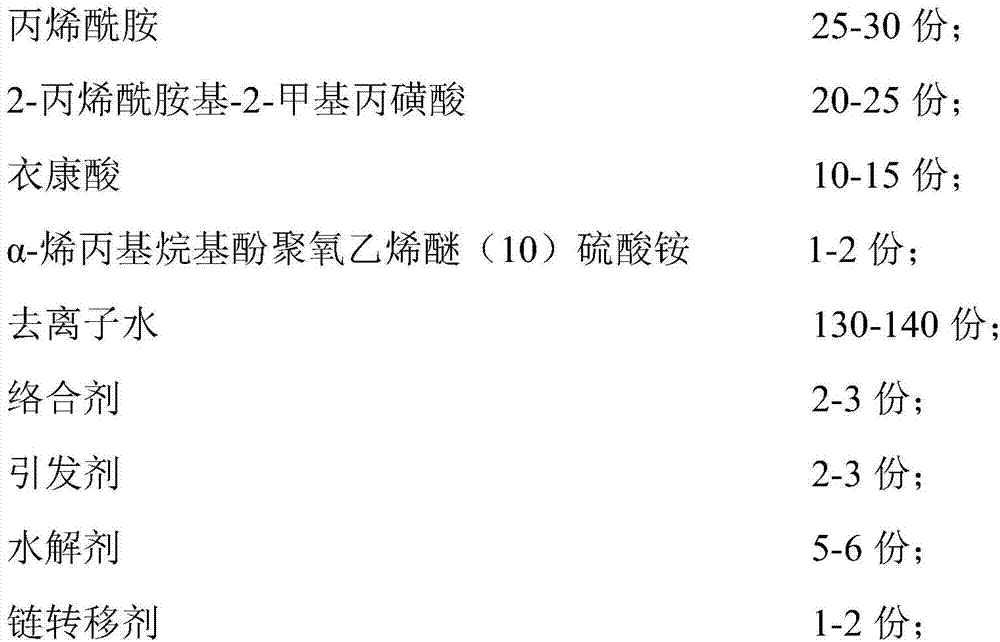

High temperature and salt resistant fluid loss reducer for drilling fluid and preparation method thereof

A fluid loss reducer, high temperature resistant technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of inability to take into account rheology, increase production costs, and high production costs, and achieve high-efficiency resistance to high temperature fluid loss reduction. The effect of reducing the production cost and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

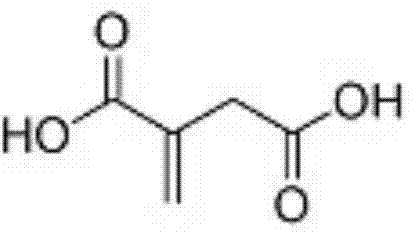

[0040] (1) Add 2g of special monomer into 134mL of deionized water, stir to dissolve completely, add 25.2g of acrylamide, 24g of 2-acrylamido-2-methylpropanesulfonic acid, 10.8g of itaconic acid, stir to dissolve into the total A mixed aqueous solution with a concentration of about 30% by mass.

[0041] (2) Add the mixed solution to the reactor, add 2.4 mL of 5 wt% EDTA solution, stir and heat up, and pass nitrogen for protection for 30 minutes;

[0042] (3) The temperature was increased to 55°C, and 3wt% of ammonium persulfate and 2 mL of sodium bisulfite were added, maintaining the reaction temperature, and reacting for 4 hours;

[0043] (4) Add 5g NaOH and 2mL isopropanol, stir well for 30min to obtain a viscous liquid;

[0044] (5) The viscous liquid is washed with absolute ethanol to obtain a white precipitate, dried at 105°C and pulverized to obtain a high temperature resistant fluid loss agent for drilling fluid.

Embodiment 2

[0046] (1) Add 1.5g of special monomer to 124mL of deionized water, stir to dissolve completely, add 29.4g of acrylamide, 28g of 2-acrylamido-2-methylpropanesulfonic acid, 12.6g of itaconic acid, stir to dissolve into A mixed aqueous solution with a total mass percentage concentration of about 35%.

[0047] (2) Put the mixed solution into the reactor, add 2.8mL 5wt% EDTA solution, stir and raise the temperature, and pass nitrogen protection for 40min;

[0048] (3) The temperature was raised to 50°C, and 2.3 mL each of 3wt% ammonium persulfate and sodium bisulfite were added, the reaction temperature was maintained, and the reaction was carried out for 5 hours;

[0049] (4) Add 6g NaOH and 2mL isopropanol, stir well for 20min to obtain a viscous liquid;

[0050] (5) The viscous liquid is washed with absolute ethanol to obtain a white precipitate, dried at 105°C and pulverized to obtain a high temperature resistant fluid loss agent for drilling fluid.

Embodiment 3

[0052] (1) Add 1.5g of special monomer into 134mL of deionized water, stir to dissolve completely, add 25.2g of acrylamide, 24g of 2-acrylamido-2-methylpropanesulfonic acid, 10.8g of itaconic acid, stir to dissolve into A mixed aqueous solution with a total mass percentage concentration of about 30%.

[0053] (2) Add the mixed solution to the reactor, add 2.4 mL of 5 wt% EDTA solution, stir and increase the temperature, and pass nitrogen for protection for 40 minutes;

[0054] (3) The temperature was increased to 55°C, 3wt% ammonium persulfate and sodium bisulfite each 3mL were added, the reaction temperature was maintained, and the reaction was carried out for 4.5h;

[0055] (4) Add 2.5g Na 2 CO 3 And 2mL 1,4-butanediol, fully stirred for 30min, to obtain a viscous liquid;

[0056] (5) The viscous liquid is washed with absolute ethanol to obtain a white precipitate, dried at 105°C and pulverized to obtain a high temperature resistant fluid loss agent for drilling fluid.

[0057] Perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com