Method for applying a coating onto workpieces, and device for coating workpieces

A cladding and workpiece technology, applied in wood processing appliances, manufacturing tools, other plywood/plywood appliances, etc., can solve the problems of complex structure, high cost, high position requirements of laser components, etc., and achieve the effect of high energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

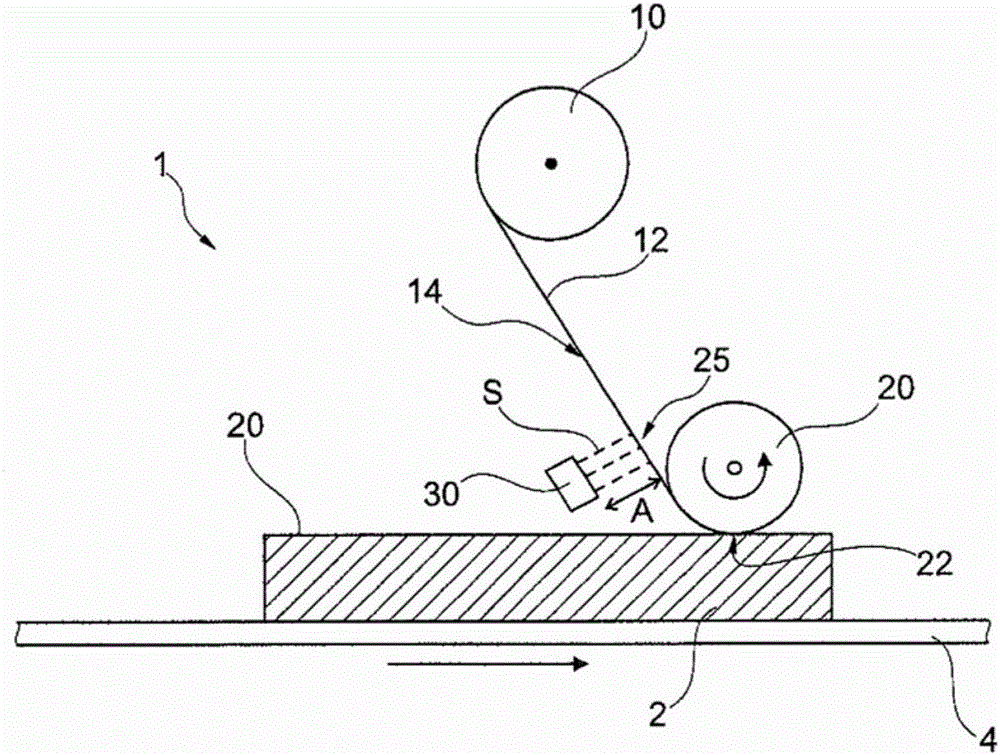

[0029] as in figure 1 As shown in the side view, the device or coating device 1 coats the workpiece 2 in the connection region 25 by connecting the coating 12 in the form of a strip material and the workpiece 2 . The connecting region 25 is arranged upstream of the pressing device 20 when activated, which produces the pressing region 22 on the workpiece 2 by pressing the coating 12 onto the workpiece 2 . Typically, the pressing area 22 is identical to the connecting area 25 after the previously activated area has been completely pressed onto the workpiece.

[0030] In the illustrated continuous method, a receiving or transport device 4 is used to accommodate and transport one or more workpieces 2 . In the embodiment shown the transmission is from left to right, as in figure 1 as illustrated by the arrow.

[0031] The coating 12 consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com