Temperature control device and temperature control method

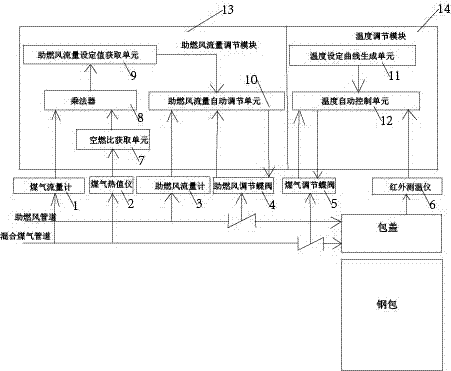

A technology of temperature control device and combustion-supporting air, which is applied in the direction of temperature control, electric temperature control, multiple fluid ratio control, etc. It can solve the problems of shortening the service life of refractory materials, energy waste, overtime baking, etc., and achieve improvement The effect of baking temperature, ensuring product quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

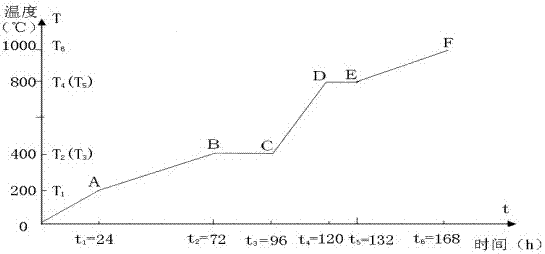

[0121] A steelmaking baker bakes overhaul bag, the gas flow rate is 0-1300Nm3 / h, the combustion air flow rate is 0-3000Nm3 / h, the calorific value Q=2290kcal / m3 displayed by the calorific value meter, the relationship between the temperature of the baking overhaul bag and the baking time As shown in table 2.

[0122] Table 2: The relationship between the temperature of the baker's baking overhaul bag and the baking time

[0123]

[0124] The temperature control method of the steelmaking toaster is as follows:

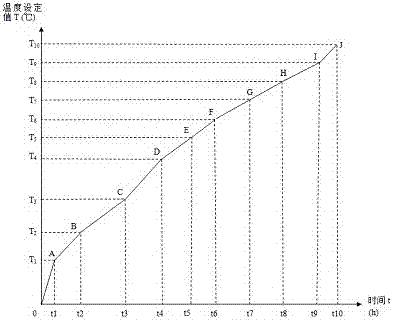

[0125] 1. The temperature setting curve generation unit 11 generates the baking temperature curve of the baker

[0126]The temperature setting curve is completed in the PLC control system 13 . According to Table 2, the number of input inflection points is 6, and the input time value (unit: h): the first inflection point t1=24, the second inflection point t2=72, the third inflection point t3=96, the fourth inflection point t4 =120, 5th turning point t5=132, 6th turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com