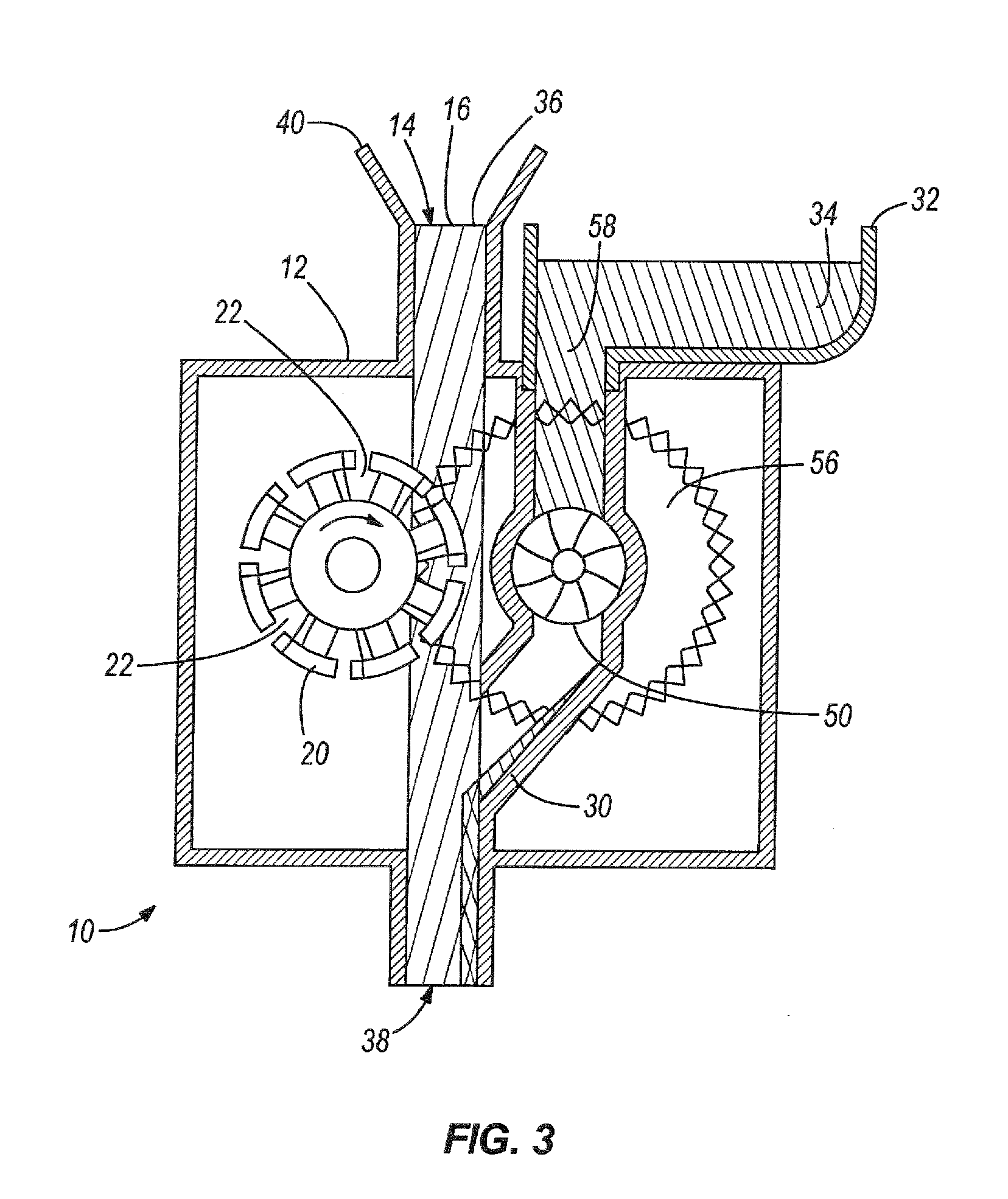

Metering devices for an agricultural implement are provided for applying a field input, for example, pneumatically delivered granular product including seed or fertilizer or sprayed liquid product including fertilizer and the like, to an agricultural field. In the applying of the field input, the rate of application of the dispensers of one section of the implement can be collectively varied in relation to the rate of application of the dispensers of a different section of the implement frame.

Owner:RAVEN INDUSTRIES INC

Implement for adjustably metering an agricultural field input according to different frame sections

ActiveUS20130333601A1Limit wasteImprove efficiencyControl using interconnected flow control elementsLiquid fertiliser regulation systemsLiquid productEngineering

Metering devices for an agricultural implement are provided for applying a field input, for example, pneumatically delivered granular product including seed or fertilizer or sprayed liquid product including fertilizer and the like, to an agricultural field. In the applying of the field input, the rate of application of the dispensers of one section of the implement can be collectively varied in relation to the rate of application of the dispensers of a different section of the implement frame.

Owner:RAVEN INDUSTRIES INC

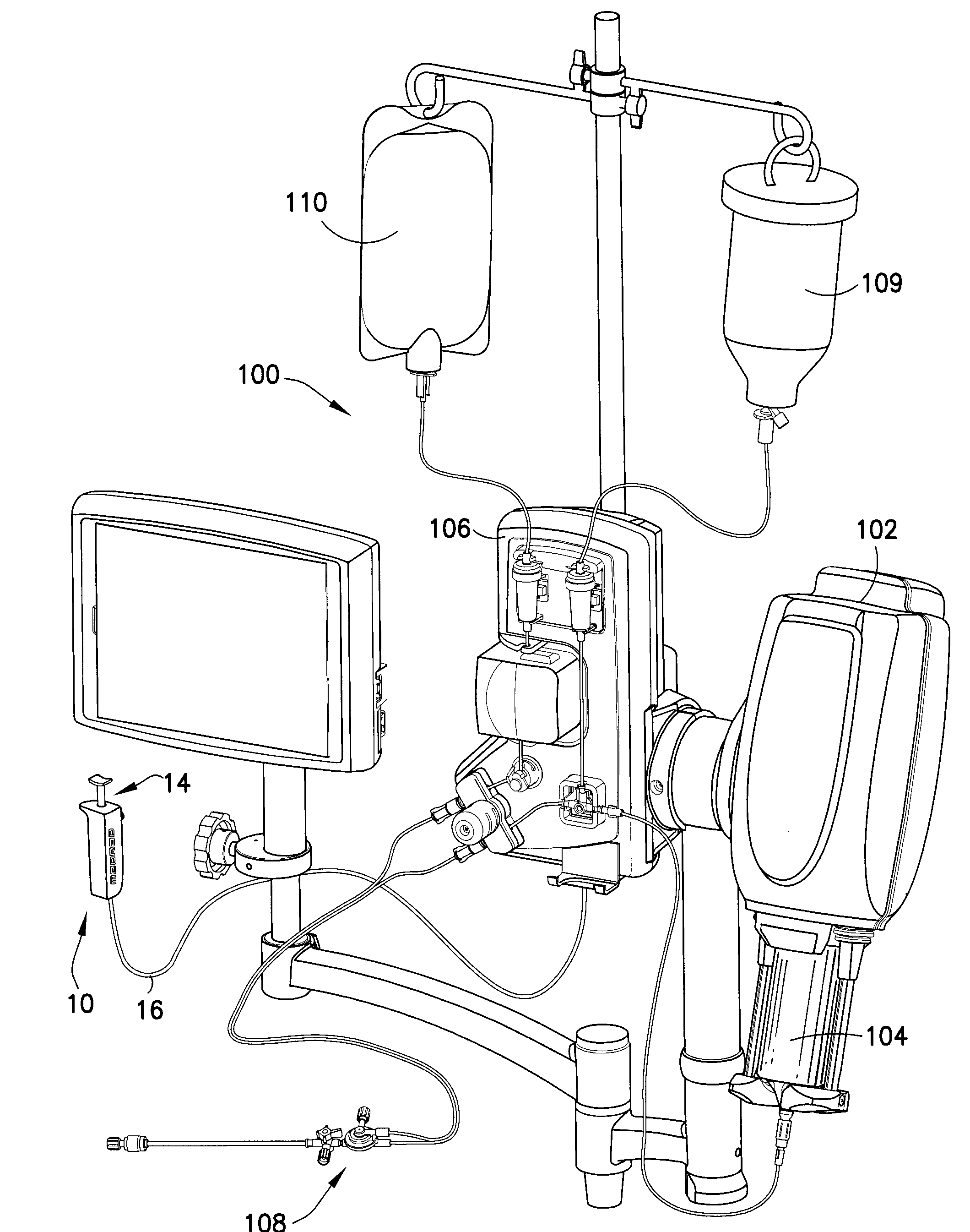

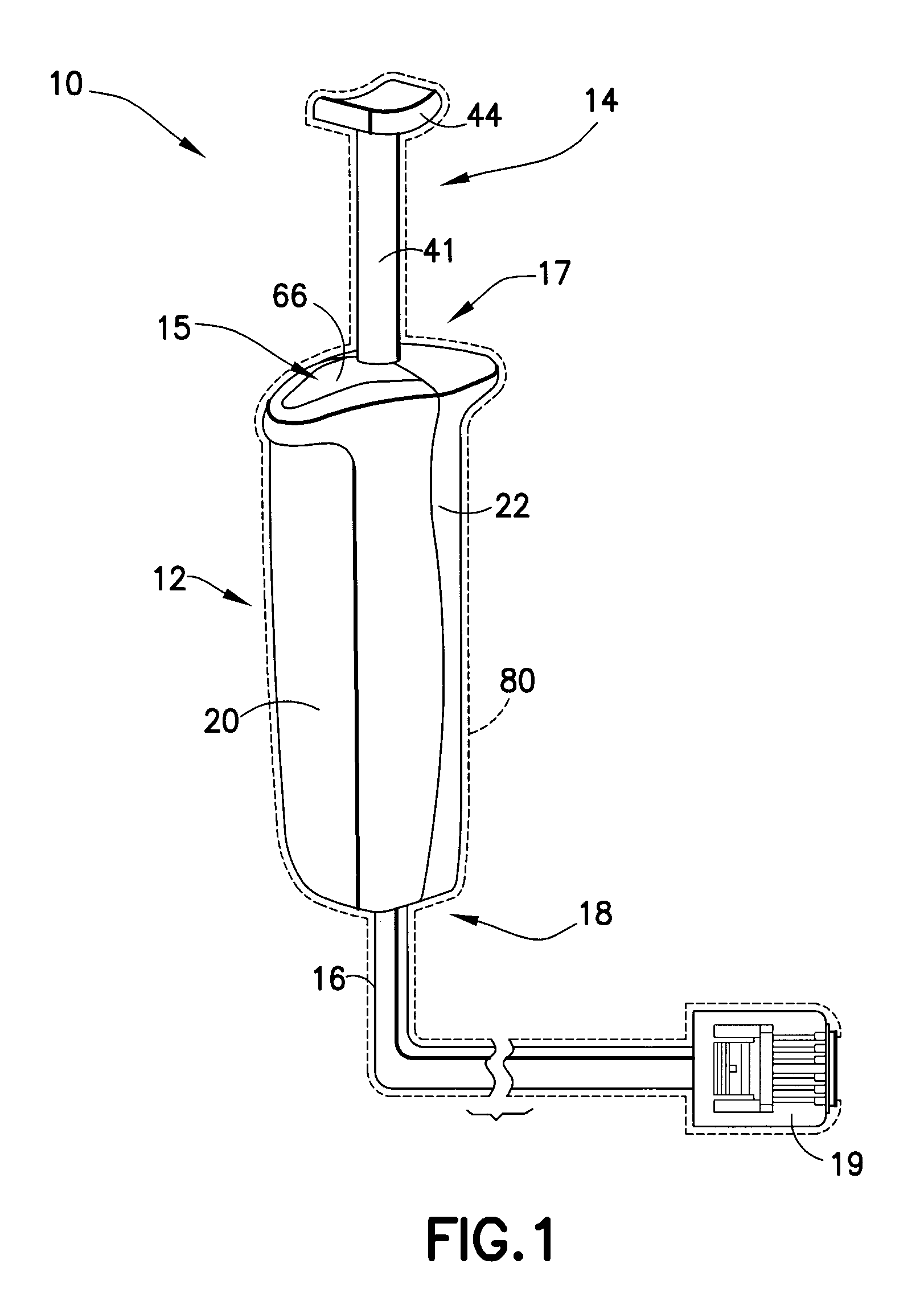

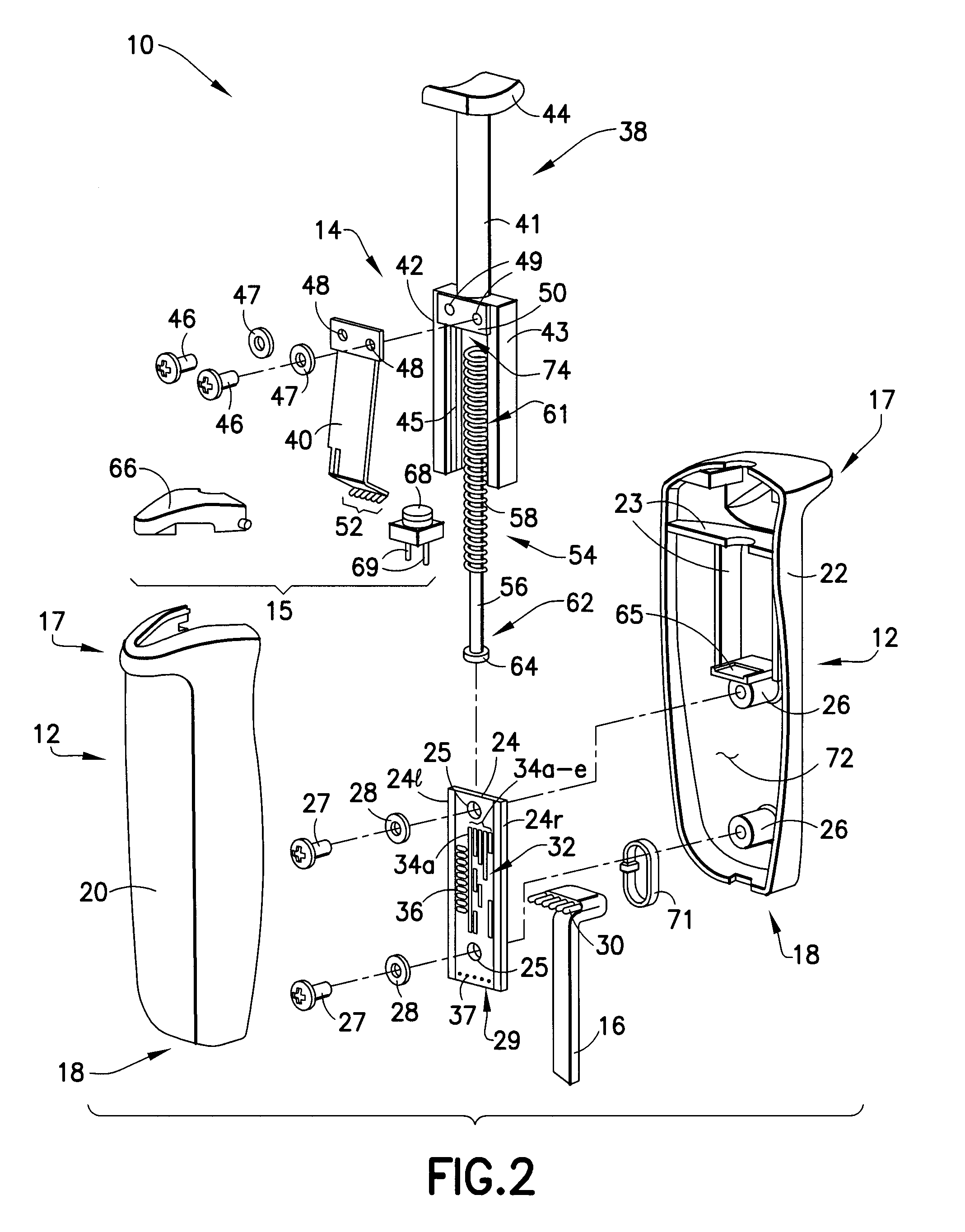

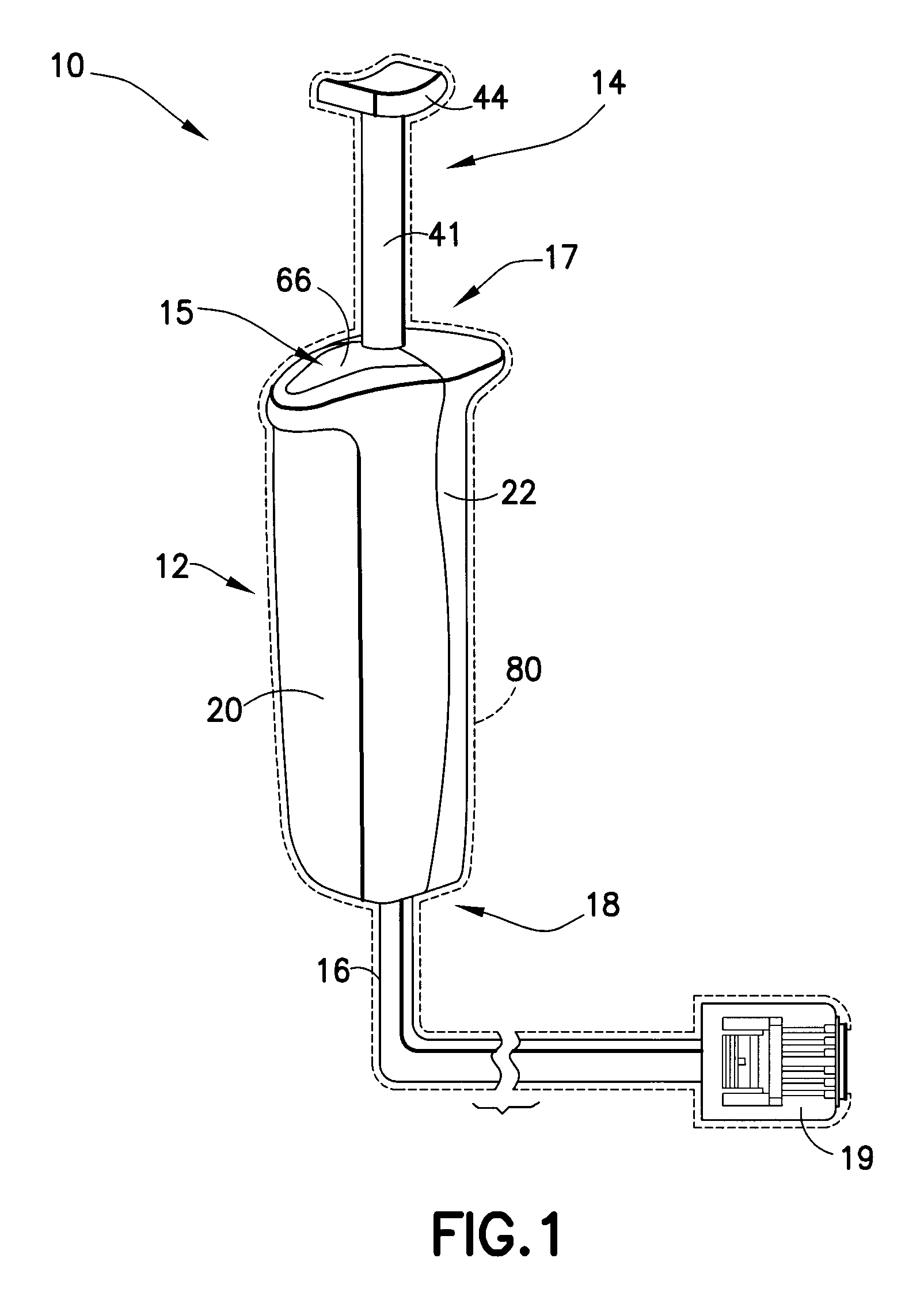

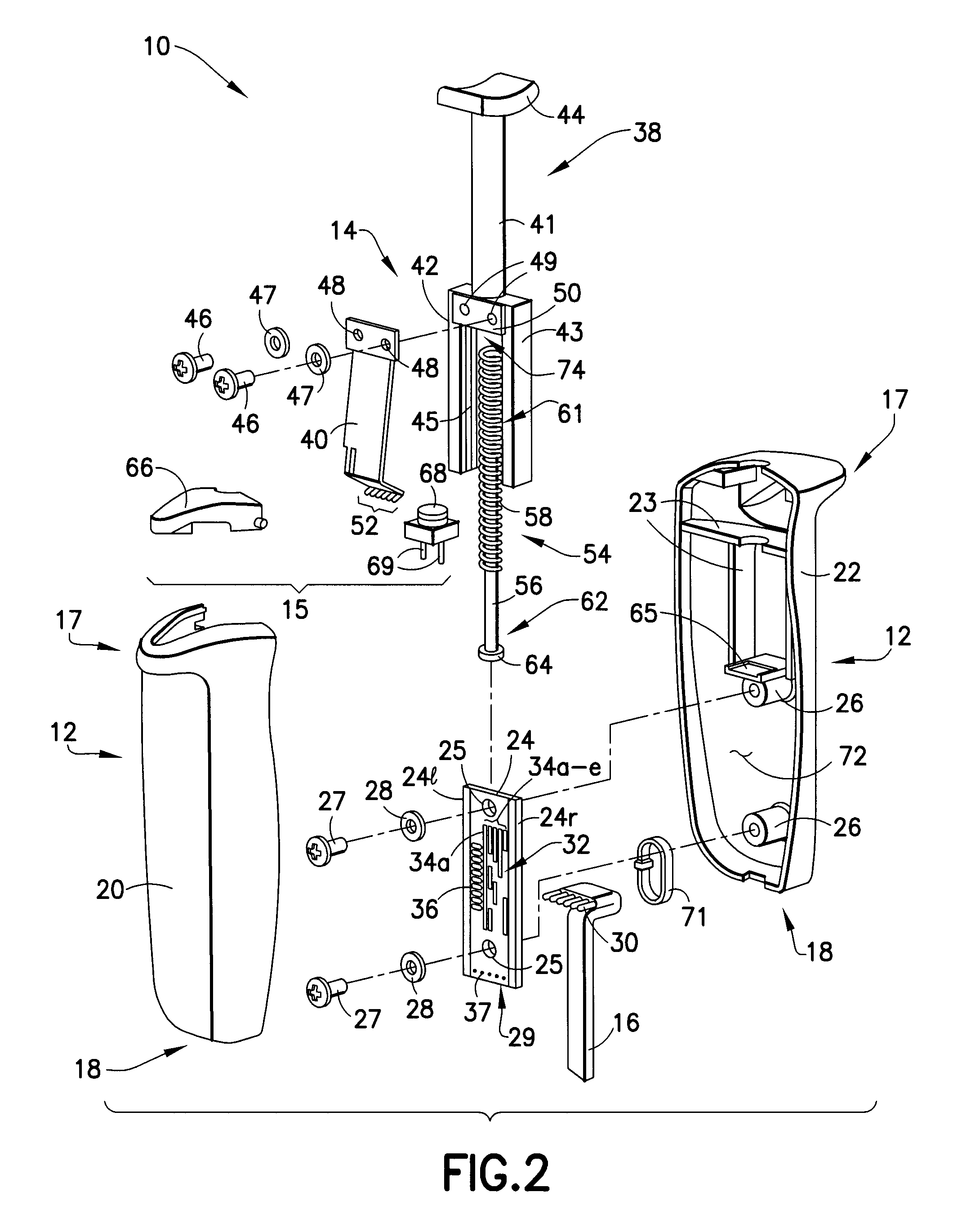

Fluid mixing control device for a multi-fluid delivery system

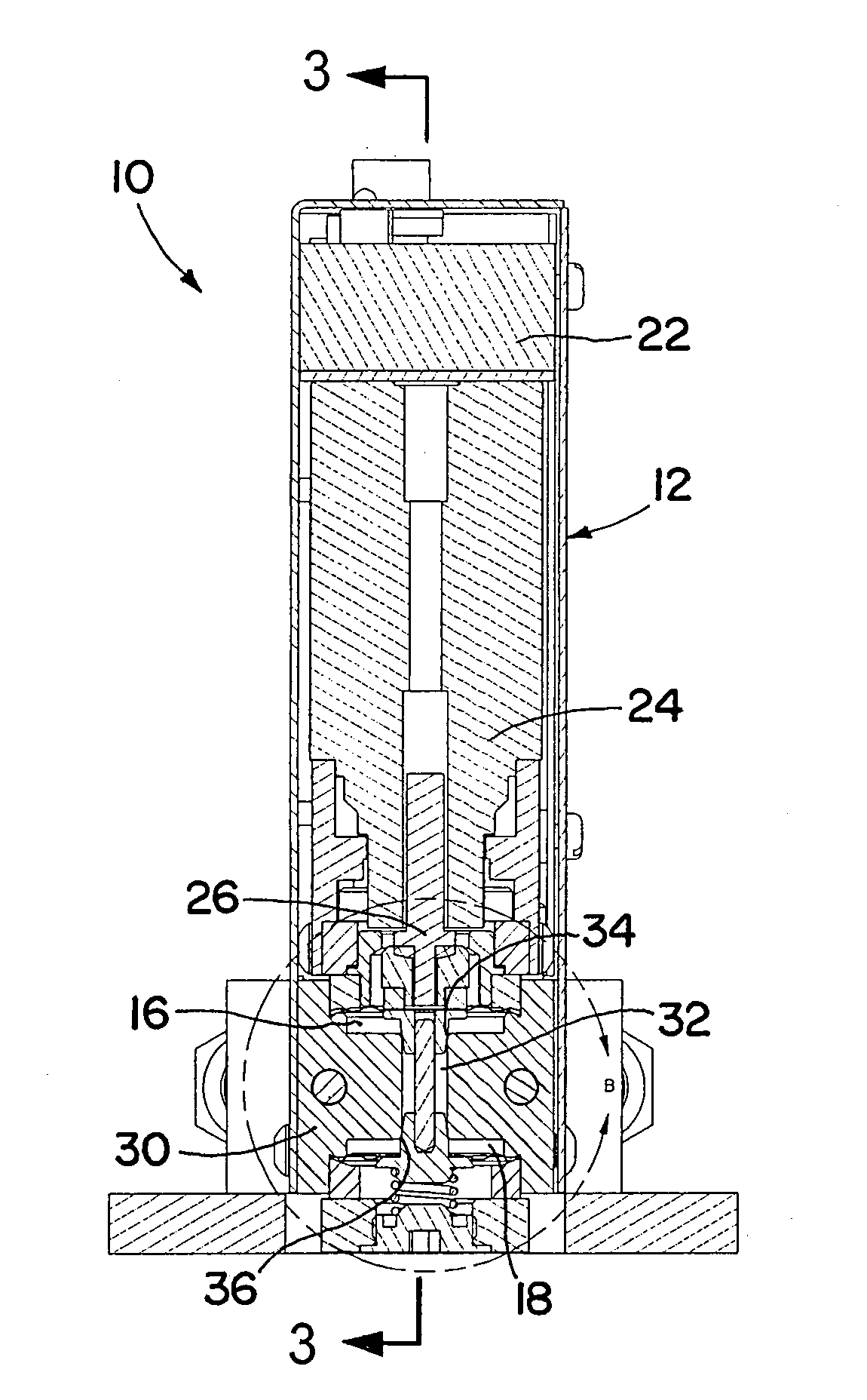

ActiveUS20100114040A1Control using synchronised pumpsControlling ratio of multiple fluid flowsEngineeringActuator

The control device is used to control delivery of fluids from a multi-fluid delivery system during a medical injection procedure. The fluid delivery system includes an injector used to deliver injection fluids to a patient. The control device is operatively associated with the injector for controlling discrete flow rates of injection fluids delivered to the patient. The control device includes a housing, first and second actuators associated with the housing, and an electronic substrate disposed within the housing and having a conductive pattern. The first actuator is operatively associated with the conductive pattern. The conductive pattern includes a plurality of predetermined digital values corresponding to discrete flow rates of injection fluids to be delivered by the injector. The second actuator is operatively associated with the electronic substrate and initiates output signals to the injector corresponding to desired mixture ratios of the injection fluids to be delivered by the injector.

Owner:BAYER HEALTHCARE LLC

Implement for adjustably metering an agricultural field input according to different frame sections

ActiveUS20150257331A1Improve efficiencyLimit wasteControl using interconnected flow control elementsFlow control using electric meansLiquid productEngineering

Metering devices for an agricultural implement are provided for applying a field input, for example, pneumatically delivered granular product including seed or fertilizer or sprayed liquid product including fertilizer and the like, to an agricultural field. In the applying of the field input, the rate of application of the dispensers of one section of the implement can be collectively varied in relation to the rate of application of the dispensers of a different section of the implement frame.

Owner:RAVEN INDUSTRIES INC

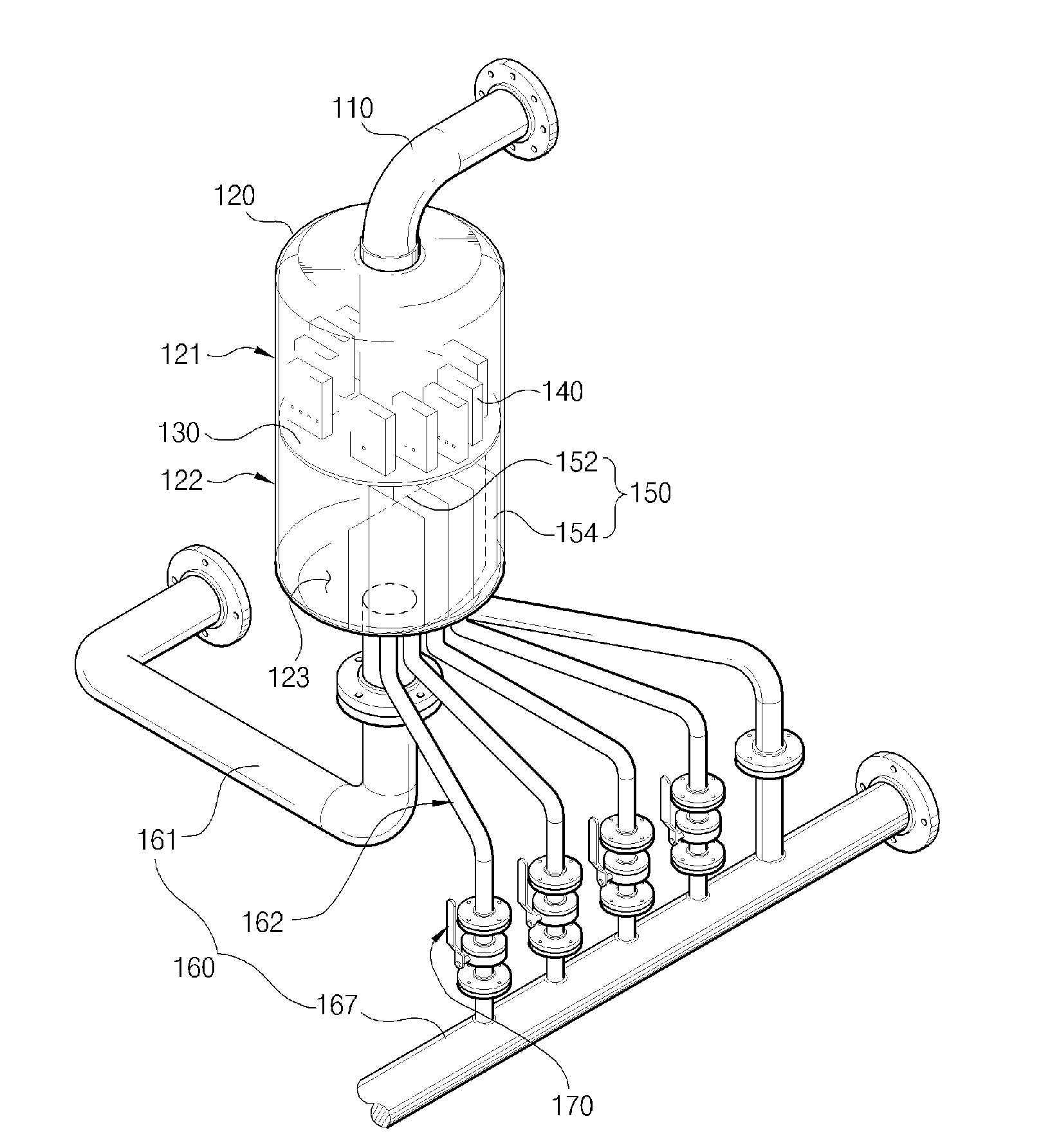

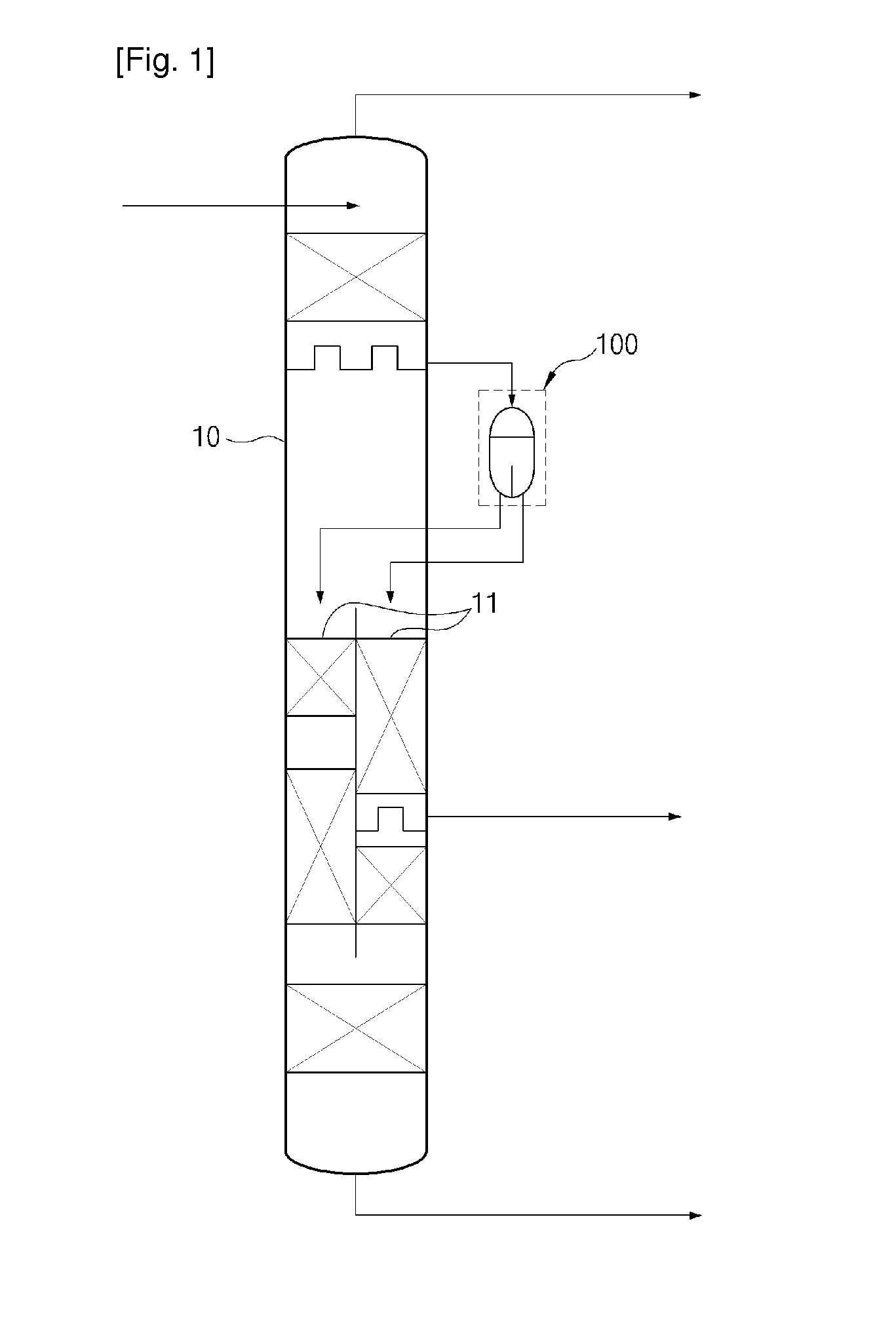

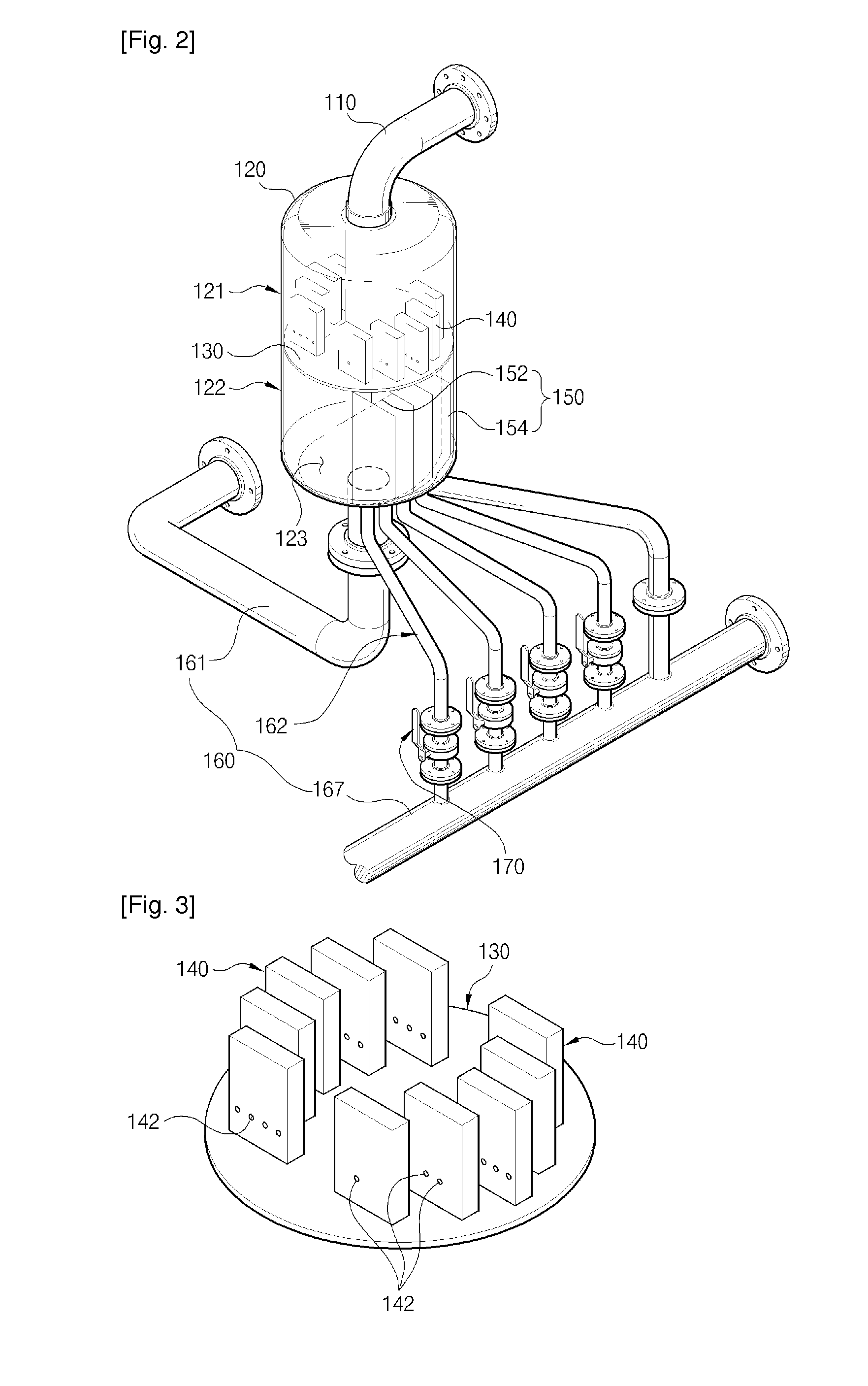

Liquid distribution device

ActiveUS20150153746A1Guaranteed continuous supplyAutomatic controlControl using interconnected flow control elementsDispersed particle separationConstant rateEngineering

The present invention is capable of precisely controlling a supply ratio of liquid and continuously supplying liquid at a constant rate by using partition plates for controlling the amount of liquid distribution.

Owner:AMTPACIFIC

Device and method for dilution control

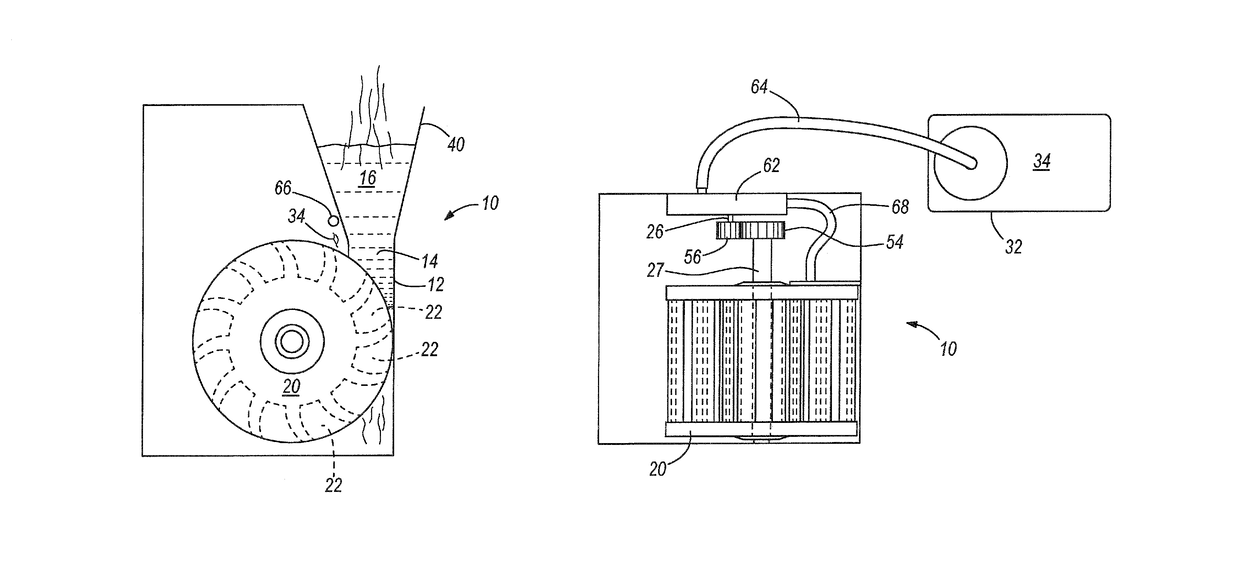

ActiveUS20110197972A1Controlling ratio of multiple fluid flowsControl with discontinuous actionEngineeringControl theory

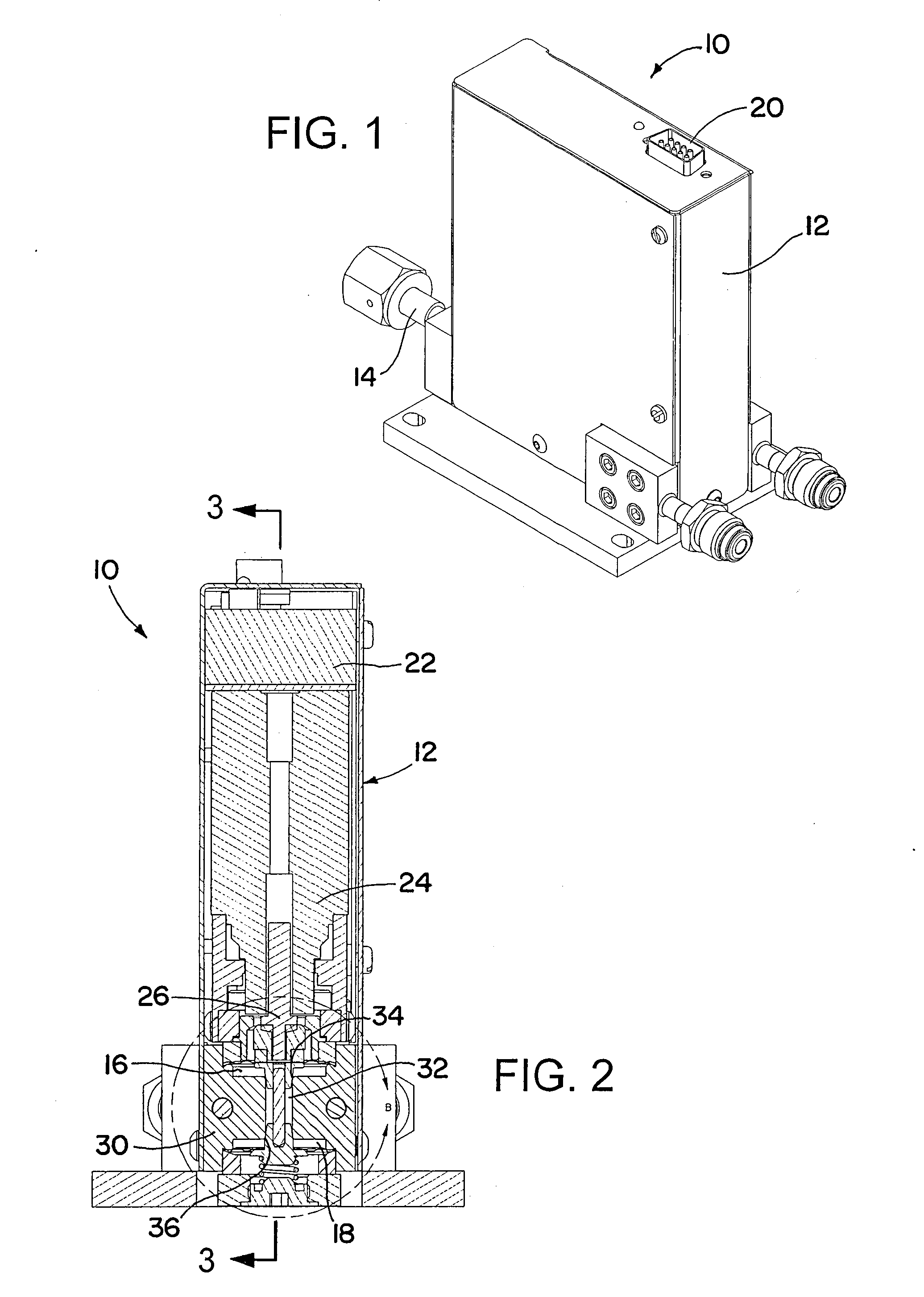

A dilution control device and method of operating the same. The dilution control device can include a structure for dispensing concentrate and diluent fluid in a desired dilution ratio utilizing volumetric dosing. In some embodiments, diluent fluid drives a wheel or compresses a pliable concentrate bag in order to dispense concentrate in the desired ratio with the diluent fluid. In some embodiments, one or more floats can be used to drive a pump or actuate a valve to dispense concentrate at a particular rate proportional with the flow rate of the diluent fluid. In some embodiments, a rocker is responsive to the flow of diluent fluid to pump concentrate. In some embodiments, the dilution control device can be operable to automatically modulate the dispense rate of concentrate when the diluent fluid flow rate is varied in order to maintain a predetermined dilution ratio.

Owner:JOHNSONDIVERSEY INC

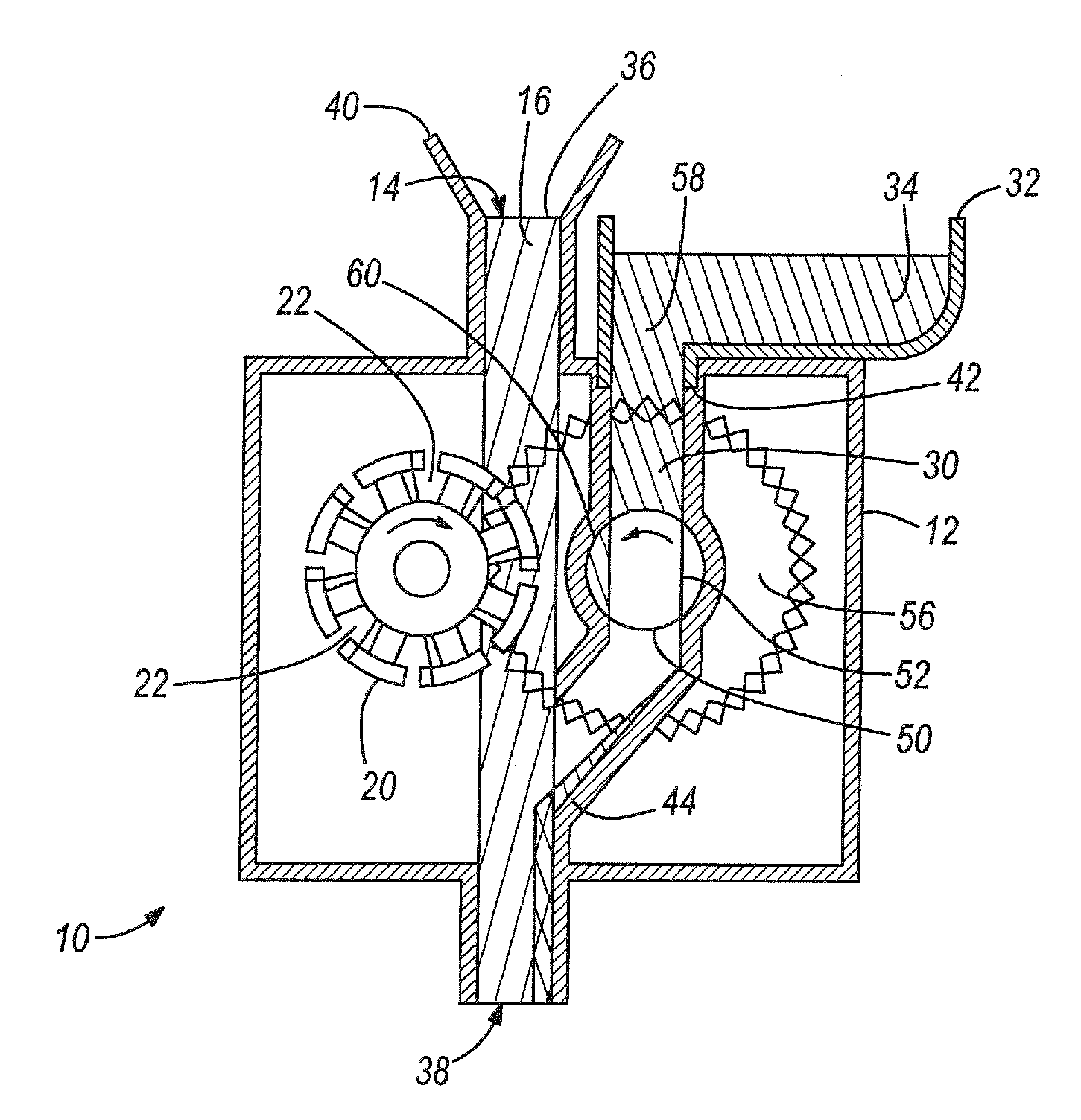

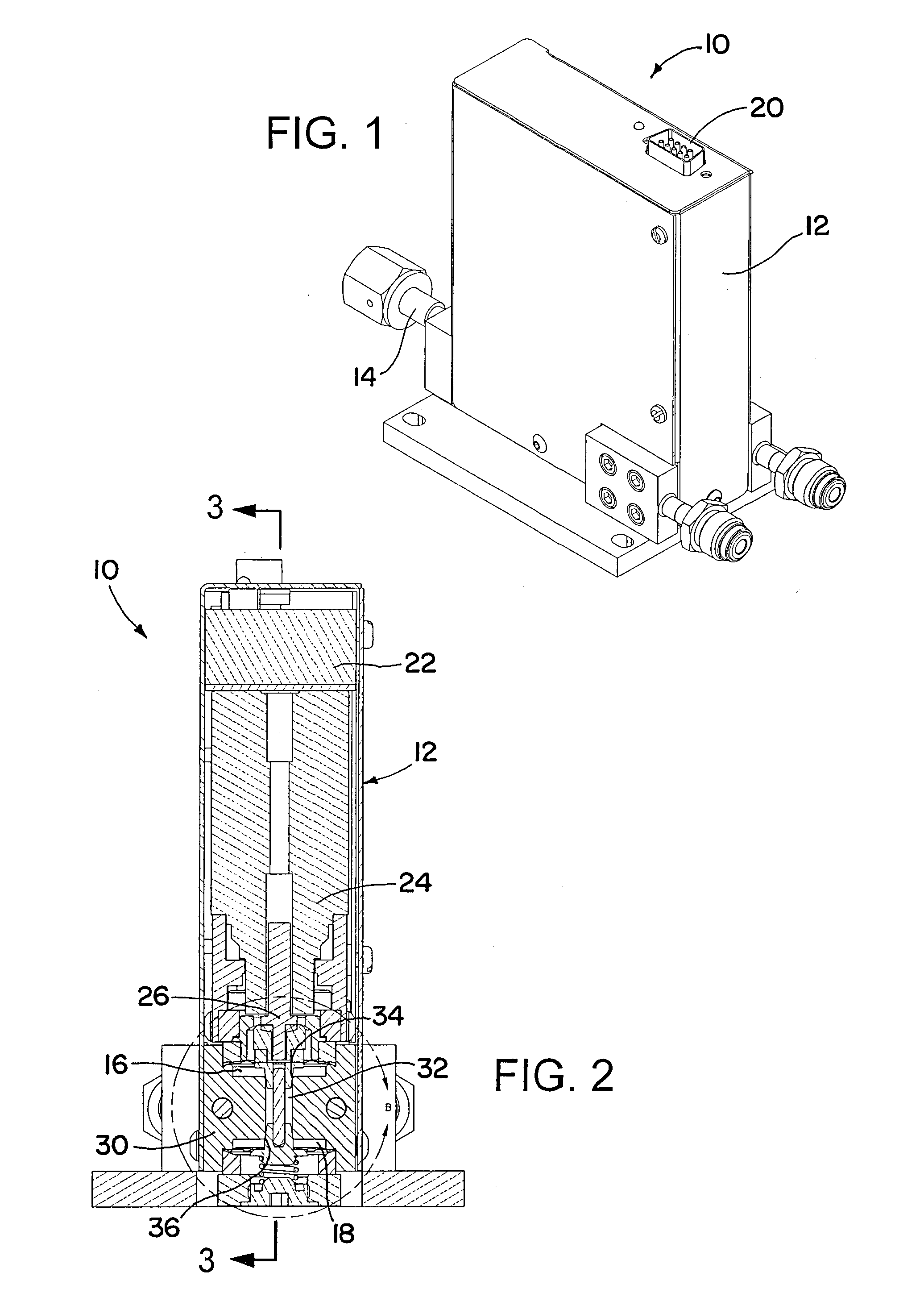

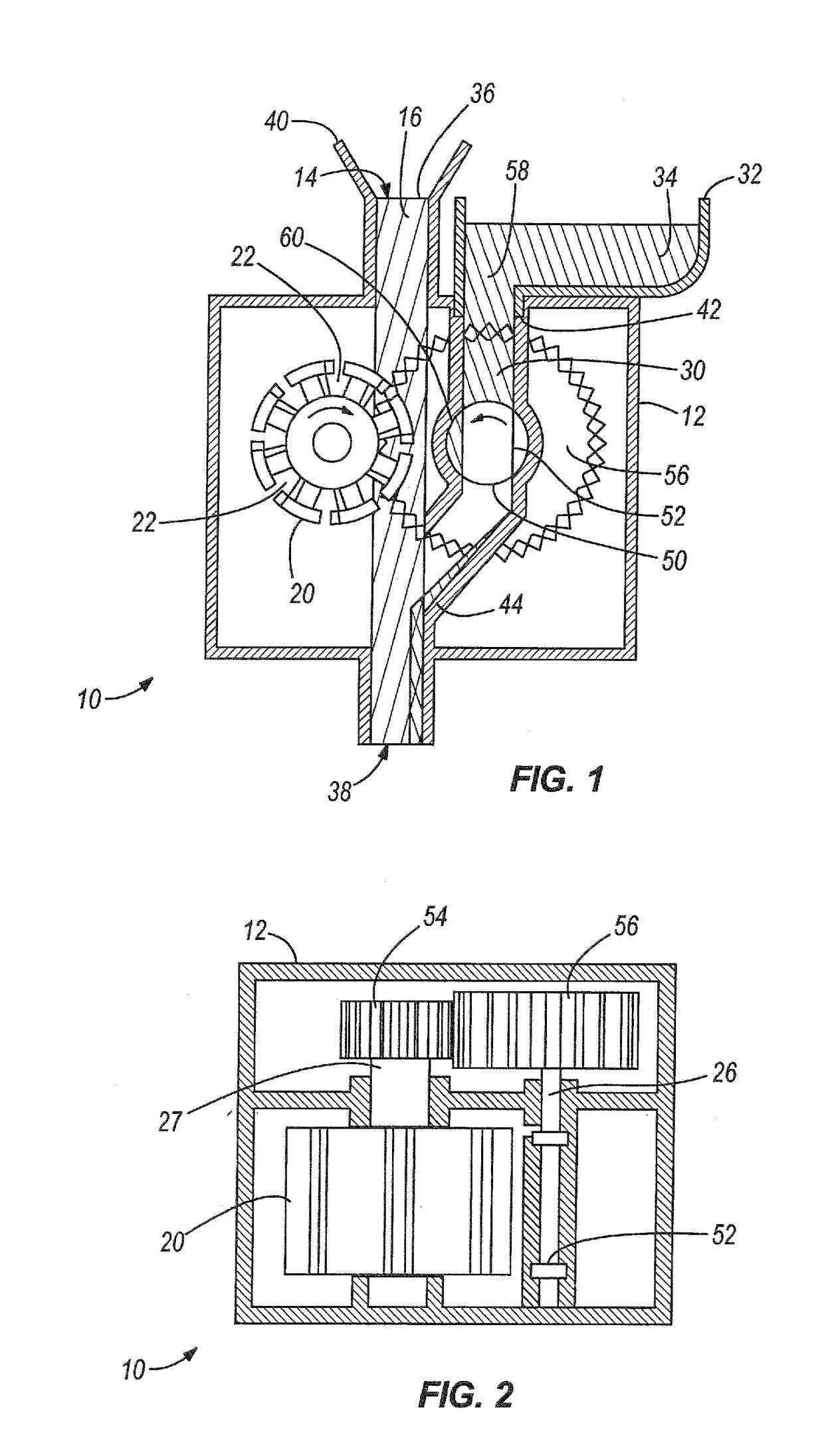

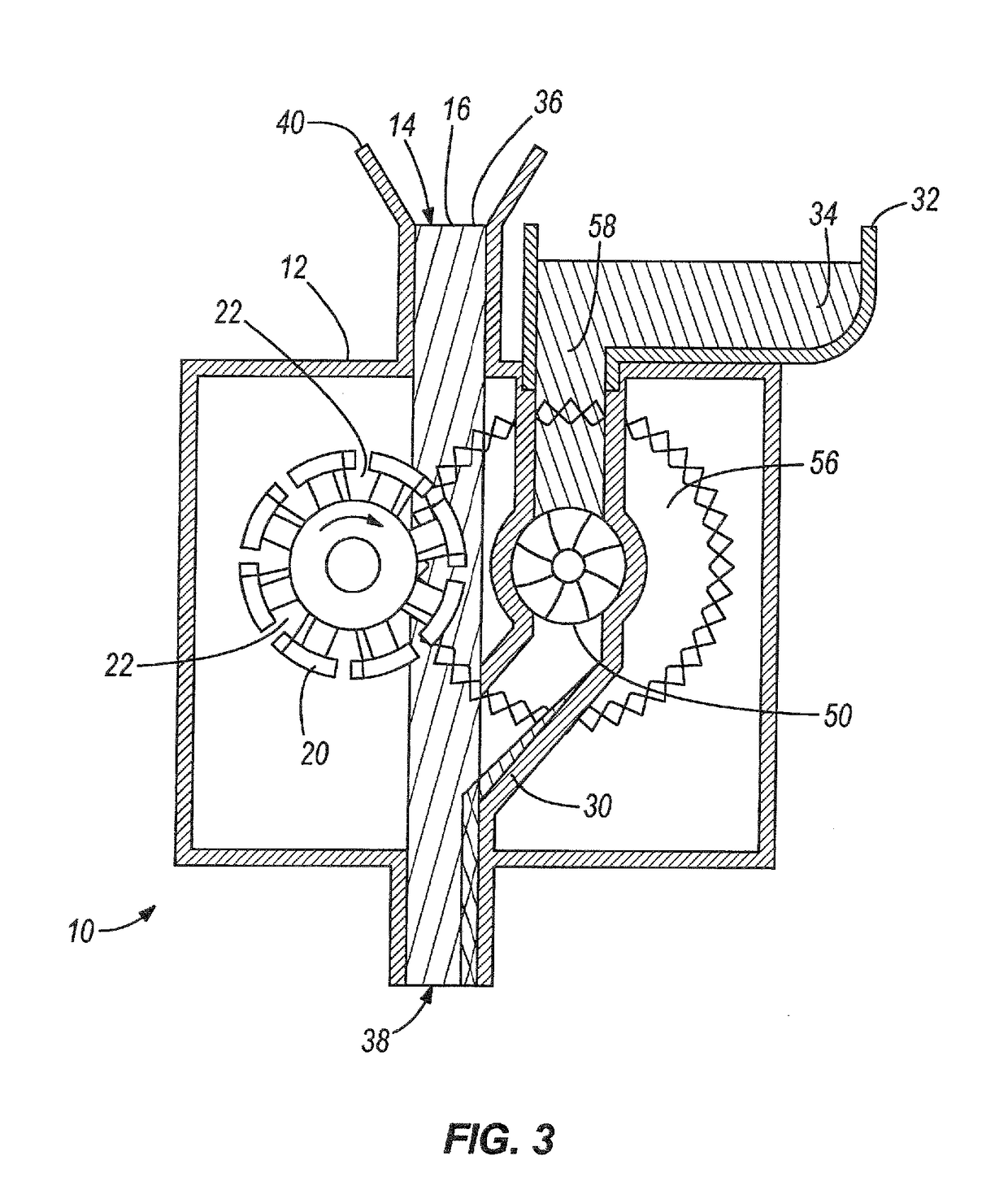

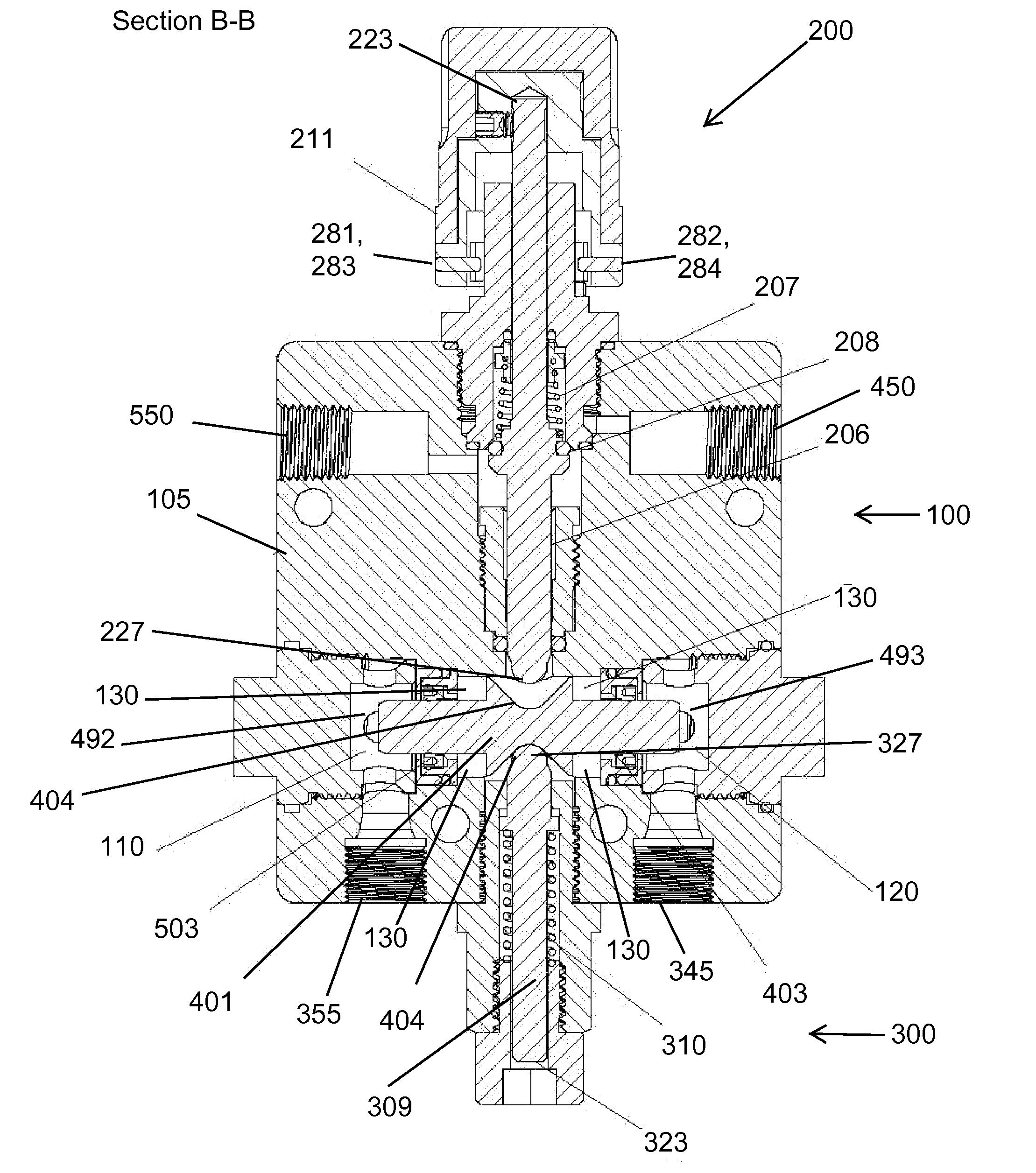

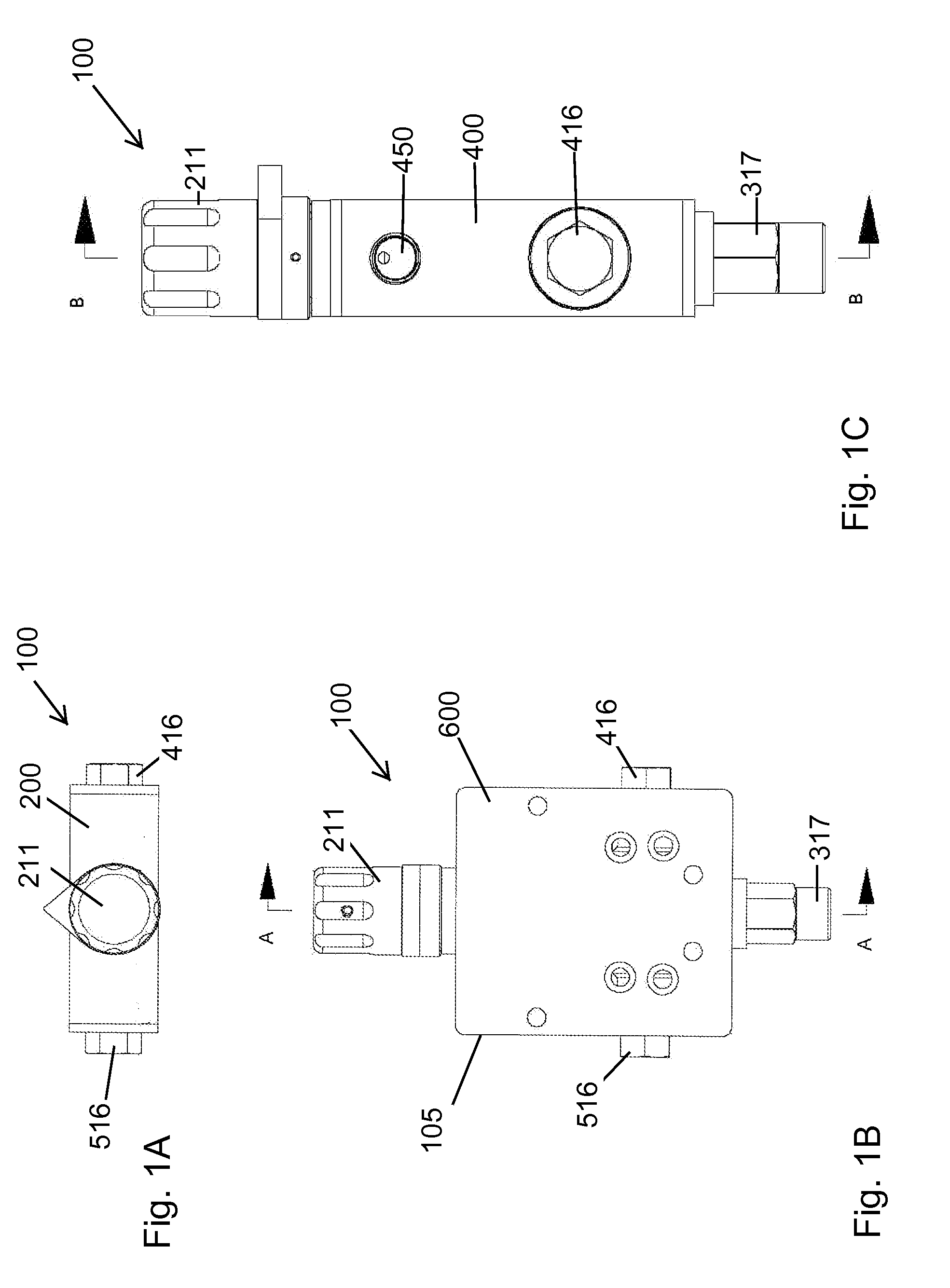

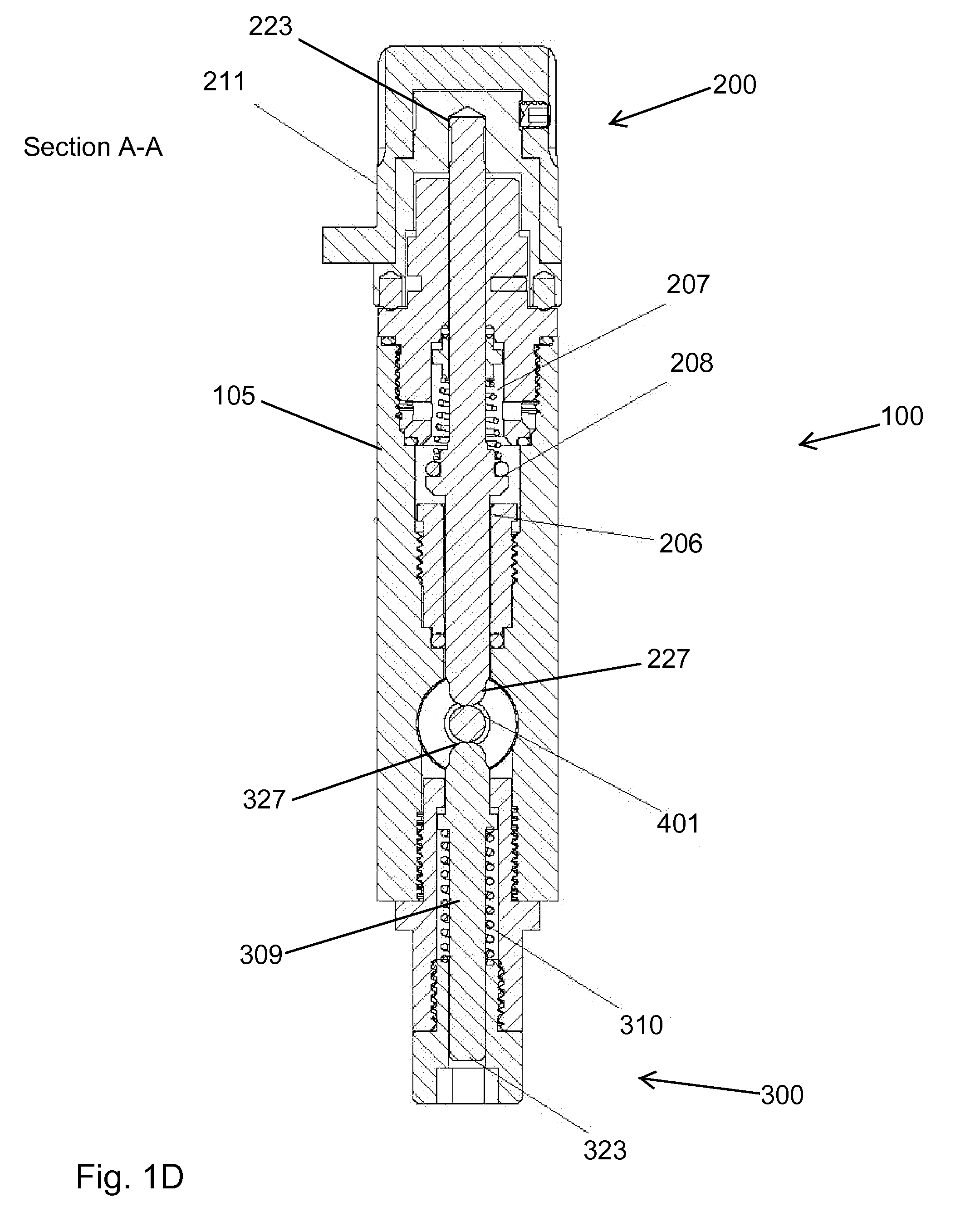

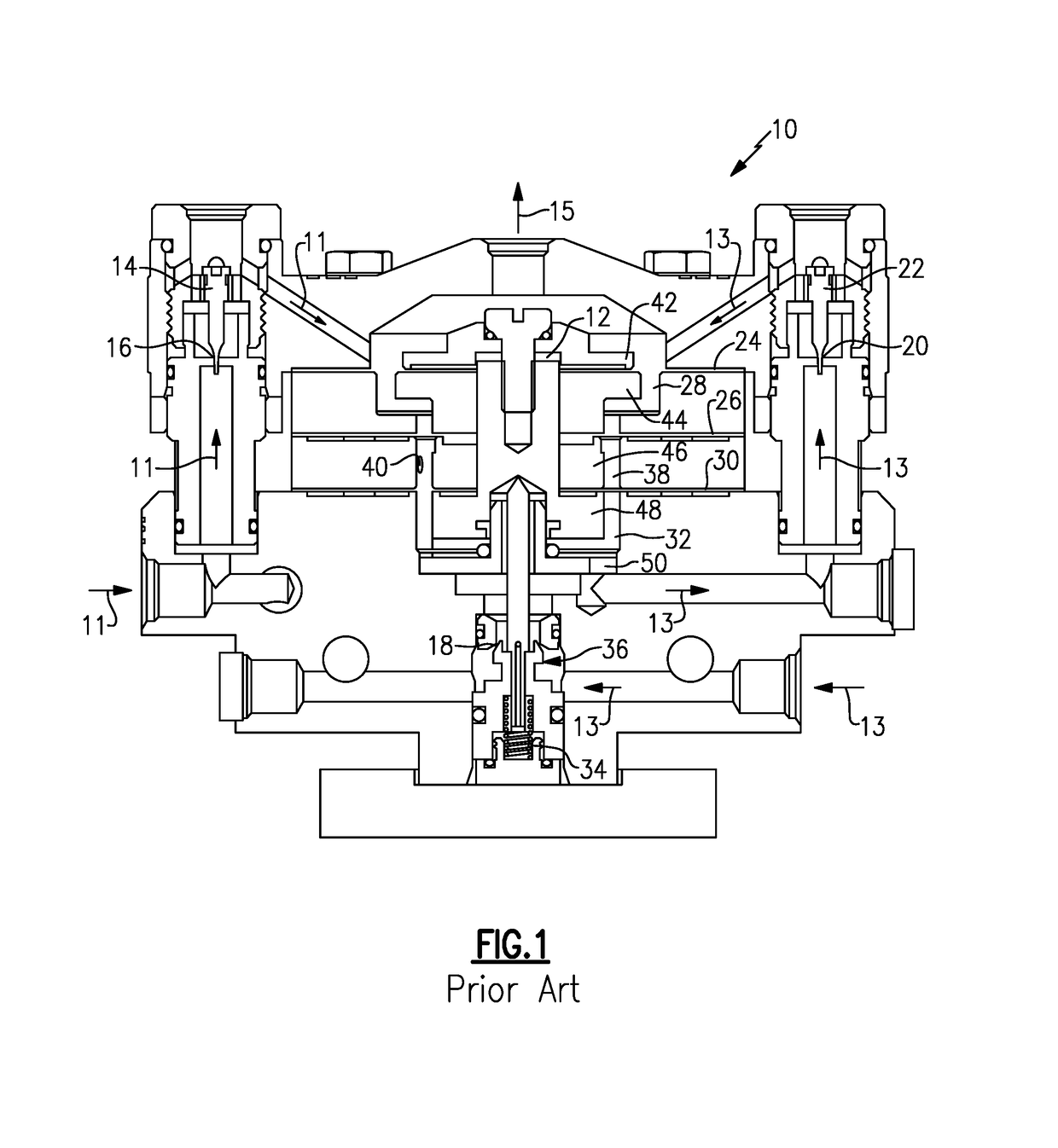

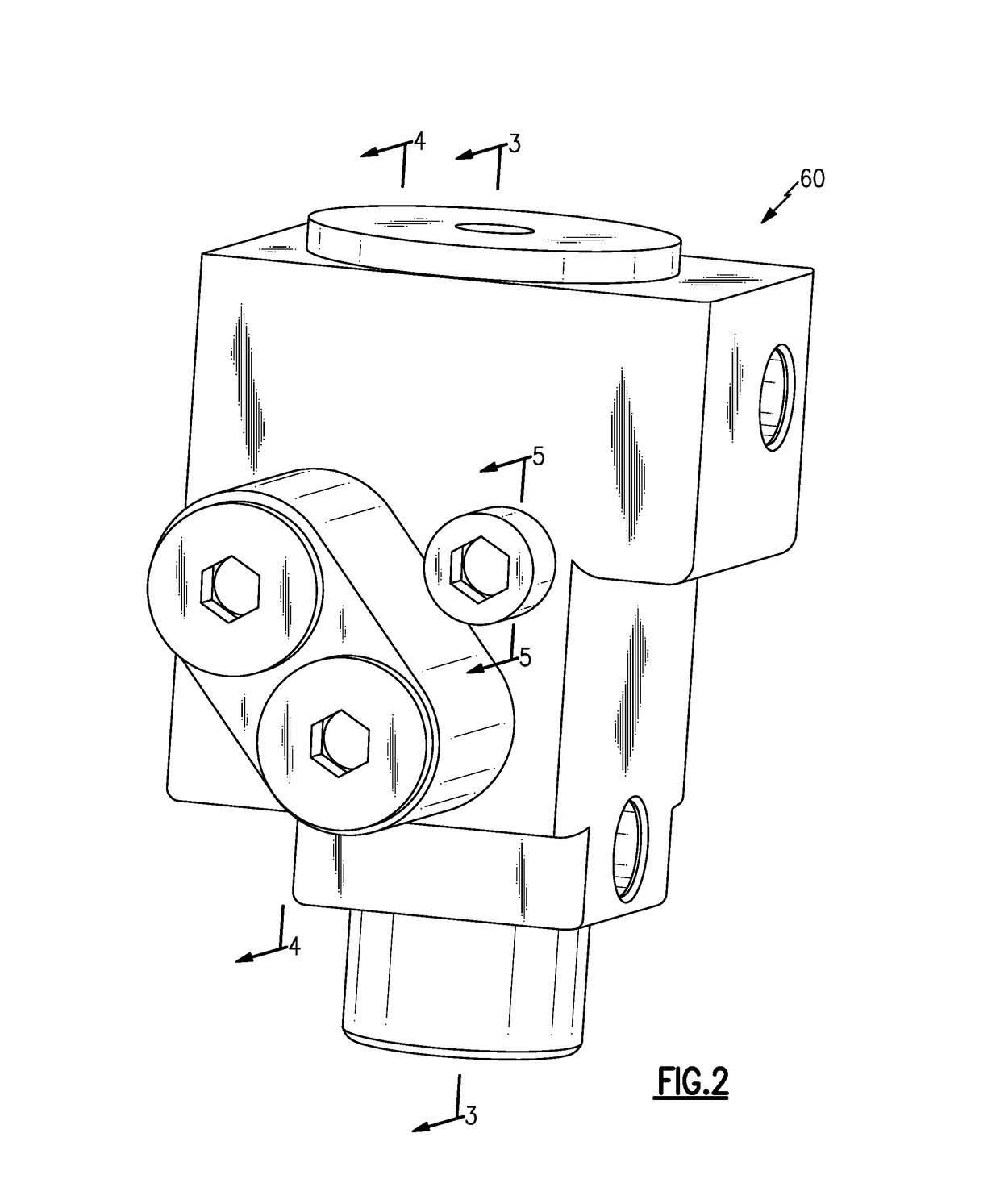

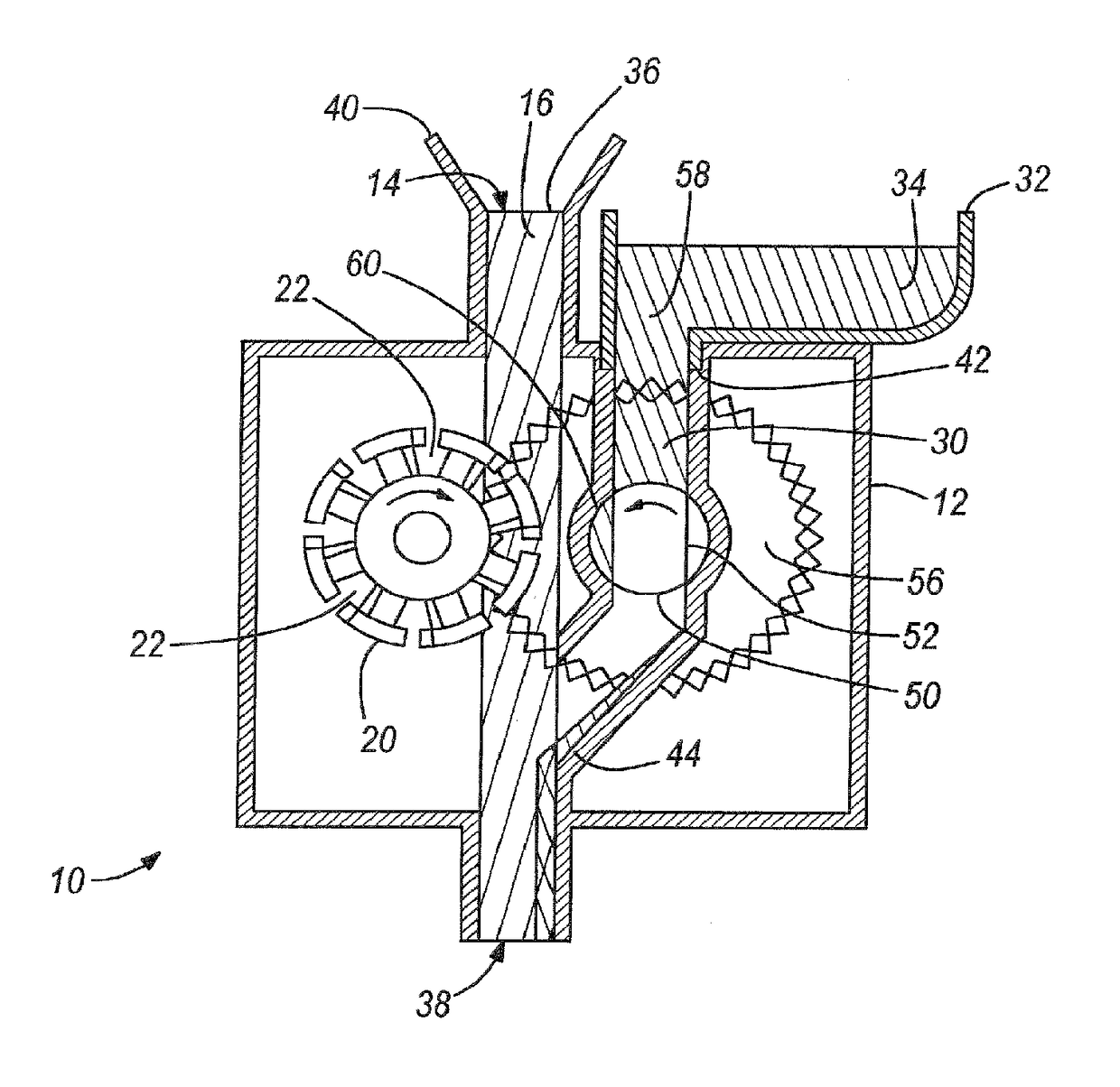

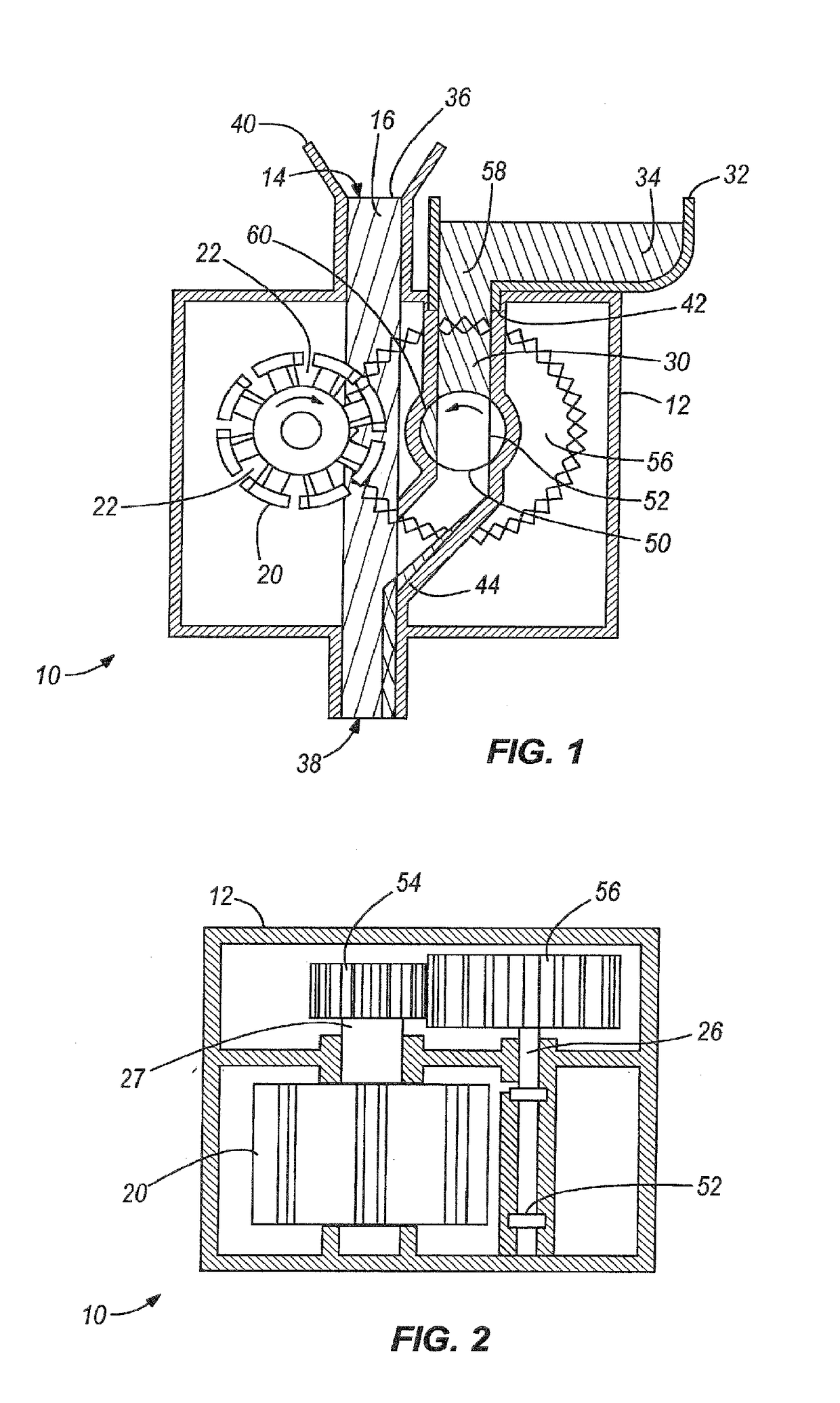

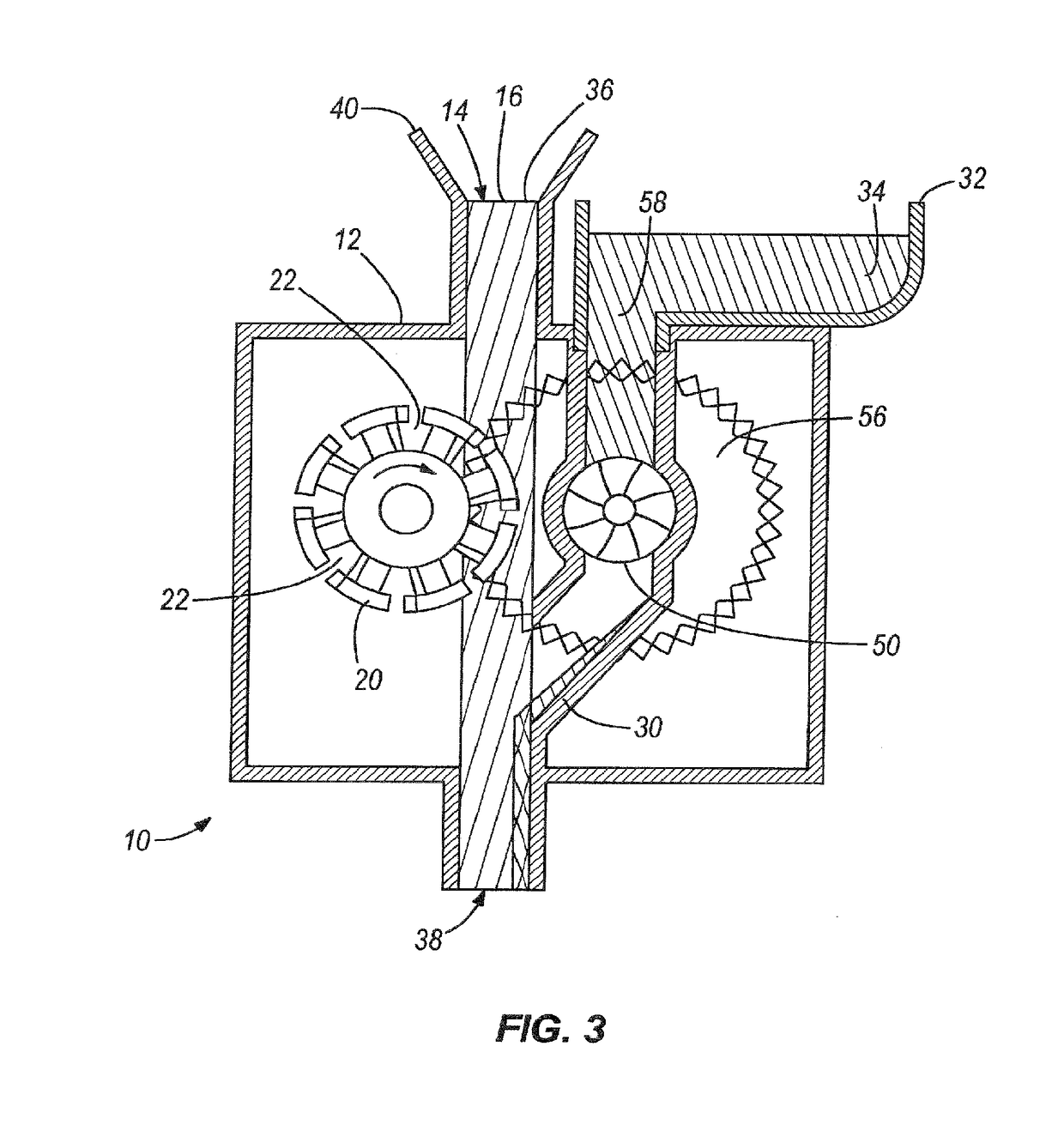

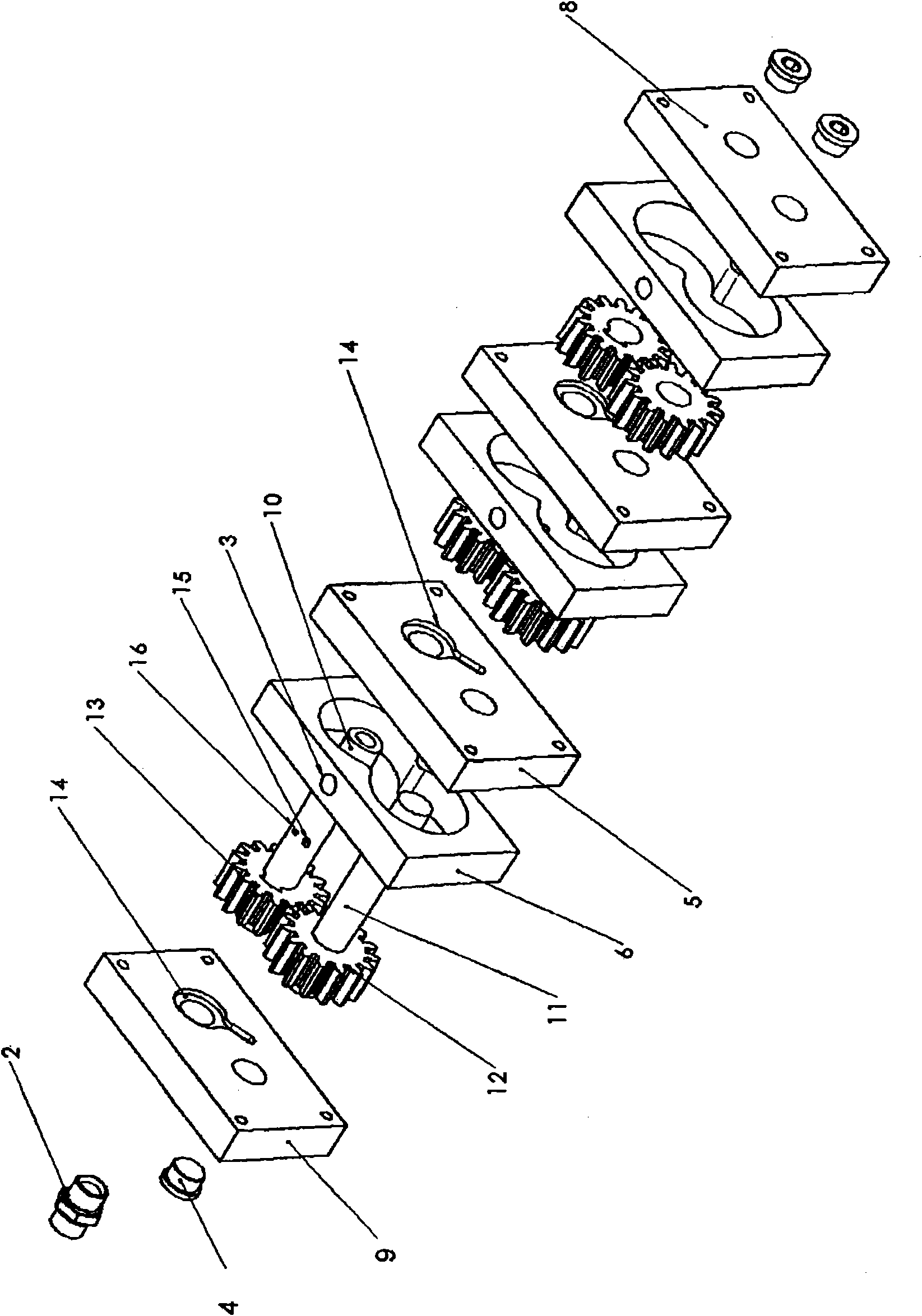

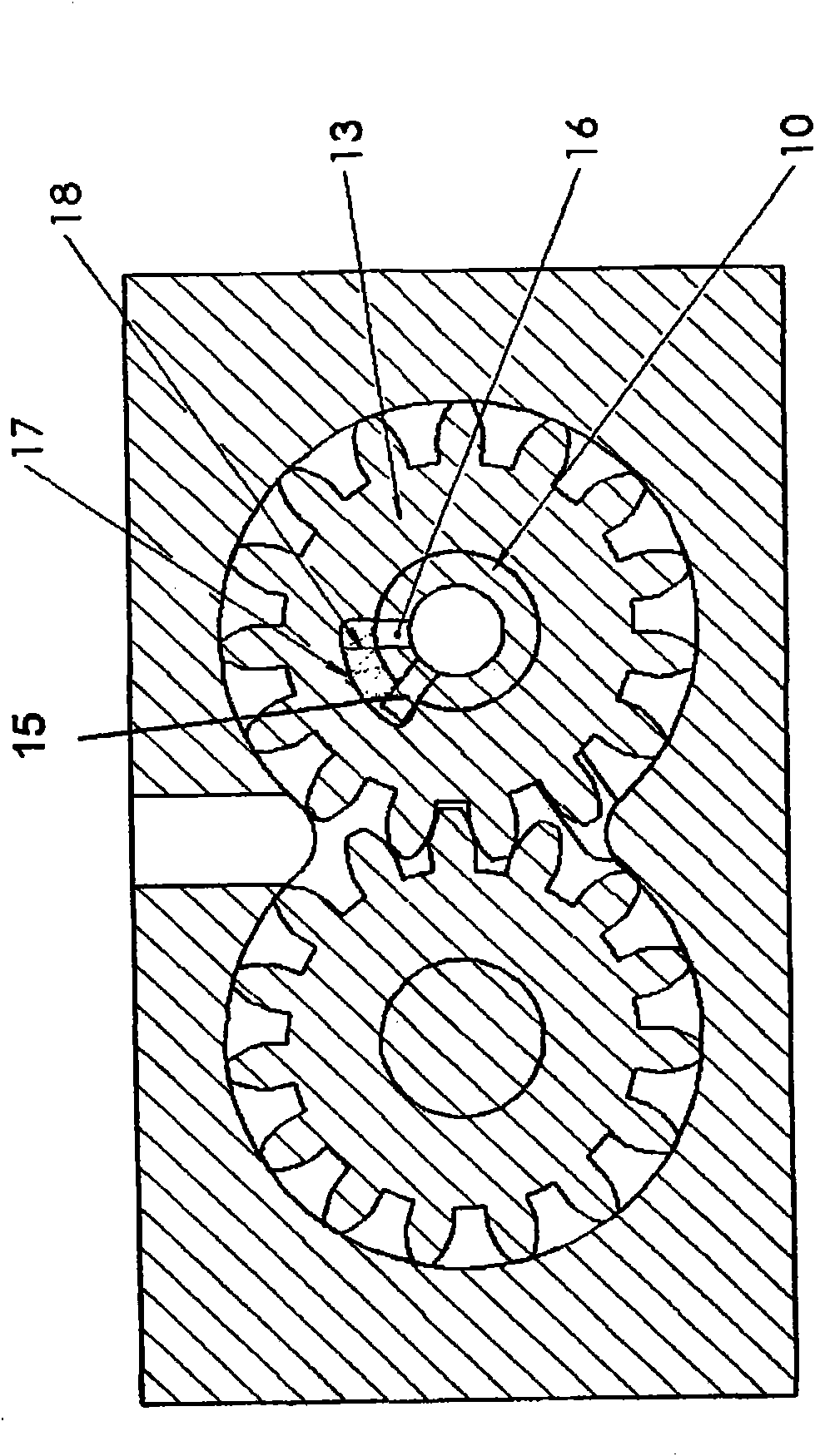

Flow splitter

ActiveUS20100200071A1Eliminate needDiaphragm valvesOperating means/releasing devices for valvesEngineeringDiaphragm valve

A flow splitter (10) that is uniquely characterized by the use of two diaphragm valves in a single valve body that are arranged in opposition to one another. The diaphragm valves are coupled together for common movement by a coupler, such that the flow rate through respective outlets is a function of the position of either diaphragm valve. That is, the position of one valve is a function of the position of the other valve, and vice versa. With this construction a single actuator can control the ratio of total flow that will be delivered to each of two outlet ports. Moreover, such construction eliminates the need for thermal or pressure sensors and thus the drawbacks associated therewith.

Owner:PARKER INTANGIBLES LLC

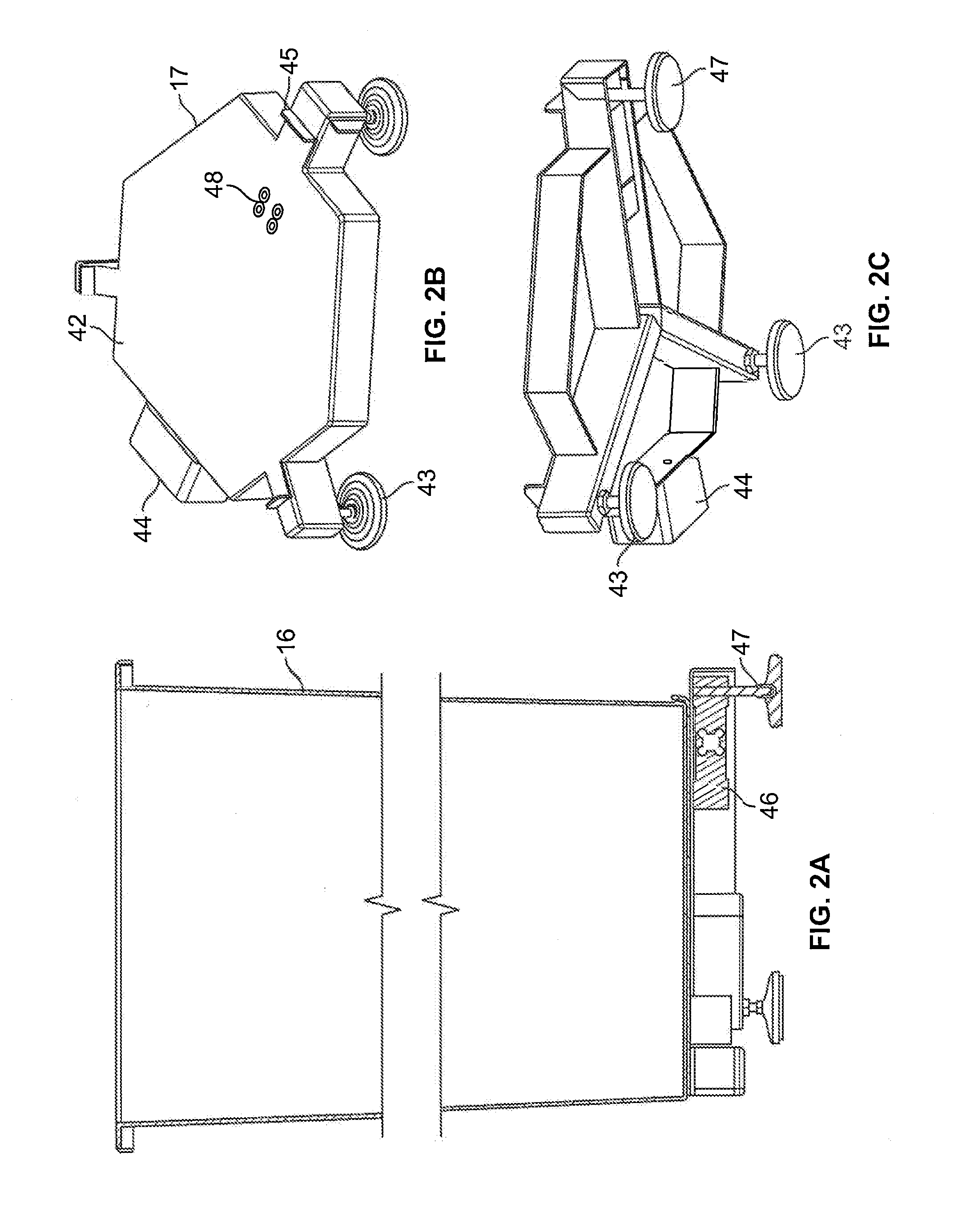

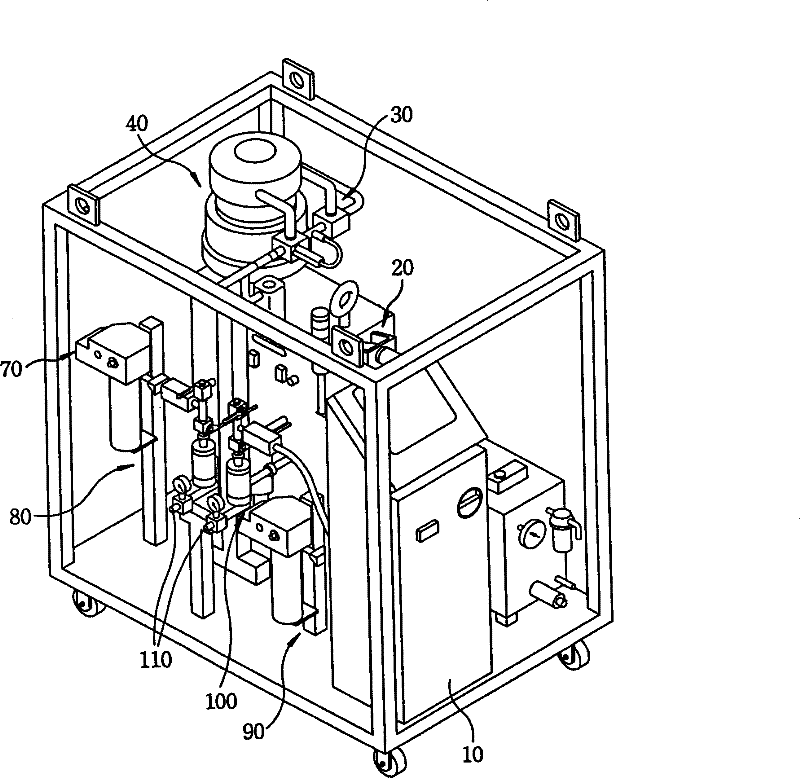

Volumetric mixer control system

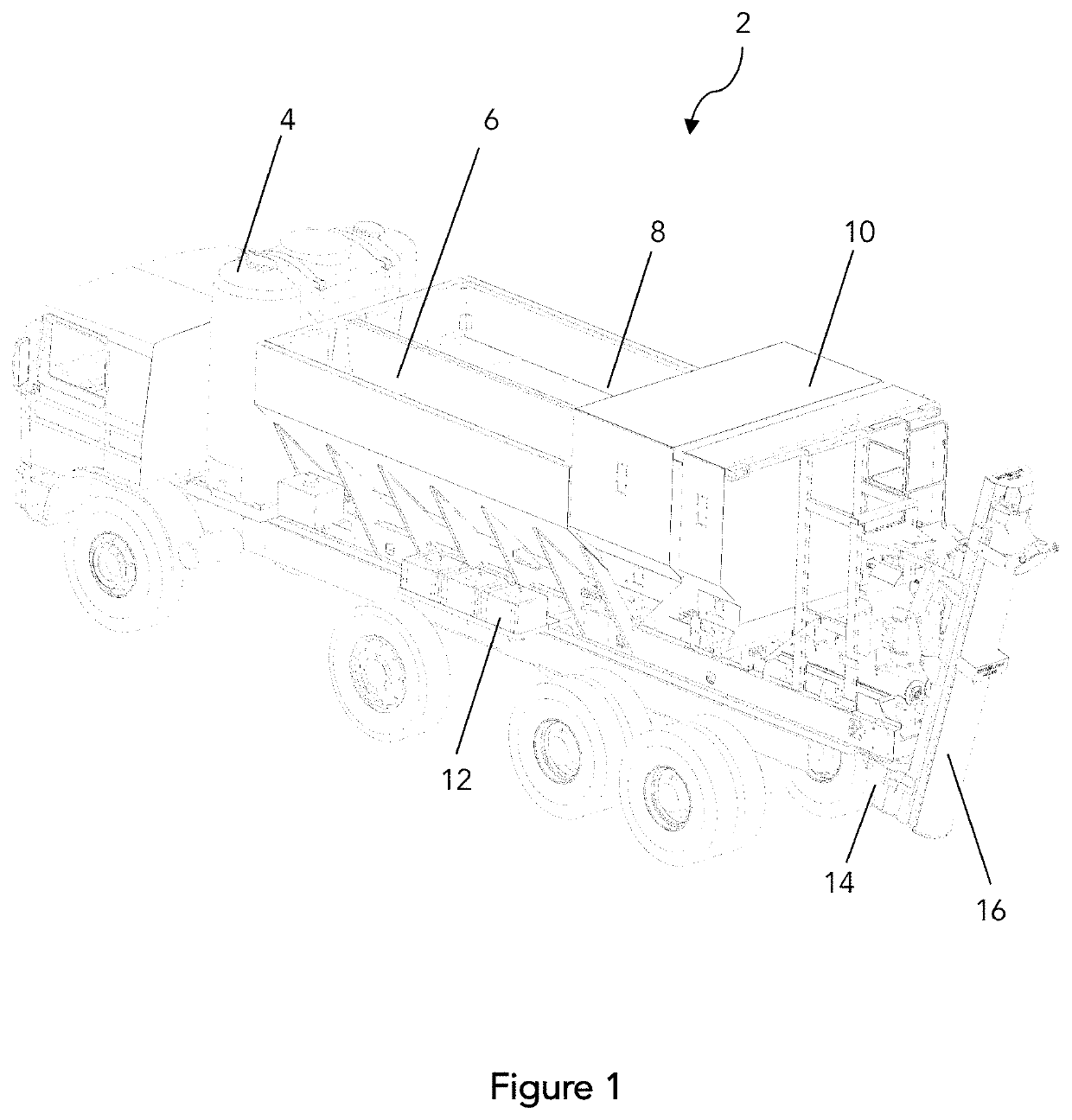

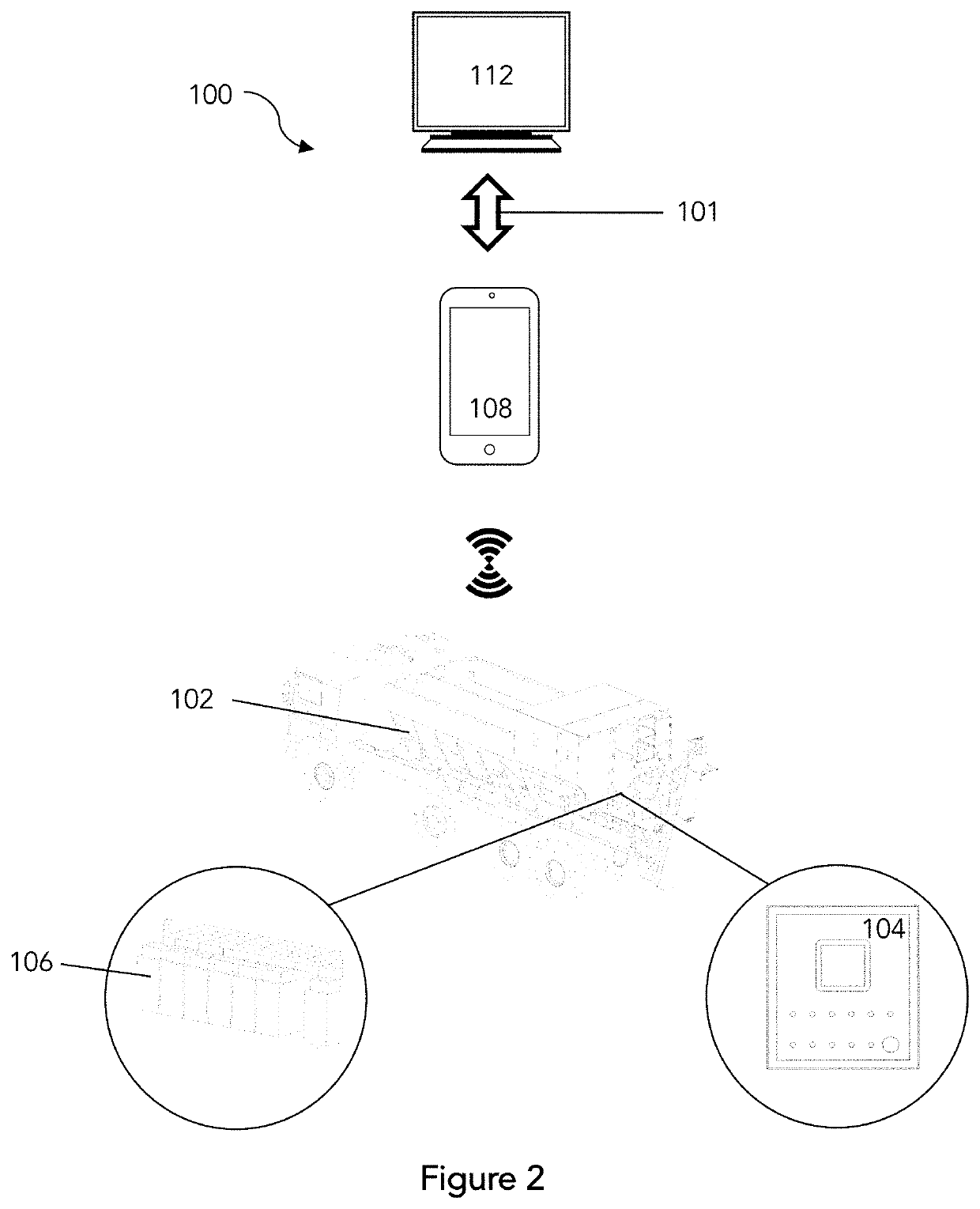

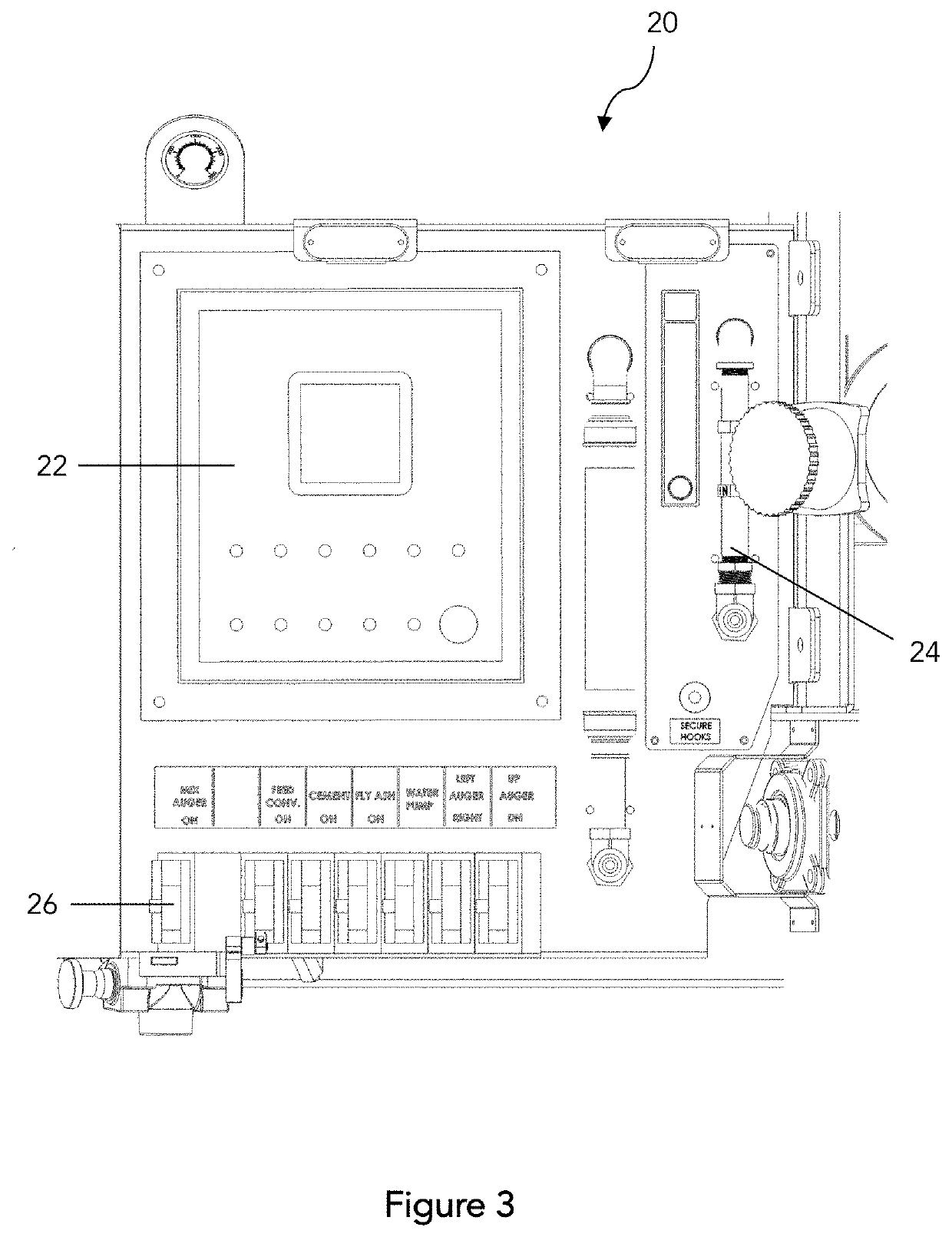

PendingUS20200223097A1Easy to operateControlling ratio of multiple fluid flowsConcrete transportationArea networkProgrammable logic controller

A volumetric mixer control system for a mobile volumetric mixer for controlling a mix recipe produced by the mobile volumetric mixer. The control system on the mobile volumetric mixer has a programmable logic controller, electronic control units for controlling flow control devices, and a controller area network for controlling the mixer control system. A mobile electronic device connects the controller area network on the mobile volumetric mixer to a remote terminal for providing a control signal to the mobile electronic device to control the mix produced by the volumetric mixer.

Owner:BAY LYNX MFG INC

Monitoring hydraulic fracturing

ActiveUS20140277745A1Water/sewage treatment by neutralisationWater/sewage treatment by substance additionWater sourceOil and natural gas

This disclosure relates to systems, methods, and devices useful for monitoring and controlling water to be used, for example, in oil and natural gas production and hydraulic fracturing processes. An on-line unit for measuring, controlling, and optimizing the quality of water being used during the hydrocarbon production or hydraulic fracturing processes is also disclosed. Optimizing and controlling can include measuring one or more properties associated with the production water to be sure that the one or more properties are within an acceptable range and, if the one or more properties are not within the acceptable range for each respective property being measured, causing a change in flow of one or more water sources and / or one or more chemicals.

Owner:CHAMPIONX USA INC

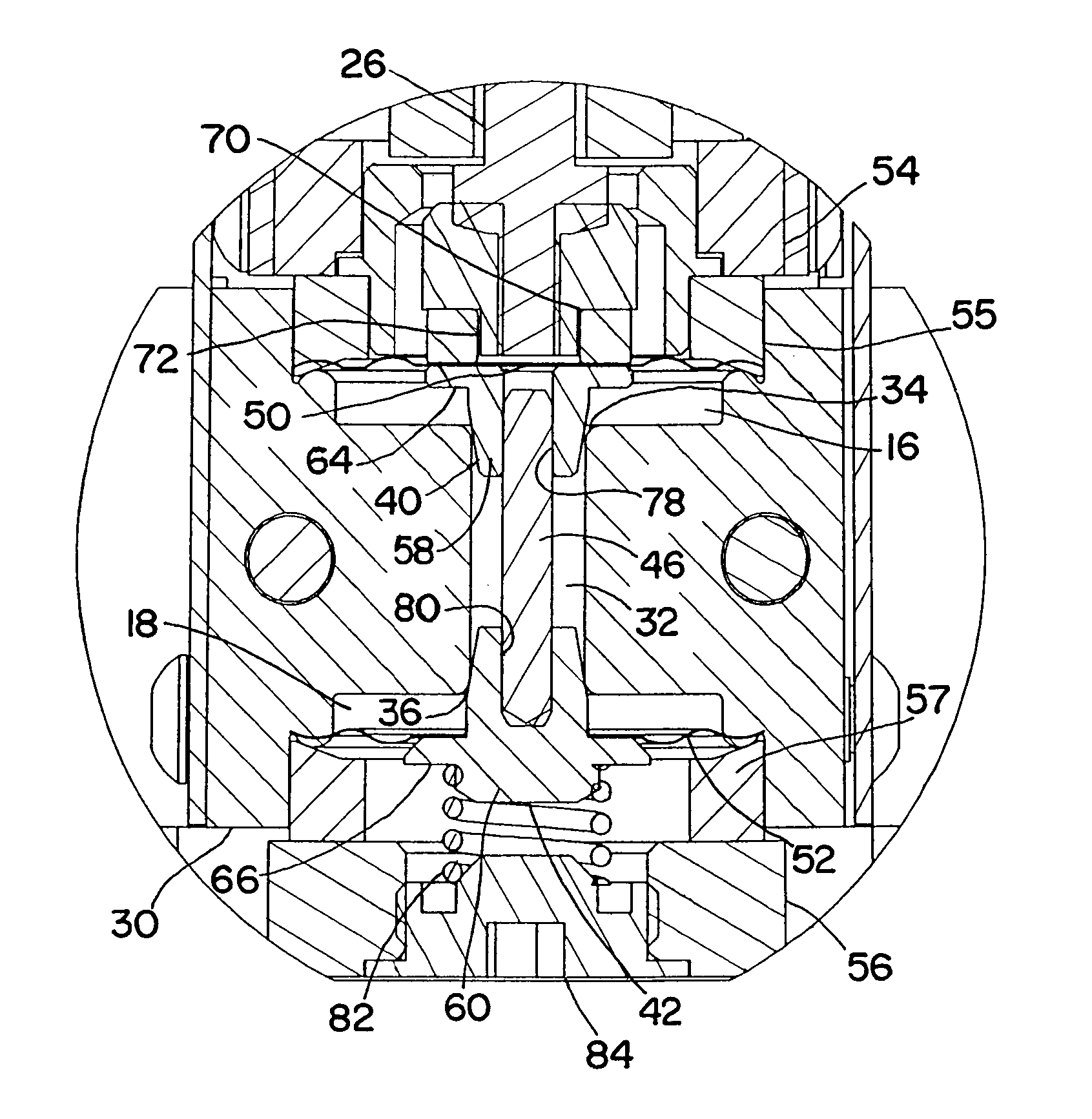

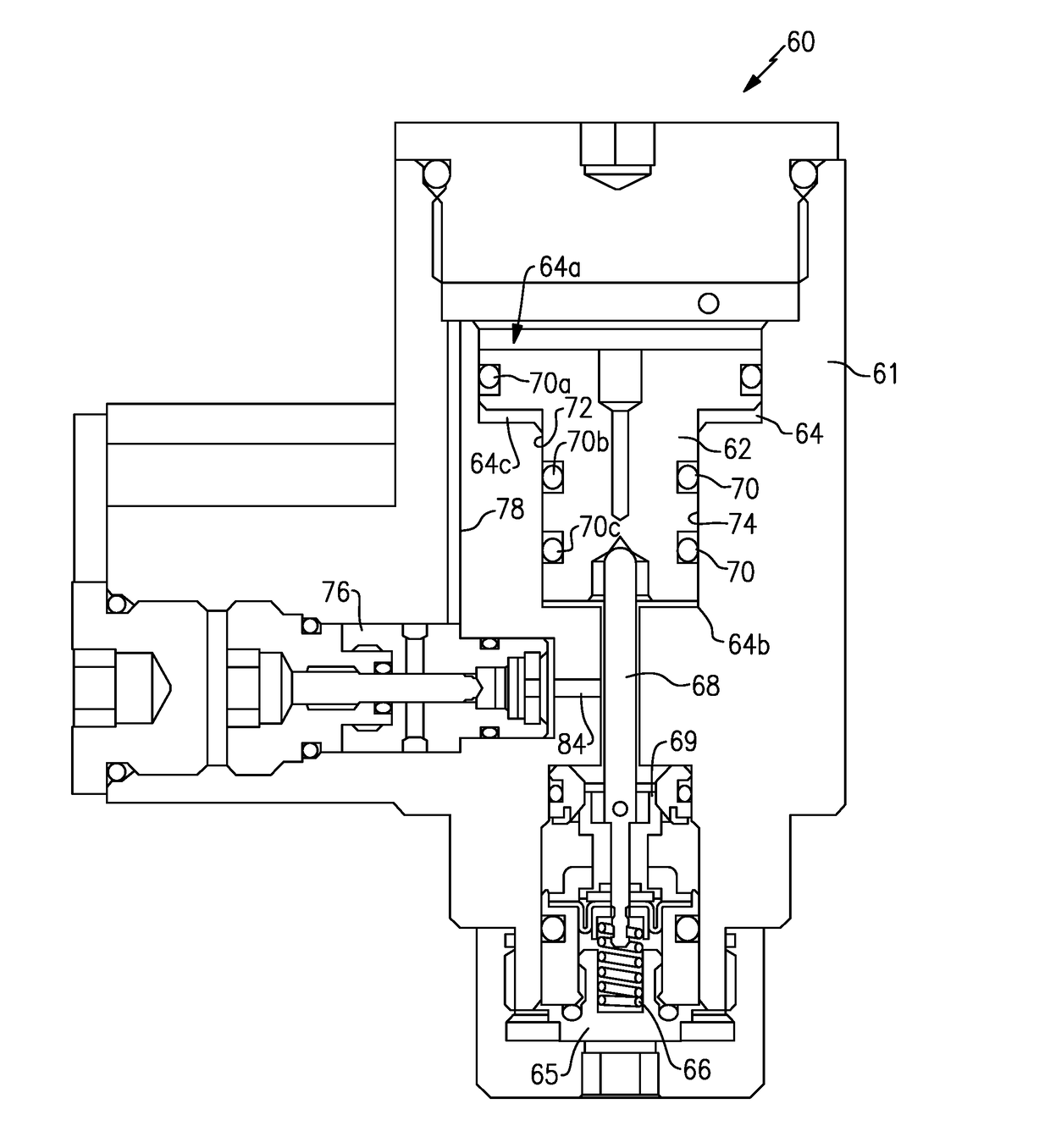

Flow splitter

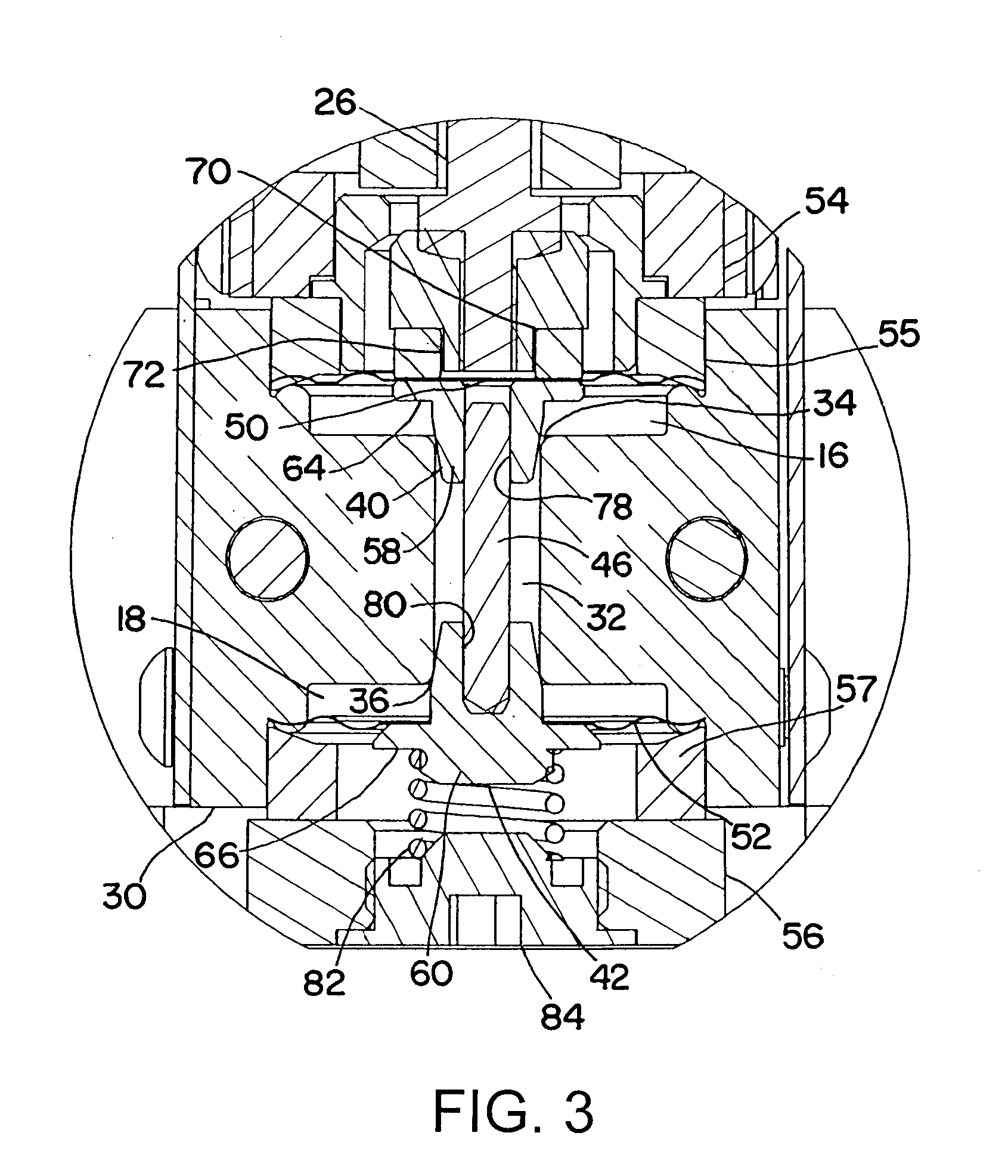

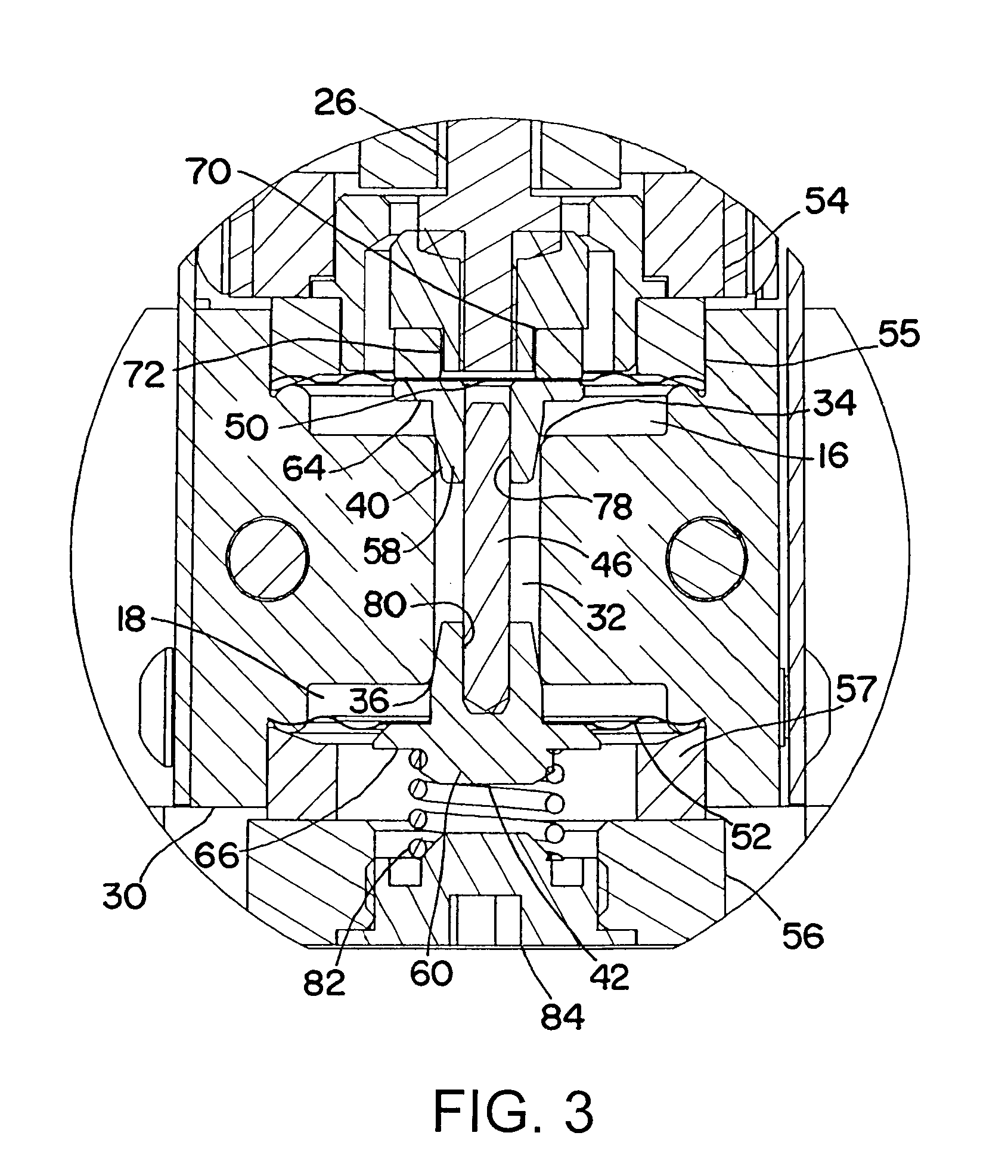

ActiveUS8528598B2Eliminate needOperating means/releasing devices for valvesControl using interconnected flow control elementsEngineeringDiaphragm valve

A flow splitter (10) that is uniquely characterized by the use of two diaphragm valves in a single valve body that are arranged in opposition to one another. The diaphragm valves are coupled together for common movement by a coupler, such that the flow rate through respective outlets is a function of the position of either diaphragm valve. That is, the position of one valve is a function of the position of the other valve, and vice versa. With this construction a single actuator can control the ratio of total flow that will be delivered to each of two outlet ports. Moreover, such construction eliminates the need for thermal or pressure sensors and thus the drawbacks associated therewith.

Owner:PARKER INTANGIBLES LLC

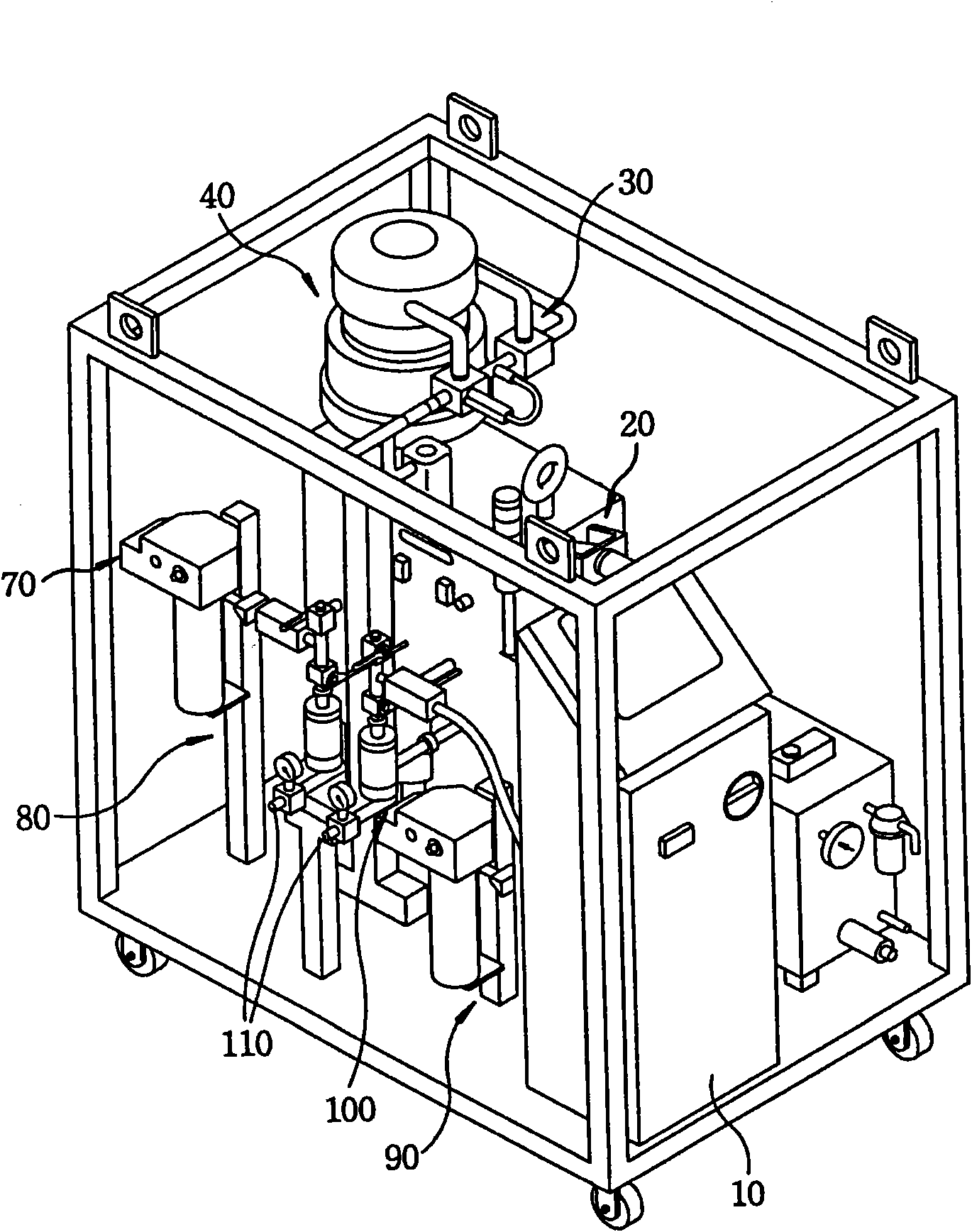

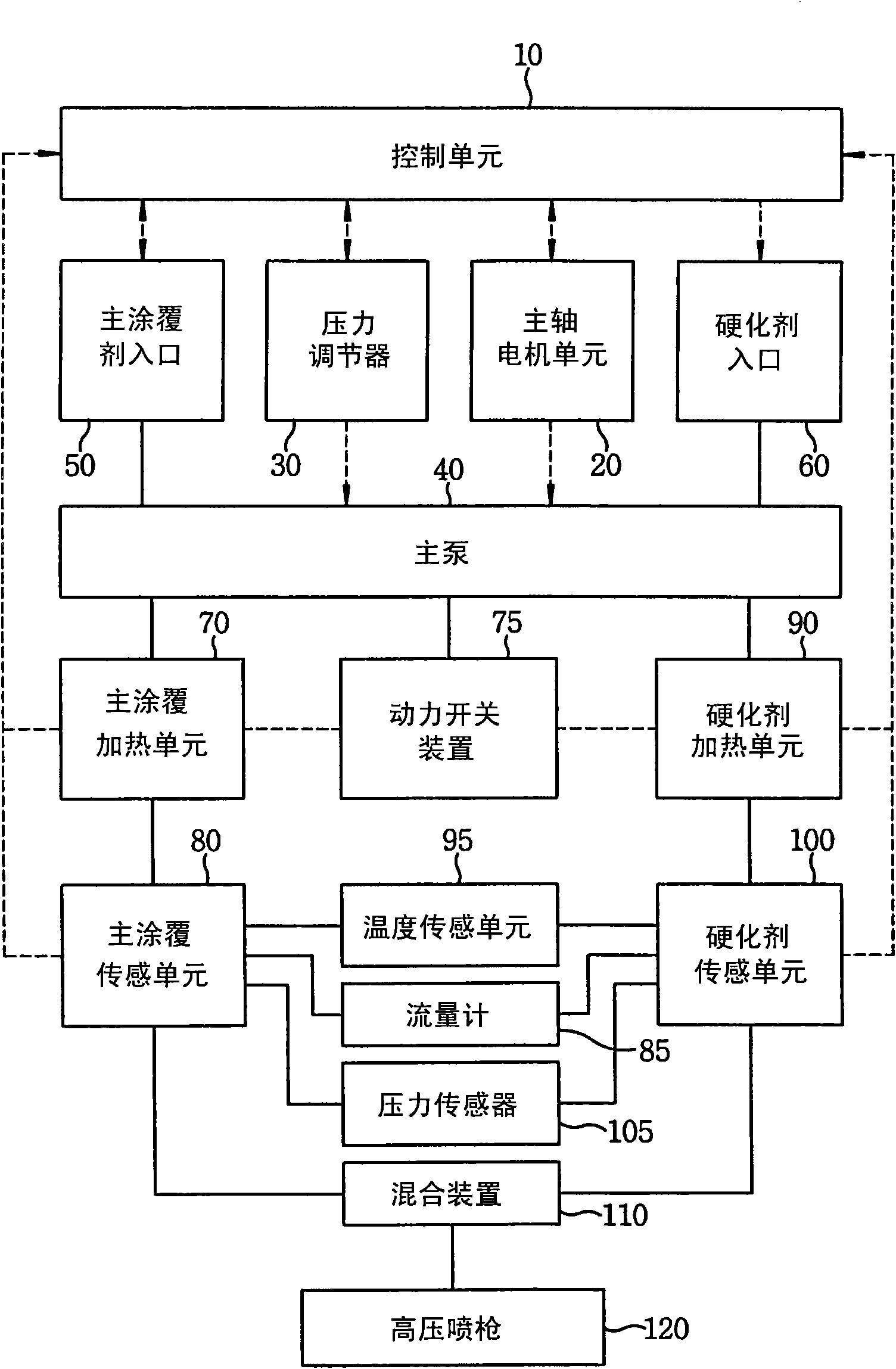

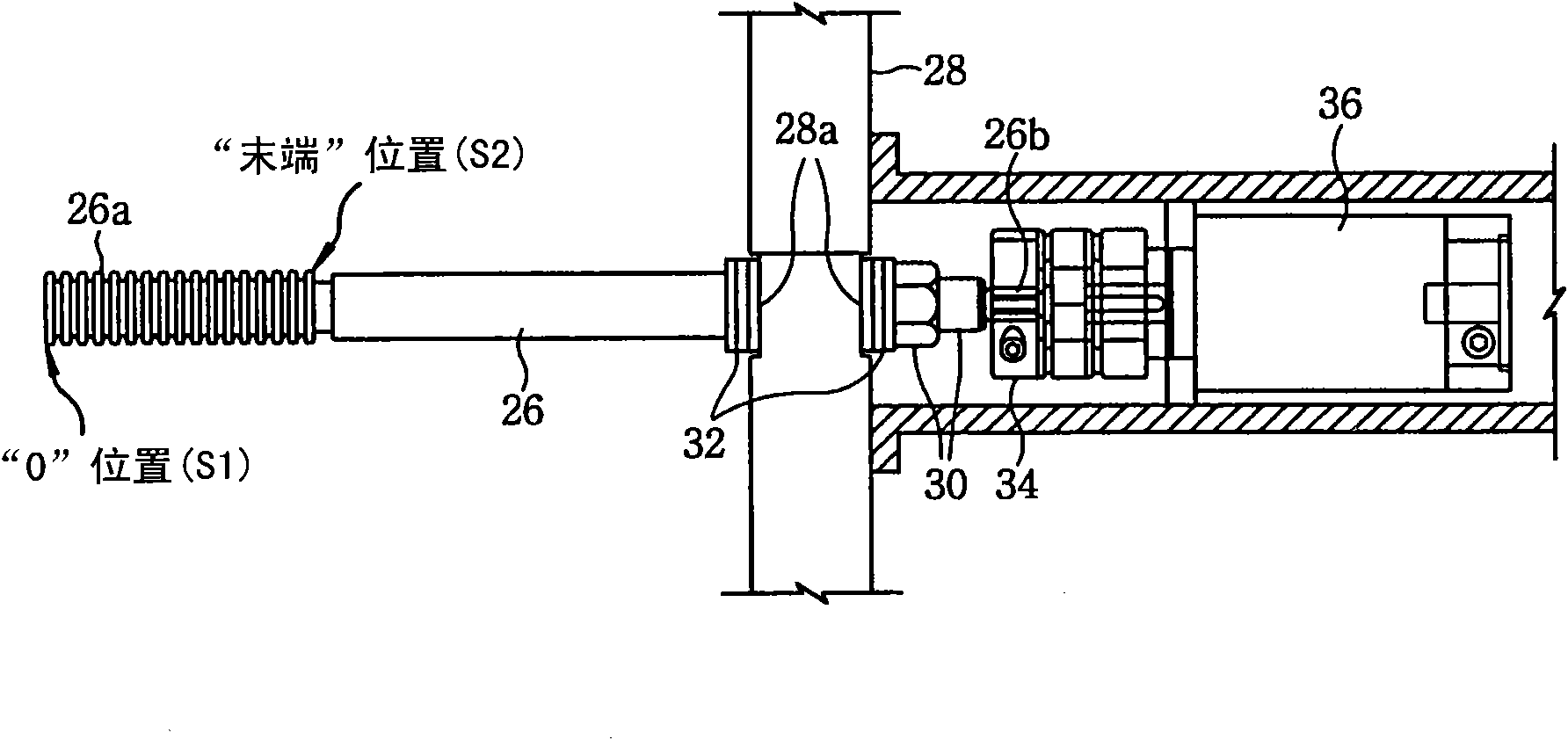

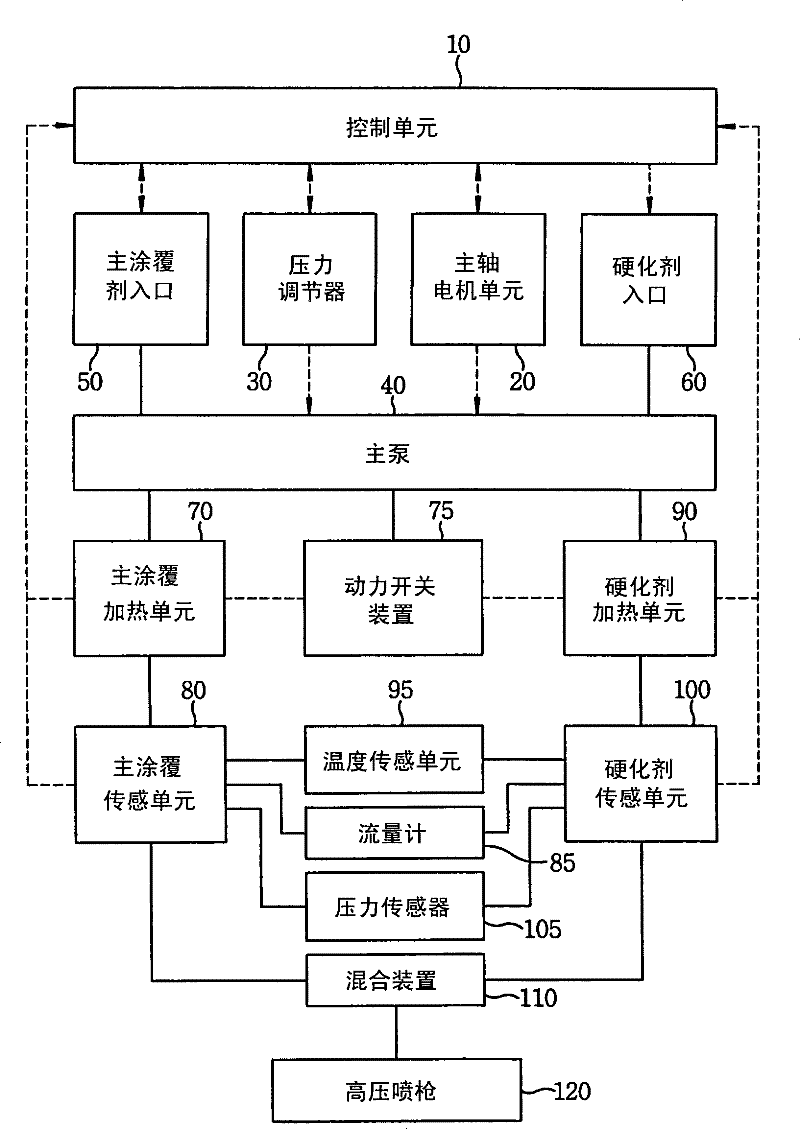

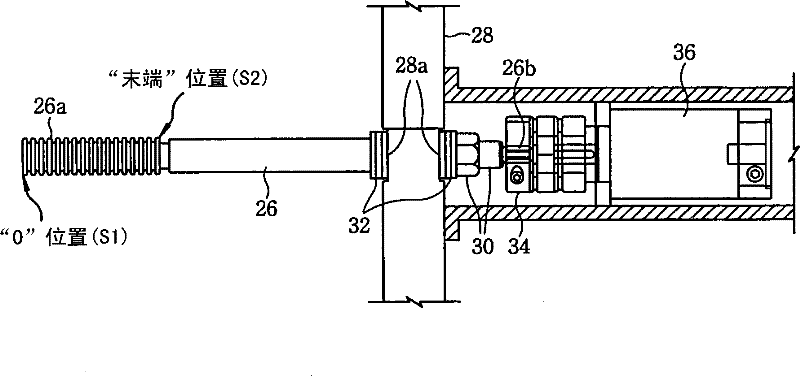

Coating apparatus capable of controlling mixing ratio and method thereof

ActiveCN101569880AQuick changeLiquid surface applicatorsControl using interconnected flow control elementsControl theoryMixing ratio

A coating apparatus capable of controlling a mixing ratio includes a spindle motor unit having a spindle with which an upper end portion of a mixing ratio control shaft is engaged, the upper end portion of the control shaft being moved on the spindle in accordance with rotation of the spindle; and a control unit for calculating the mixing ratio of a main coating agent and a hardening agent based on measured flow rates thereof and controlling the rotation of the spindle when the calculated mixing ratio of the main coating agent and the hardening agent falls outside a tolerance range of a preset mixing ratio. The mixing ratio of the main coating agent and the hardening agent is adjusted depending on the positions of the upper end portion of the mixing ratio control shaft on the spindle.

Owner:SAMSUNG HEAVY IND CO LTD

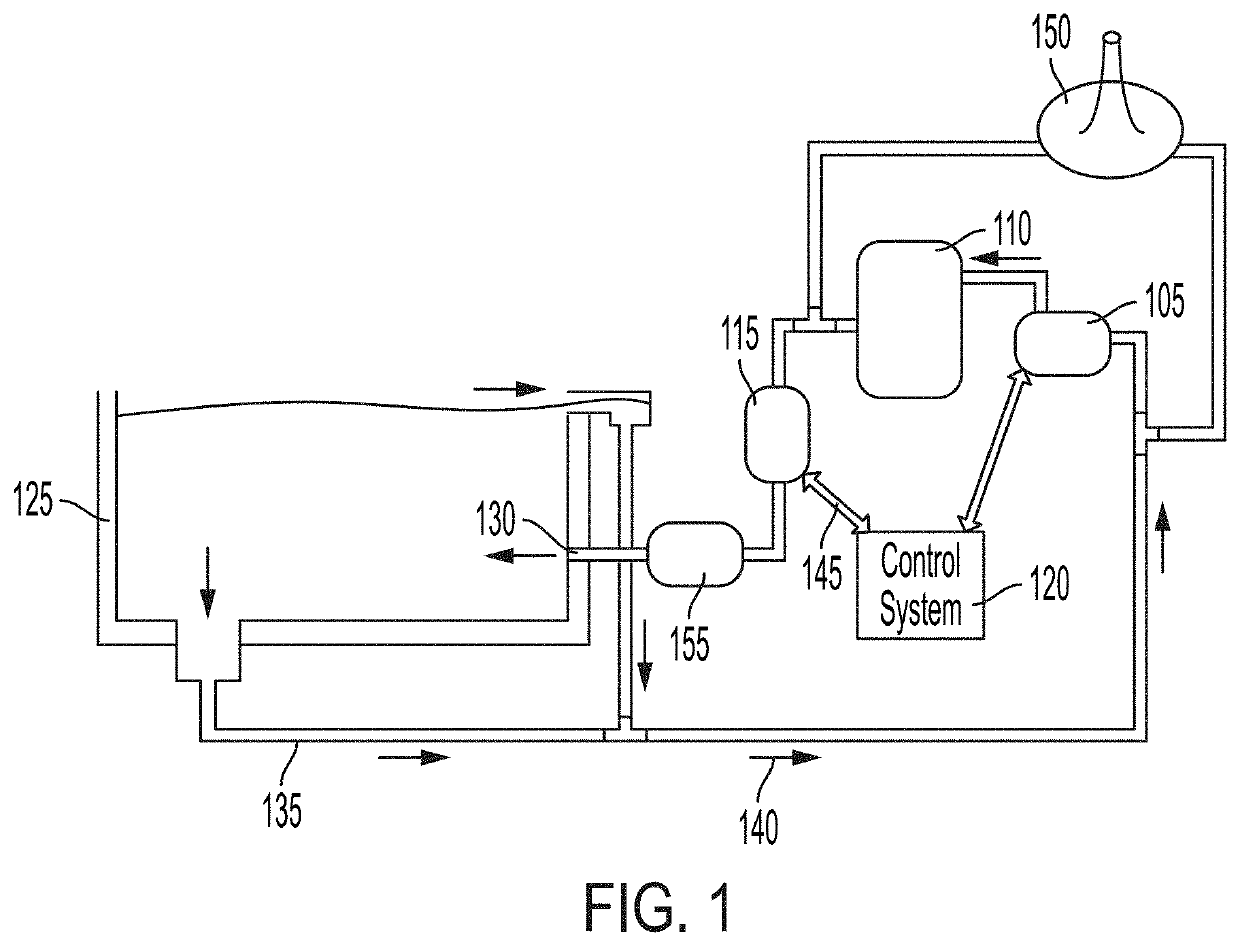

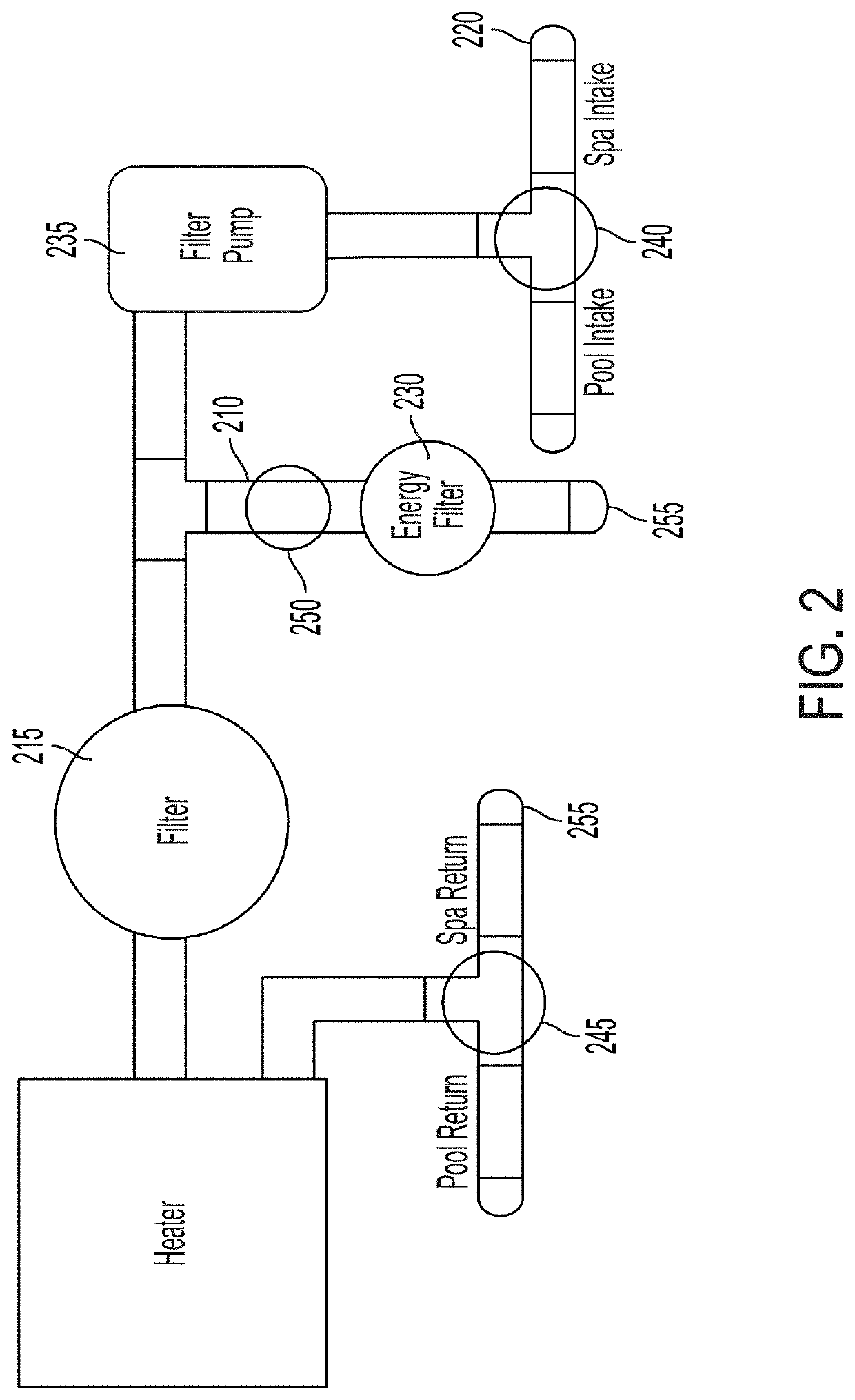

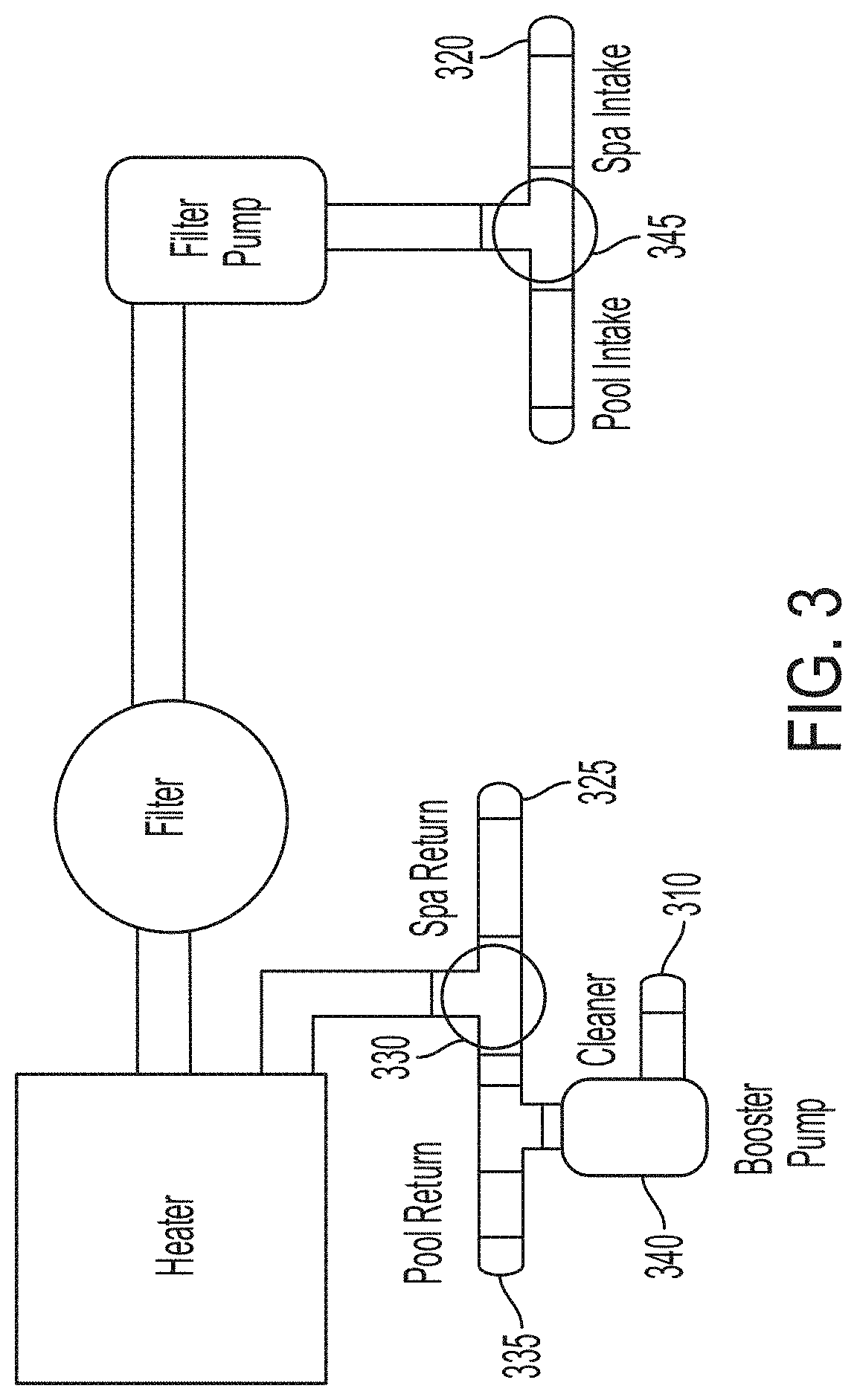

Methods for determining fluidic flow configurations in a pool system

One aspect of the invention provides a computer-implemented method for controlling a swimming pool or spa system. The computer-implemented method includes: creating a data structure representing a plurality of swimming pool system components and fluidic connections between subsets of the plurality of swimming pool system components; receiving a request to control one or more of the plurality of swimming pool system components; calculating fluidic flows through the plurality of swimming pool system components based on one or more potential configurations of the plurality of swimming pool system components capable of fulfilling the request; and detecting whether the one or more potential configurations result in unsatisfactory conditions.

Owner:POOLSIDE TECH LLC

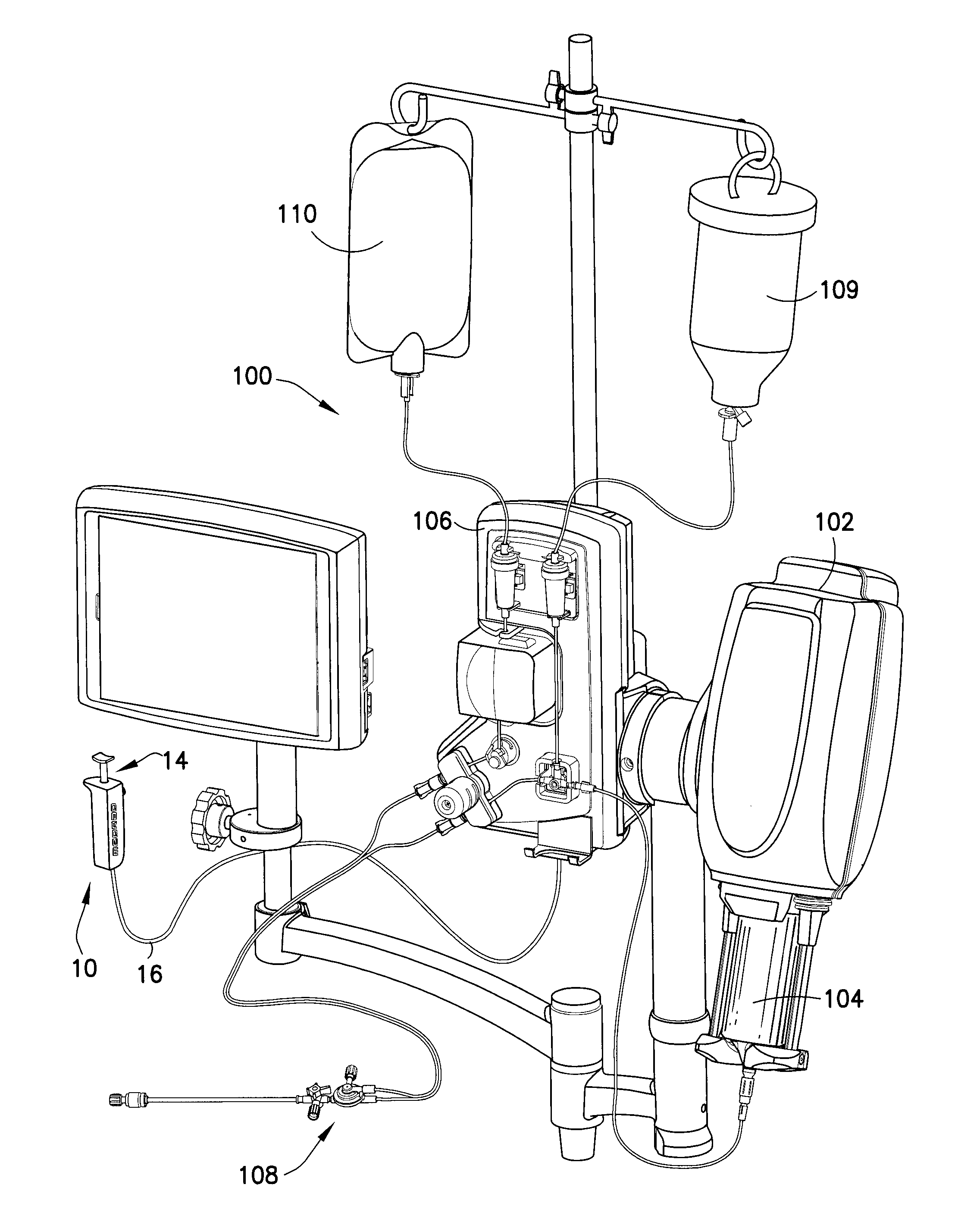

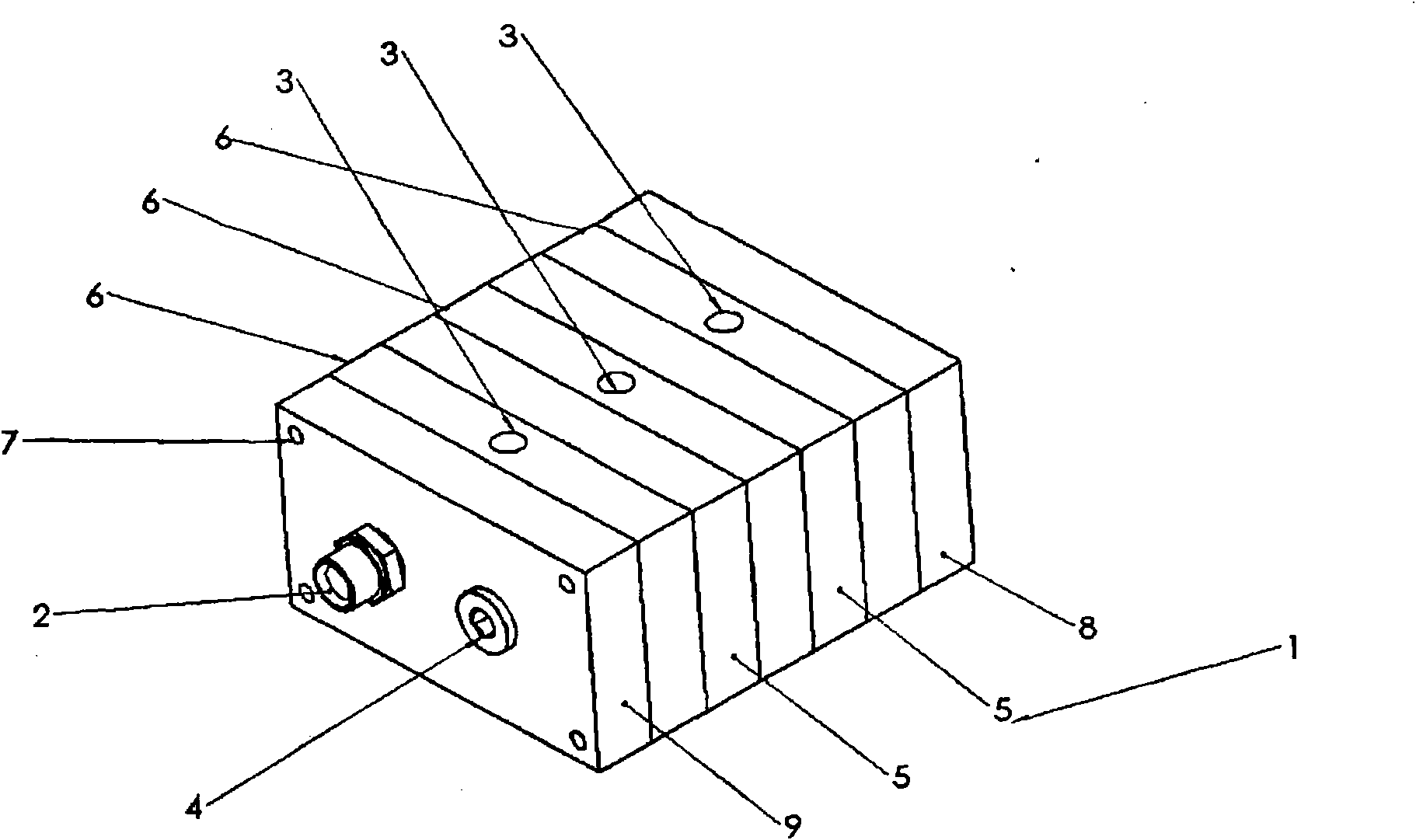

Fluid mixing control device for a multi-fluid delivery system

ActiveUS9011377B2Control using synchronised pumpsControlling ratio of multiple fluid flowsEngineeringActuator

The control device is used to control delivery of fluids from a multi-fluid delivery system during a medical injection procedure. The fluid delivery system includes an injector used to deliver injection fluids to a patient. The control device is operatively associated with the injector for controlling discrete flow rates of injection fluids delivered to the patient. The control device includes a housing, first and second actuators associated with the housing, and an electronic substrate disposed within the housing and having a conductive pattern. The first actuator is operatively associated with the conductive pattern. The conductive pattern includes a plurality of predetermined digital values corresponding to discrete flow rates of injection fluids to be delivered by the injector. The second actuator is operatively associated with the electronic substrate and initiates output signals to the injector corresponding to desired mixture ratios of the injection fluids to be delivered by the injector.

Owner:BAYER HEALTHCARE LLC

Device and method for dilution control

ActiveUS9766636B2Controlling ratio of multiple fluid flowsControl with discontinuous actionAuto regulationDiluent

A dilution control device and method of operating the same. The dilution control device can include a structure for dispensing concentrate and diluent fluid in a desired dilution ratio utilizing volumetric dosing. In some embodiments, diluent fluid drives a wheel or compresses a pliable concentrate bag in order to dispense concentrate in the desired ratio with the diluent fluid. In some embodiments, one or more floats can be used to drive a pump or actuate a valve to dispense concentrate at a particular rate proportional with the flow rate of the diluent fluid. In some embodiments, a rocker is responsive to the flow of diluent fluid to pump concentrate. In some embodiments, the dilution control device can be operable to automatically modulate the dispense rate of concentrate when the diluent fluid flow rate is varied in order to maintain a predetermined dilution ratio.

Owner:JOHNSONDIVERSEY INC

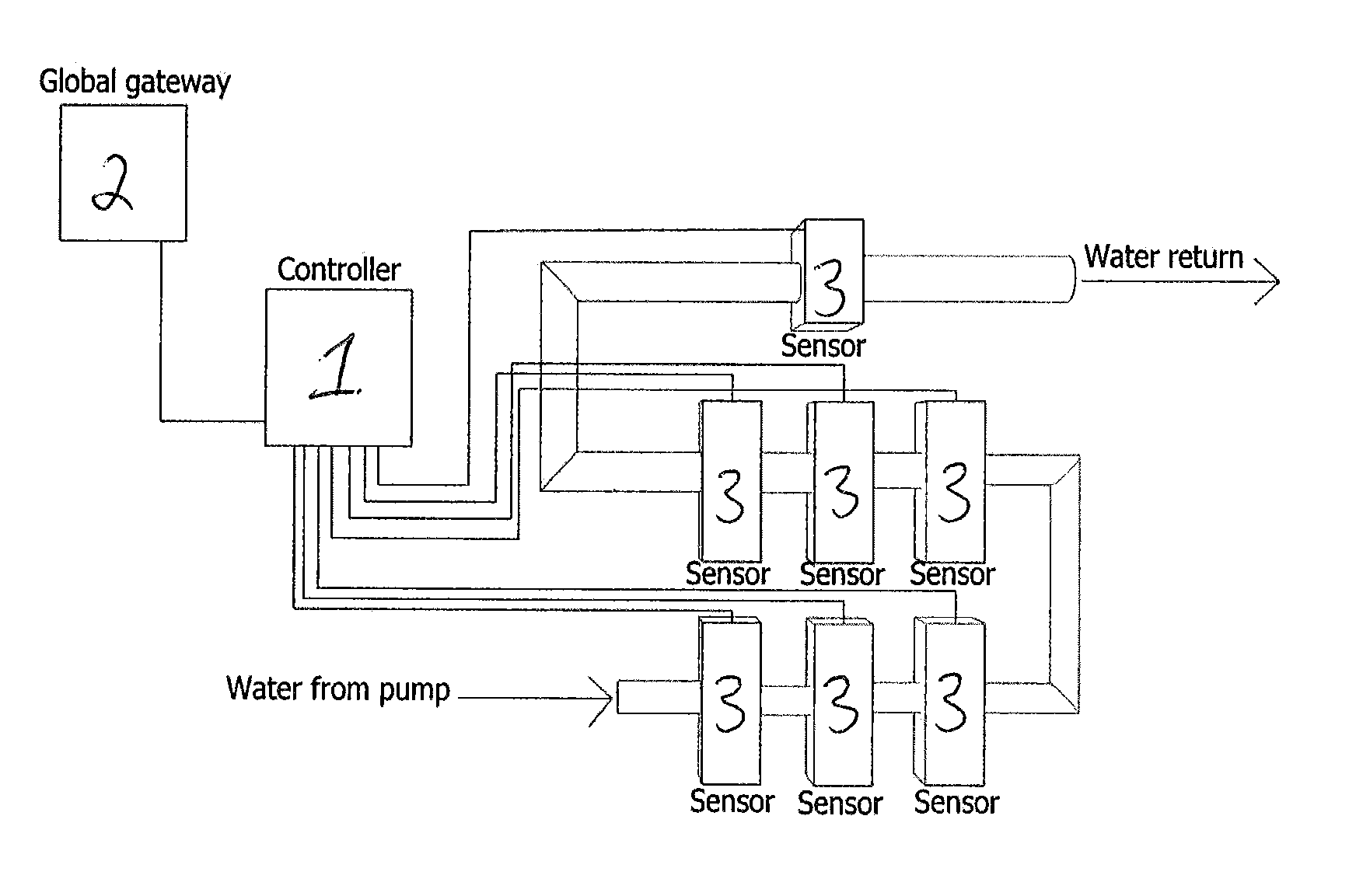

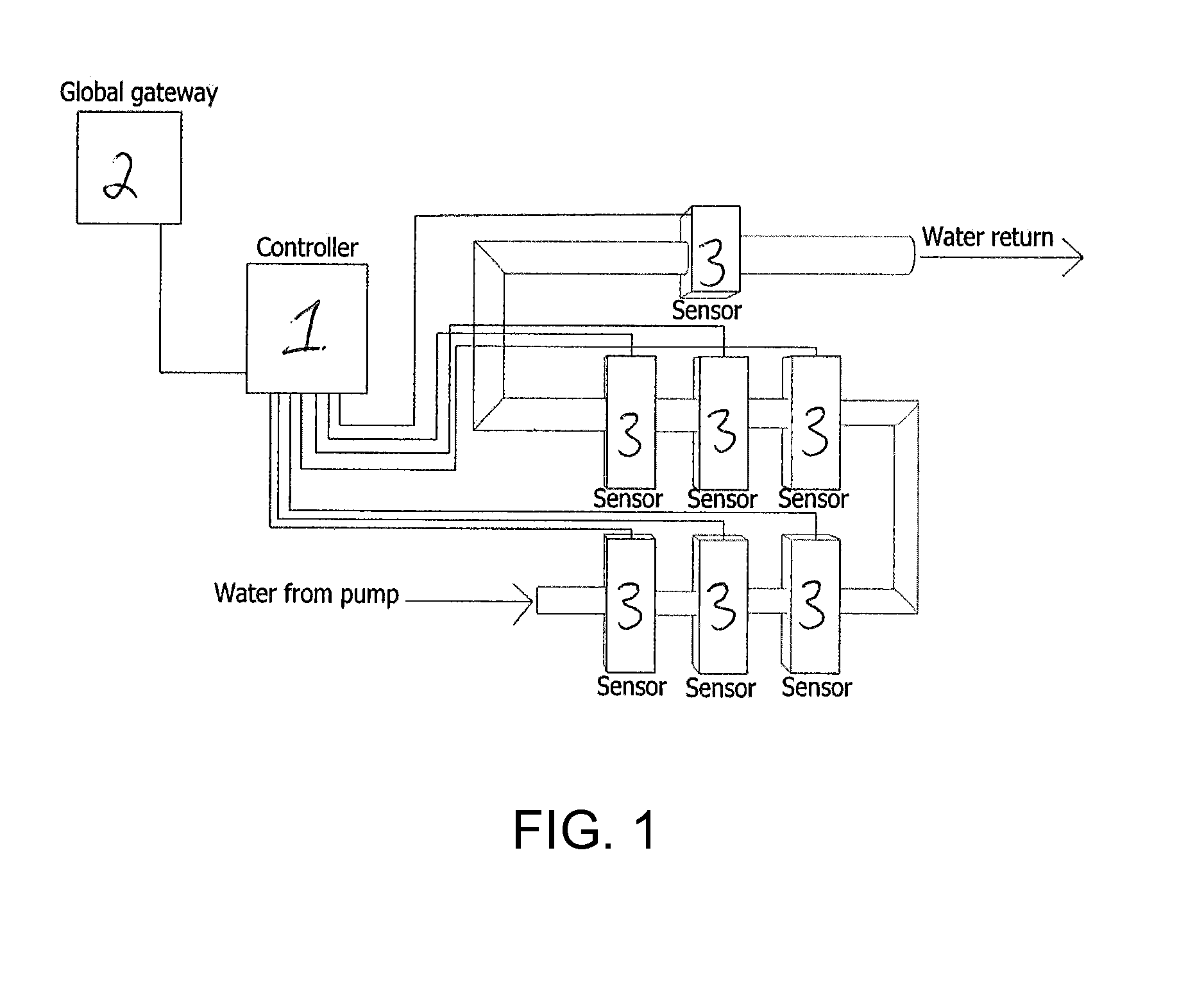

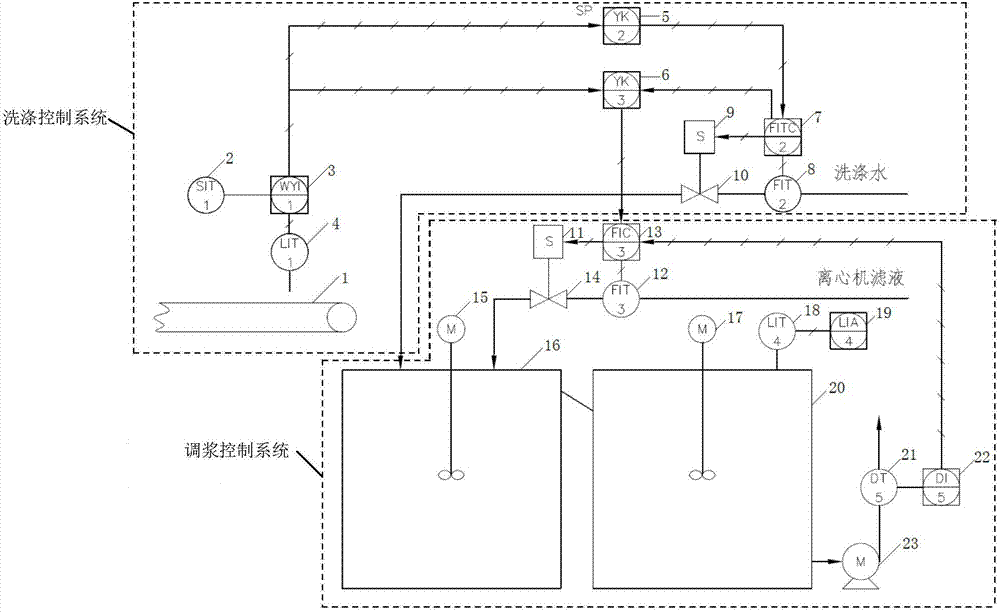

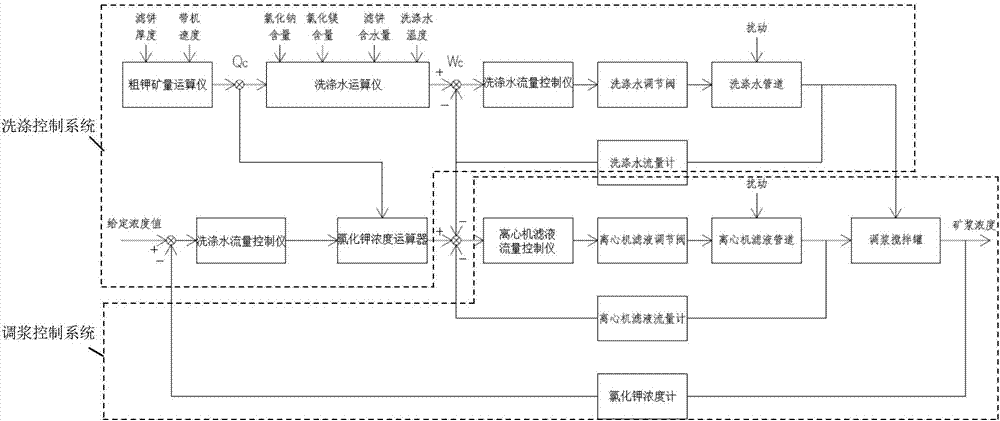

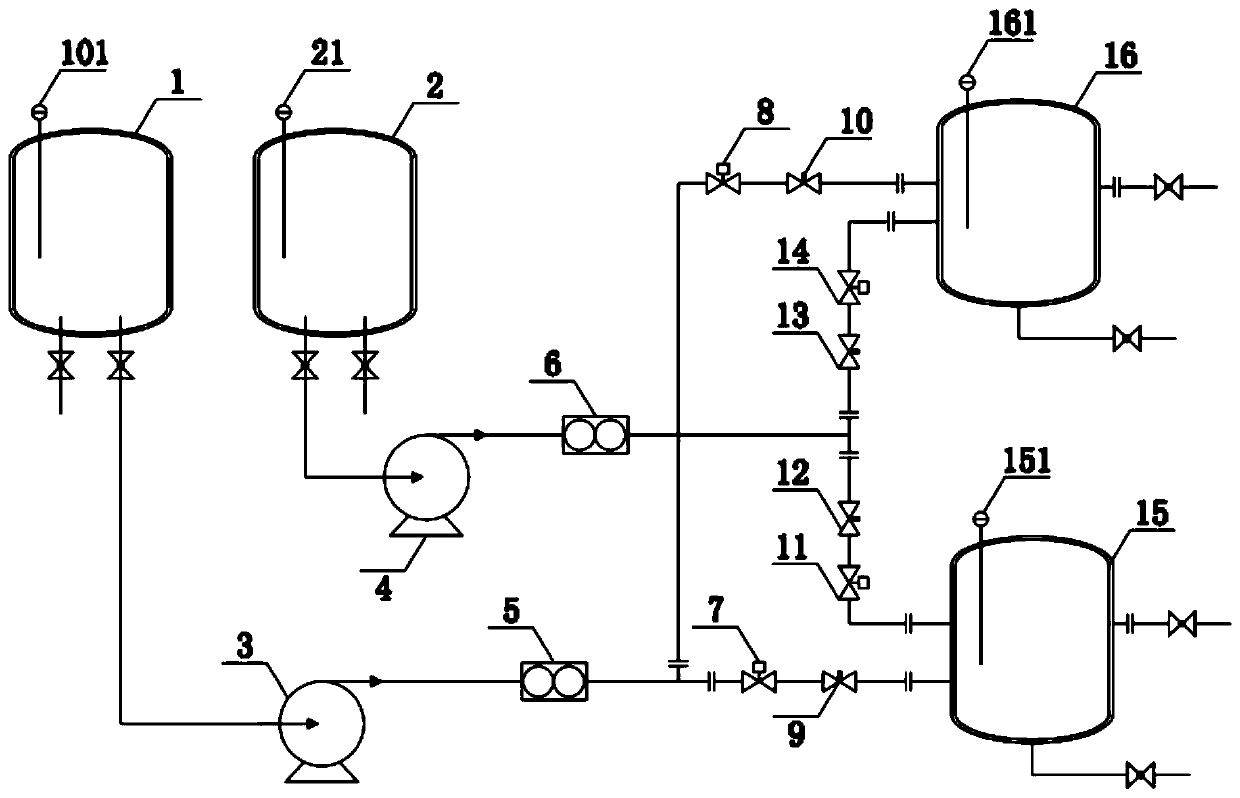

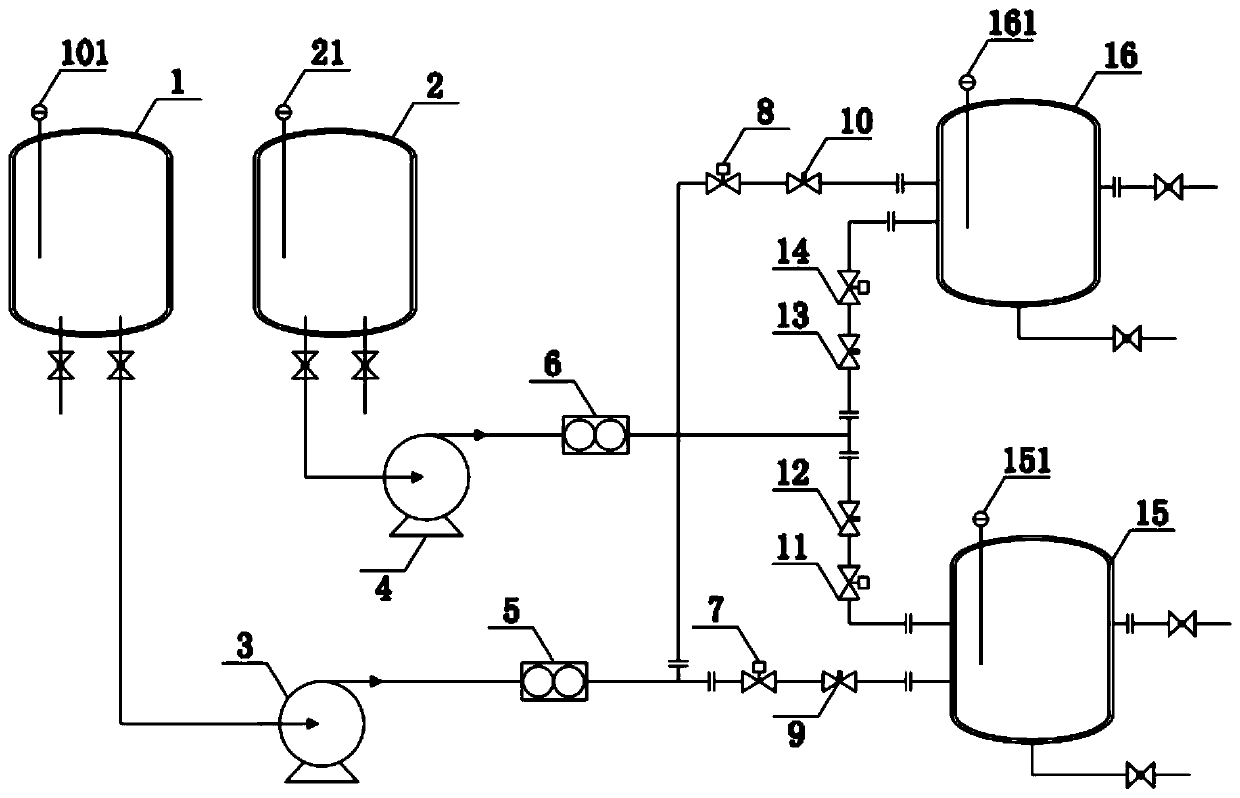

Automatic control system for re-pulping and washing in potash fertilizer production

ActiveCN107247470AProcess is easy to controlReduce misuseControlling ratio of multiple fluid flowsControl using interconnected flow control elementsAutomatic controlControl system

The invention discloses an automatic control system for re-pulping and washing in potash fertilizer production, which comprises a washing control system and a pulp mixing control system, and is characterized in that the washing control system comprises a crude potassium ore inlet quantity computing instrument (3), a washing water flow setting arithmetic device (5), a washing water flow controller (7), a washing water regulation valve actuator (9) and a washing water regulation valve (10) which are sequentially connected; and the pulp mixing control system comprises a centrifuge filtrate flow setting arithmetic device (6), a centrifuge filtrate regulation valve actuator (11), a centrifuge filtrate flow controller (13), a centrifuge filtrate regulation valve (140 and a refined potassium pulp density display instrument (22).

Owner:QINGHAI SALT LAKE IND

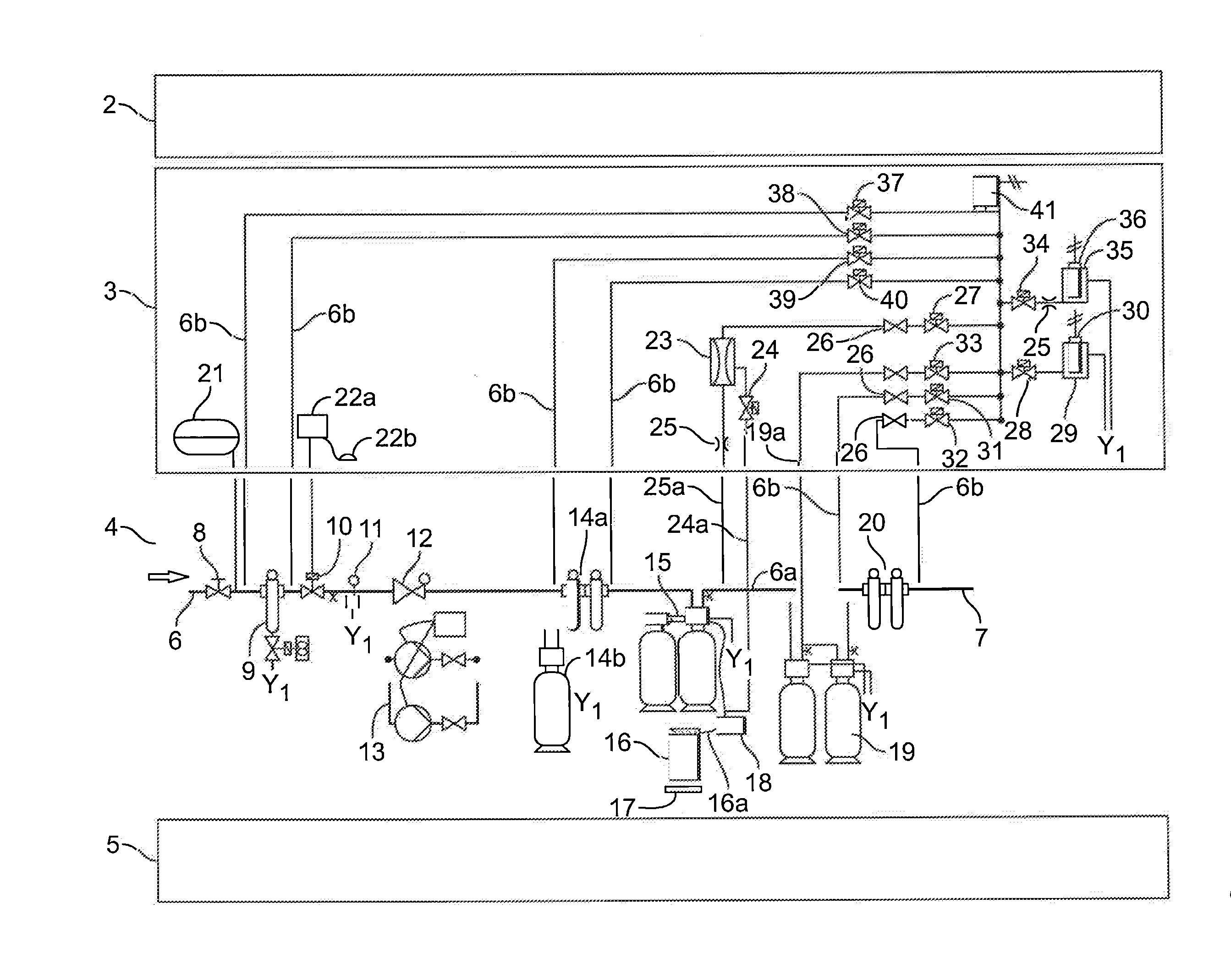

Chlorine measurement/filter testing/brine container monitoring of a water treatment system

ActiveUS20150014229A1Reduce microbial growthReduce in quantityIon-exchanger regenerationMaterial analysis by electric/magnetic meansElectrolysisWater treatment system

The water treatment system, particularly pre-filtration unit of the water treatment system, comprising at least one chlorine sensor device, includes a salt-water treatment device which is connected to the chlorine sensor device, an electrolysis cell being disposed in the associated line, and thereafter a pump and a release valve.

Owner:VIVONIC GMBH

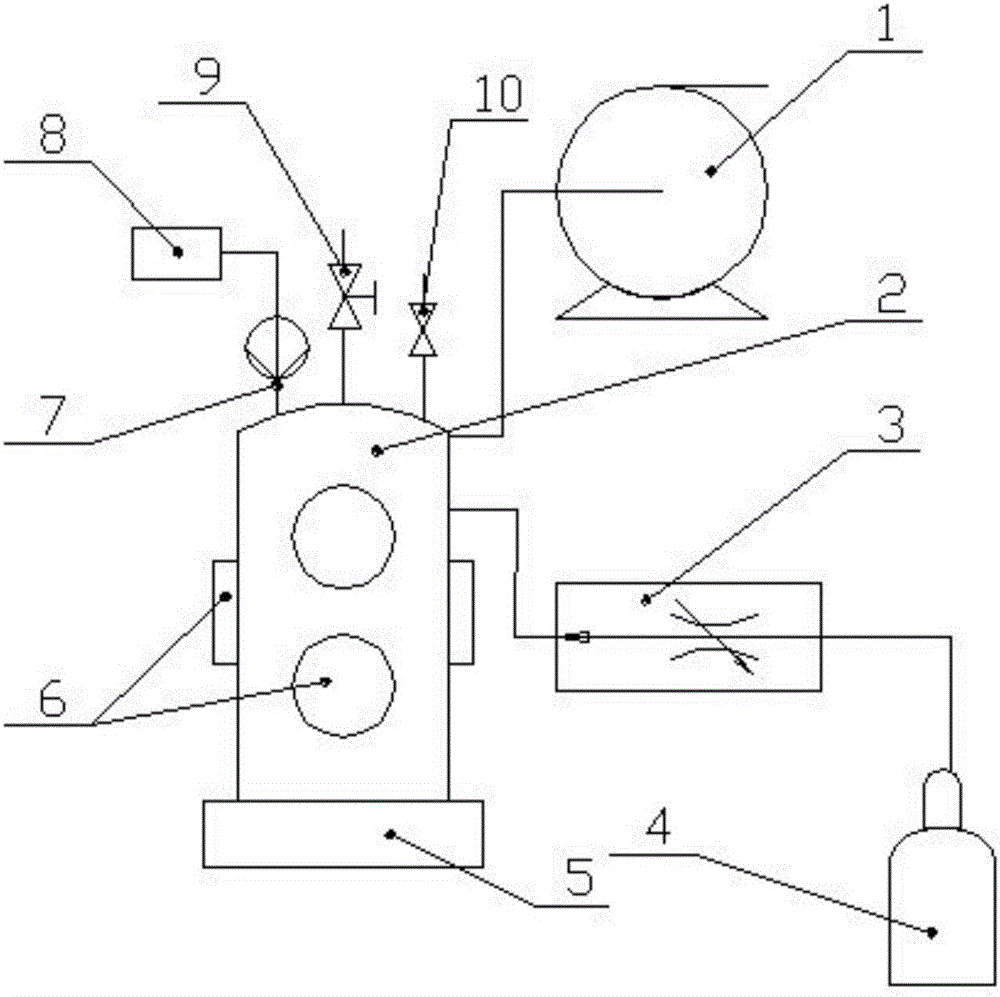

Accuracy control device of dissolved oxygen content in liquid fuel

InactiveCN106557094AAccurately monitor oxygen levelsEnter exactlyControlling ratio of multiple fluid flowsControl using interconnected flow control elementsChemical reactionOxygen sensor

The present invention discloses an accuracy control device of dissolved oxygen content in the liquid fuel. The device comprises a vacuum pump, a stirrer, an oxygen bottle, an oxygen sensor, a flow controller and a vacuum tank. The vacuum pump is connected with the oxygen bottle through a connection pipeline which is provided with a control valve and the flow controller, the vacuum pump is connected with the vacuum tank through the pipeline, the stirrer is disposed at the lower portion of the vacuum tank, the oxygen sensor is fixed at the top of the vacuum tank, one end of the oxygen sensor is connected with a dissolved oxygen parameter transmitter, the other end of the oxygen sensor is inserted into the vacuum tank, and the top portion of the vacuum tank is provided with a valve. The accuracy control device of dissolved oxygen content in the liquid fuel is simple to operate to greatly improve the deoxygenization efficiency and accuracy, and the deoxygenization process does not need the usage of the chemical medicine so as to avoid the generation of the additional impurity products in the chemical reaction process and realize the accurate input of the dissolved oxygen in the liquid fuel in the oxygenation process.

Owner:TSINGHUA UNIV

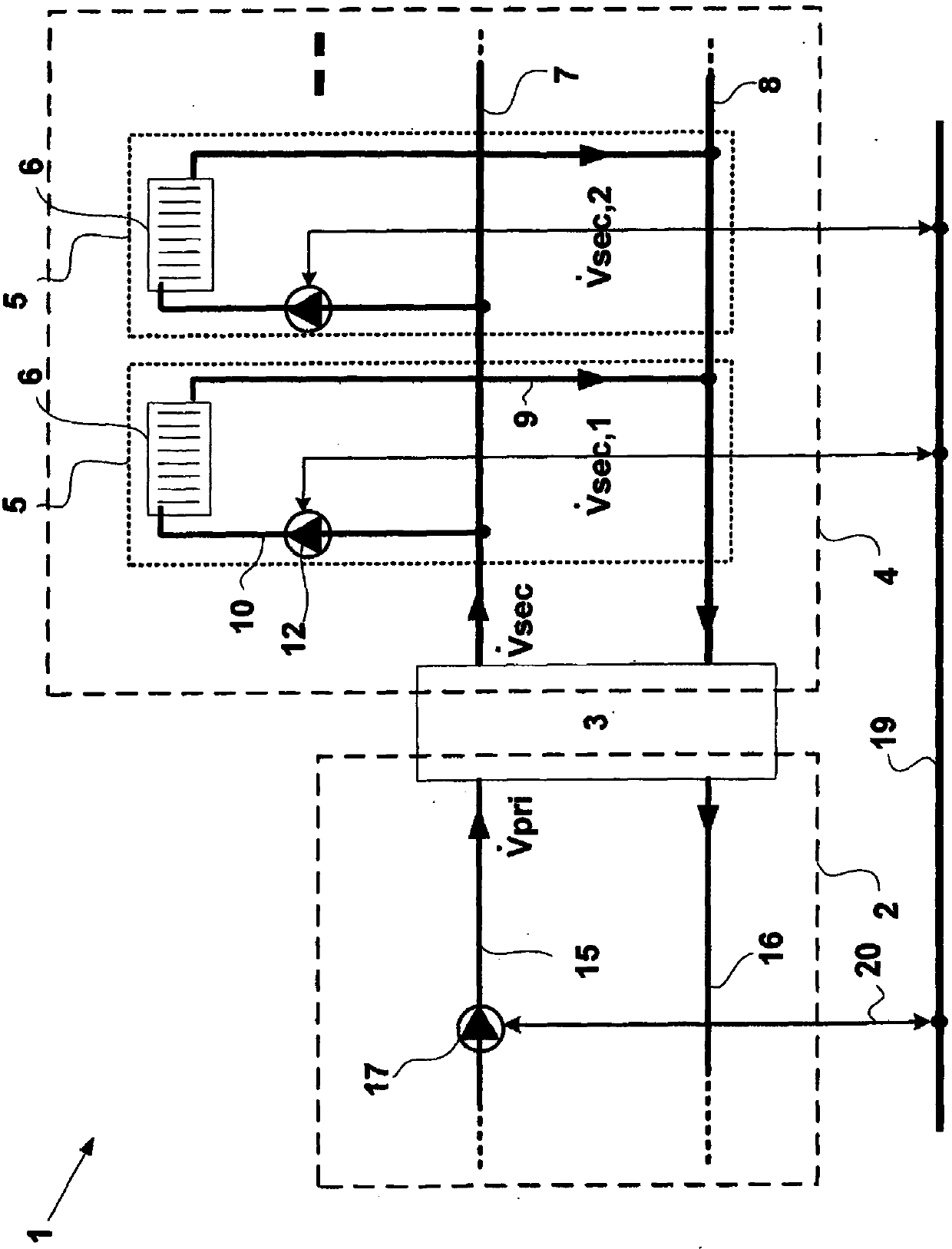

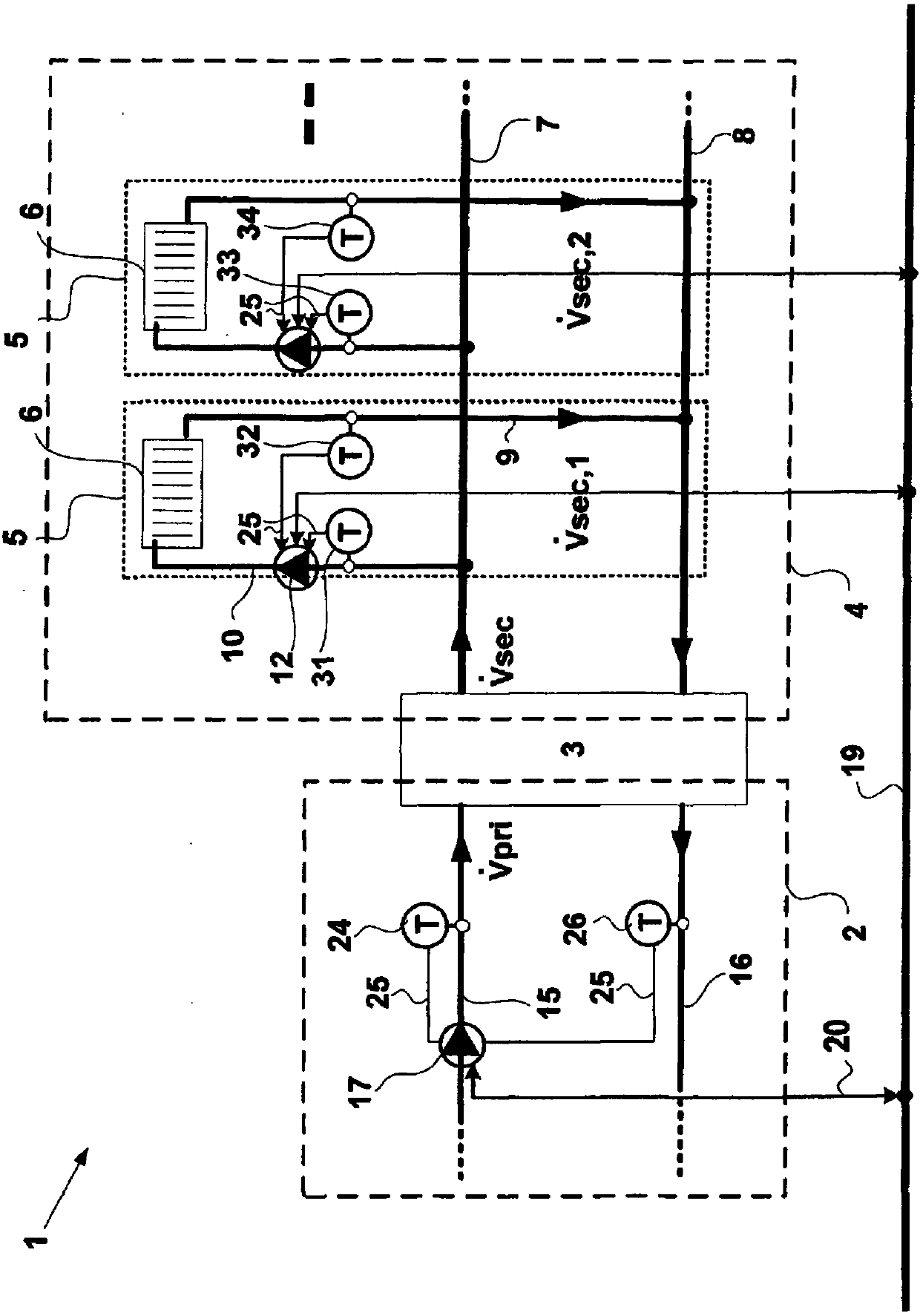

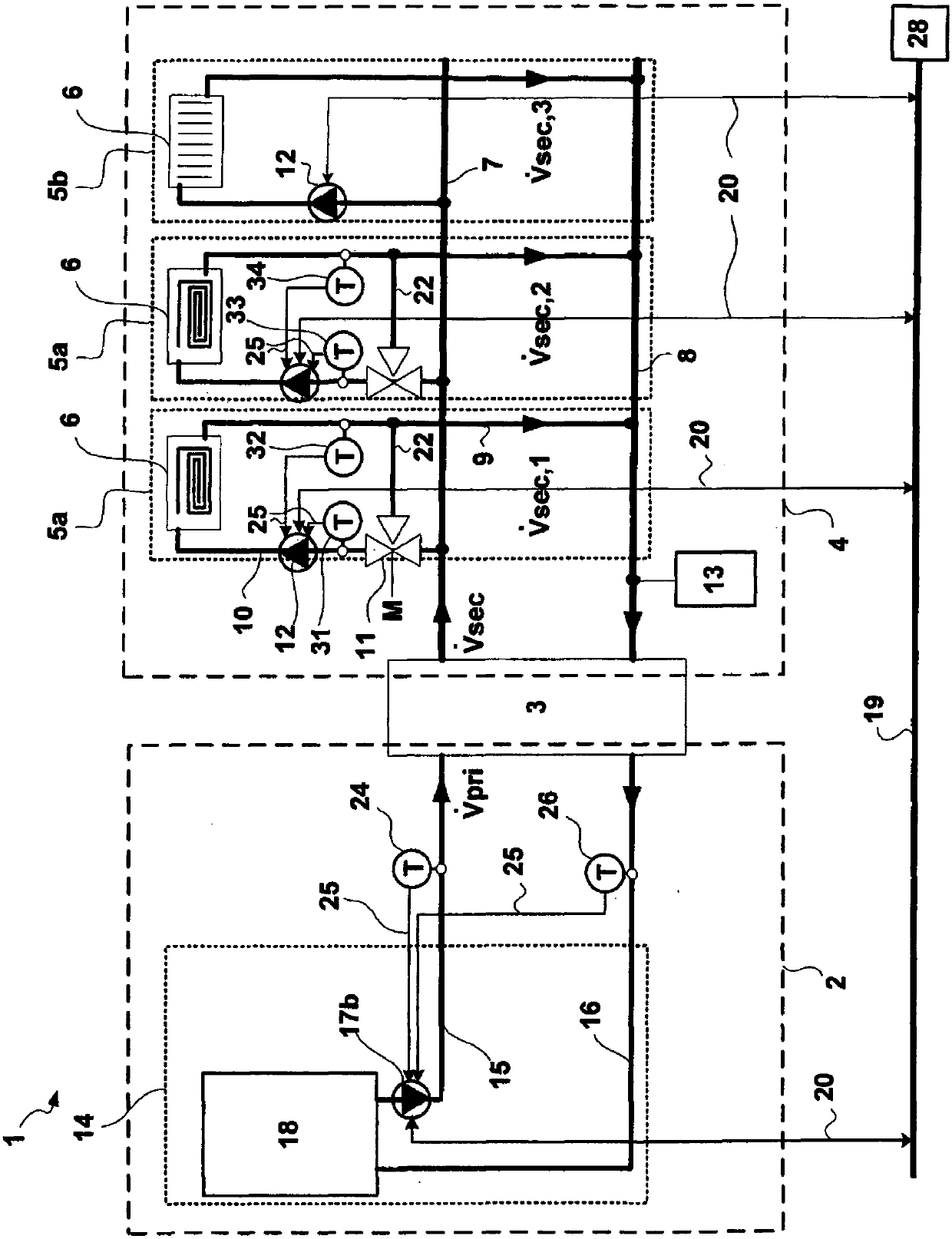

Method for controlling centrifugal pump, and associated pump system

ActiveCN108463672ALighting and heating apparatusControl using interconnected flow control elementsEngineeringCirculating pump

The invention relates to a method for controlling at least one first circulation pump (17b, 17c) of a heating or cooling system (1) having a primary circuit (2, 2a) and a secondary circuit (4, 30a) coupled therewith at a transfer point (3, 29). The first circulation pump (17, 17b, 17c, 17b') conveys a heating or cooling medium in the primary circuit (2, 2a), and in the second secondary circuit (4,30a), at least one second circulation pump (12, 17d) is located that conveys a heating or cooling medium in at least one partial area of the secondary circuit (4, 30a). The volume flow rate (formulaI) of the first circulation pump (17, 17b, 17c, 17b') is controlled in functional dependence on the volume flow rate (formula II) of the secondary circuit (4, 30) behind the transfer point (3, 29). Inthis way, a demand-based, and thus an energy-efficient control of the primary-side circulation pump is achieved. The invention further relates to a pump system, comprising the at least one first andthe at least one second circulation pump for carrying out the method.

Owner:WILO SE

Device and method to prevent improper fluid mixing ratios in two component materials

InactiveUS20120180874A1Increase the pressure valueControl using interconnected flow control elementsPipeline systemsEngineeringPressure difference

The present invention relates to an apparatus and method for maintaining a fluid mixing ratio. The apparatus according to various embodiments prevents a fluid flow imbalance between two proportionate fluid streams based on a pressure difference, and may be configured to alert the user and / or stop the fluid flow in the event of a fluid flow imbalance. The apparatus is formed such that two plunger components engage a shuttle piston, the shuttle piston configured to move one or more plunger components given a selectable fluid flow imbalance.

Owner:MELLETTE ROBERT RAY

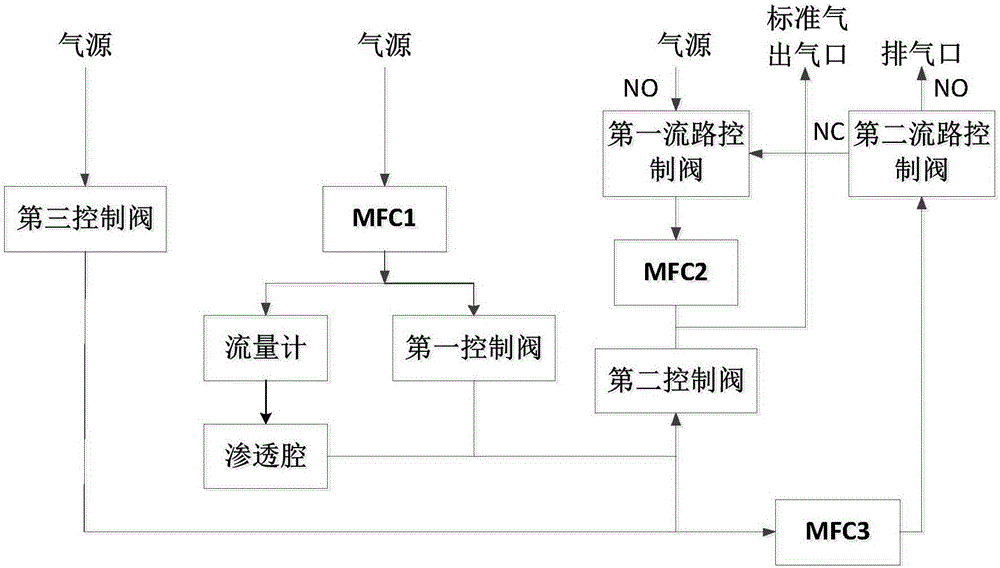

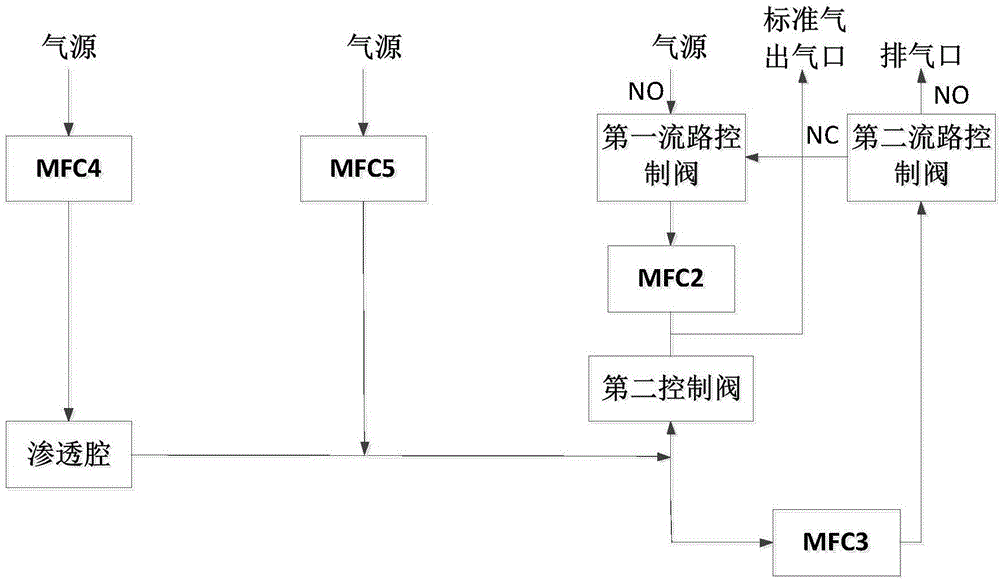

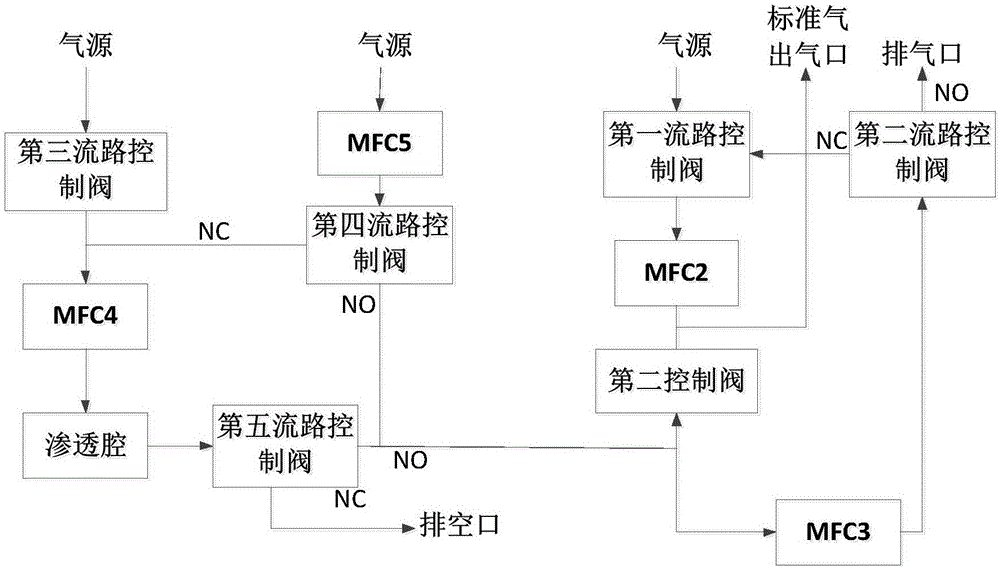

Wide concentration range standard gas distributor with correction function and correction method of standard gas distributor

PendingCN107519773AIncrease concentrationEnsure Concentration AccuracyControlling ratio of multiple fluid flowsControl using interconnected flow control elementsStream flowEngineering

The invention relates to the technical field of gas detectors, in particular to a wide concentration range standard gas distributor with a correction function and a correction method of the standard gas distributor. The provided wide concentration range standard gas distributor comprises a carrier gas pathway, a first diluent gas pathway and a second diluent gas pathway; the carrier gas pathway and the first diluent gas pathway are connected in parallel with a first mixing chamber, a first outlet of the first mixing chamber is connected with an exhaust port, a second outlet and the second diluent gas pathway are connected in parallel with a second mixing chamber, and the second mixing chamber is connected with a standard gas outlet; the second diluent gas pathway is provided with a first flow path control valve and a second flow controller, and a third flow controller and a second flow path control valve are arranged at the first outlet of the first mixing chamber; the second flow path control valve is connected with the first flow path control valve. The wide concentration range standard gas distributor is simple in structure and the range of concentrations of the prepared standard gas is wide; during correction, the gas path where correction is performed continues to be involved in following correction, the correction structure flow path is simplified, and the gas distribution accuracy is high.

Owner:LIHE TECH (HUNAN) CO LTD

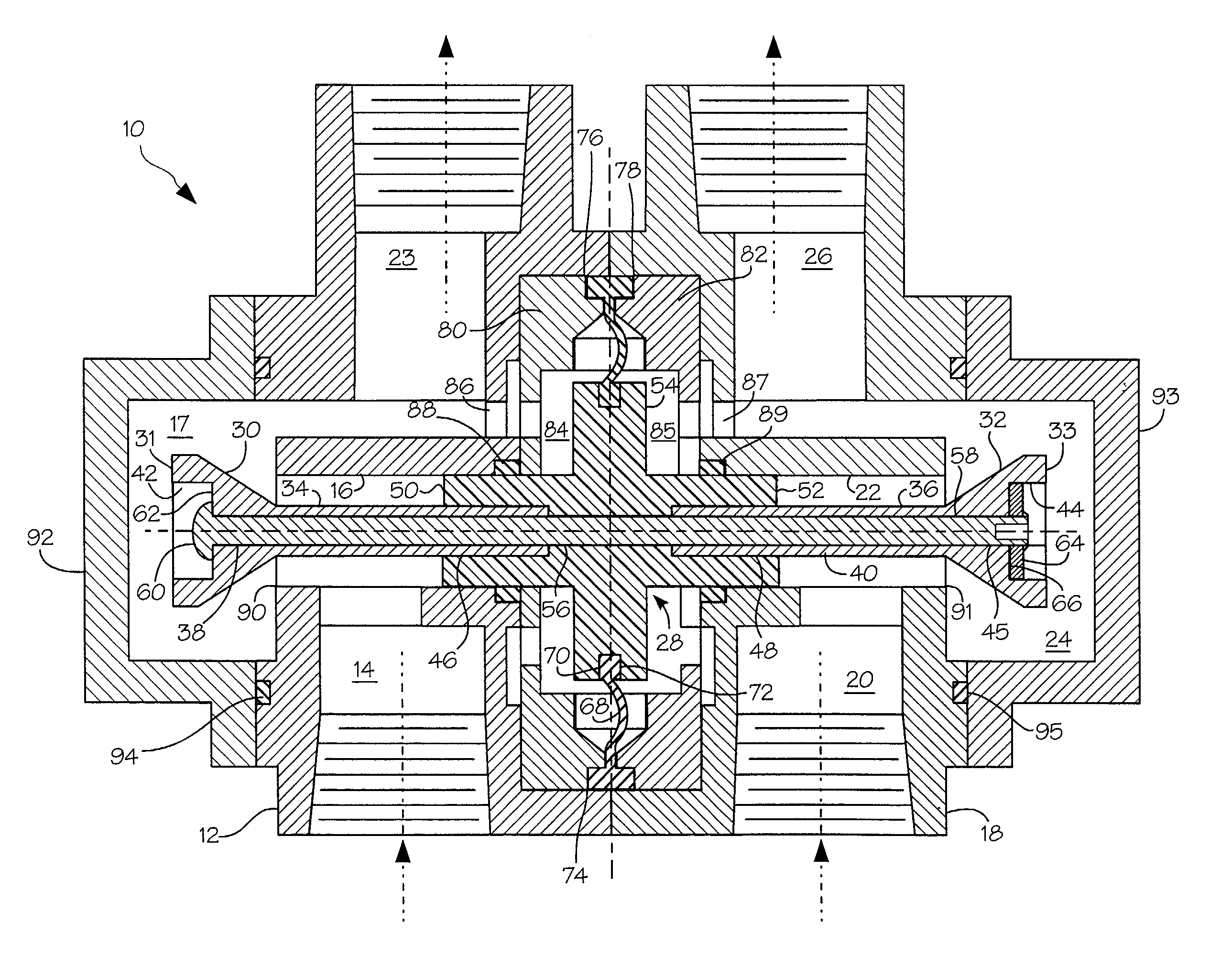

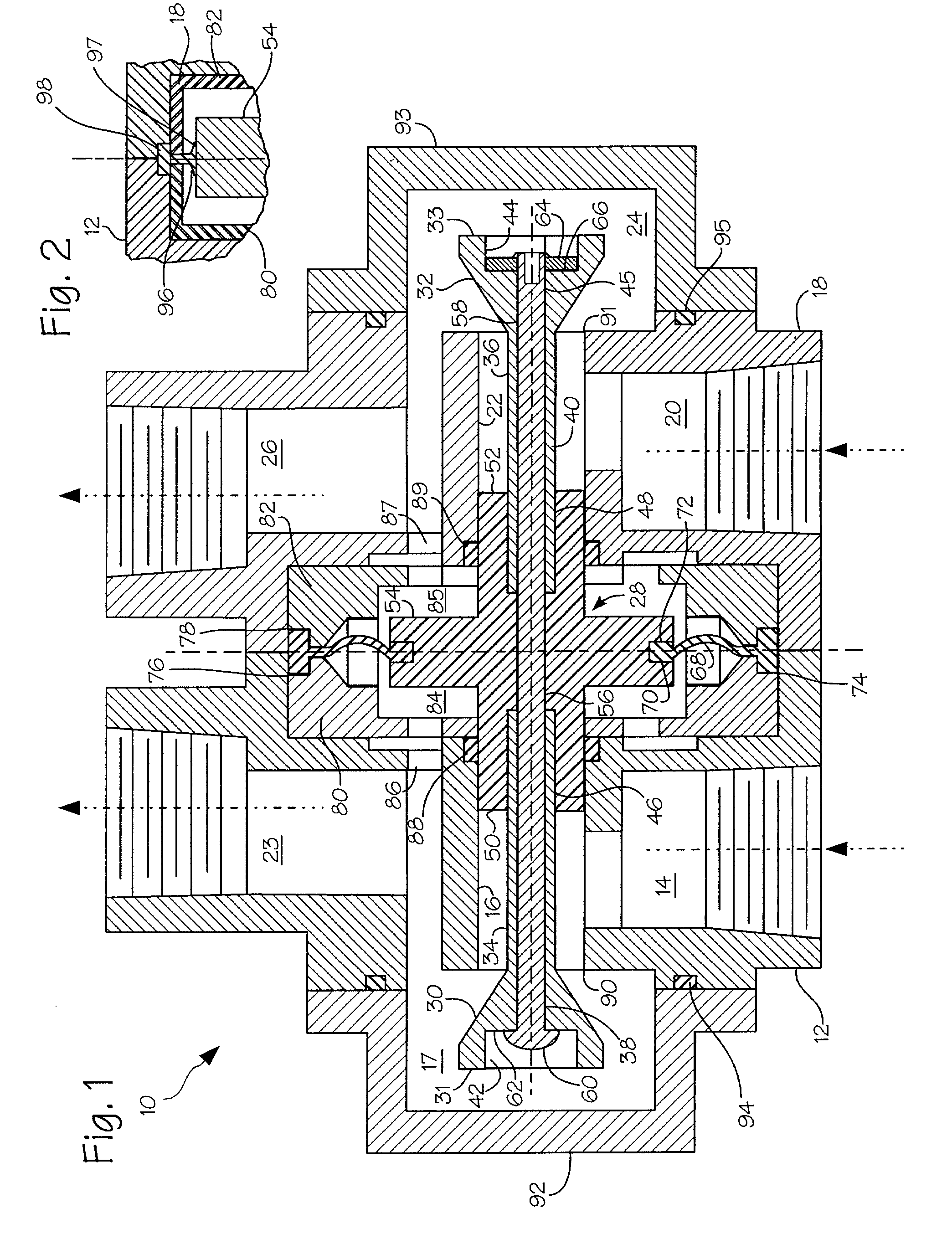

Pressure balancing valve

InactiveUS20030131882A1Elimination of pressure bleed passageRelieve stressControlling ratio of multiple fluid flowsControl using interconnected flow control elementsDifferential pressurePressure sense

An improved structural arrangement of a pressure balancing valve of the type where flow between two unequal pressure flowing fluids introduced at the valve inlets is regulated to produce substantially equal pressure flowing fluids at its outlets. The valve assembly incorporates a reciprocating spool member having fluid regulating members at its opposite ends, a pressure sensing member such as a diaphragm or piston member centrally connected to the spool to sense outlet differential pressures of the two fluids and thereby actuate the spool in reciprocating directions whereby said fluid flows are varied by the regulating members to substantially balance the pressure between the two flowing fluids. The structural arrangement permits the balance of pressure forces acting axially across the spool without the need of pressure bleed passages and their possible fluid blockage and also offers advantages of improved corrosion resistance, potential valve size and cost reduction, and high reliability.

Owner:KOLZE

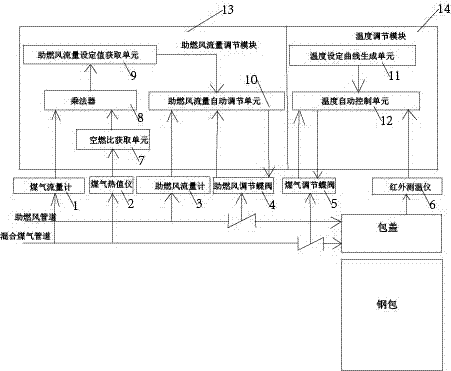

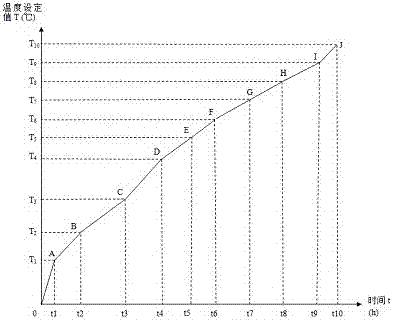

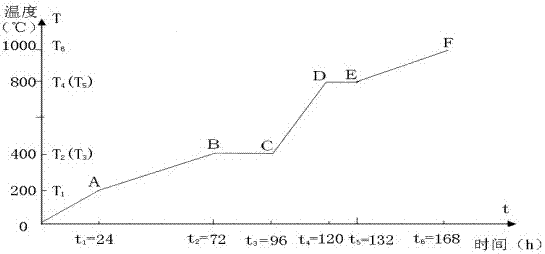

Temperature control device and temperature control method

PendingCN107092187AAccurate measurementEasy to controlMelt-holding vesselsControlling ratio of multiple fluid flowsSteelmakingButterfly valve

The invention discloses a temperature control device and a temperature control method, which relate to the technical field of steel making. The temperature control device comprises a combustion-supporting air flow regulating module and a temperature regulating module, wherein the combustion-supporting air flow regulating module is connected with a mixed gas pipeline through a gas flow meter; the combustion-supporting air flow regulating module is connected with the mixed gas pipeline through a gas calorimeter; the combustion-supporting air flow regulating module is connected with a combustion-supporting air pipeline through a combustion-supporting air flow meter; the combustion-supporting air flow regulating module is connected with the combustion-supporting air pipeline through a combustion-supporting air regulating butterfly valve; the temperature regulating module acquires the temperature of a clad through an infrared thermometer; and the temperature regulating module is connected with the mixed gas pipeline through a gas regulating butterfly valve, electric signals are acquired, and according to the electric signals, the gas regulating valve is controlled to regulate the flow of the gas in the mixed gas pipeline. Thus, the operation is simple and convenient; accurate measurement and accurate control on the temperature are realized; energy is saved; the product quality is ensured; the service life of a ladle heater is prolonged; and the cost is saved.

Owner:HEBEI IRON AND STEEL

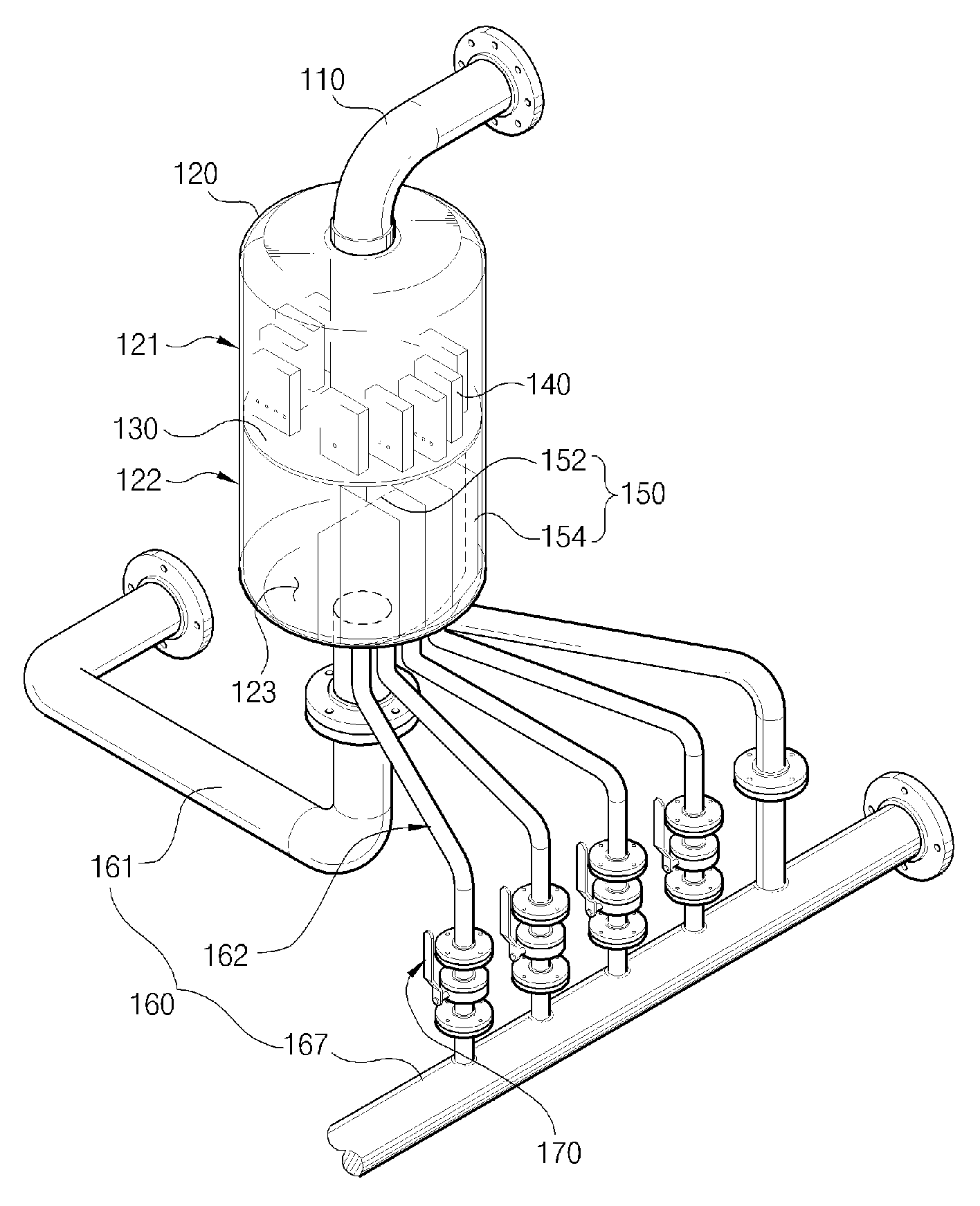

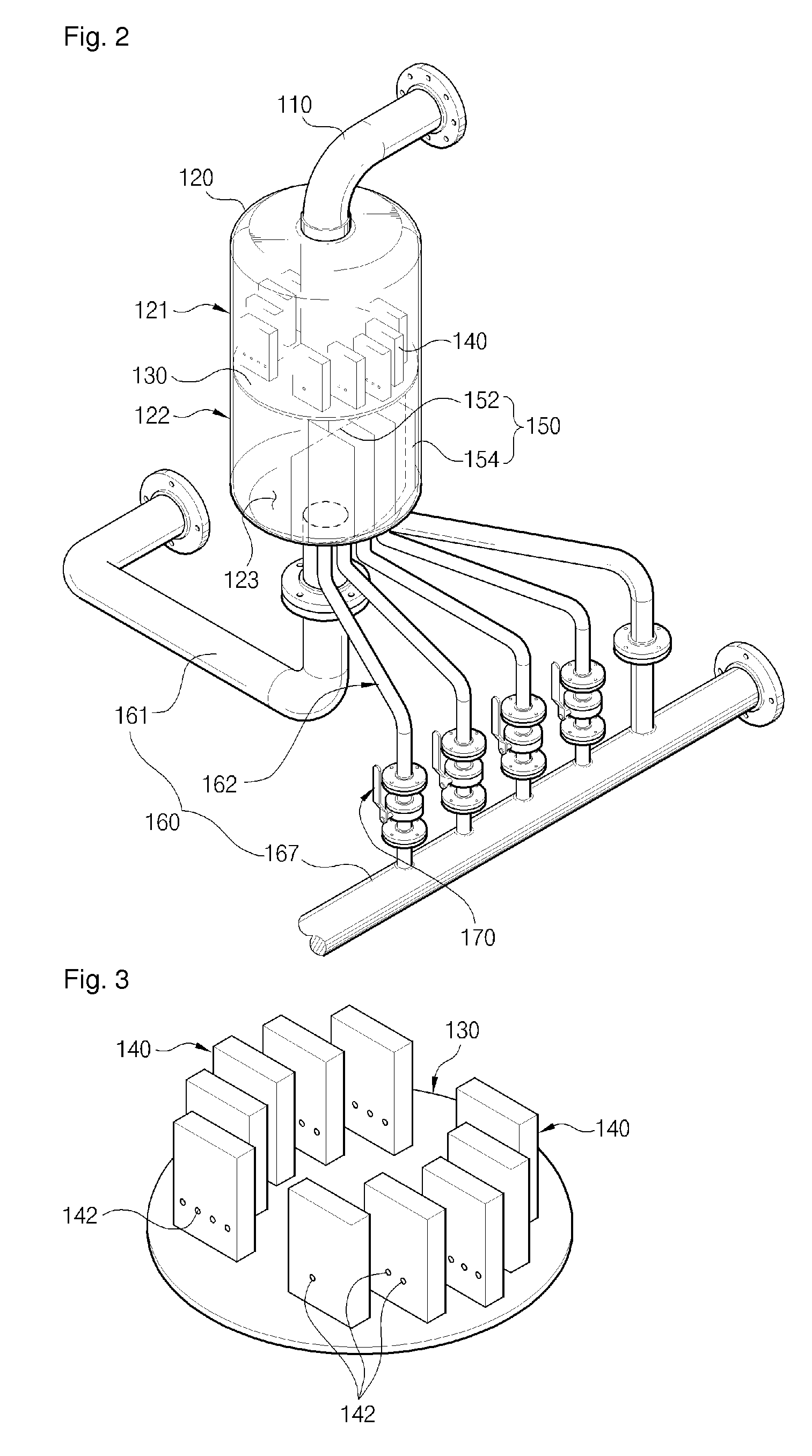

Liquid distribution device

ActiveUS9446327B2Guaranteed continuous supplyAutomatic controlControl using interconnected flow control elementsDispersed particle separationEngineeringConstant rate

The present invention is capable of precisely controlling a supply ratio of liquid and continuously supplying liquid at a constant rate by using partition plates for controlling the amount of liquid distribution.

Owner:AMTPACIFIC

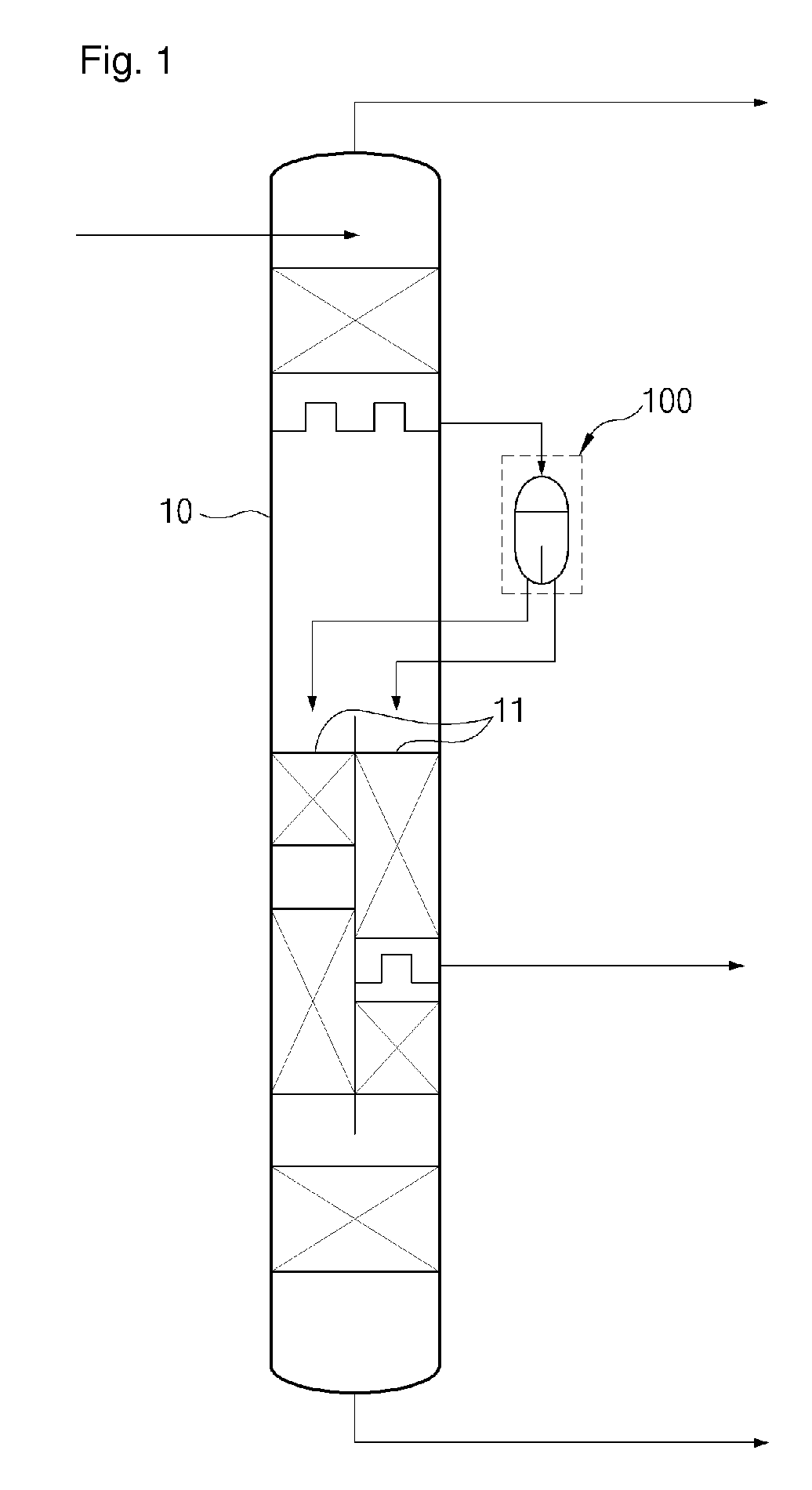

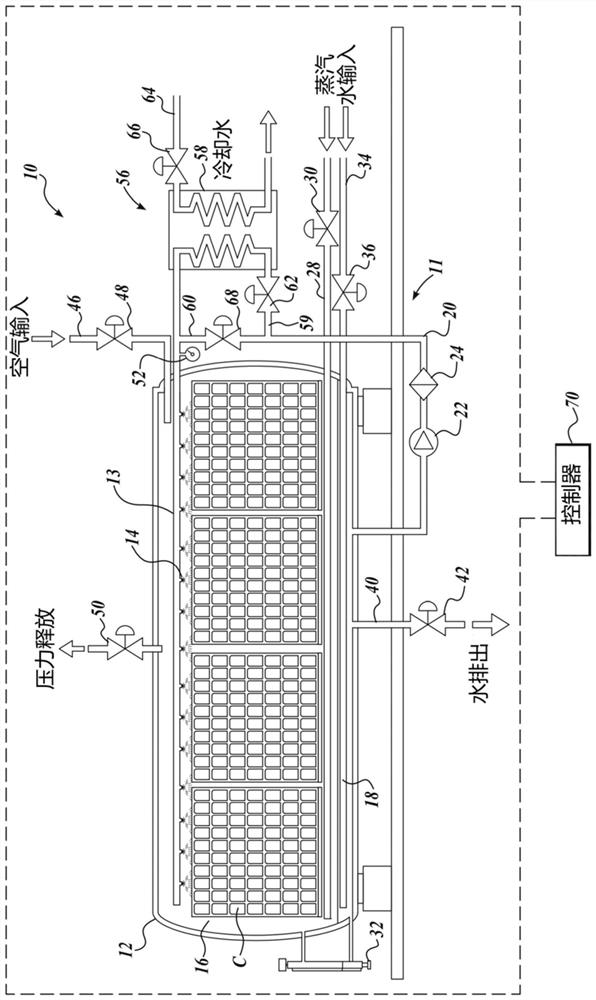

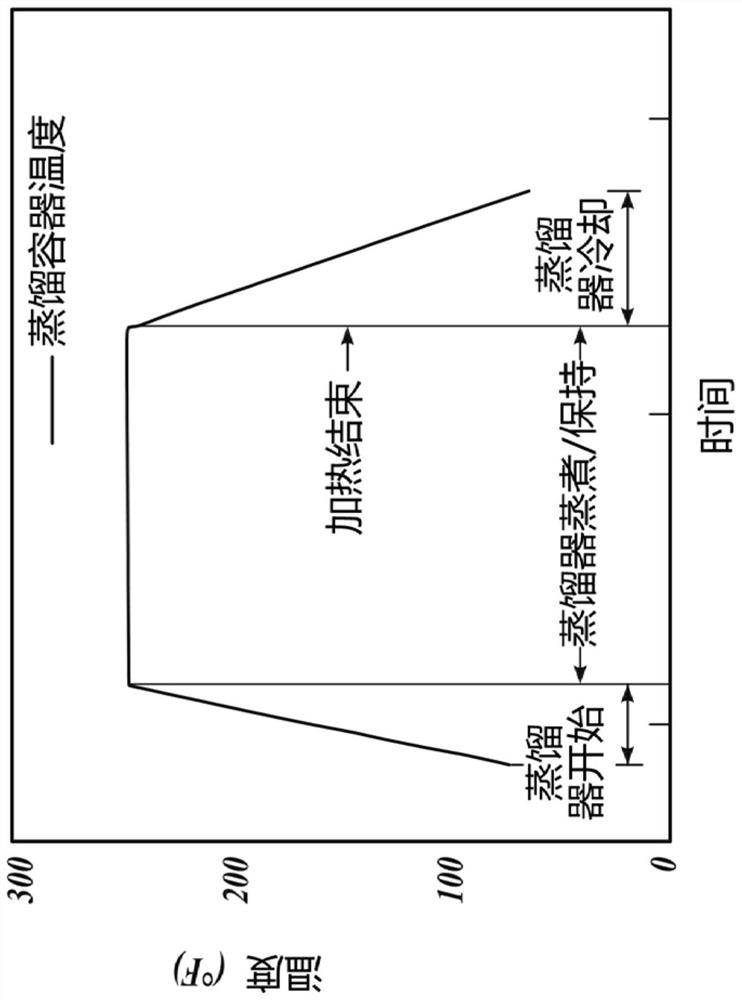

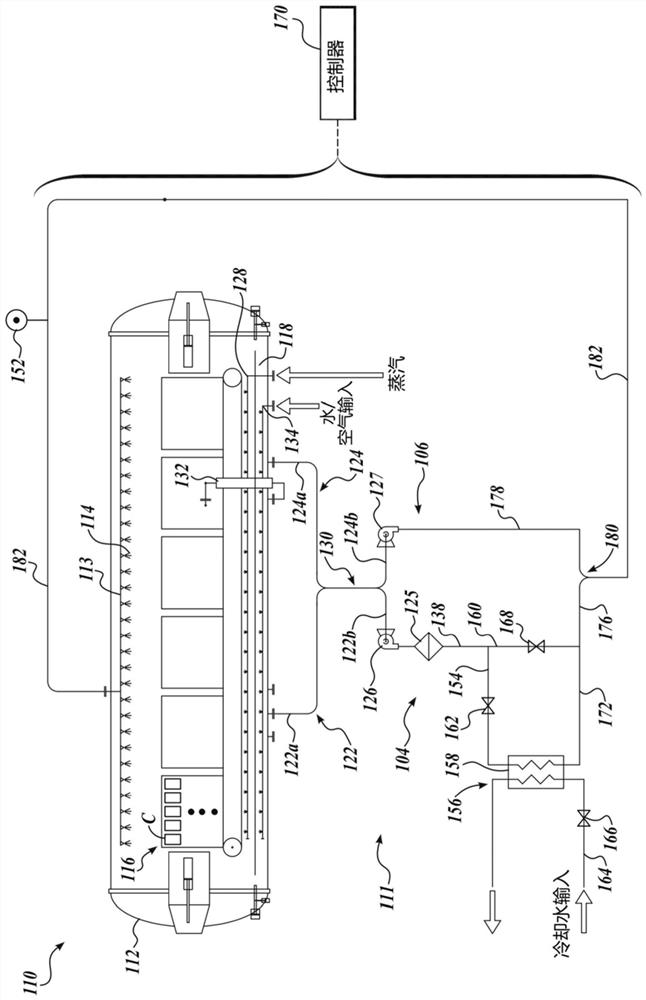

Fluid distillation apparatus and method for circulating process fluid

PendingCN113923999AControl using interconnected flow control elementsMaintainance of heating chambersMechanicsHeat exchanger

A recirculation circuit for a processing vessel is configured to process a load with a process fluid. The recirculation circuit includes a first circuit portion configured to recirculate a first portion of the process fluid through the vessel. The first circuit portion includes a first pump having a first flow rate and a first output pressure and a heat exchanger in fluid communication with the first pump. A second circuit portion is configured to recirculate a second portion of the process fluid through the vessel. The second circuit portion includes a second pump having a second flow rate higher than the first flow rate and a second output pressure lower than the first output pressure.

Owner:JOHN BEAN TECH CORP

Semi-closed circuit underwater breathing apparatus ratio regulator

ActiveUS20170297665A1Control using interconnected flow control elementsFluid pressure control with auxillary non-electric powerDifferential pressureUnderwater

An apparatus for adjusting the partial pressure of gaseous mixtures comprises a housing and piston. The housing defines a chamber coupled to an oxygen metering orifice, diluent metering orifice, vent port and gas outlet. The oxygen metering orifice provides oxygen to the chamber and the diluent metering orifice provides diluent gas to the chamber. The piston is movably positioned in the chamber and includes first and second sealing devices. The chamber is sectioned into a mixing chamber, a diluent chamber and a reference chamber located between the mixing chamber and diluent chamber. The diluent chamber receives a diluent gas referenced at ambient pressure and the reference chamber is charged with a gas having a reference pressure. The piston changes positions within the chamber depending on a force balance created by a pressure differential between the reference pressure and ambient pressure.

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

Coating apparatus capable of controlling mixing ratio and method thereof

ActiveCN101569880BQuick changeLiquid surface applicatorsControl using interconnected flow control elementsEngineeringControl theory

A coating apparatus capable of controlling a mixing ratio includes a spindle motor unit having a spindle with which an upper end portion of a mixing ratio control shaft is engaged, the upper end portion of the control shaft being moved on the spindle in accordance with rotation of the spindle; and a control unit for calculating the mixing ratio of a main coating agent and a hardening agent based on measured flow rates thereof and controlling the rotation of the spindle when the calculated mixing ratio of the main coating agent and the hardening agent falls outside a tolerance range of a presetmixing ratio. The mixing ratio of the main coating agent and the hardening agent is adjusted depending on the positions of the upper end portion of the mixing ratio control shaft on the spindle.

Owner:SAMSUNG HEAVY IND CO LTD

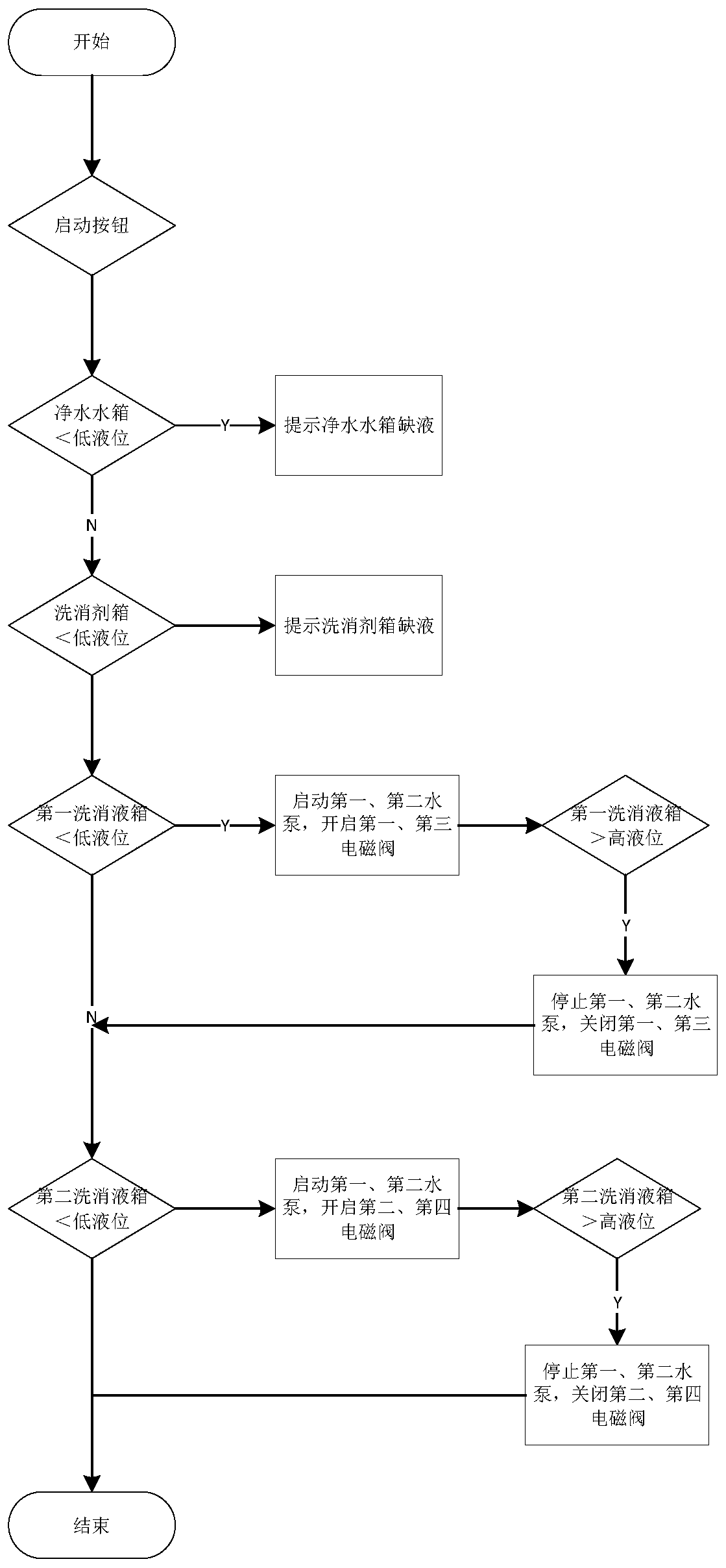

Decontamination liquid ratio even mixing control device and method

InactiveCN109976396AEasy to controlProportioning automationControlling ratio of multiple fluid flowsControl using interconnected flow control elementsElectrical controlLiquid level sensor

The invention relates to the technical field of electrical control and discloses a decontamination liquid ratio even mixing control device and method. The device comprises a clean water box and a decontaminant box. A first liquid level sensor which penetrates and extends to the interior of the clean water box is set on the top of the clean water box. A second liquid level sensor which penetrates and extends to the interior of the decontaminant box is set on the top of the decontaminant box. A first water pump is connected with the bottom of the clean water box through utilization of a pipe. Afirst flow sensor is fixedly connected with a liquid outlet of the first water pump through utilization of the pipe. A first electromagnetic valve and a first adjustment valve are fixedly connected with the first flow sensor in sequence from left to right through utilization of the pipe. According to the decontamination liquid ratio even mixing control device and method, decontamination liquid ratio even mixing can be controlled; through observation of a reading number of the flow sensor, the opening degree of the adjustment valve is adjusted; a ratio of clean water tothe decontaminant can bemanually adjusted, thereby adapting to a requirement for different concentrations of decontaminants; and effects of the automatic ratio, the precise ratio and convenient use are achieved.

Owner:中国人民解放军第八一医院

Device and method for dilution control

InactiveUS20180196447A1Controlling ratio of multiple fluid flowsControl with discontinuous actionDiluentControl theory

A dilution control device and method of operating the same. The dilution control device can include a structure for dispensing concentrate and diluent fluid in a desired dilution ratio utilizing volumetric dosing. In some embodiments, diluent fluid drives a wheel or compresses a pliable concentrate bag in order to dispense concentrate in the desired ratio with the diluent fluid. In some embodiments, one or more floats can be used to drive a pump or actuate a valve to dispense concentrate at a particular rate proportional with the flow rate of the diluent fluid. In some embodiments, a rocker is responsive to the flow of diluent fluid to pump concentrate. In some embodiments, the dilution control device can be operable to automatically modulate the dispense rate of concentrate when the diluent fluid flow rate is varied in order to maintain a predetermined dilution ratio.

Owner:JOHNSONDIVERSEY INC

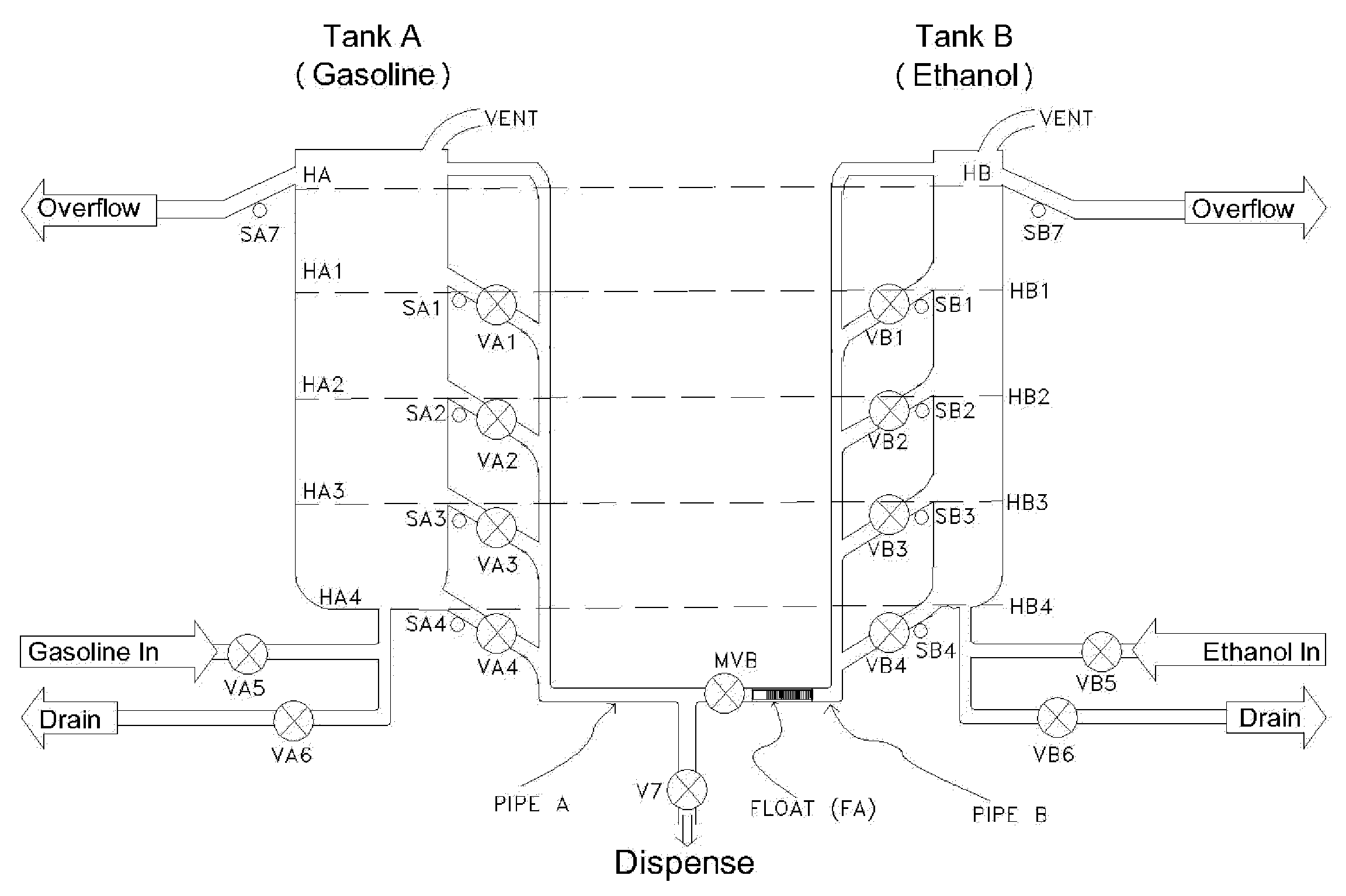

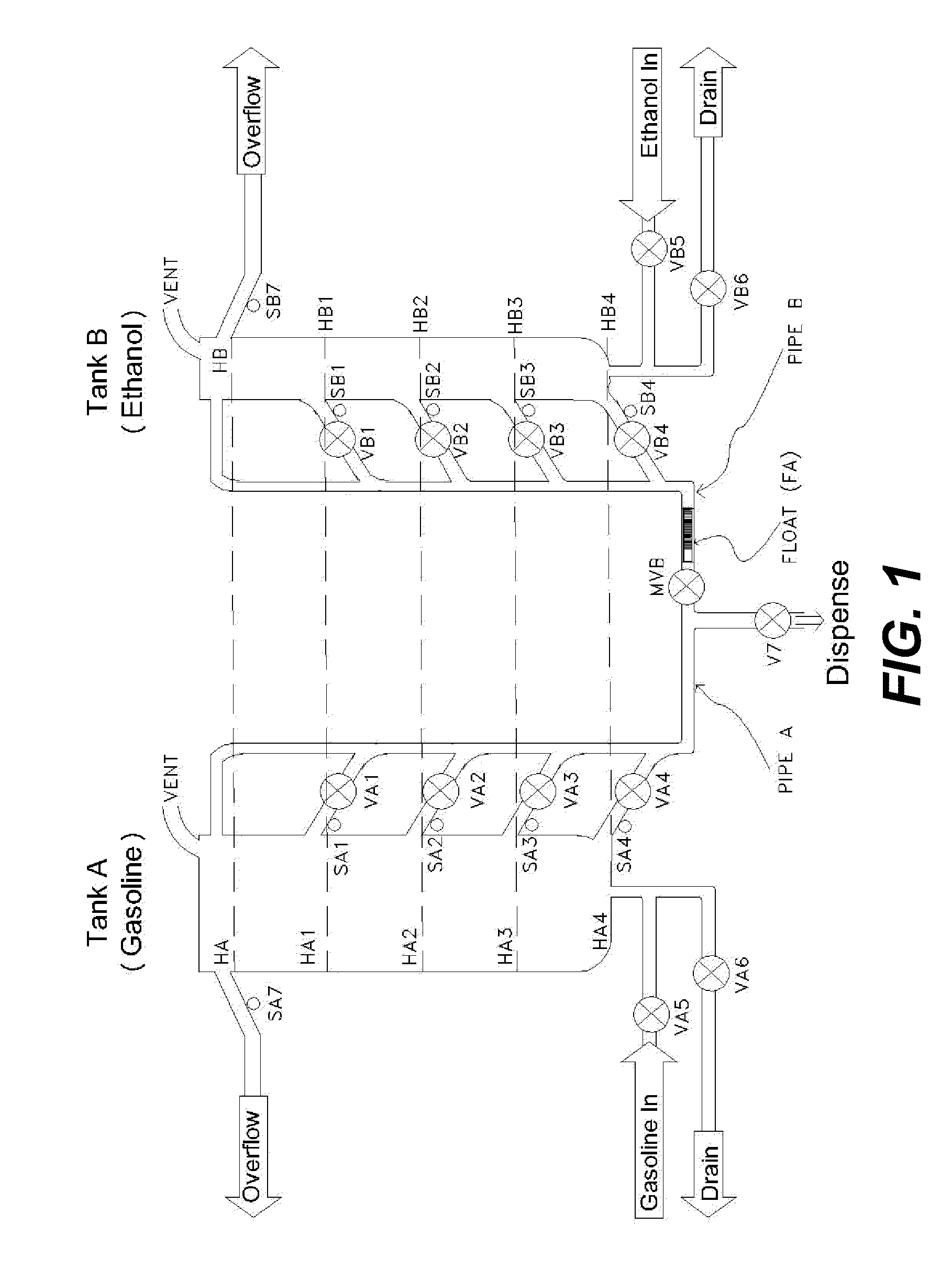

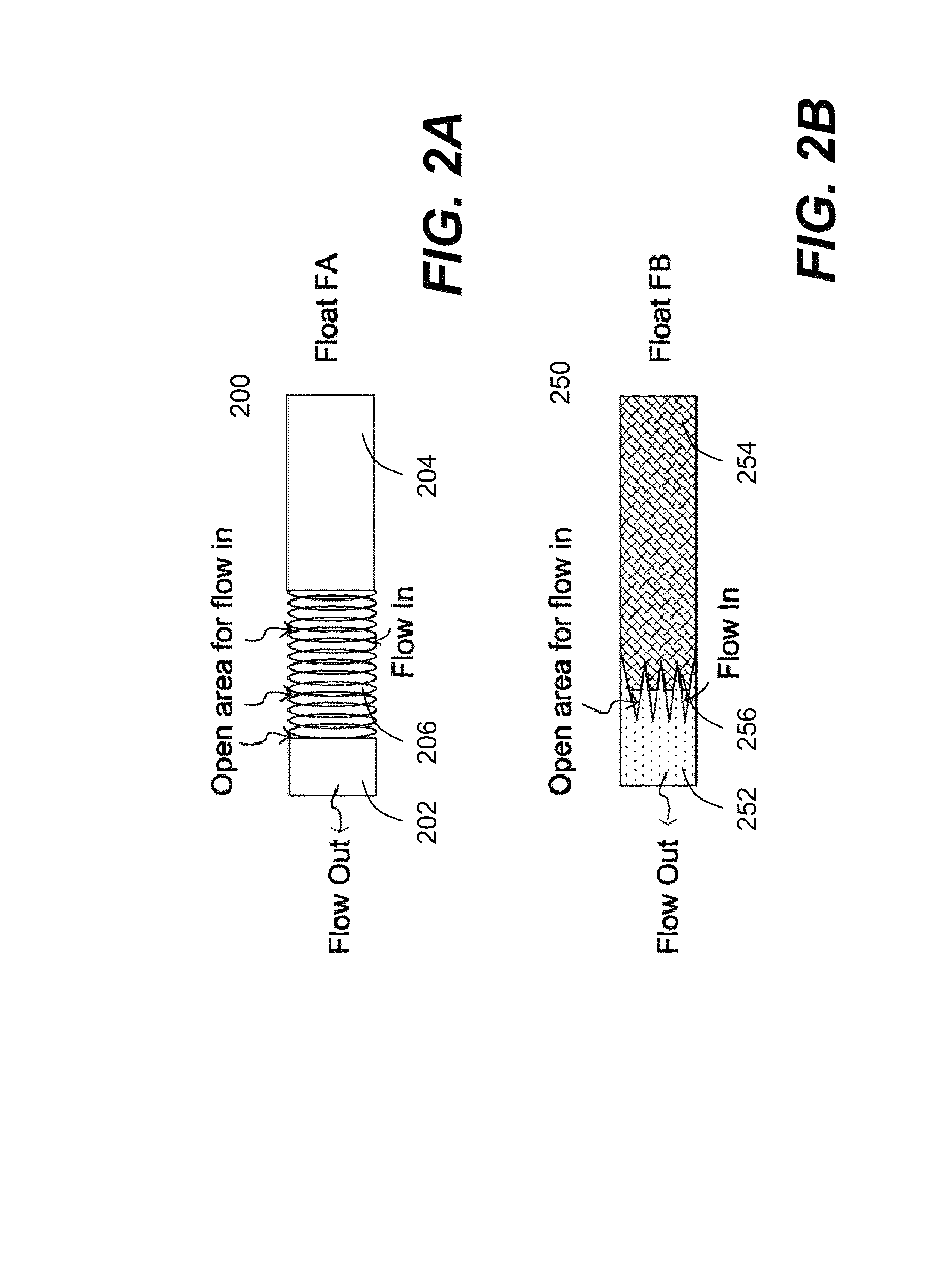

Apparatus and method for synchronized flow from volumetric tanks

InactiveUS8292123B2Control using interconnected flow control elementsLiquid transferring devicesStreamflowWaste management

Techniques for mixing liquids in a specific ratio at synchronized flows are disclosed. According to one aspect of the present invention a dispensing system comprises a plurality of tanks, each of the tanks includes an overflow outlet to limit a liquid therein to a certain measurement, and an array of volumetric outlets spaced apart and vertically arranged. The corresponding overflow outlet and the volumetric outlets of the tanks are located at the same height. The dispensing system further comprises a dispensing assembly including a manifold coupled to the volume outlets of the tanks via respective pipes, and further a flow-regulating device in at least one but not all of the pipes to control a flow of the liquid coming downwards from each of the tanks through one of the volumetric outlets thereof.

Owner:ZHANGJIAGANG CHEMFLOW TECH +1

Device for dividing a flow equally between two or more objects

InactiveCN101939544AControl using synchronised pumpsControlling ratio of multiple fluid flowsDevice formEngineering

Owner:P·莱斯基宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com