Low-temperature-resistant and low-pressure-change hydrogenated butadiene-acrylonitrile rubber for wind power and preparation method thereof

A technology for converting hydrogenated nitrile and hydrogenated nitrile raw rubber, which is applied in the field of rubber, can solve the problems of low temperature resistance and low pressure at the same time, poor wear resistance of hydrogenated nitrile, poor low temperature resistance, etc., to achieve excellent wear resistance, Excellent low temperature resistance, less affected by pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

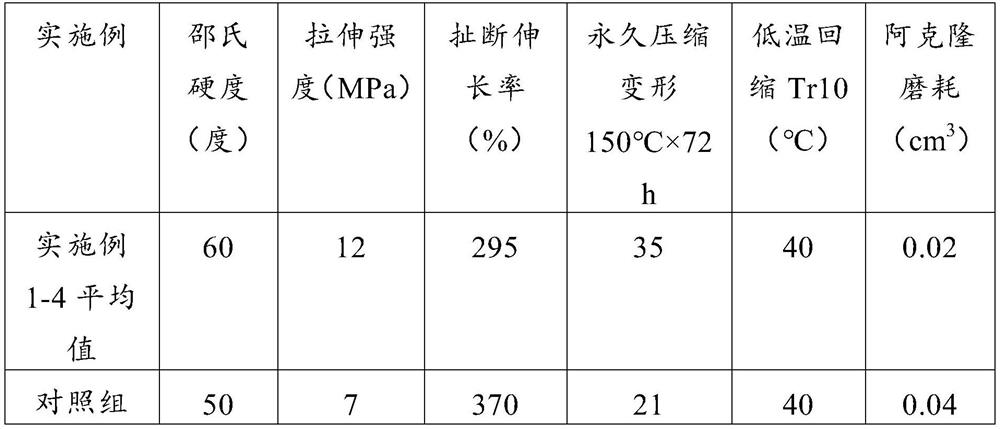

Examples

Embodiment 1

[0025] The invention provides a low-temperature and low-pressure resistant hydrogenated nitrile rubber for wind power, the raw materials used (by weight) include 100 parts of hydrogenated nitrile raw rubber, 30-50 parts of filler, 10-30 parts of plasticizer, and anti-aging agent 1-5 parts, 1-10 parts of vulcanizing agent, 1-10 parts of accelerator, 1-20 parts of clay.

[0026] And specifically in this embodiment: the raw materials used (in parts by weight) include 100 parts of hydrogenated nitrile raw rubber, 30 parts of fillers, 10 parts of plasticizers, 1 part of anti-aging agent, 1 part of vulcanizing agent, and 1 part of accelerator , 1 part of pottery clay, and the hydrogenated nitrile rubber is Zeon 4310.

[0027] The filler is formed by mixing silicon dioxide, active calcium silicate, calcium oxide, barium sulfate, magnesium silicate, and industrial fly ash in a ratio of 2:2:1:1:1:1. The plasticizer is dioctyl adipate, and the anti-aging agent is 2-thiol methylbenzimid...

Embodiment 2

[0032] The invention provides a low-temperature and low-pressure resistant hydrogenated nitrile rubber for wind power, the raw materials used (by weight) include 100 parts of hydrogenated nitrile raw rubber, 30-50 parts of filler, 10-30 parts of plasticizer, and anti-aging agent 1-5 parts, 1-10 parts of vulcanizing agent, 1-10 parts of accelerator, 1-20 parts of clay.

[0033] And specifically in this embodiment: the raw materials used (by weight) include 100 parts of hydrogenated nitrile raw rubber, 40 parts of fillers, 20 parts of plasticizers, 2 parts of antioxidants, 4 parts of vulcanizing agents, and 4 parts of accelerators. , 10 parts of pottery clay, and the hydrogenated nitrile rubber is Zeon 4310.

[0034] The filler is formed by mixing silicon dioxide, active calcium silicate, calcium oxide, barium sulfate, magnesium silicate, and industrial fly ash in a ratio of 2:2:1:1:1:1.

[0035] The plasticizer is 2-n-hexyl adipate, and the anti-aging agent is 2-thiol methylbe...

Embodiment 3

[0040] The invention provides a low-temperature and low-pressure resistant hydrogenated nitrile rubber for wind power, the raw materials used (by weight) include 100 parts of hydrogenated nitrile raw rubber, 30-50 parts of filler, 10-30 parts of plasticizer, and anti-aging agent 1-5 parts, 1-10 parts of vulcanizing agent, 1-10 parts of accelerator, 1-20 parts of clay.

[0041] Specifically in this embodiment: the raw materials used (by weight) include 100 parts of hydrogenated nitrile raw rubber, 45 parts of fillers, 25 parts of plasticizers, 4 parts of antioxidants, 7 parts of vulcanizing agents, and 7 parts of accelerators. , 15 parts of pottery clay, and the hydrogenated nitrile rubber is Zeon 4310.

[0042] The filler is formed by mixing silicon dioxide, active calcium silicate, calcium oxide, barium sulfate, magnesium silicate, and industrial fly ash in a ratio of 2:2:1:1:1:1.

[0043] The plasticizer is n-oct-n-decyl adipate, and the anti-aging agent is 2-mercaptan meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com