Star-structure copolymer for reducing filtration loss, preparation method and application of star-structure copolymer, drilling fluid and application of drilling fluid

A technology for copolymer and fluid loss reduction, applied in the field of drilling fluids, can solve the problem that the copolymer fluid loss reducer cannot have both temperature resistance and calcium resistance properties, etc., and achieves excellent fluid loss reduction effect, good high temperature resistance, good Anti-high calcium effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

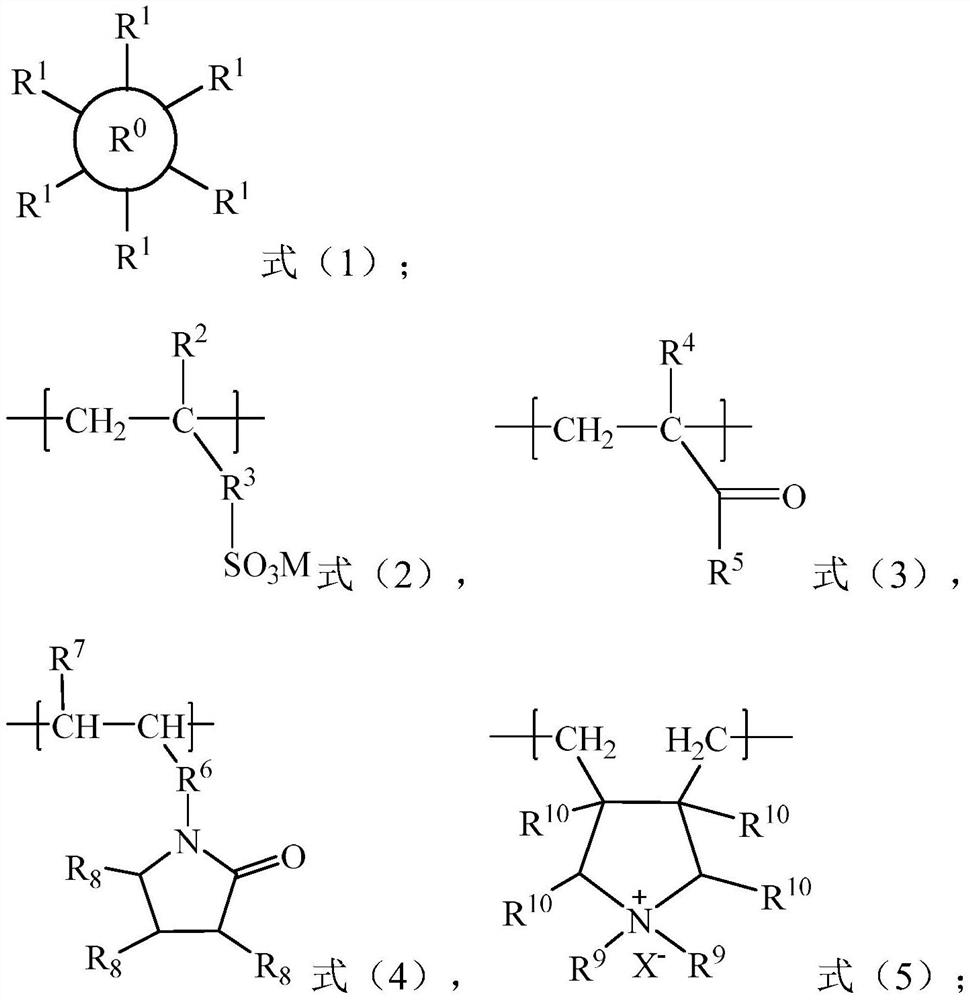

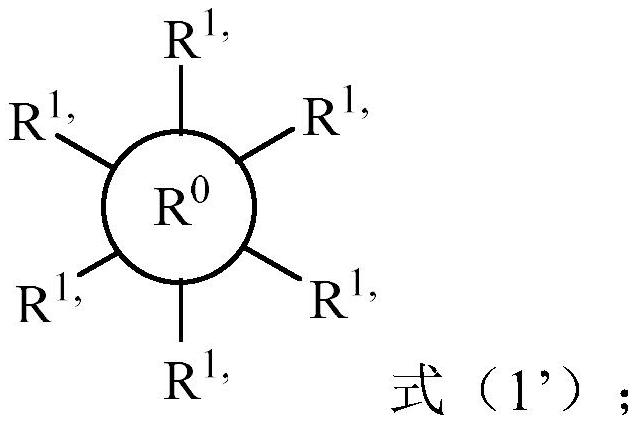

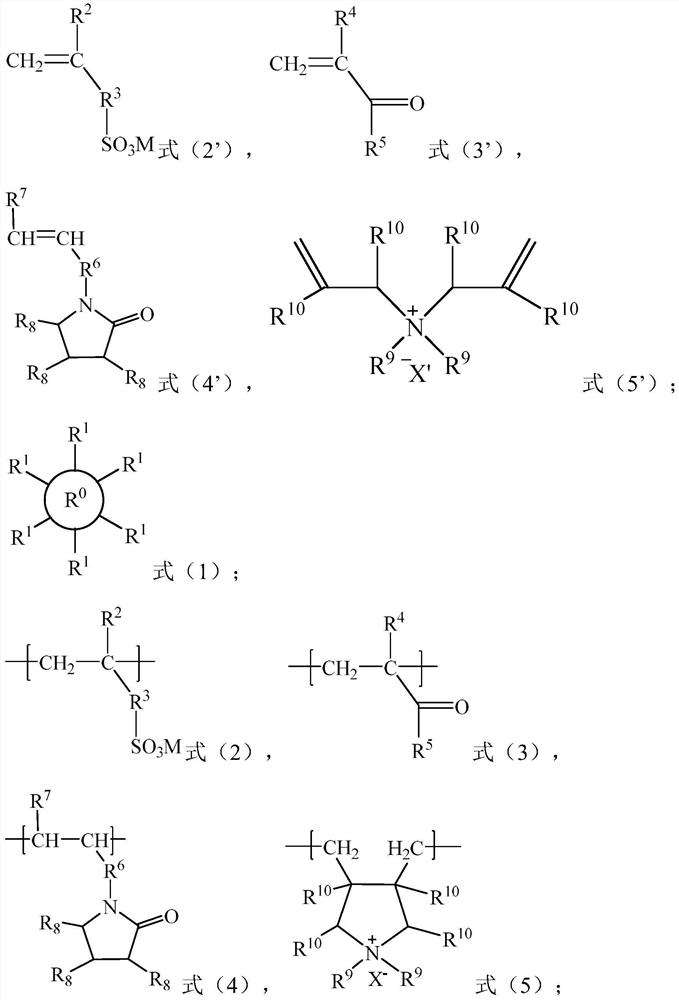

Method used

Image

Examples

specific Embodiment approach

[0151] In the present invention, according to a particularly preferred embodiment, the preparation method of the copolymer comprises the following steps:

[0152] (1) Mixing the monomer A' with the aqueous solvent I, the conditions of the mixing I include: the temperature is 10-15°C, and the time is 10-30min;

[0153] (2) introducing the redox free radical initiation system into the product in step (1) to carry out free radical polymerization, the conditions of the free radical polymerization include: the temperature is 5-20°C, and the time is 12- 24h, the stirring speed is 100-400rpm;

[0154] (3) The monomer B', the monomer C', the monomer D', and the monomer E' are mixed II, and the conditions of the mixing II include: the temperature is 10-50°C, The time is 10-60min, the pH value is 7-9, and an inert atmosphere is optionally introduced and maintained;

[0155] (4) Introducing the product in step (3) into the product in step (2) to carry out free radical polymerization, t...

preparation example 1

[0211] Fluid loss reducer: Add 0.0166mol of nano-silica monomer A' into vacuum bottle I containing 50g of distilled water, ultrasonically disperse for 2h at a frequency of 40KHz, then cool down to 10°C with liquid nitrogen, and pass nitrogen for 30min, then Add the redox system ammonium persulfate / sodium bisulfite (mass ratio 1:1) aqueous solution of 2 weight ‰ of the mass of monomer A', and react at a stirring speed of 300 rpm at 10°C for 12 hours; add 0.1352 mol of 2-propene Amide-2-methylpropanesulfonic acid, 0.0564mol of N,N-dimethylacrylamide, 0.0504mol of N-vinylpyrrolidone and 0.1040mol of dimethyl diallyl ammonium chloride were added to a container containing 50g of distilled water In the vacuum bottle II, stir at 300rpm for 20min, adjust the pH value to 7 with sodium hydroxide aqueous solution, then use liquid nitrogen to cool down to 10°C, pass nitrogen gas for 30min, and then transfer the system in the vacuum bottle II to the vacuum bottle I. React for 12 hours; fre...

preparation example 2

[0213] This preparation example adopts the method similar to preparation example 1 to carry out, and difference is, in this preparation example, nano silicon dioxide monomer A ' is not carried out ultrasonic dispersion when mixing with distilled water;

[0214] Other conditions were the same, and the fluid loss control agent A2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com