Cross-linking agent composition, acidic pad fluid, and application of acidic pad fluid

A technology of pre-fluid and cross-linking agent, which is applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as reducing the fracture-making performance of pre-fluid, and achieve obvious effect, high viscosity, and obvious filtration reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

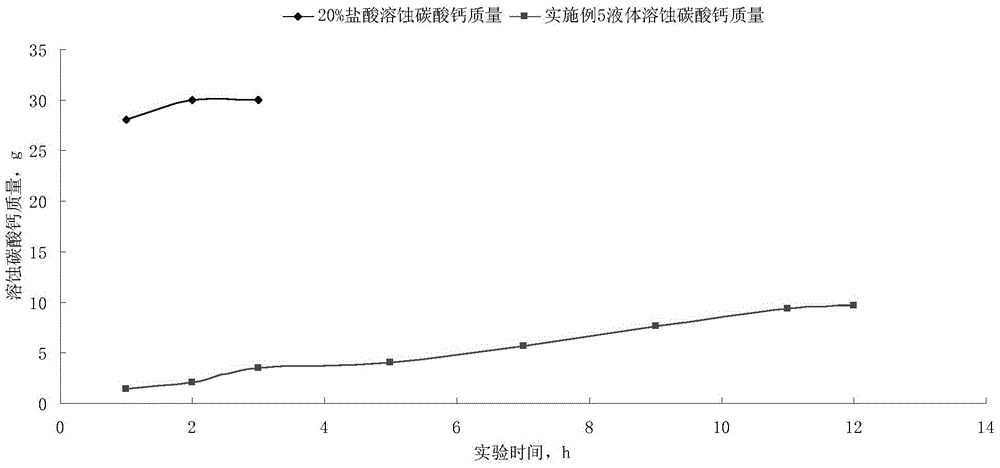

Examples

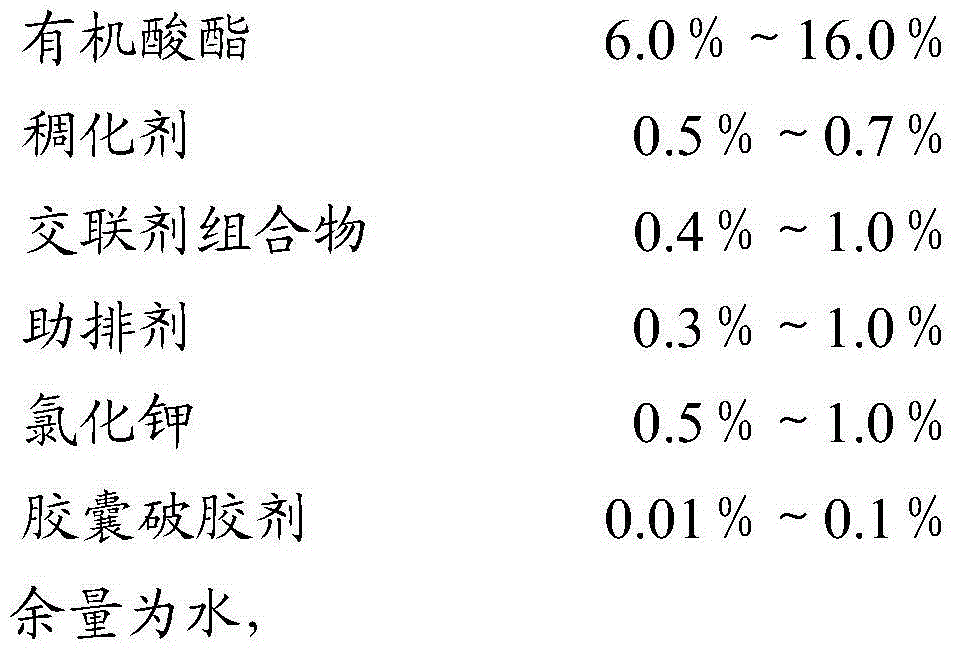

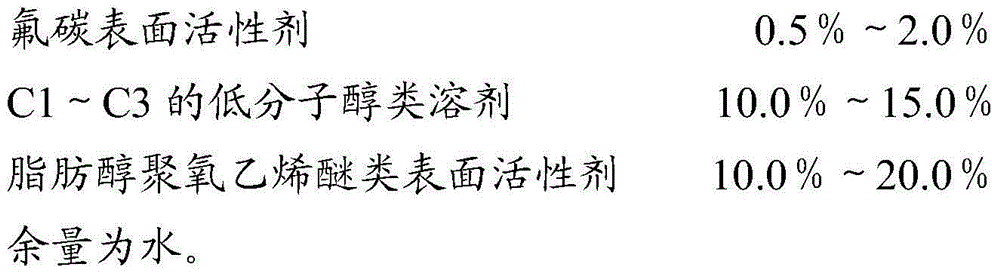

Embodiment 1

[0034] Measure 468mL of water and place it in a mixer, add 30.0g of methyl acetate and 3.0g of potassium chloride in sequence, stir for 1min to dissolve, then slowly add 2.75g of polyacrylamide thickener (molecular weight 4.30-4.8 million), and stir until Liquid thickening, add 2.0g drainage aid (mass percentage of drainage aid consists of 1.2% of FSN-100 fluorocarbon surfactant, 13% of ethanol, Pingping plus o-15 fatty alcohol polyoxyethylene ether surfactant 15.0 %, and the balance is water), stir for 30 minutes until uniform, leave for 1 to 2 hours, and prepare the pre-liquid base liquid for later use. Get 100mL of the prepared front liquid base liquid, add 0.02g potassium persulfate capsule gel breaker, 0.6g cross-linking agent composition successively (the mass percent of cross-linking agent composition is composed of: zirconium acetate 23.0%, aluminum chloride 8.0%, glycerol 15.0%, the balance is water), cross-linked to form jelly-like acidic pre-fluid, carry out followi...

Embodiment 2

[0036] Measure 437.5 mL of water and place it in a mixer, add 60.0 g of methyl acetate and 5.0 g of potassium chloride in sequence, stir for 1 min to dissolve, then slowly add 3.0 g of polyacrylamide thickener (molecular weight 360-4.1 million), and stir To liquid thickening, add 2.5g drainage aid (mass percentage of drainage aid consists of FSN-100 fluorocarbon surfactant 1.5%, ethylene glycol 12%, add o-15 fatty alcohol polyoxyethylene ether surface 16.0% active agent, the balance being water), stirring for 30 minutes until uniform, left for 1 to 2 hours, and prepared as a pre-liquid base liquid for later use. Take 100mL of the prepared front liquid base liquid, add 0.01g potassium persulfate capsule gel breaker, 0.7g cross-linking agent composition in sequence (the mass percentage of cross-linking agent composition is composed of: zirconium acetate 23.0%, aluminum chloride 6.0%, glycerol 15.0%, and the balance is water), cross-linked to form a jelly-like acidic pre-fluid, c...

Embodiment 3

[0038] Measure 457.5 mL of water and place it in a mixer, add 40.0 g of ethyl lactate and 2.5 g of potassium chloride in sequence, stir for 1 min to dissolve, then slowly add 2.75 g of polyacrylamide thickener (molecular weight 360-4.1 million), and stir To liquid viscosification, add 2.5g drainage aid (mass percentage of drainage aid consists of 1.2% of FSN-100 fluorocarbon surfactant, 15% of ethanol, plus o-15 fatty alcohol polyoxyethylene ether surfactant 16.0%, and the balance is water), stir for 30 minutes until uniform, leave for 1 to 2 hours, and prepare the pre-liquid base liquid for later use. Take 100mL of the prepared front liquid base liquid, add 0.05g of ammonium persulfate capsule gel breaker, 0.7g of crosslinking agent composition successively (the mass percentage of crosslinking agent composition is composed of: zirconium acetate 22.0%, aluminum chloride 9.0%, glycerol 16.0%, the balance is water), cross-linked to form jelly-like acidic pre-fluid, carry out fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com