Patents

Literature

60results about How to "Good fluid loss control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

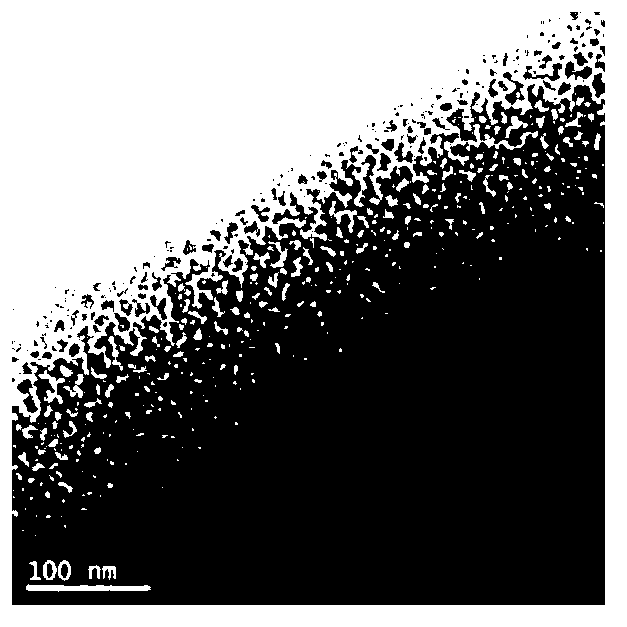

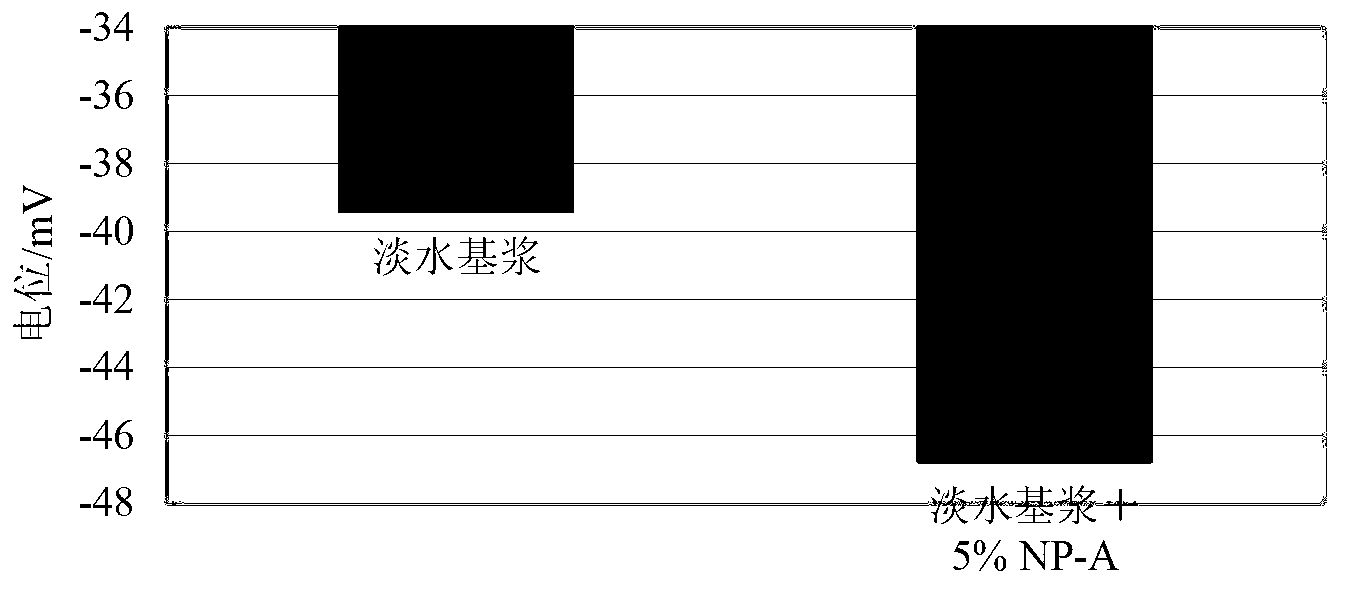

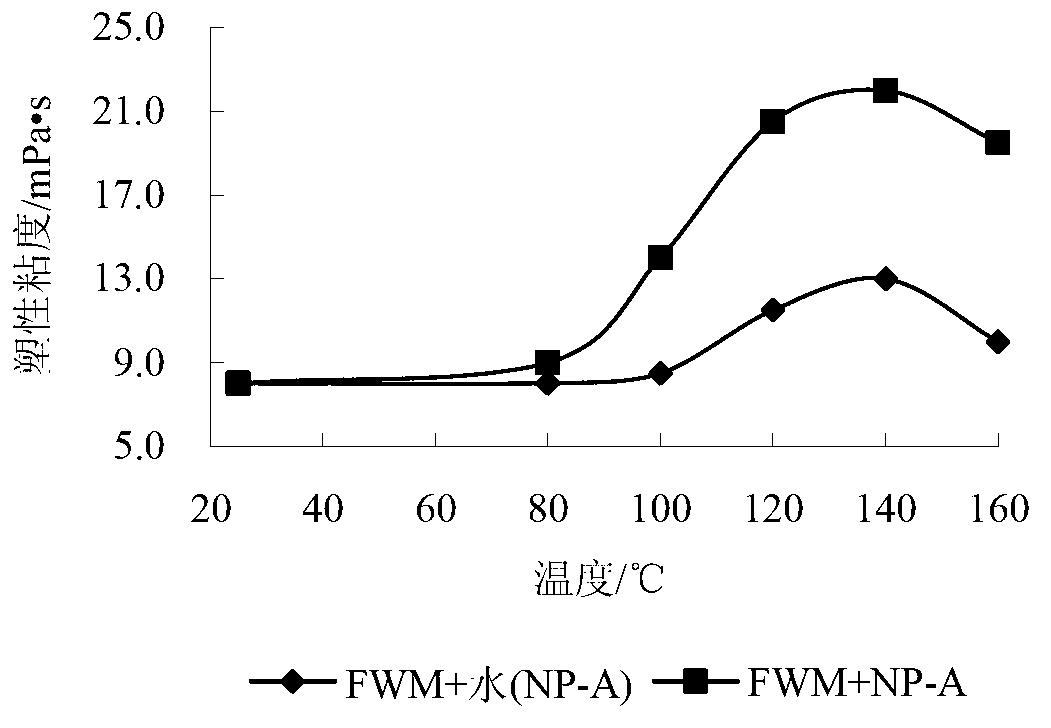

Method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures

ActiveCN103013469AImprove the blocking effectImprove stabilityDrilling compositionWater basedFiltration

The invention provides a method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures. The method comprises a step of adding a nanometer silicon dioxide dispersing agent into base mud, wherein the mass of the nanometer silicon dioxide particle in the nanometer silicon dioxide dispersing agent is 5-10% of total mass of the base mud and the nanometer silicon dioxide dispersing agent. Due to the nano-scale particle size, the nanometer silicon dioxide material can be filled into small holes and cracks of the shale stratum to improve the plugging effect of the water-based drilling fluid, slow down the trend of permeation of the drilling fluid to the stratum and expansion and chipping of the stratum after water absorption, and improve the stability of the borehole wall. The nanometer silicon dioxide can strengthen the stability of fresh-water base mud and bentonite base mud by increasing the negative charge level of the system. The nanometer silicon dioxide also can enable the base mud to form thinner and compact mud cakes and facilitate the de-filtration effect to be obvious.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

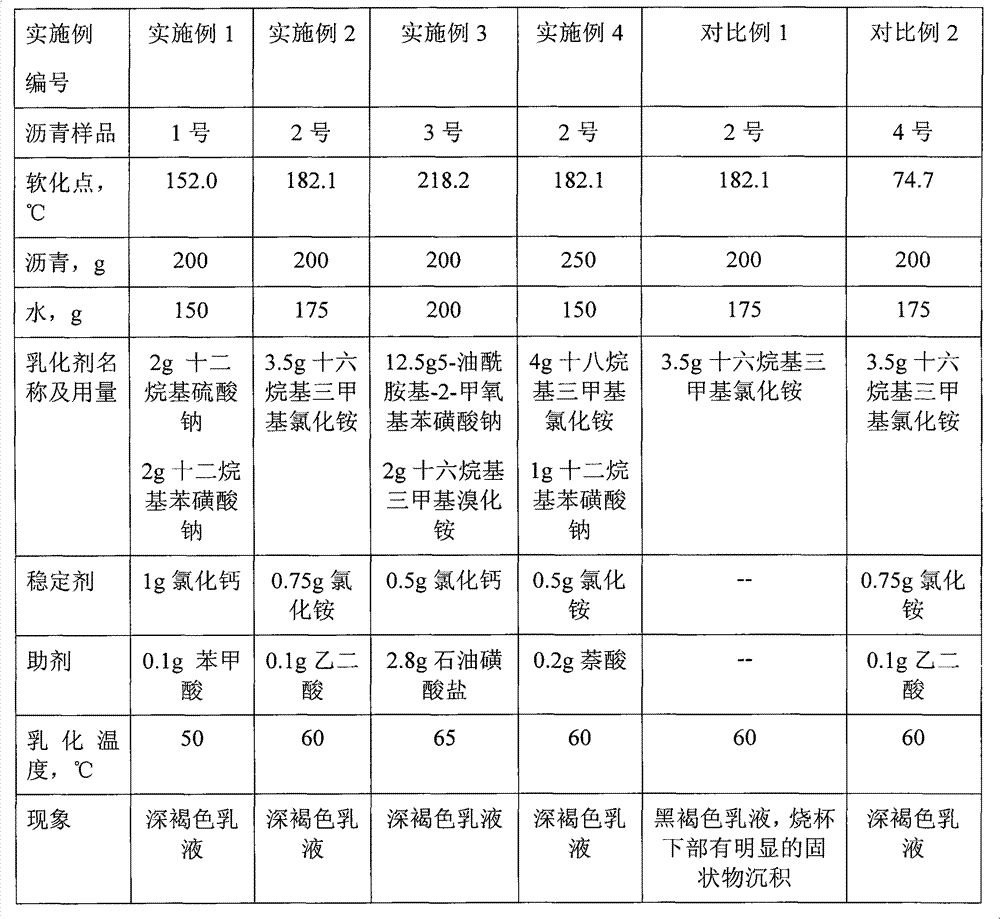

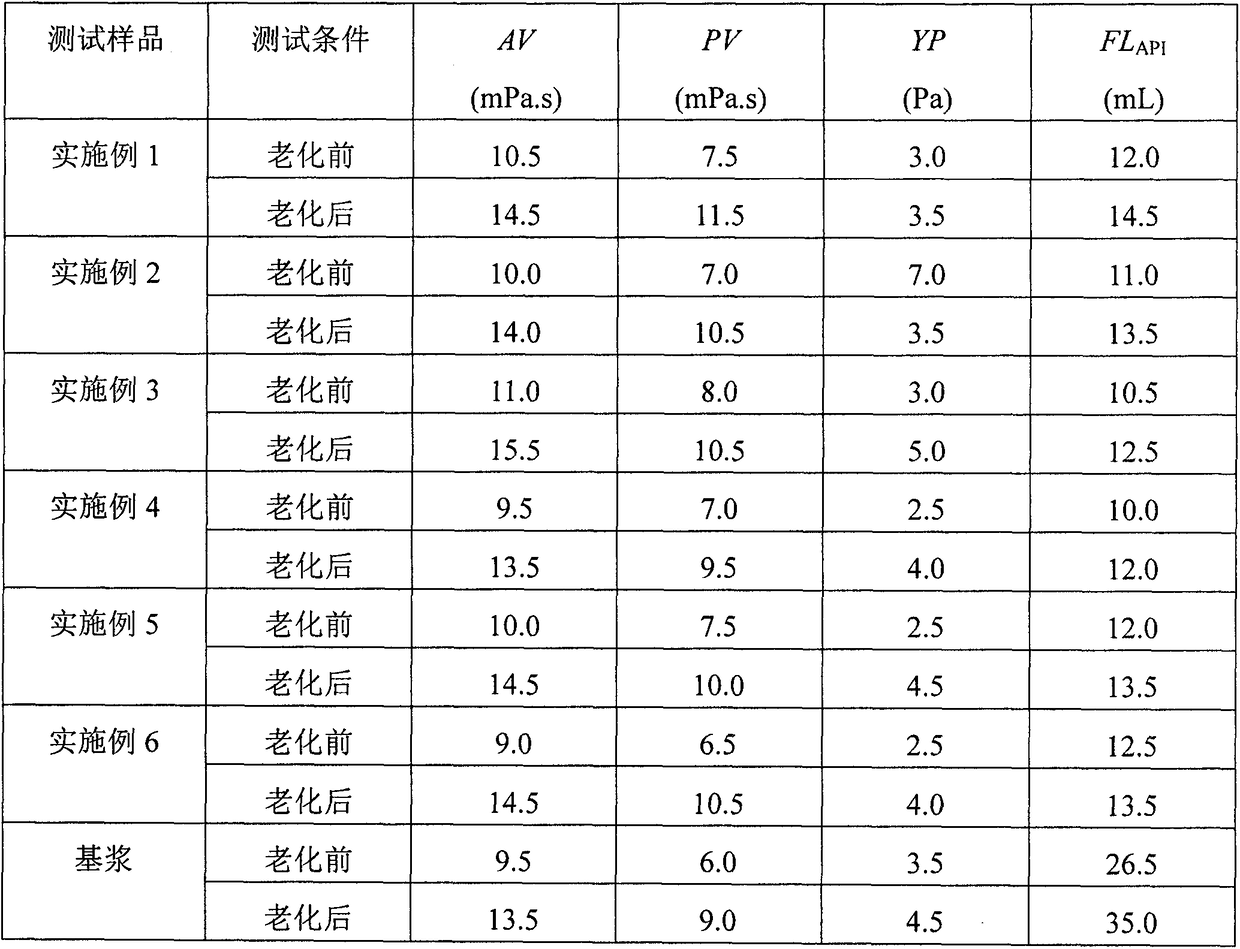

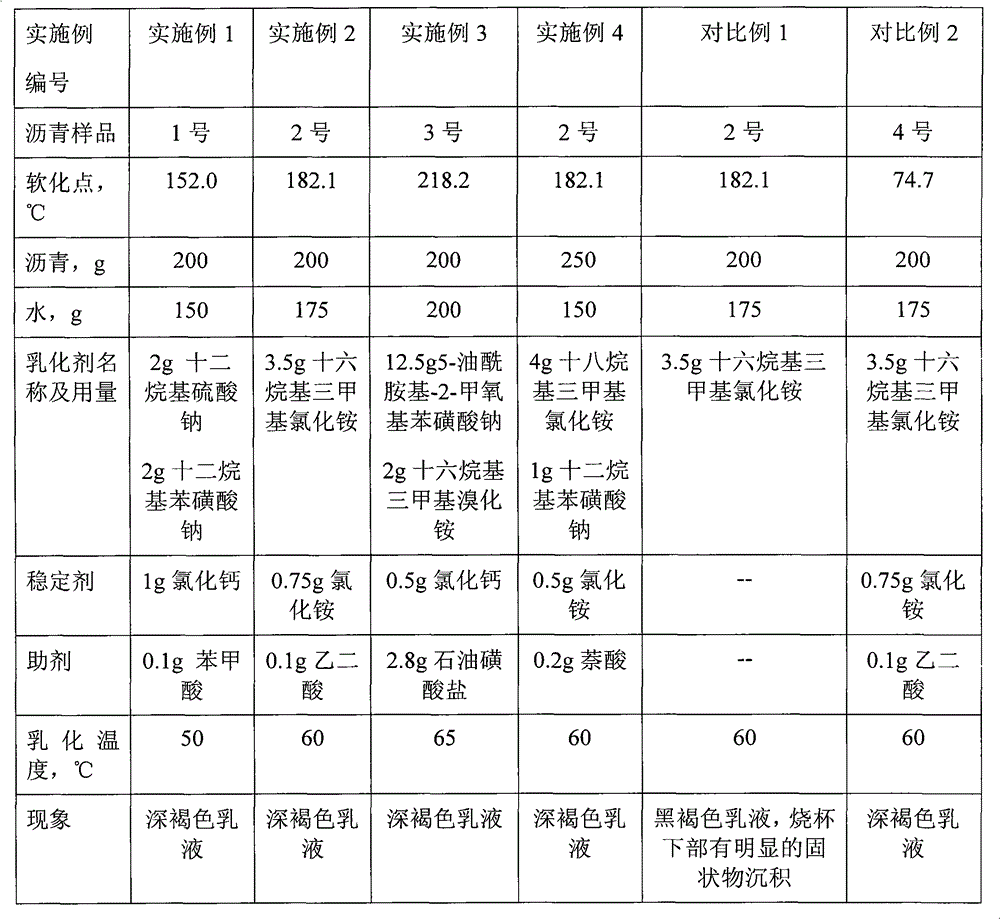

High-softening point emulsified asphalt water-based drilling fluid additive and preparation method thereof

ActiveCN102952526AGood miscibilityMeet high temperature and high pressure requirementsDrilling compositionWater basedPolymer science

A high-softening point emulsified asphalt water-based drilling fluid additive and a preparation method thereof. The drilling fluid additive comprises 40-70 wt% of asphalt with a softening point of 150 DEG C-240 DEG C, 35-50 wt% of water, 0.02-2 wt% of an auxiliary agent, 0.05-5 wt% of an emulsifier, and 0.01-1 wt% of a stabilizer; the charge of the additive is anion; the storage stability for 1 day is not more than 1%; the storage stability for 5 day is not more than 5%; the high-temperature high-pressure filter loss at 220 DEG C and at 3.45 MPa is not more than 25 ml. The preparation method of the additive comprises the following steps: mixing water, the anion emulsifier, the stabilizer, and the auxiliary agent, then adding the asphalt fine powder with a softening point of 150 DEG C-240 DEG C into the above solution, and stirring. The drilling fluid additive provided by the invention has good high-temperature high-pressure filter loss effect, and is suitable for drilling of high-temperature high-pressure deep wells and extradeep wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

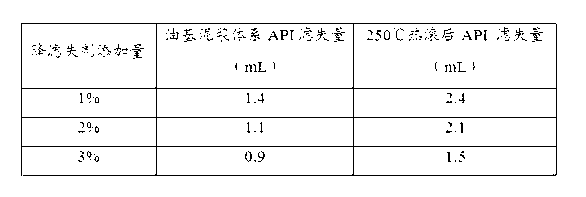

Oil base drilling fluid filtrate reducer as well as preparation method and application of oil base drilling fluid filtrate reducer

ActiveCN103013460ASatisfy the requirements of filtration volumeStrong oil solubilityDrilling compositionSolubilityWell drilling

The invention discloses an oil base drilling fluid filtrate reducer as well as a preparation method and application of the of oil base drilling fluid filtrate reducer. The oil base drilling fluid filtrate reducer comprises the following components in parts by weight: 70-90 parts of rubber powder and 10-30 parts of natural asphalt, wherein 2-8 parts of anti-sticking agent and calcium carbonate superfine powder is required to be added in the preparation process. The preparation method comprises the following steps of: simultaneously feeding three raw materials namely, the rubber powder, the natural asphalt and the calcium carbonate superfine powder to a winnowing crusher according to a weight ratio, controlling the material temperature to be 18-30 DEG C for mixing and crushing, and passing through a sieve with the particle size of 60 meshes, thereby obtaining the oil base drilling fluid filtrate reducer, wherein the oil base drilling fluid filtrate reducer accounts for 1-3 percent in the drilling fluid. The oil base drilling fluid filtrate reducer can resist high temperature of 250 DEG C, the filtrate reduction effect is good, the oil solubility is up to 98 percent, and the oil base drilling fluid filtrate reducer is easily biologically degraded and is harmless to the stratum.

Owner:河北华运鸿业化工有限公司

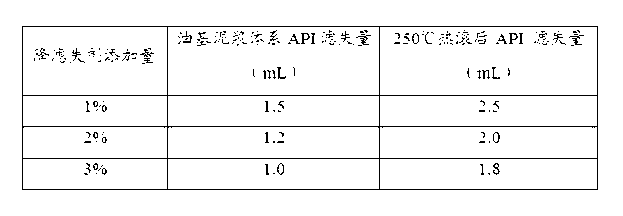

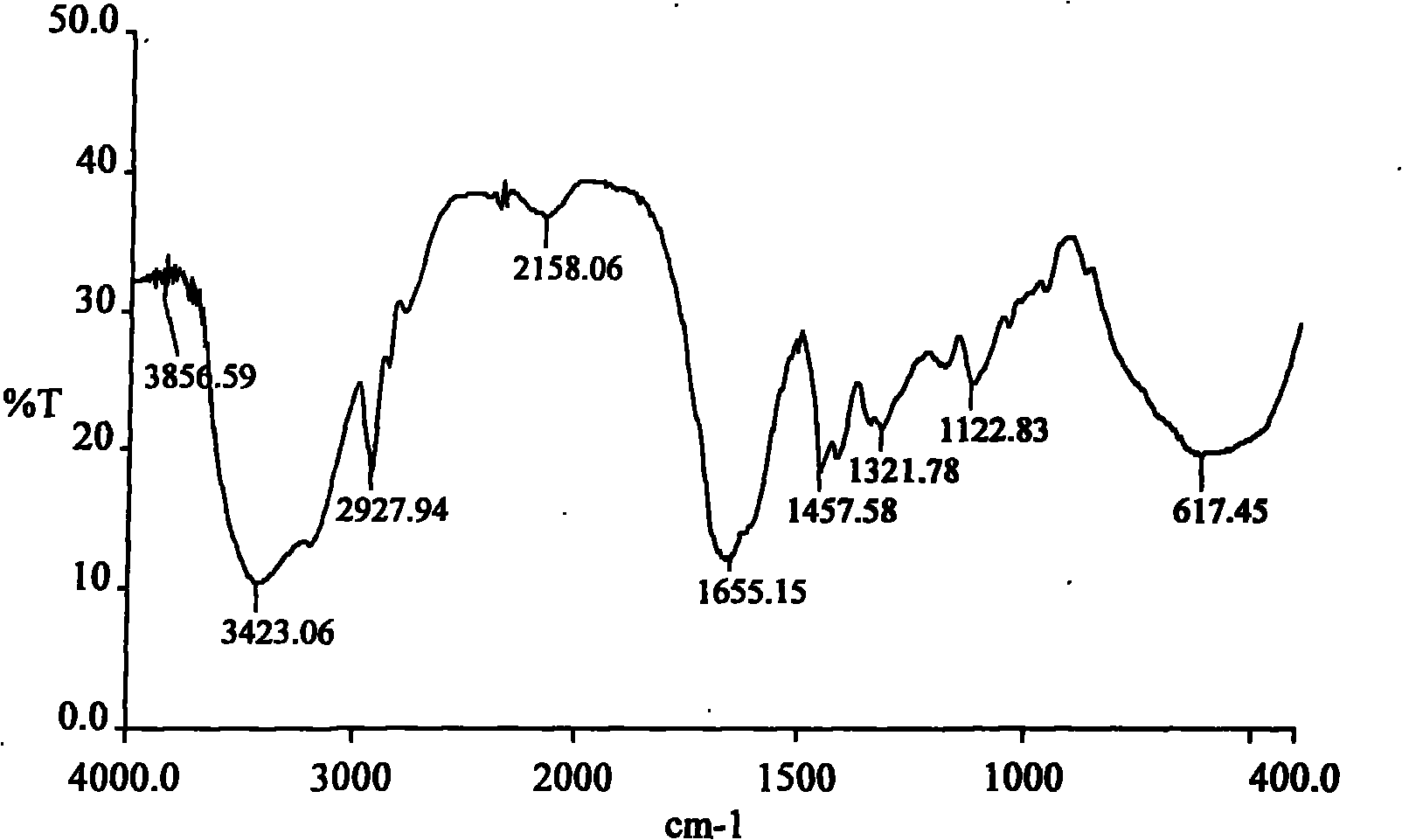

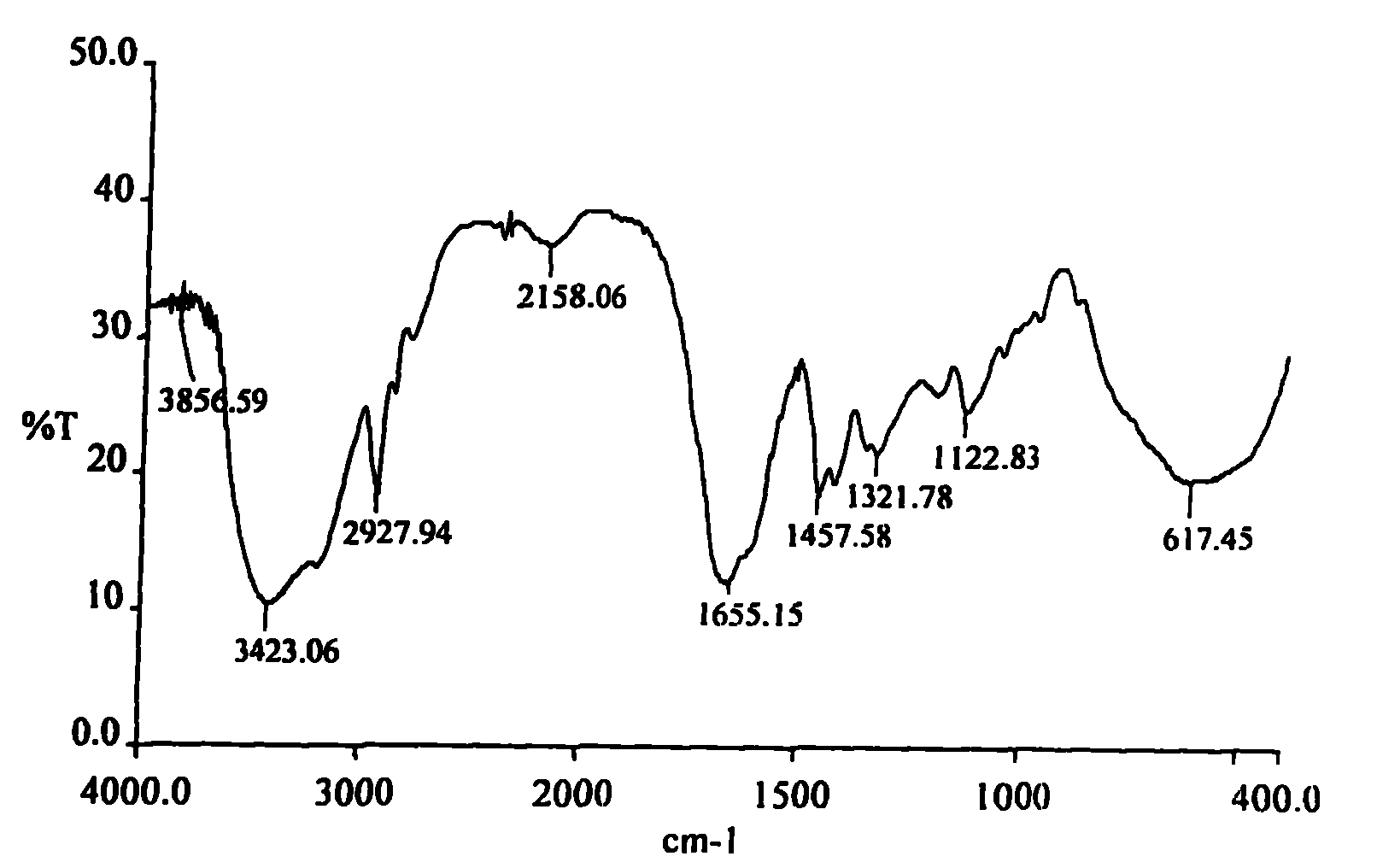

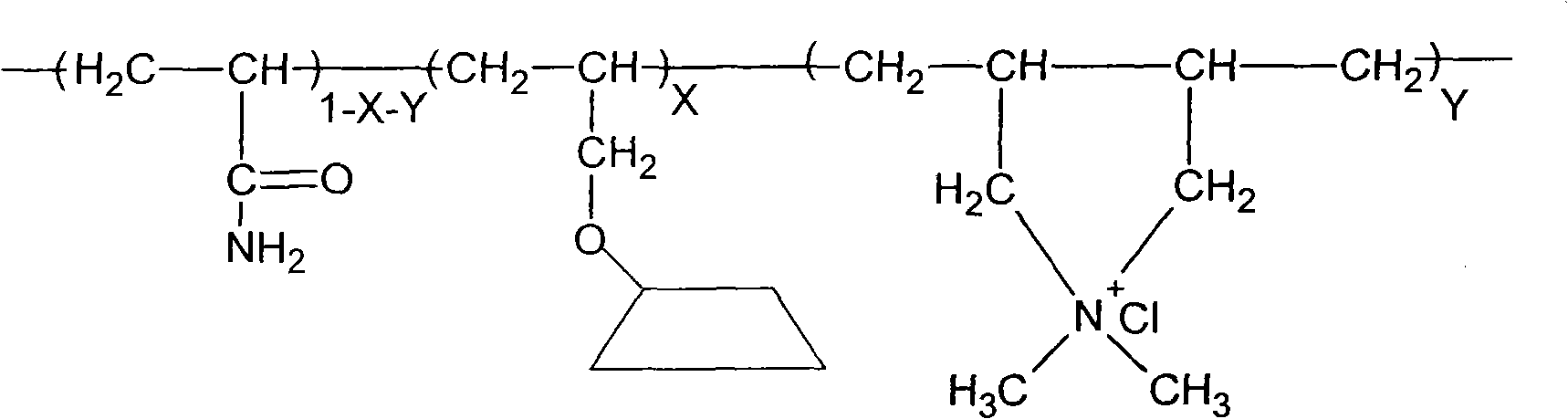

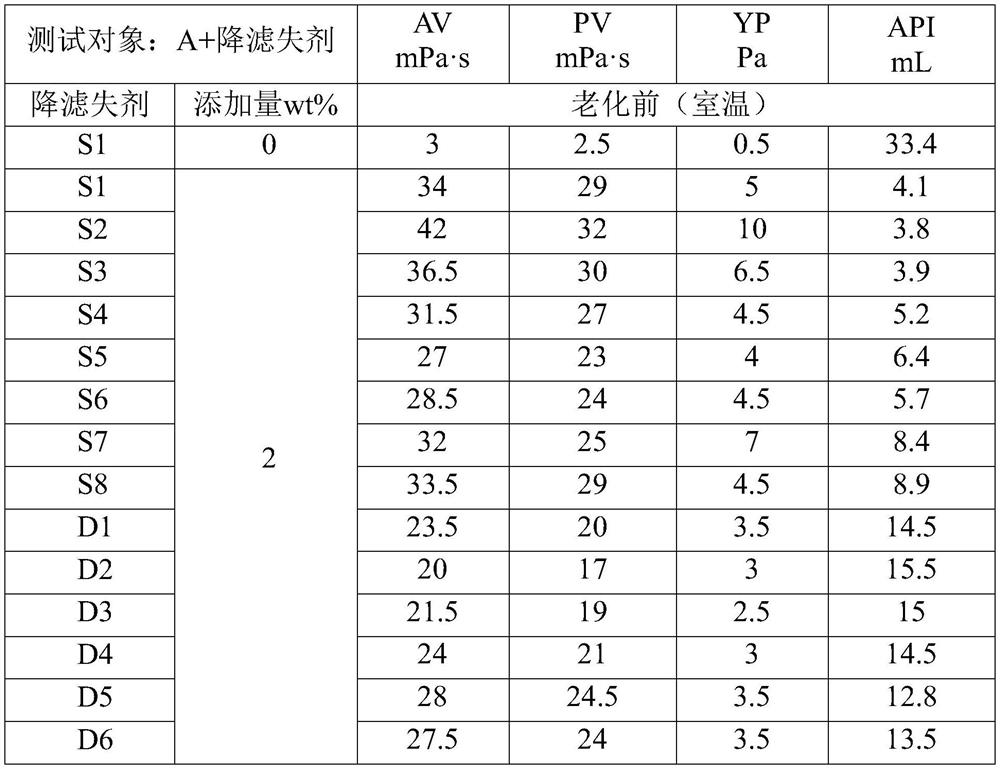

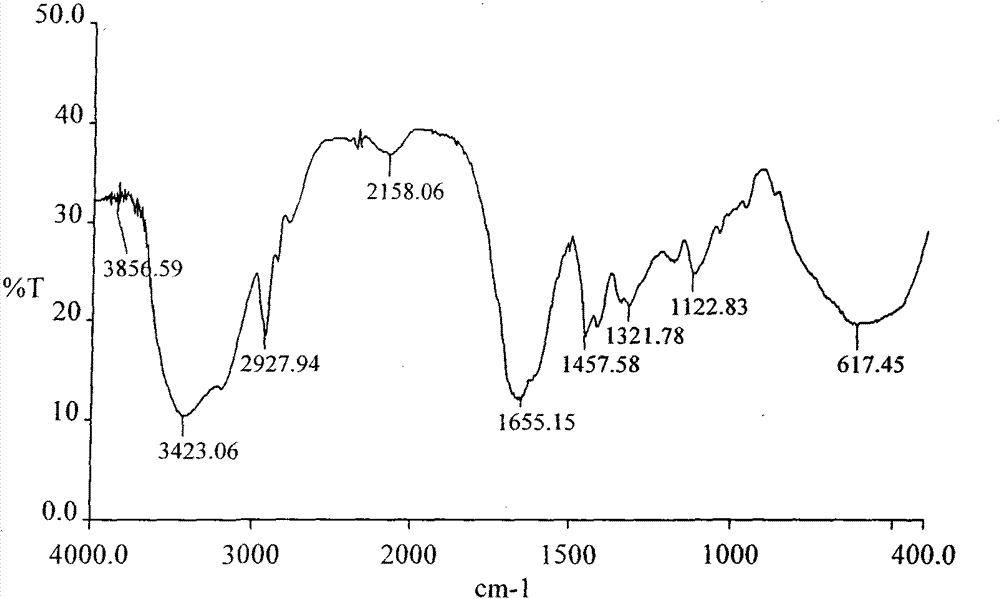

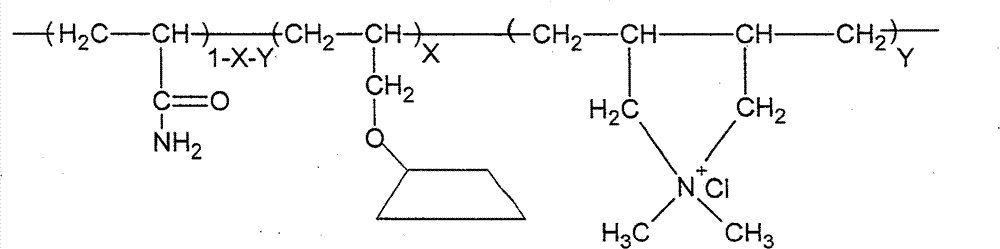

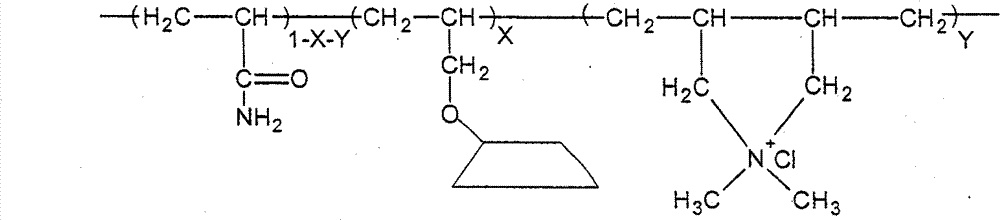

AM (Acrylamide)/DMDAAC (Dimethyl Diallyl Ammonium Chloride)/cyclodextrin polymer filtrate reducer and preparation method thereof

InactiveCN101818051AThe preparation method is simple and feasibleMild reaction conditionsDrilling compositionNitrogenReducer

The invention relates to an AM (Acrylamide) / DMDAAC (Dimethyl Diallyl Ammonium Chloride) / cyclodextrin polymer filtrate reducer used in petroleum and gas drilling fluid and a preparation method thereof. The invention can solve the technical problems that a well wall is not stable as water loss increases at the pit bottom under the condition of high temperature, and the like. The AM / DMDAAC / cyclodextrin polymer filtrate reducer is characterized by comprising three monomers of AM, DMDAAC and cyclodextrin; the preparation method comprises the following steps of: firstly adding the AM and the DMDAAC into an allyl cyclodextrin water solution according to the mol ratio among the allyl cyclodextrin water solution, the AM and the DMDAAC of 69.2-84.2:30-15:0.8 in sequence; then adding a chelating agent, an oxidant and a reducing agent in sequence; finally evenly mixing, then injecting nitrogen for 20-40min and deoxidizing, and reacting at 30-50 DEG C for 6-8h to obtain the AM / DMDAAC / cyclodextrin polymer filtrate reducer. The preparation method of the polymer is simple, convenient and available and mild in reaction conditions; and the polymer has good filtrate reduction effect in the drilling fluid, is resistant to temperature up to more than 250 DEG C and used in the petroleum and gas drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Oil-based drilling fluid filtrate reducer containing cross-linked structure, and preparation method

ActiveCN103184036AEnhanced plugging and wall building performanceImprove filtration loss reduction effectDrilling compositionOrganic acidChemistry

The invention provides an oil-based drilling fluid filtrate reducer containing a cross-linked structure, and a preparation method. the method is carried out according to the following steps: (1) adding 0.1-30 parts by mass of a long-chain alkyl fatty acid and 1 part by mass of a polyene polyamine into a reaction vessel, stirring uniformly, driving oxygen for 20-30 min with nitrogen, heating to a temperature of 80-160 DEG C and reacting for 15 min-8 h; (2) cooling a temperature of the system to 75-85 DEG C, adding 0.5-25 parts by mass of a humic acid, stirring uniformly, driving the oxygen for 20-30 min with the nitrogen, heating to a temperature of 90-180 DEG C and reacting for 15 min-10 h; (3) adding 0.005-5 parts by mass of a binary or multiple organic acid, stirring uniformly and reacting for 15 min-16 h at a temperature of 100-200 DEG C; and (4) cooling a product obtained by the step (3) to a room temperature, smashing the product, and screening with a 50-100 mesh sieve to obtain the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

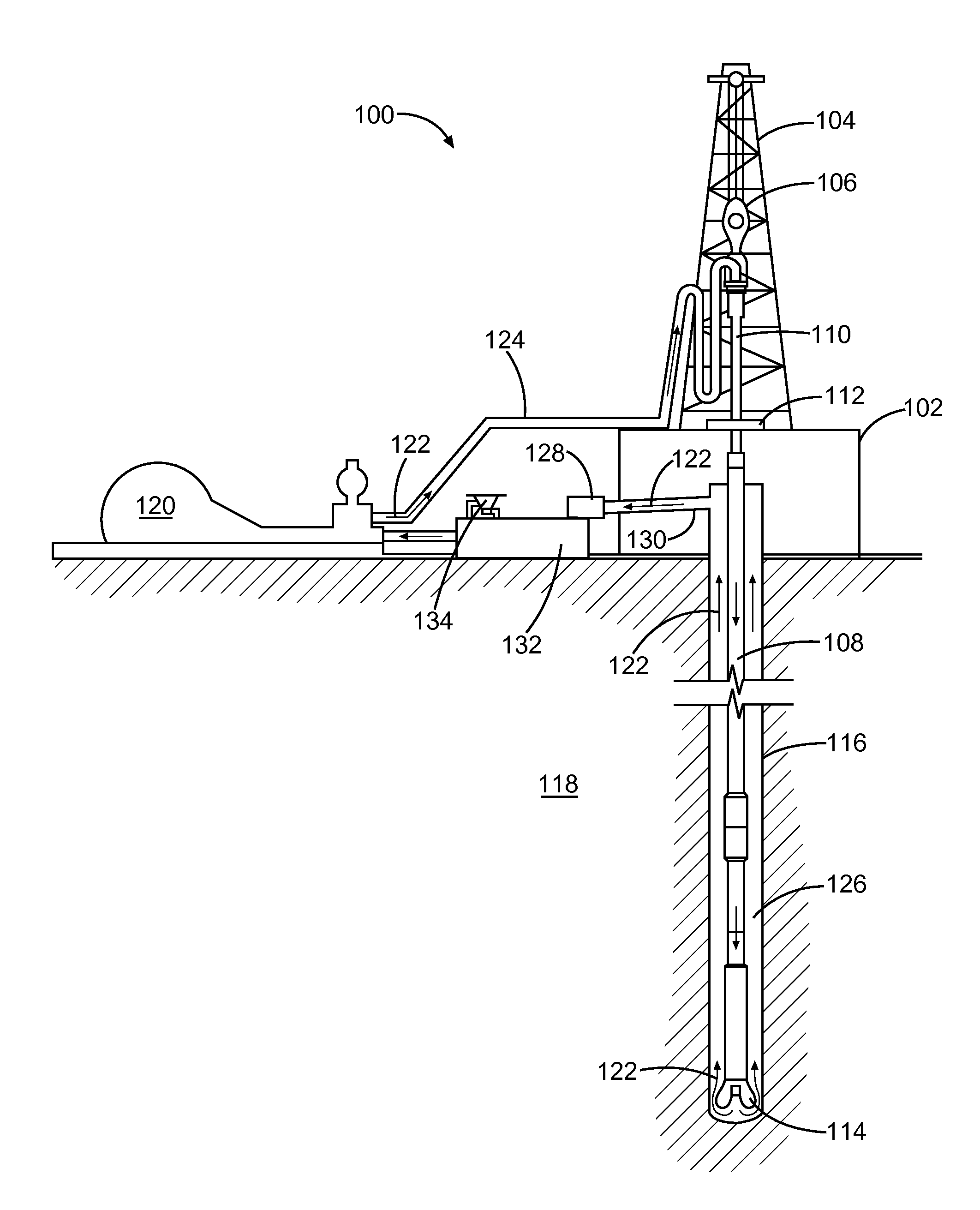

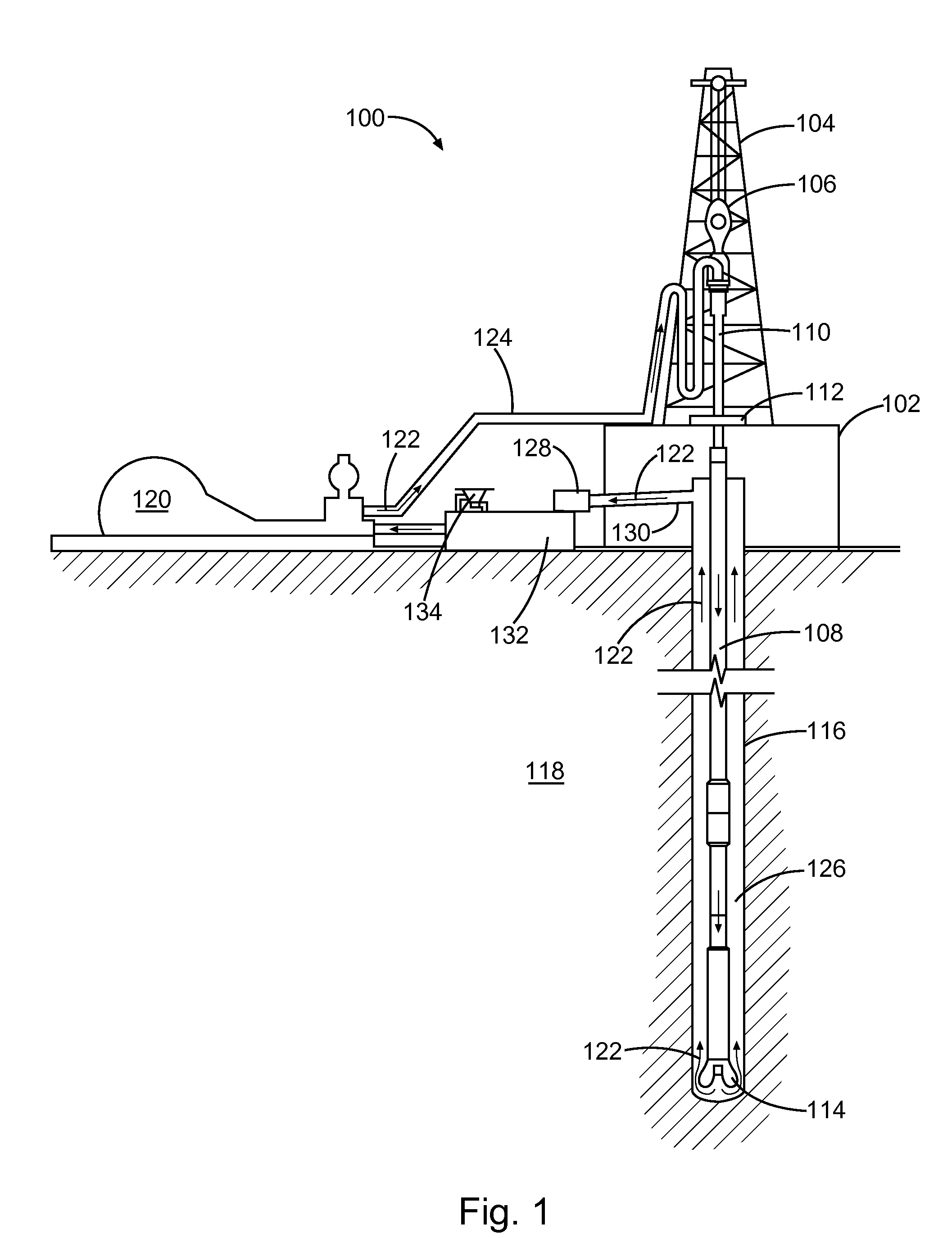

Drilling fluid composition including viscosifier and method of using the same

ActiveUS20160122613A1High viscosityGood fluid loss controlDrilling rodsFluid removalFluid compositionCopolymer

The present invention relates to drilling fluid compositions and methods of using the same. In various embodiments, the present invention provides a method of treating a subterranean formation including obtaining or providing a drilling fluid composition including a viscosifier including at least one of a poly(vinyl alcohol) copolymer, a crosslinked poly(vinyl alcohol), and a crosslinked poly(vinyl alcohol) copolymer. The method also includes placing the composition in a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Filtrate loss reducer for full oil-based drilling fluid, and preparation method of filtrate loss reducer

The invention provides a filtrate loss reducer for full oil-based drilling fluid, and a preparation method of the filtrate loss reducer. The filtrate loss reducer comprises the following raw materials in parts by weight: 130-140 parts of an emulsion micelle compound and 20 parts of humic acid acetamide, wherein the emulsion micelle compound comprises the following raw materials in parts by weight: 60 parts of diesel oil, 10 parts of an emulsifying agent, and 60-70 parts of a macromolecular micelle compound. The filtrate loss reducer for full oil-based drilling fluid, which is provided by the invention, is simple in preparation technology, the performance of products is good, the rheological property and filtration reducing property of drilling fluids can be remained, the oil-gas layers can be effectively protected, the collapse of oil-gas layers is avoided, and the borehole diameter is prevented from enlarging.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of environment-friendly ultrahigh-temperature-resistant filtrate reducer for water-based drilling fluid

ActiveCN111875758AImprove temperature resistanceImprove hydrolysis resistanceDrilling compositionPhysical chemistryCross linker

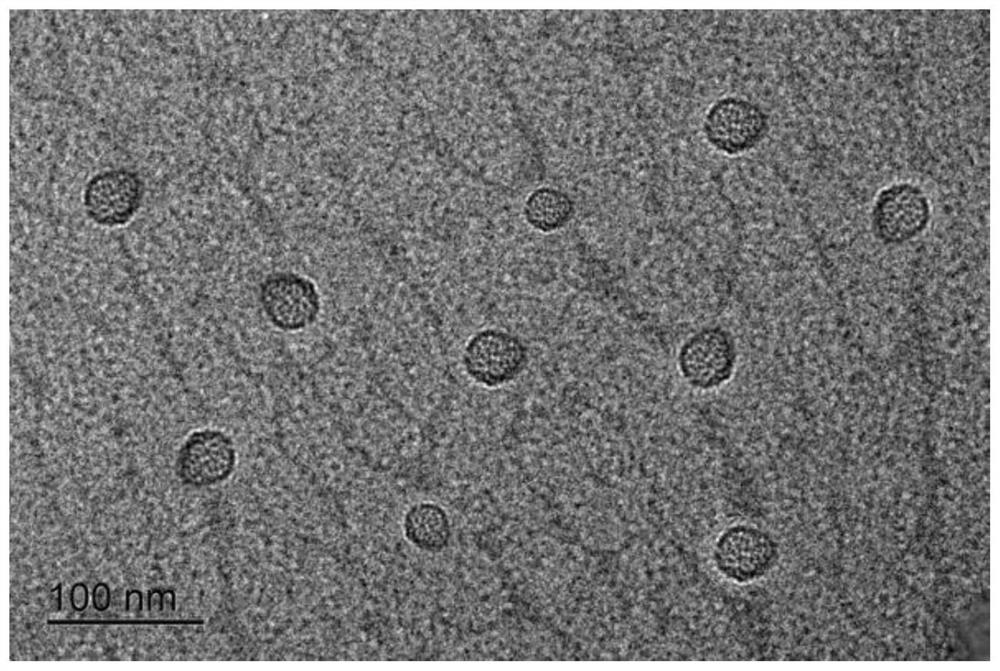

The invention provides a preparation method of an environment-friendly ultrahigh-temperature-resistant filtrate reducer for a water-based drilling fluid, which comprises the following steps: reactingnano hectorite with a silane coupling agent to obtain a nano cross-linking agent; and in the presence of a nano cross-linking agent and an initiator, carrying out polymerization reaction on an amide monomer, a high-temperature-resistant monomer, a cationic monomer and a polyene monomer by using an inverse emulsion polymerization method to obtain the environment-friendly ultrahigh-temperature-resistant filtrate reducer. The filtrate reducer prepared by the preparation method disclosed by the invention can resist high temperature and has an excellent filtrate reduction effect and good environmental protection performance. The filtrate reducer disclosed by the invention is not only suitable for deep and ultra-deep oil and gas drilling, but also suitable for drilling of geothermal wells and environment-sensitive areas.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-temperature-resistant viscosity-reduction filtrate reducer for drilling fluid and preparation method of filtrate reducer

The invention relates to a high-temperature-resistant viscosity-reduction filtrate reducer for a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer comprises the raw materials of waste acrylon fibers, alkali, mineral acid, hydrogen peroxide, lignite, a sulfonating agent, formaldehyde, copperas and water, wherein the waste acrylon fibers and part of alkali are added in water for reaction at the temperature of 85-95 DEG C; the mineral acid and the hydrogen peroxide are added when the temperature is reduced to 80-85 DEG C, and then the temperature is increased to 85-95 DEG C for reaction for 1-3 h; the remained alkali, lignite, sulfonating agent and formaldehyde are added for reaction for 1-3 hours at the temperature of 85-95 DEG C; the temperature is reduced to 60-80 DEG C, and then ferrous sulfate is added for reaction for 10-30 min; and finally, the product is fetched for drying and smashing. The obtained filtrate reducer not only can reduce the drilling fluid viscosity, but also has a good de-filtration effect and is resistant to high temperature. The filtrate reducer takes the waste acrylon fibers and the lignite as main raw materials, is low in cost and simple in process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Filtrate reducer for oil-based drilling fluids and production method thereof

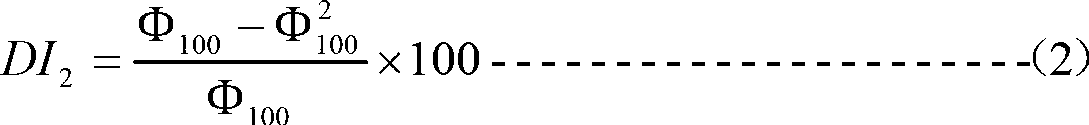

InactiveCN105586017AImprove lipophilicityDoes not affect high temperature resistanceDrilling compositionFiltrationCarbon chain

The invention provides a filtrate reducer for oil-based drilling fluids and a production method thereof. The production method is characterized in that humic acid undergoes surface modification and the humic acid is grafted with an alkyl group of long carbon chain, and a product which has oleophylic emulsifying property and ammonium salt undergo polymerization so as to obtain the required product. The production method comprises the following concrete operations: stirring a certain amount of brown coal, caustic soda and water and reacting for a period of time, and extracting a humic acid solution; preparing grafted humic acid from the obtained humic acid solution and octadecylamine and octadecyl trimethyl ammonium chloride; preparing fatty acid amide from oleic acid, diethanolamine and concentrated hydrochloric acid; and preparing humic acid acetamide, dispersing, filtering and drying to obtain a finished product. According to the method, humic acid is modified to be grafted with the alkyl group of long carbon chain, and then the humic acid filtrate reducer has remarkable lipophilicity, can be dissolved or dispersed in oil and can be directly used in water-in-oil drilling fluids. Humic acid and amine are combined firmly, and high temperature resistance is strong. The product has a certain emulsification capability and good filtration reduction effects. The production method is simple, and the environment is not polluted.

Owner:TIANJIN TIANCHENG TUOYUAN TECH DEV

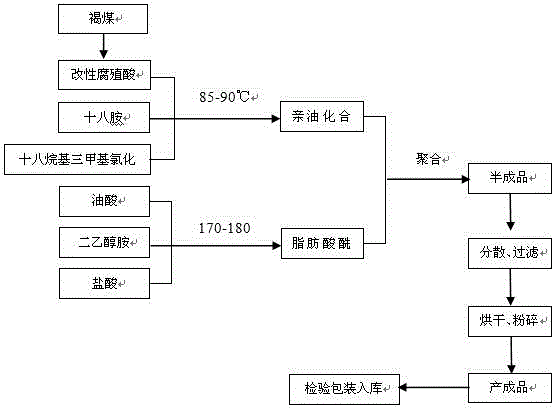

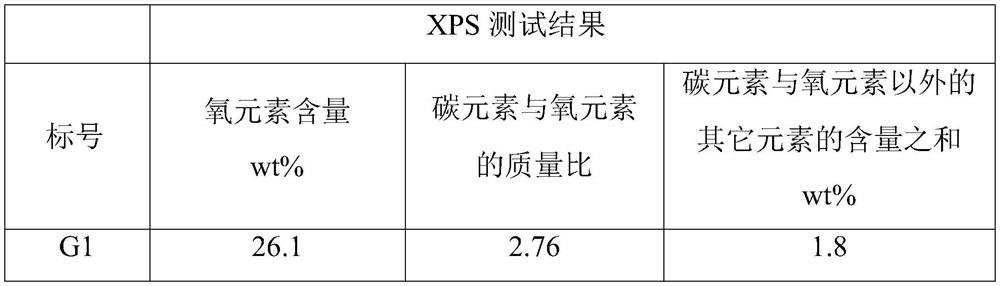

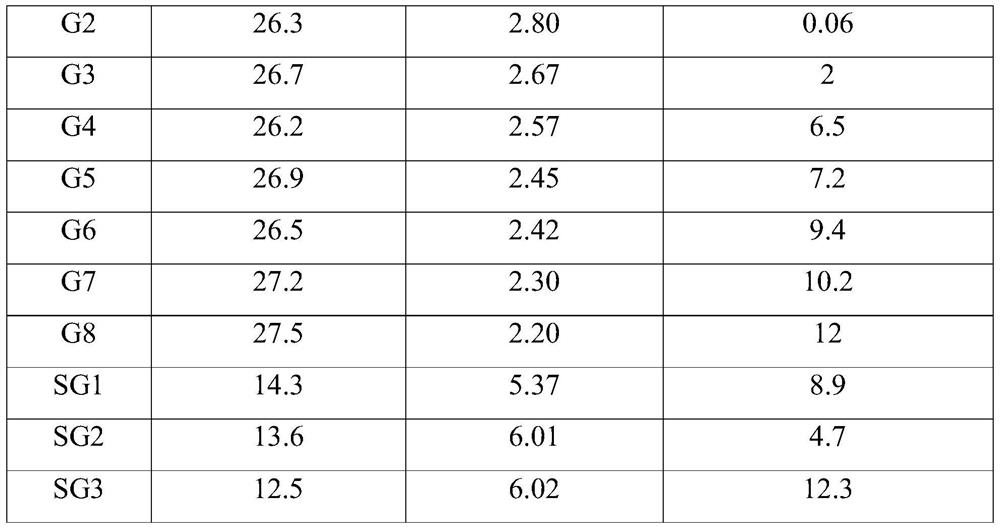

Carboxyl-modified graphene graft polymer as well as preparation method and application thereof

ActiveCN112574368AImprove temperature resistanceLow API filtration lossDrilling compositionPyrrolidinonesOil phase

The invention relates to the field of oil exploitation, and discloses a carboxyl-modified graphene graft polymer as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving acrylamide, benzenesulfonic acid and N-vinyl pyrrolidone in water, adding carboxyl-modified graphene, adding a first emulsifier to prepare an aqueous phase system, and dissolving a second emulsifier in an oil phase to prepare an oil phase system; (2) preparing an inverse emulsion system from the aqueous phase system and the oil phase system; (3) carrying out a first polymerization reaction on the inverse emulsion system to obtain an intermediate product system, and carrying out a second polymerization reaction on the intermediate product system to obtain a pre-product; (4) purifying, drying and crushing the pre-product to obtain the carboxyl-modified graphene graft polymer, wherein the content of the oxygen element in an XPS test result of the carboxyl-modified graphene is not lower than 26 wt%. The polymer provided by the invention is used as a drilling fluid filtrate reducer and has excellent temperature resistance and salt resistance.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

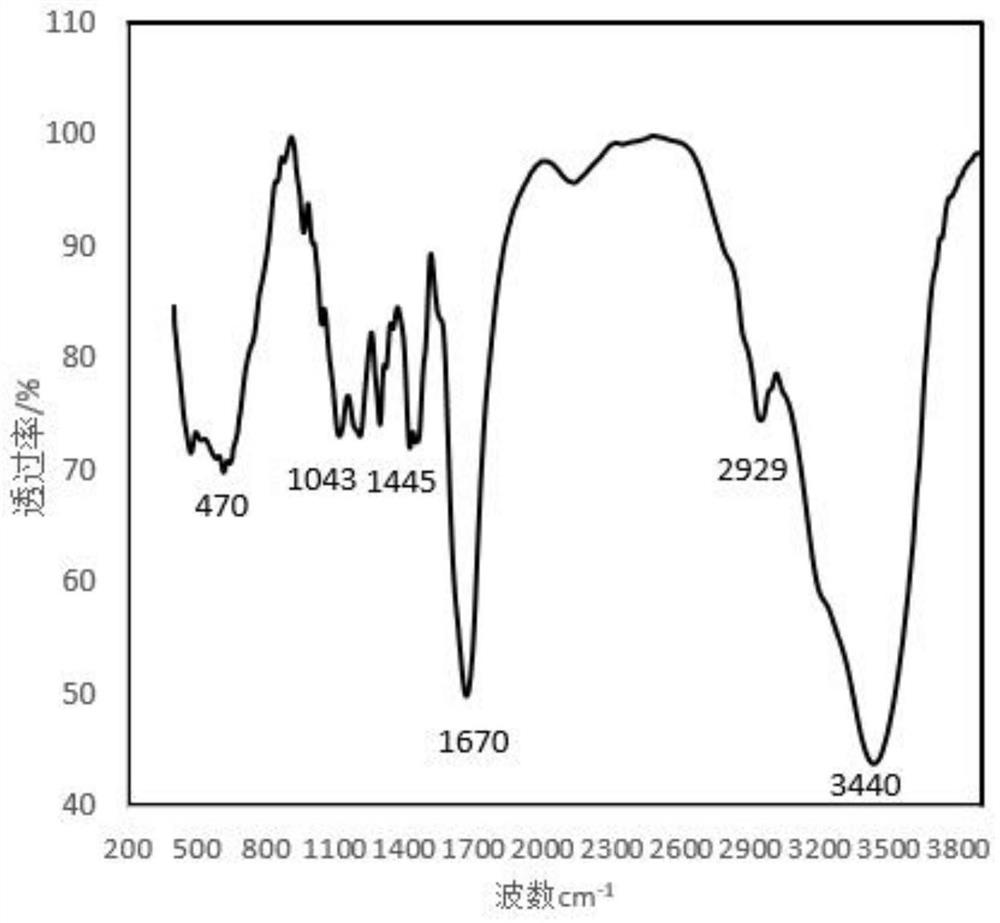

High-temperature-resistant organic/inorganic hybrid polymer filtrate reducer and preparation method thereof

PendingCN112457454AEasy to prepareNon pollutingDrilling compositionPyrrolidinonesUltrasonic dispersion

The invention discloses a water-based drilling fluid high-temperature-resistant organic / inorganic hybrid polymer filtrate reducer and a preparation method thereof. The preparation method comprises thefolloiwng steps: uniformly mixing three organic monomers including acrylamide, dimethyl diallyl ammonium chloride and N-vinyl pyrrolidone in proportion, adjusting the pH value to 9, transferring themixture into a three-neck flask, adding inorganic monomer modified nano silicon dioxide while introducing nitrogen, performing ultrasonic dispersion for 25 minutes by an ultrasonic dispersion instrument, transferring the mixture into the three-neck flask, heating to 70 DEG C, adding an initiator, reacting for 7 hours under stirring to obtain milk white viscous liquid, cooling, drying, grinding andcrushing to obtain the organic / inorganic hybrid quaternary graft copolymer. In the invention, the four reaction monomers do not contain sulfonation groups, and the filtrate loss reduction effect of the four reaction monomers at 150-210 DEG C is better than that of a common sulfonation type high-temperature-resistant filtrate loss reducer for an oil field, so that the filtrate loss reducer is environment-friendly and has good filtrate loss reduction property, and the temperature resistance can reach 210 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

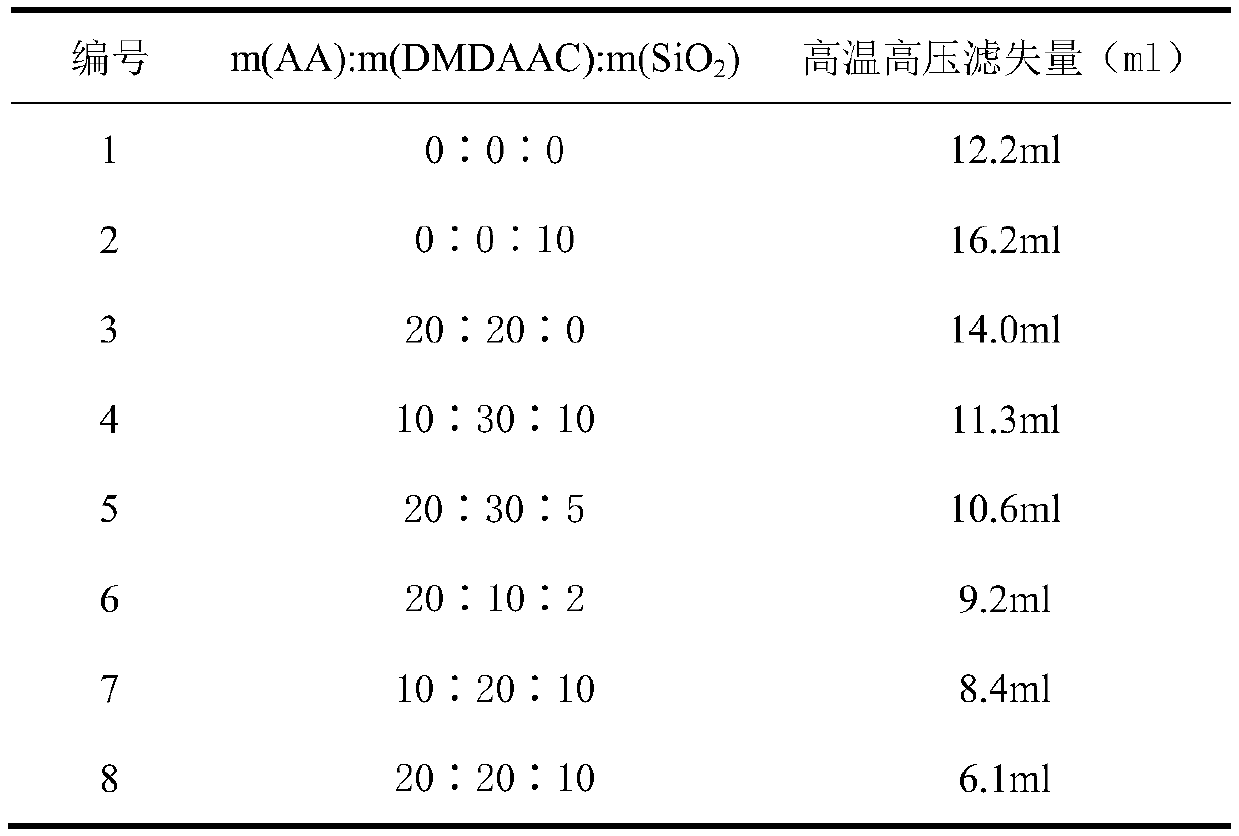

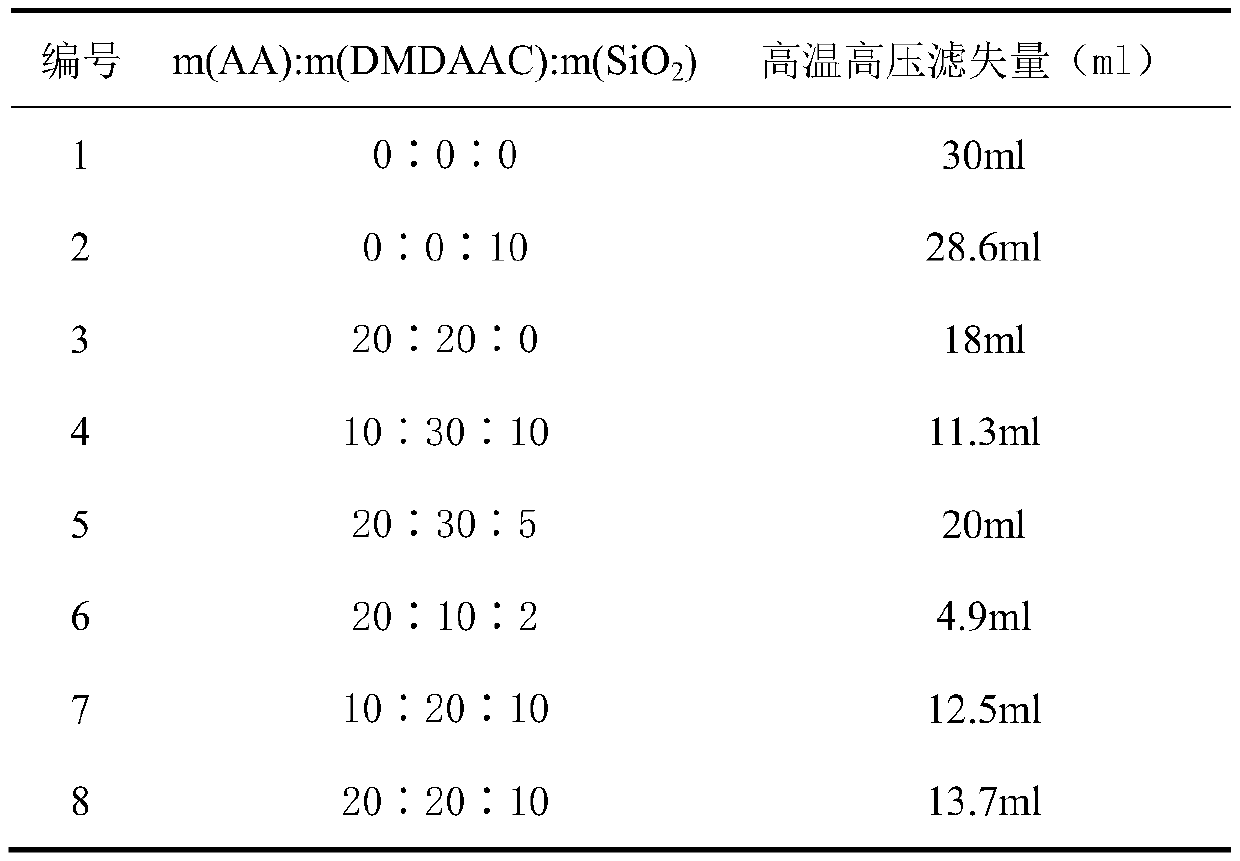

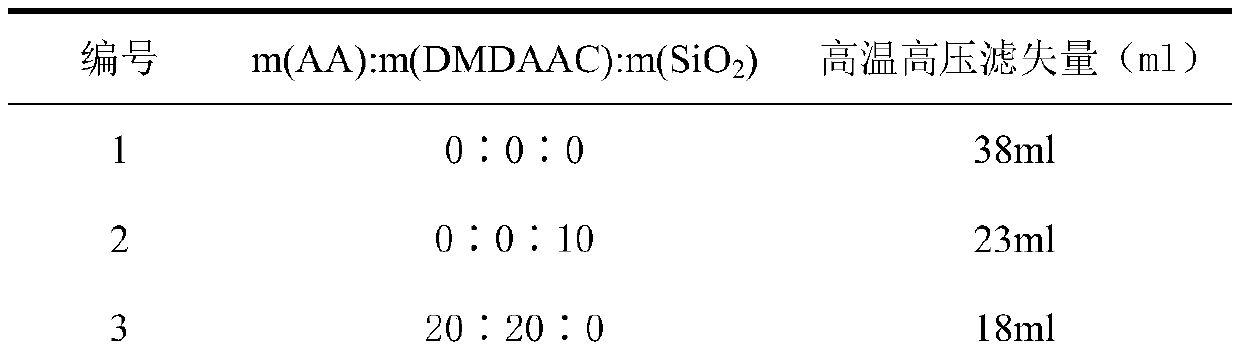

Non-sulfonated temperature-resistant filtrate reducer for drilling fluid, and synthetic method thereof

The invention discloses a high-temperature-resistant filtrate reducer for non-sulfonated drilling fluid, and a synthetic method thereof, and belongs to the technical field of oilfield exploitation drilling treatment agents. The preparation method comprises the following steps: dissolving organosilane coupling agent modified nano silicon dioxide in water, and stirring at normal temperature to fullydisperse the modified nano SiO2 to obtain an inorganic modified nano SiO2 suspension; and mixing acrylic acid (AA), dimethyl diallyl ammonium chloride (DMDAAC) and the inorganic modified nano SiO2 suspension in a weight part ratio of (0-20):(0-30):(0-10). According to the invention, a non-sulfonated monomer is preferably selected and inorganic nano SiO2 is added, the advantages and disadvantagesof the organic polymer and the inorganic nanometer are comprehensively considered, and the temperature-resistant filtrate reducer for the non-sulfonated water-based drilling fluid is synthesized, caneffectively reduce the water loss, has good filtrate reduction performance and temperature resistance under the conditions of normal temperature and 180-200 DEG C, and still has certain temperature resistance and salt resistance after being added into saline water-based slurry and saturated saline water-based slurry.

Owner:SOUTHWEST PETROLEUM UNIV

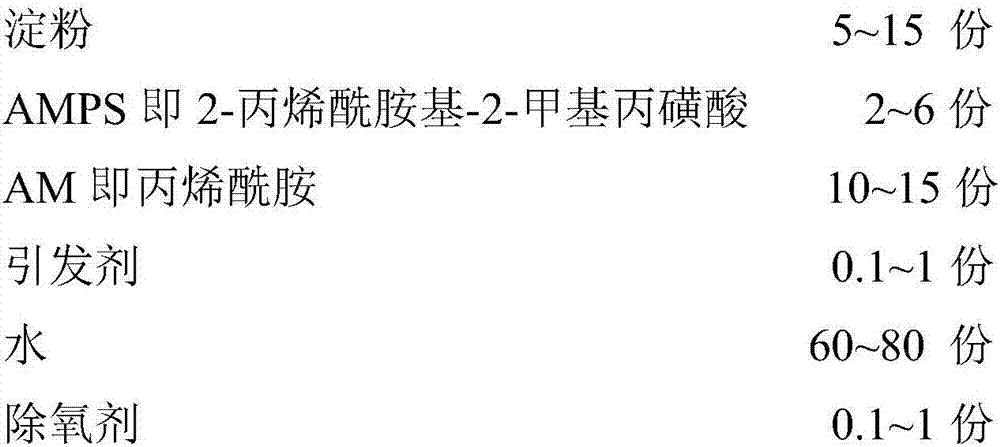

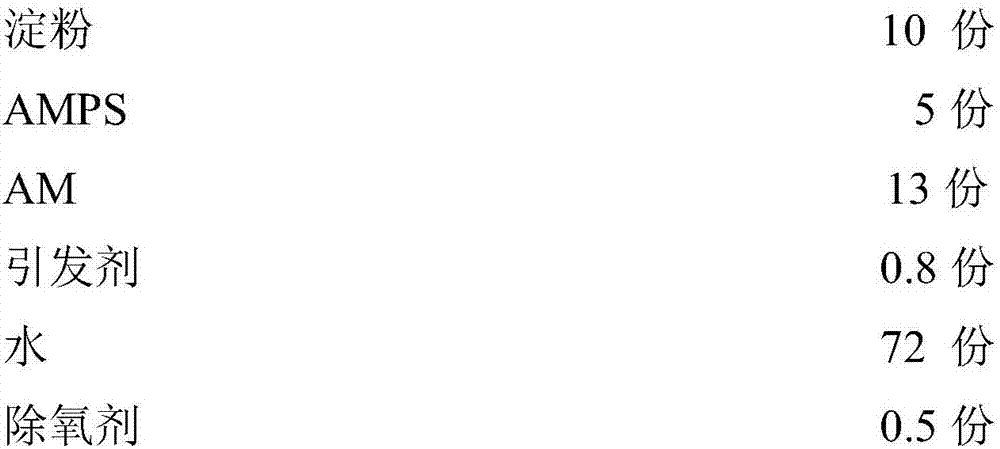

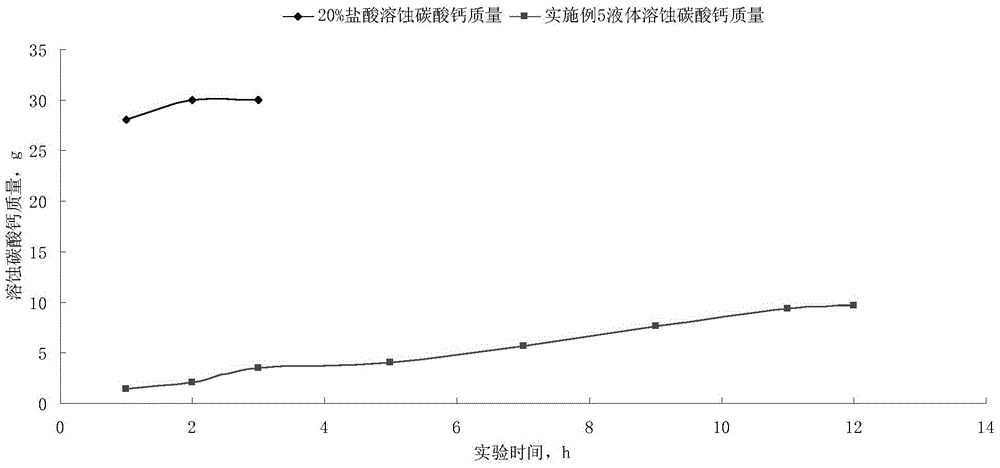

Natural polymer for filtrate loss reducer for drilling fluid and preparation method thereof

A natural polymer for a filtrate loss reducer for a drilling fluid and a preparation method thereof are disclosed, the natural polymer is prepared from the following raw materials by weight: 5-15 parts of starch, 2-6 parts of AMPS, 10-15 parts of AM, 0.1-1 part of an initiator, 60-80 parts of water and 0.1-1 part of a deoxidizer. The preparation method comprises the following steps: starch hydrolysis, acidification of a starch solution, deoxidization of a starch acid solution and graft copolymerization of the starch acid solution. The performance of the natural polymer is as follows: 4% saline API filtration loss is equal to or less than 8.0mL, after aging at 150 DEG C, the API filtration loss is equal to or less than 14.0mL, saturated brine API filtration loss is equal to or less than 8.0mL, after aging at 150 DEG C, API filtration loss is equal to or less than 13.0mL, compound brine API filter loss is equal to or less than 13.0mL, after aging at 150 DEG C, API filtration loss is equal to or less than 18.0mL. The natural polymer has good performance, can reduce the filtrate loss of the drilling fluid, avoids or reduces the occurrence of complex drilling accidents, improves drilling quality and efficiency, and produces a good environmental protection effect.

Owner:石家庄华莱鼎盛科技有限公司

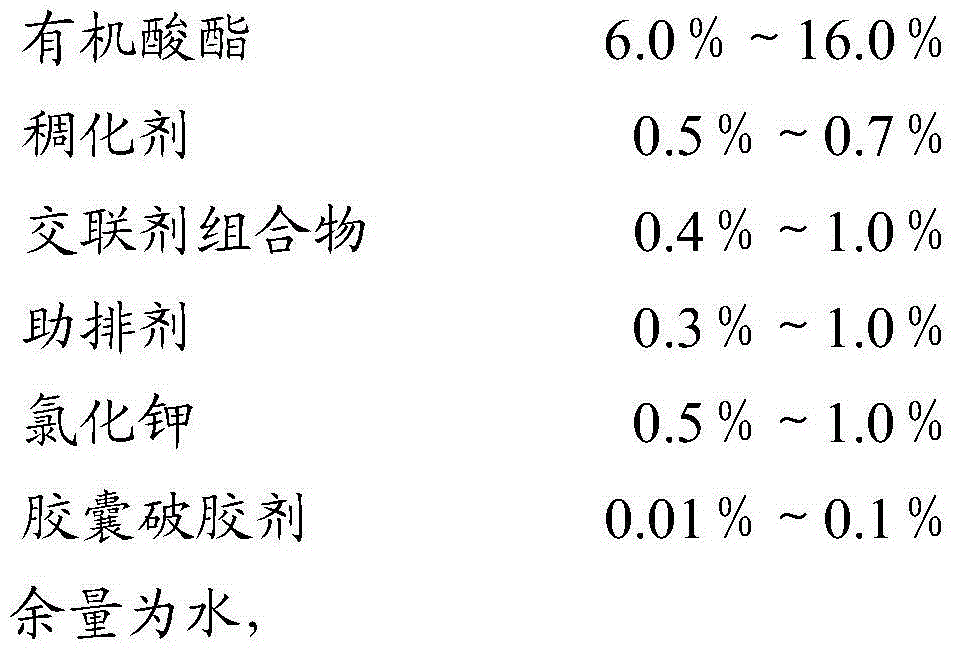

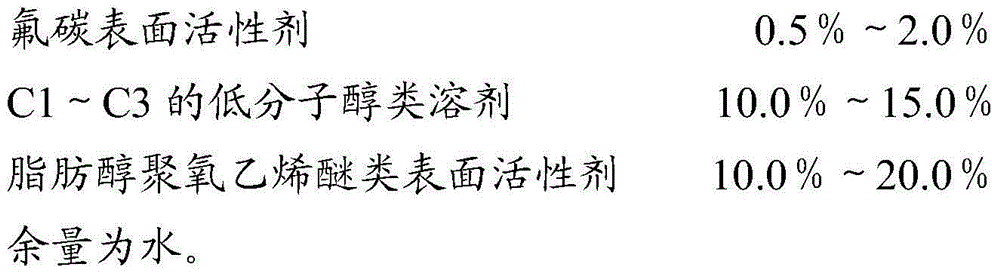

Cross-linking agent composition, acidic pad fluid, and application of acidic pad fluid

The invention provides a cross-linking agent composition, an acidic pad fluid containing the cross-linking agent composition, and an application of the acidic pad fluid, and belongs to the fields of reservoir chemical yield increase reconstruction in petroleum and natural gas exploration. The acidic pad fluid comprises, by mass, 6.0-16.0% of organic acid ester, 0.5-0.7% of a densifier, 0.4-1.0% of the cross-linking agent composition, 0.3-1.0% of a cleanup additive, 0.5-1.0% of potassium chloride, 0.01-0.1% of a capsule breaker, and the balance of water, the densifier is polyacrylamide, and the cross-linking agent composition comprises, by mass, 20.0-30.0% of zinc acetate, 5.0-10.0% of aluminum chloride, 10.0-20.0% of glycerol, and balance of water. The acidic pad fluid keeps high viscosity in acidifying reconstruction, has multiple effects of fracture forming, filtration reducing and acidifying, and realizes high-temperature reservoir deep acid fracturing reconstruction.

Owner:PETROCHINA CO LTD

High-temperature resistant viscosity-increasing filtration-loss reducing agent and preparation method thereof used for drilling fluid

InactiveCN102911648ANo pollutionGood viscosity increasing effectDrilling compositionEthylene diamineFiltration

The invention relates to a high-temperature resistant viscosity-increasing filtration-loss reducing agent and a preparation method thereof used for a drilling fluid. The viscosity-increasing filtration-loss reducing agent is prepared by adopting the method: adding waste polyacrylonitrile fibre yarns, alkali and ethylene diamine into water, and reacting for 2-9h at a temperature of 90-95 DEG C; cooling down to below 30 DEG C, adding acrylamide, acrylic acid, 2-acrylamido-2-methyl propanesulfonic acid and an initiating agent, heating up to 30-50 DEG C, and continuing reacting for 1-5h; and taking out a product, drying, crushing, and uniformly mixing with auxiliary materials to obtain the high-temperature resistant viscosity-increasing filtration-loss reducing agent. The high-temperature resistant viscosity-increasing filtration-loss reducing agent has the advantages of simple preparation technology, low cost, good viscosity-increasing performance and filtration-loss reducing function, good compatibility with the drilling fluid, no pollution to the environment, and capability of resisting high temperature above 180 DEG C.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Carboxyl-modified graphene graft polymer and its preparation method and application

ActiveCN112574368BImprove temperature resistanceLow API filtration lossDrilling compositionOil phaseGraphene

The invention relates to the field of petroleum exploitation, and discloses a carboxyl-modified graphene graft polymer as well as a preparation method and application thereof. The method comprises: (1) dissolving acrylamide, benzenesulfonic acid, and N-vinylpyrrolidone in water, adding carboxyl-modified graphene, and adding a first emulsifier to obtain an aqueous phase system; adding the second emulsifier Dissolve in the oil phase to obtain an oil phase system; (2) prepare an inverse emulsion system by combining the water phase system with the oil phase system; (3) perform the first polymerization reaction on the inverse emulsion system , to obtain an intermediate product system; the intermediate product system is carried out to a second polymerization reaction to obtain a pre-product; (4) the pre-product is purified, dried and pulverized to obtain a carboxyl-modified graphene graft polymer; wherein , the oxygen element content in the XPS test result of the carboxyl-modified graphene is not less than 26wt%. The polymer provided by the invention is used as a fluid loss reducer for drilling fluid and has excellent temperature and salt resistance.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

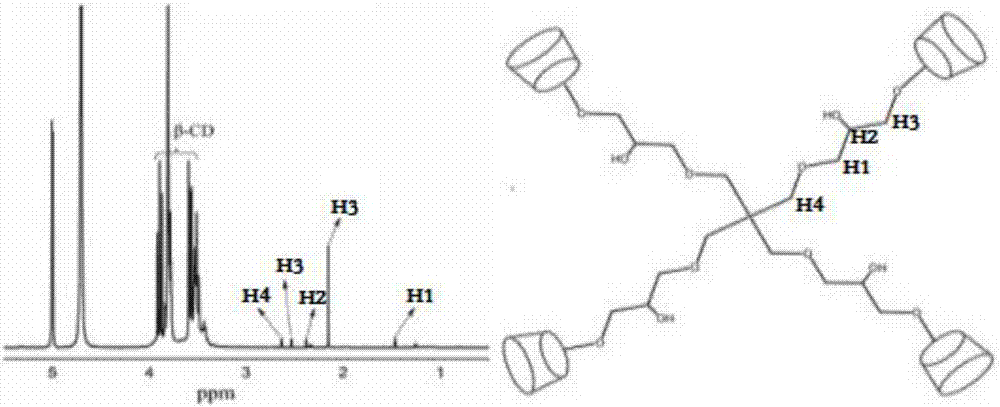

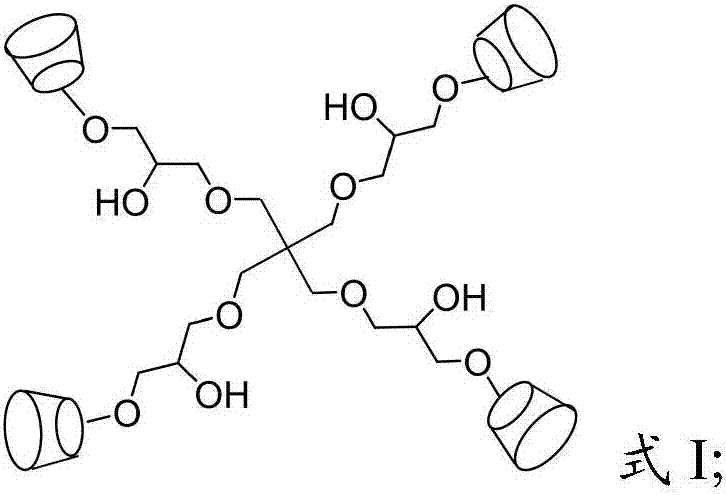

Neopentane beta-cyclodextrin hydroxypropyl tetraether and preparation method and application thereof

InactiveCN107011465AImprove high temperature resistanceImprove salt resistanceDrilling compositionSalt resistanceNeopentane

The invention provides neopentane beta-cyclodextrin hydroxypropyl tetraether and a preparation method and application thereof. The neopentane beta-cyclodextrin hydroxypropyl tetraether is a tetrapod compound, structurally comprises four beta-cyclodextrin groups, is high in beta-cyclodextrin group cavity proportion, can form a supermolecule clathrate compound with polymer or surfactant in drilling fluid, is high in high temperature resistance, good in salt resistance and stable in rheological property, can have an excellent filter loss lowering effect under the downhole high temperature condition and is promising in application prospect.

Owner:JILIN INST OF CHEM TECH

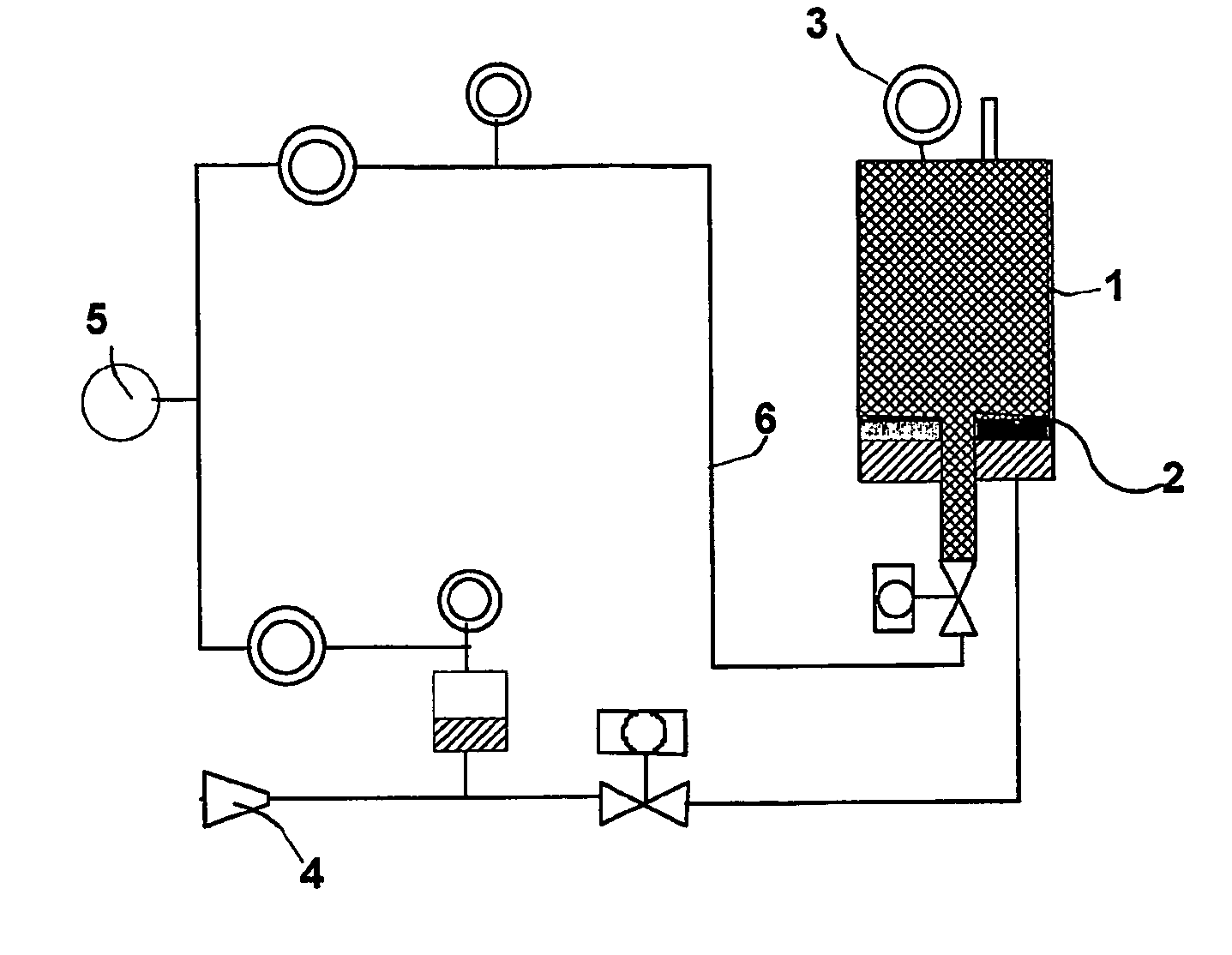

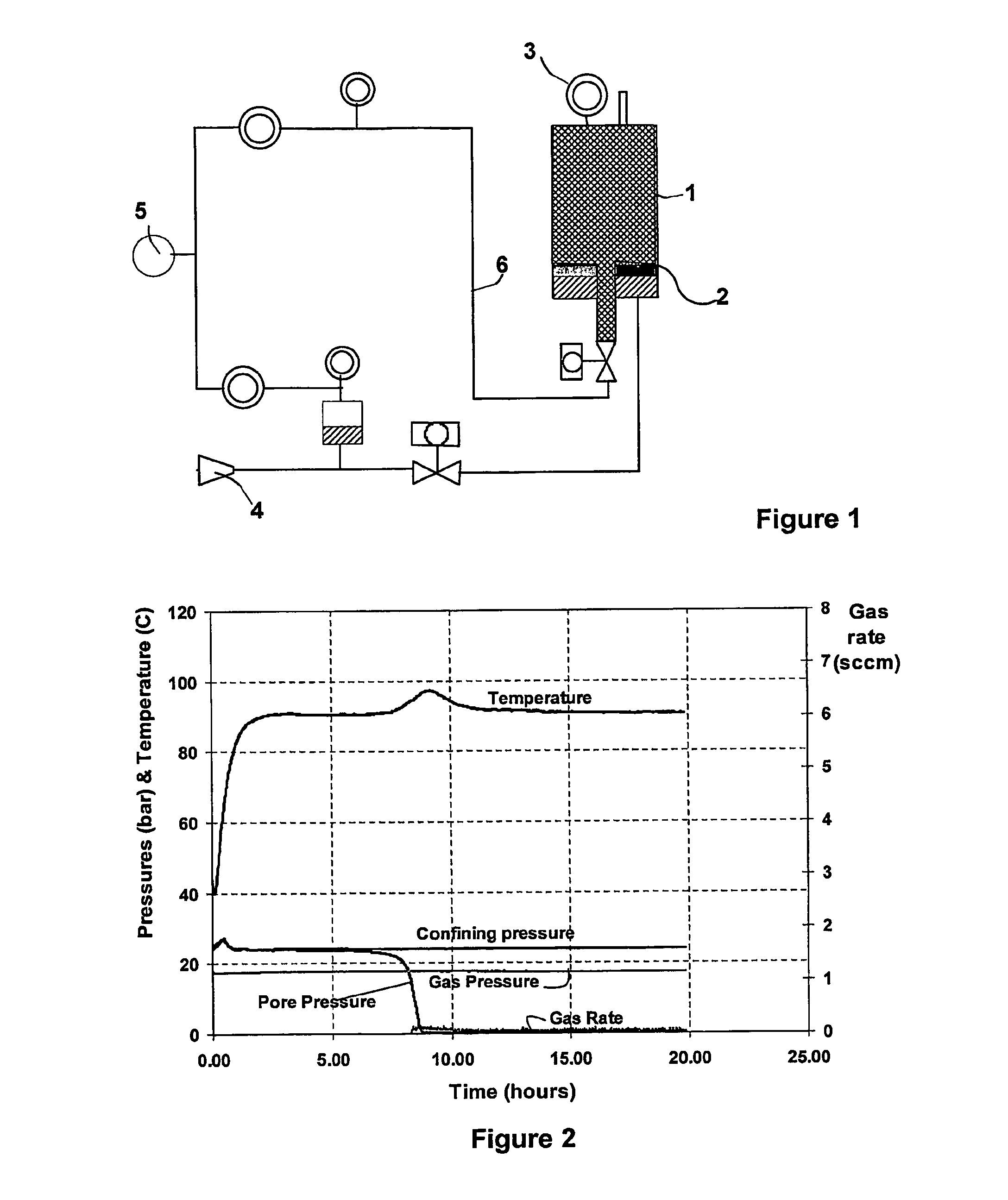

Control of the properties of cement slurries of normal densities with optimized polymers combination

ActiveUS8124569B2Good fluid loss controlImprove performanceFlushingDrilling compositionSulfonateNormal density

Owner:SCHLUMBERGER TECH CORP

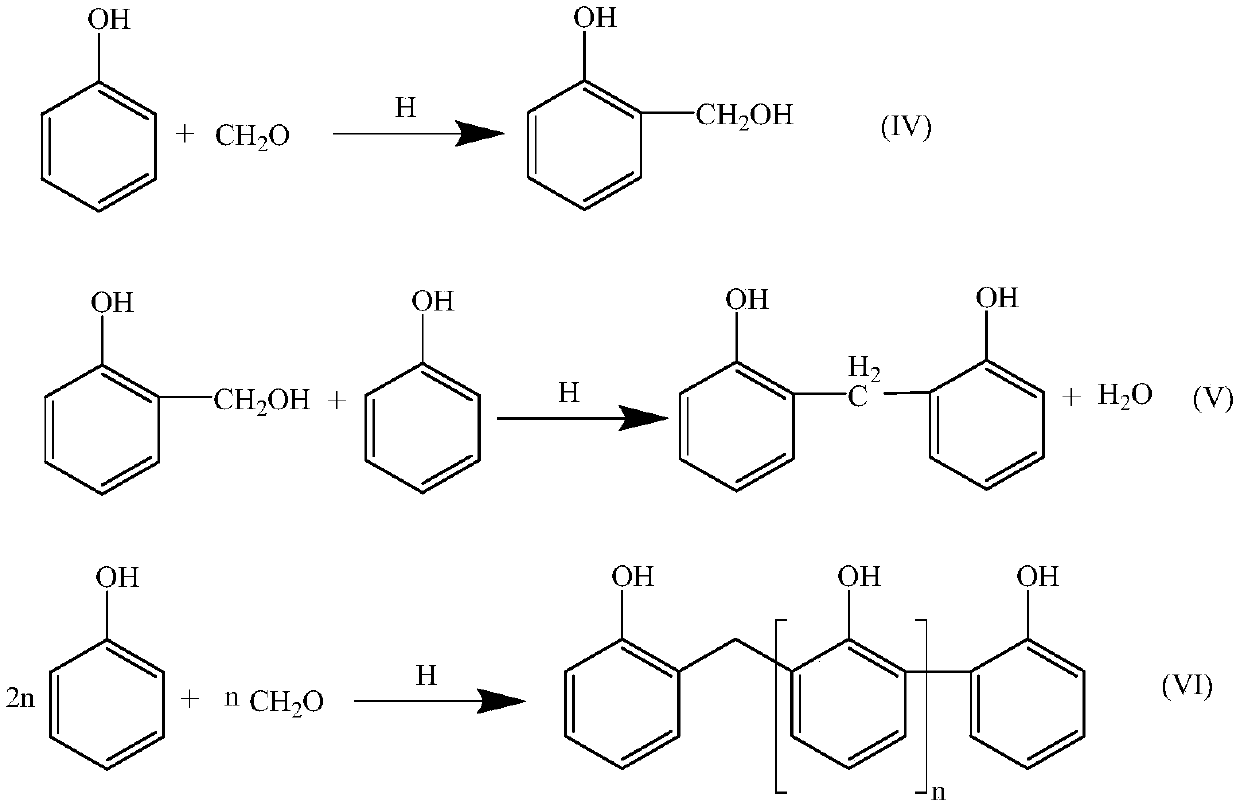

Filtrate reducer for drilling fluid and preparation method thereof

ActiveCN110607168AReduced desorptionHigh bond energyDrilling compositionCarboxymethyl celluloseAluminium chlorohydrate

The invention discloses a filtrate reducer for drilling fluid and a preparation method thereof. The filtrate reducer comprises sulfonated resin, polymer microcrystals, polyaluminum chloride, carboxymethyl cellulose and calcium carbonate. The sulfonated resin is preferably sulfomethyl phenolic resin, and the polymer microcrystals are preferably modified microcrystalline cellulose. The preparation method comprises the following steps: uniformly mixing polyaluminum chloride, sodium carboxymethyl cellulose and calcium carbonate to obtain mixed powder A, heating the polymer microcrystals to 55-60 DEG C, adding the heated polymer microcrystals and the mixed powder A into sulfonated resin, and uniformly stirring all the materials to obtain the filtrate reducer. The filtrate reducer provided by the invention can effectively solve the problems that the drilling speed is reduced and the environmental pollution is caused by the existing filtrate reducer.

Owner:重庆威能钻井助剂有限公司 +1

Cellulose nanocrystal used as water-based drilling fluid anti-collapse agent and preparation method of cellulose nanocrystal

InactiveCN108559463ANo fluorescenceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention relates to a cellulose nanocrystal used as a water-based drilling fluid anti-collapse agent and a preparation method of the cellulose nanocrystal and belongs to the field of petroleum and natural gas resource exploration and development and natural polymer material preparation. The cellulose nanocrystal used as the water-based drilling fluid anti-collapse agent is prepared from, by weight, 3-12% of cellulose pulp, 54-75% of oxalate dihydrate, 0.25-3.5% of high-priced metal salt and balance water, and made by a reaction at 95-100 DEG C for 7-16 hours under mechanical stirring conditions. The product size is 100-700nm, the cellulose nanocrystal has the advantages of being excellent in anti-collapse capability, free of toxicity and fluorescence, environmentally friendly and thelike and also has good filtrate loss performance, and the temperature resistance is up to 180 DEG C. Since the cellulose nanocrystal is prepared by using natural biomaterials, the cellulose nanocrystal automatically degrades after a period of time to achieve automatic deblocking, and damage to a reservoir is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

High-softening point emulsified asphalt water-based drilling fluid additive and preparation method thereof

ActiveCN102952526BGood miscibilityMeet high temperature and high pressure requirementsDrilling compositionWater basedPolymer science

A high-softening point emulsified asphalt water-based drilling fluid additive and a preparation method thereof. The drilling fluid additive comprises 40-70 wt% of asphalt with a softening point of 150 DEG C-240 DEG C, 35-50 wt% of water, 0.02-2 wt% of an auxiliary agent, 0.05-5 wt% of an emulsifier, and 0.01-1 wt% of a stabilizer; the charge of the additive is anion; the storage stability for 1 day is not more than 1%; the storage stability for 5 day is not more than 5%; the high-temperature high-pressure filter loss at 220 DEG C and at 3.45 MPa is not more than 25 ml. The preparation method of the additive comprises the following steps: mixing water, the anion emulsifier, the stabilizer, and the auxiliary agent, then adding the asphalt fine powder with a softening point of 150 DEG C-240 DEG C into the above solution, and stirring. The drilling fluid additive provided by the invention has good high-temperature high-pressure filter loss effect, and is suitable for drilling of high-temperature high-pressure deep wells and extradeep wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

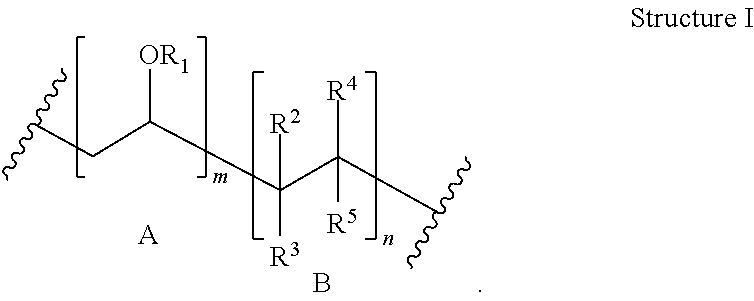

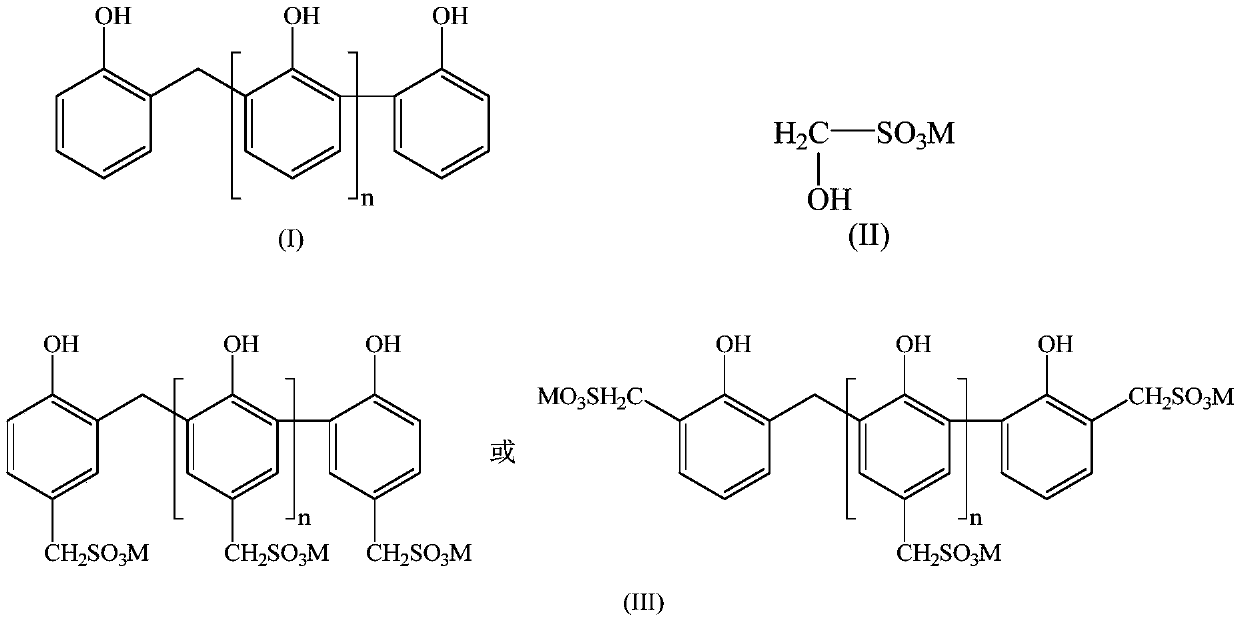

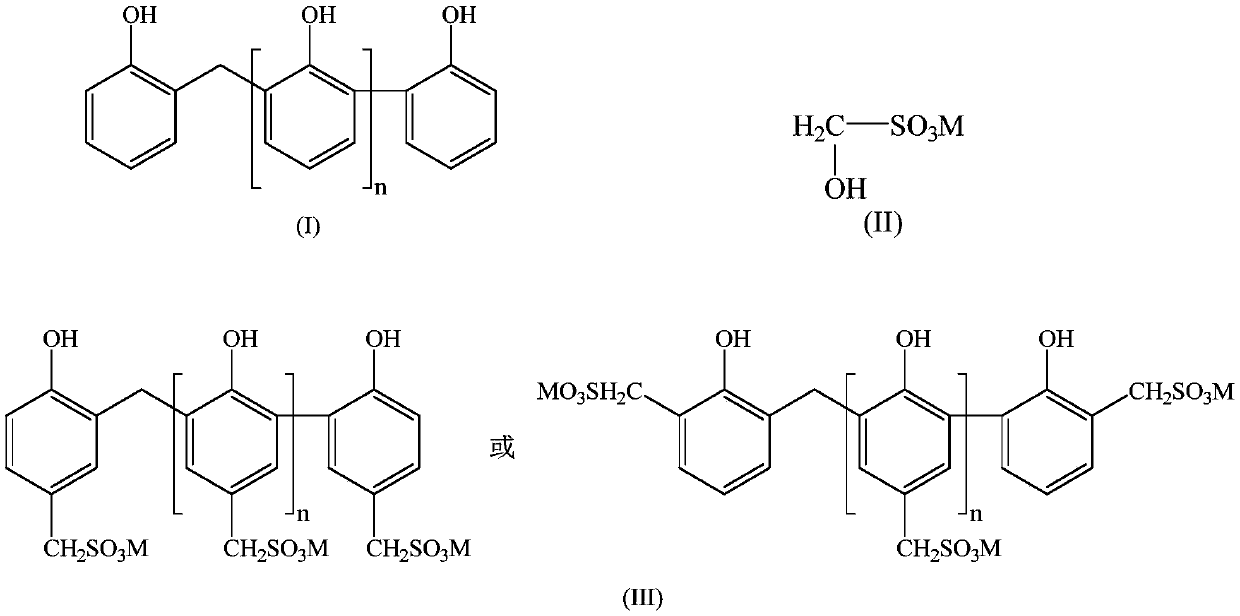

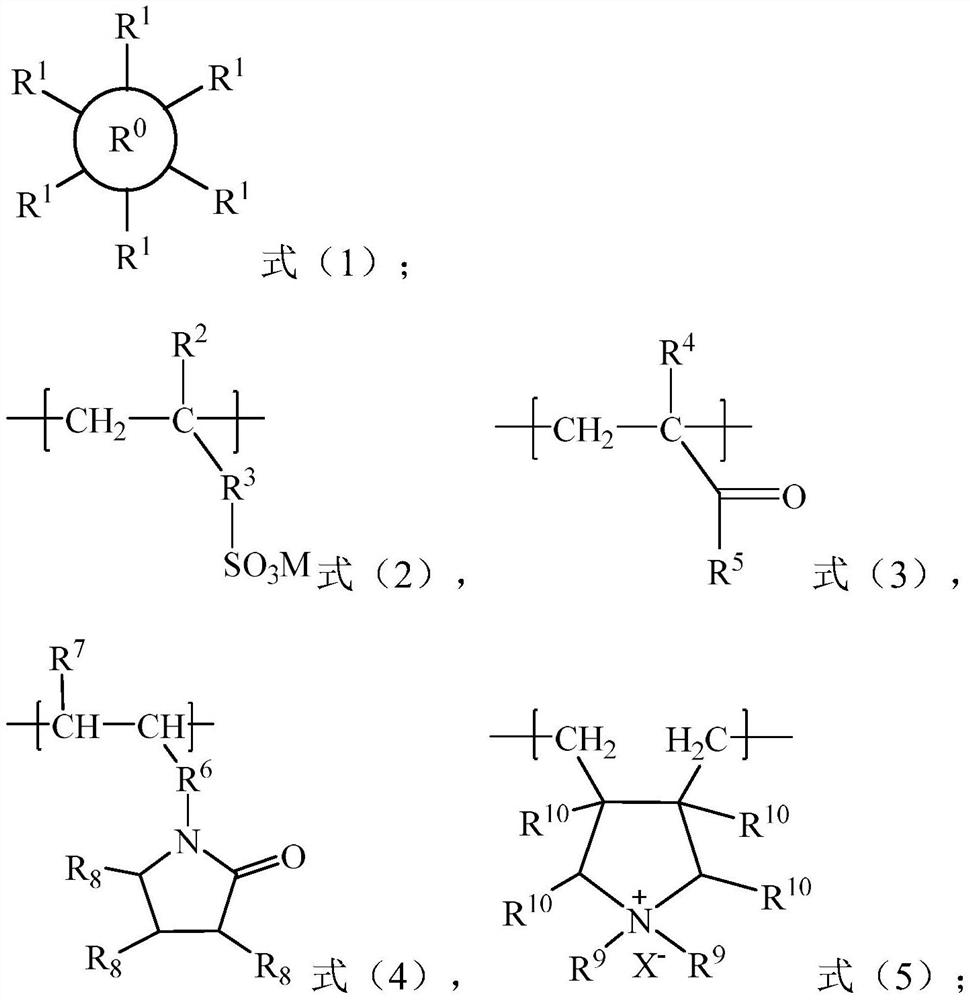

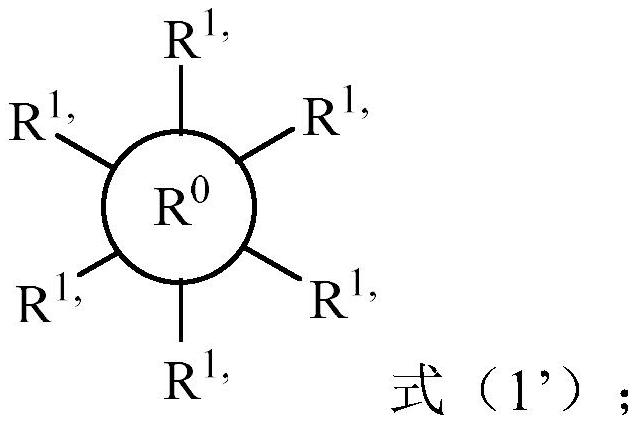

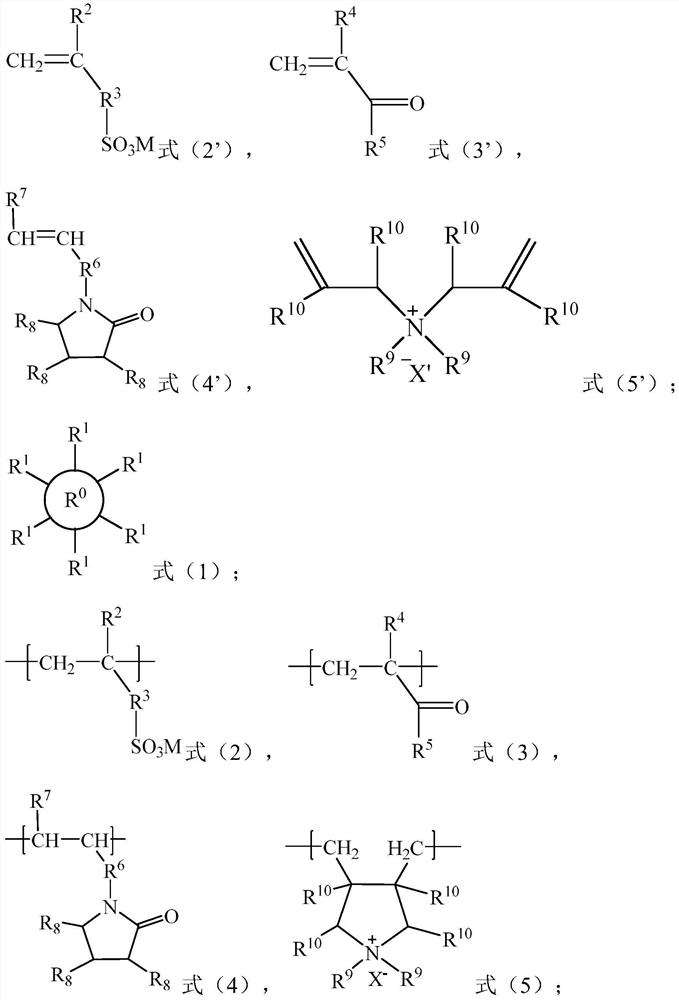

Star-structure copolymer for reducing filtration loss, preparation method and application of star-structure copolymer, drilling fluid and application of drilling fluid

ActiveCN113024746AGood fluid loss controlReduce fluid lossDrilling compositionPolymer scienceWell drilling

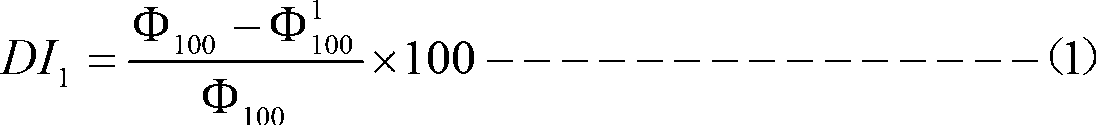

The invention relates to the field of drilling in the petroleum industry, and discloses a star-structure copolymer for reducing filtration loss, a preparation method and application of the copolymer, drilling fluid and application of the drilling fluid. The copolymer contains a structural unit A, a structural unit B, a structural unit C, a structural unit D and a structural unit E, The copolymer is selected from at least one of structural units with structures as shown in a formula (1), a formula (2), a formula (3), a formula (4) and a formula (5), and the number-average molecular weight of the copolymer is 150,000-900,000; When the copolymer is used for a filtrate reducer of the drilling fluid, good high-temperature-resistant and high-calcium-resistant effects and an excellent filtrate reduction effect can be obtained, and the copolymer is suitable for deep well and ultra-deep well operation and can maintain relatively good borehole wall stability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

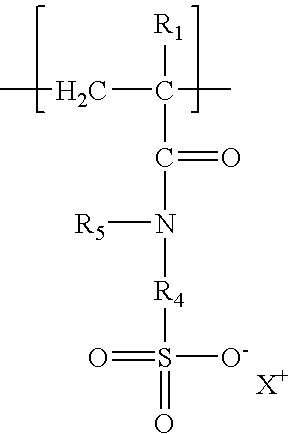

Fluid loss control agents and compositions for cementing oil and gas wells comprising said fluid loss control agent

InactiveUS8962710B2Reduce the amount requiredGood fluid loss controlDrilling compositionSealing/packingWater solubleButadiene-styrene rubber

It is proposed a new fluid loss control agent useful for the cementation of oil or gas wells. This fluid loss control agent consists of a mixture of a styrene-butadiene latex and a high molecular weight water-soluble polymer such as a copolymer AMPS-Am. The addition of the water-soluble polymer allows drastic reduction of the quantity of latex required to achieve fluid loss control performance and even gas migration control.

Owner:SCHLUMBERGER TECH CORP

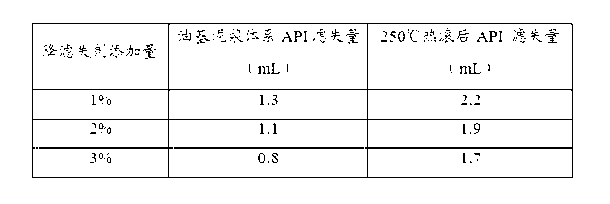

AM (Acrylamide)/DMDAAC (Dimethyl Diallyl Ammonium Chloride)/cyclodextrin polymer filtrate reducer and preparation method thereof

InactiveCN101818051BThe preparation method is simple and feasibleMild reaction conditionsDrilling compositionNitrogen gasPetroleum

The invention relates to an AM (Acrylamide) / DMDAAC (Dimethyl Diallyl Ammonium Chloride) / cyclodextrin polymer filtrate reducer used in petroleum and gas drilling fluid and a preparation method thereof. The invention can solve the technical problems that a well wall is not stable as water loss increases at the pit bottom under the condition of high temperature, and the like. The AM / DMDAAC / cyclodextrin polymer filtrate reducer is characterized by comprising three monomers of AM, DMDAAC and cyclodextrin; the preparation method comprises the following steps of: firstly adding the AM and the DMDAACinto an allyl cyclodextrin water solution according to the mol ratio among the allyl cyclodextrin water solution, the AM and the DMDAAC of 69.2-84.2:30-15:0.8 in sequence; then adding a chelating agent, an oxidant and a reducing agent in sequence; finally evenly mixing, then injecting nitrogen for 20-40min and deoxidizing, and reacting at 30-50 DEG C for 6-8h to obtain the AM / DMDAAC / cyclodextrin polymer filtrate reducer. The preparation method of the polymer is simple, convenient and available and mild in reaction conditions; and the polymer has good filtrate reduction effect in the drilling fluid, is resistant to temperature up to more than 250 DEG C and used in the petroleum and gas drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Control of the Properties of Cement Slurries of Normal Densities With Optimized Polymers Combination

ActiveUS20100018708A1Improve performanceGood fluid loss controlFlushingDrilling compositionSulfonateNormal density

Owner:SCHLUMBERGER TECH CORP

High temperature and salt resistant fluid loss reducer for drilling fluid and preparation method thereof

ActiveCN104263329BHigh degree of polymerizationExtended reaction timeDrilling compositionFiltrationTemperature resistance

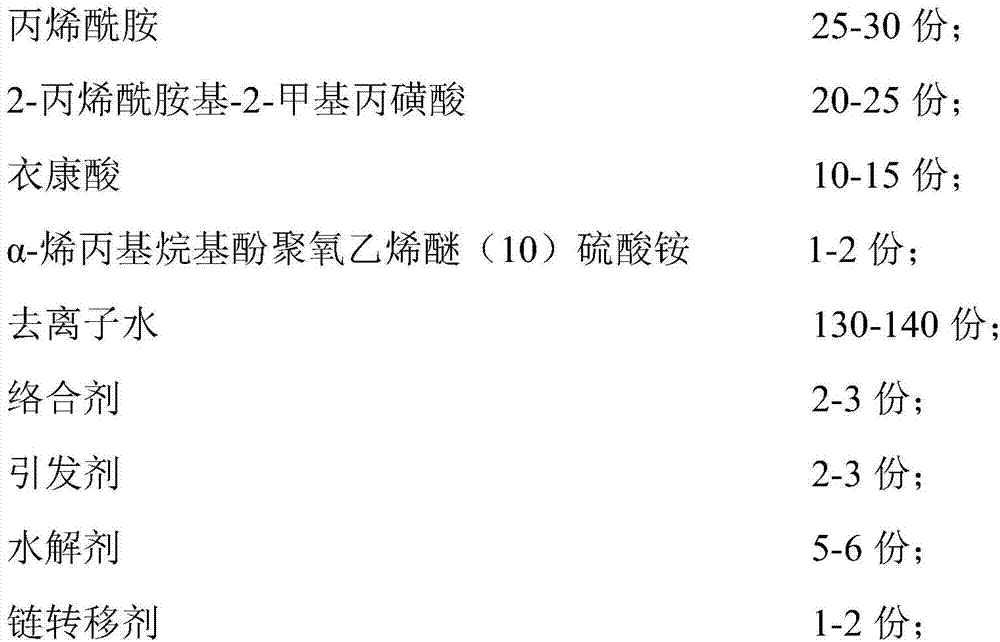

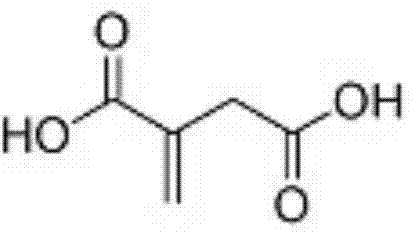

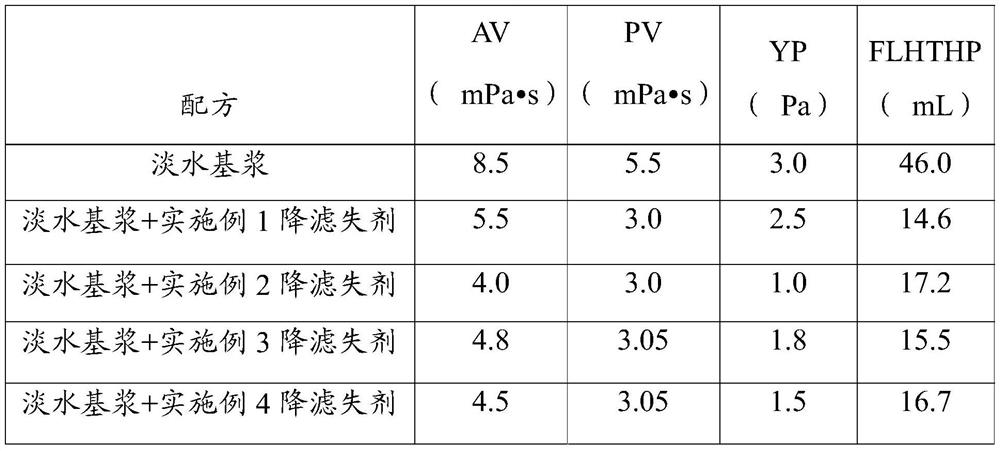

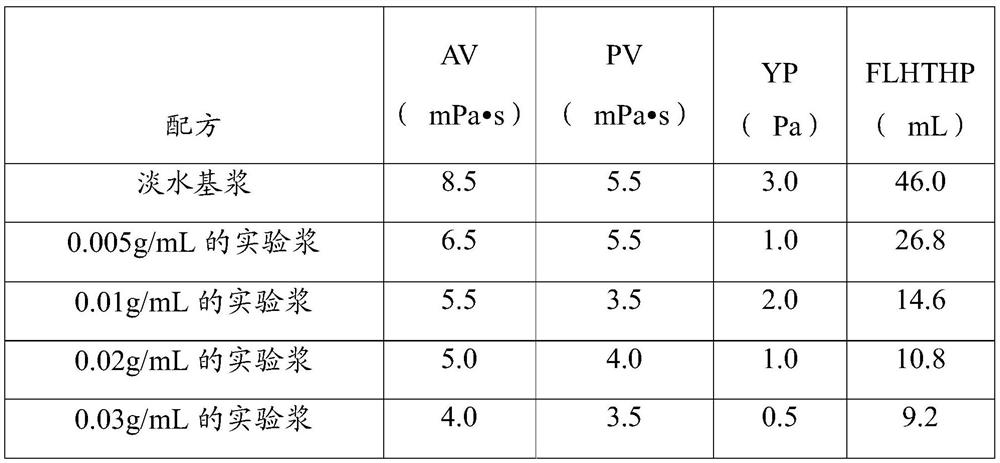

The invention discloses a high-temperature resistant and salt-tolerance filtrate reducer for drilling fluid. The method comprises the following steps: copolymerizing three monomers, namely acrylamide, 2-acrylamido-2-methyl-propanesulfonic acid and itaconic acid by using an emulsion polymerization method to obtain a copolymer, and then hydrolyzing under an alkaline condition; and participating and drying to obtain the filtrate reducer. The filtrate reducer has relatively good thermal stability and strong temperature resistance; after 0.5%-1% of high-temperature resistant filtrate reducer is added, the filtrate reducer disclosed by the invention has a good filtration reduction effect in fresh water, saline water, composite saline water and saturated brine drilling liquid. The invention also provides an emulsion polymerization method of the high-temperature resistant and salt-tolerance filtrate reducer for the drilling fluid. In comparison with a conventional polymerization method, the polymerization method disclosed by the invention has the advantages that the polymerization rate and the polymerization degree are obviously improved, the reaction time is obviously reduced, and the production cost is reduced under the premise of good product properties.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

An environment-friendly high temperature and salt resistant calcium modified natural polymer fluid loss reducer

ActiveCN111171796BImprove adsorption capacityGood fluid loss controlDrilling compositionPetroleum engineeringCalcium carbonate

The invention relates to an environment-friendly high temperature and salt resistant calcium modified natural polymer fluid loss reducer. Its technical solution is: it is made of the following components, by mass percentage: 20%-30% of modified starch, 3%-8% of partially hydrolyzed polyacrylamide, 3%-5% of aluminum citrate, and 10% of superfine calcium carbonate %‑20%, the balance is water. Beneficial effects are: the present invention is aimed at the downhole complex situation of high-temperature deep well drilling, especially the brine layer, salt rock layer, salt-gypsum layer, and gypsum-mud layer. High temperature and salt-resistant calcium fluid loss reducer is the key to improving the wall-building ability of drilling fluid; the product prepared by the present invention has outstanding fluid loss reducing effect, strong wall-building, temperature resistance up to 150°C and above, salt resistance to saturation, Resistant to 0.5% CaCl 2 . The product has good compatibility with other treatment agents, is non-toxic and environmentally friendly, and can also be used as a protection material for drilling fluid oil and gas layers.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Preparation method of filtrate reducer and filtrate reducer

PendingCN114507319AGood filter loss reduction effectAdd lessDrilling compositionMaleic anhydrideMeth-

The invention discloses a preparation method of a filtrate reducer and the filtrate reducer, and belongs to the technical field of well drilling. The preparation method comprises the following steps: carrying out polymerization reaction on preparation raw materials to obtain the filtrate reducer, wherein the preparation raw materials comprise the following components in parts by weight: 5-20 parts of a first anionic monomer, 15-22 parts of a second anionic monomer, 18-30 parts of a hydrophobic monomer, 4-15 parts of a cationic monomer, 0.6-0.8 part of an initiator, 40-60 parts of water and 12-20 parts of a pH regulator. The first anionic monomer is maleic anhydride and / or acrylic acid; and the second anionic monomer is 2-acrylamide-2-methylpropanesulfonic acid and / or sodium allysulfonate. The prepared filtrate reducer not only can resist temperature and salt, but also is safer and more environment-friendly, and is especially suitable for deep well or ultra-deep well operation.

Owner:PETROCHINA CO LTD

Multifunctional treating agent for natural gas hydrate drilling fluid in sea area as well as preparation method and application of multifunctional treating agent

The invention provides a multifunctional treating agent for natural gas hydrate drilling fluid in sea areas as well as a preparation method and application of the multifunctional treating agent. The multifunctional treating agent disclosed by the invention is prepared from the following raw materials in parts by mass: 0.1 to 10 parts of modified cellulose, 2 to 8 parts of dimethyl diallyl ammonium chloride (DMDAAC), 10 to 20 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 0.02 to 0.08 part of an initiator, the modified cellulose is cellulose modified by dimethoxy methyl vinyl silane. The multifunctional treating agent for the natural gas hydrate drilling fluid can effectively inhibit hydrate decomposition, improve the low-temperature filtration property of the drilling fluid, improve the stability of a hydrate reservoir and a wellbore and guarantee safe and smooth proceeding of hydrate drilling engineering; and the paint has salt resistance, and is environment-friendly and safe.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com