Wide concentration range standard gas distributor with correction function and correction method of standard gas distributor

A concentration range and standard gas technology, applied in the field of gas detectors, can solve the problems of low gas distribution accuracy, large error accumulation, poor gas concentration accuracy and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

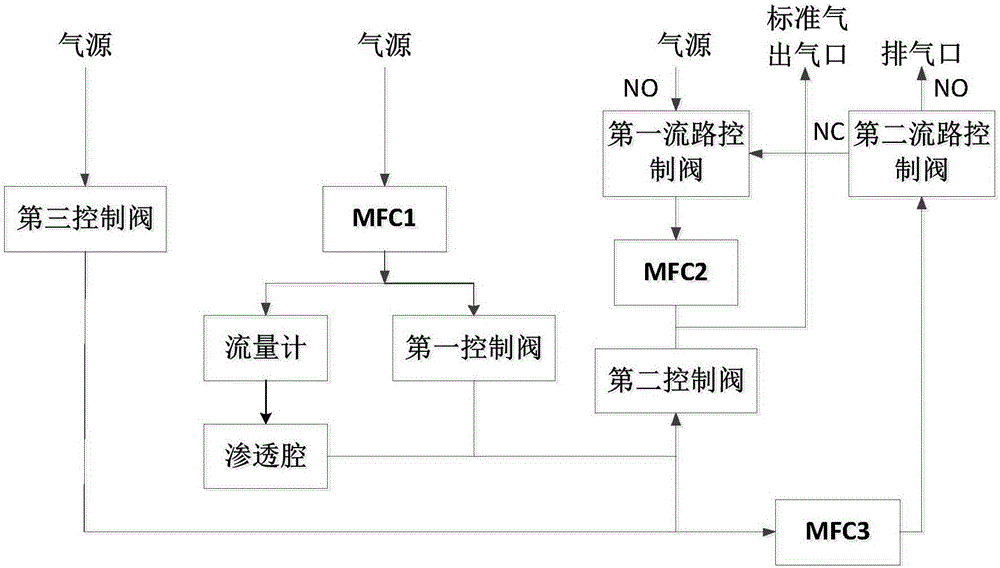

[0057] On the one hand, if figure 1 As shown, the embodiment of the present invention provides a large concentration range standard gas distribution instrument with calibration, including a carrier gas passage, a first dilution gas passage and a second dilution gas passage; the carrier gas passage and the first dilution gas passage are connected in parallel Connect to the first mixing chamber, the first outlet of the first mixing chamber is connected to the exhaust port, the second outlet of the first mixing chamber is connected to the second mixing chamber in parallel with the second dilution gas passage, and the second mixing chamber is connected to the standard gas outlet; The first flow control valve and the second flow controller (namely MFC2) are arranged sequentially from the inlet end on the second dilution gas passage, and the third flow controller (namely MFC3) and the second flow controller (namely MFC3) are arranged at the first outlet of the first mixing chamber. ...

Embodiment 2

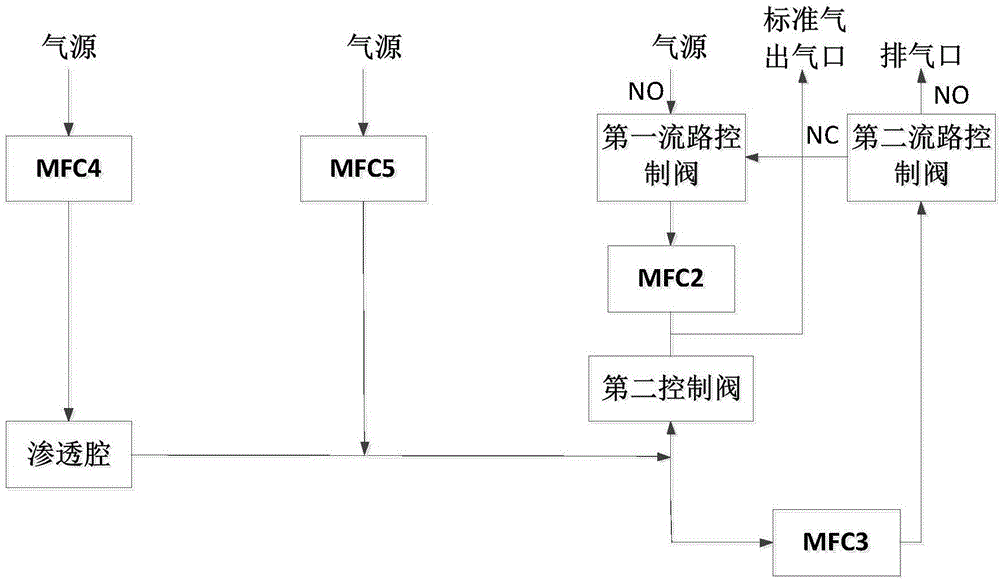

[0089] Such as figure 2 As shown, the embodiment of the present invention provides a standard gas distribution instrument, including a carrier gas passage, a first dilution gas passage and a second dilution gas passage; the carrier gas passage and the first dilution gas passage are connected in parallel to the first mixing chamber, The first outlet of the first mixing chamber is connected to the exhaust port, the second outlet of the first mixing chamber is connected to the second mixing chamber in parallel with the second dilution gas passage, and the second mixing chamber is connected to the standard gas outlet; The inlet end is provided with a first flow control valve and a second flow controller (ie MFC2) in sequence, and a third flow controller (ie MFC3) and a second flow control valve are provided at the first outlet of the first mixing chamber. The second flow control valve is connected to the exhaust port; the third flow controller is connected to the first flow contr...

Embodiment 3

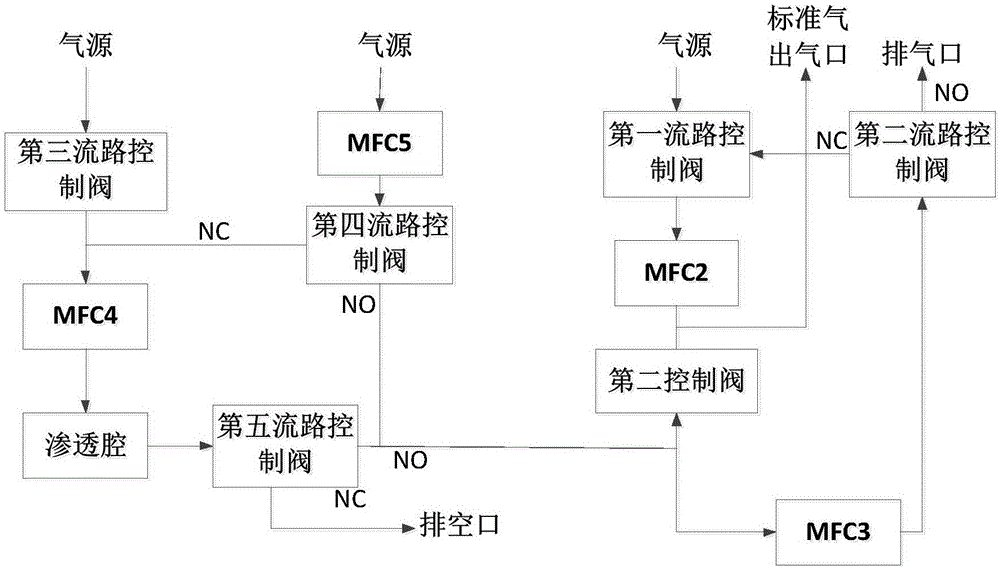

[0101] Such as image 3 As shown, the embodiment of the present invention provides a standard gas distribution instrument, including a carrier gas passage, a first dilution gas passage and a second dilution gas passage; the carrier gas passage and the first dilution gas passage are connected in parallel to the first mixing chamber, The first outlet of the first mixing chamber is connected to the exhaust port, the second outlet of the first mixing chamber is connected to the second mixing chamber in parallel with the second dilution gas passage, and the second mixing chamber is connected to the standard gas outlet; The inlet end is provided with a first flow control valve and a second flow controller (ie MFC2) in sequence, and a third flow controller (ie MFC3) and a second flow control valve are provided at the first outlet of the first mixing chamber. The second flow control valve is connected to the exhaust port; the third flow controller is connected to the first flow contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com