Filtrate reducer for oil-based drilling fluids and production method thereof

A technology of oil-based drilling fluid and fluid loss reducer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increased solid content, poor chemical properties, and no better methods, etc., to achieve production The method is simple, the ROP is improved, and the emulsification ability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

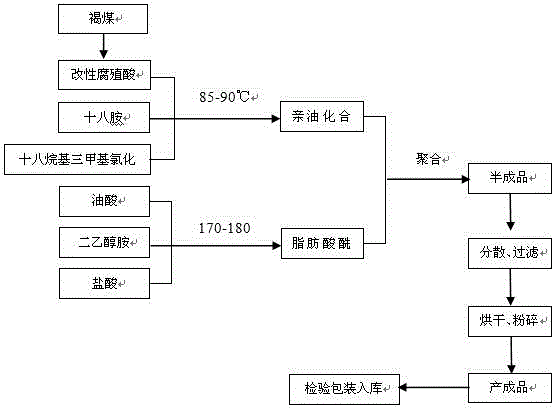

Embodiment 1

[0016] Example 1: Oil-based drilling fluid fluid loss reducer and its production method, humic acid is surface-modified with various surfactants, so that humic acid is grafted with an alkyl group with a long carbon chain, and the obtained product has Lipophilic emulsification properties, and then polymerized with ammonium salt, dispersed, filtered, dried, crushed to obtain the desired product. The specific operation steps are: dissolve 50kg of lignite in 5kg of caustic soda, add 150kg of water and stir for 2 hours, then filter and extract the humic acid solution; add 10kg of octadecylamine and 5kg of octadecane to the obtained humic acid solution Trimethylammonium chloride, heated in a water bath at 85°C for 3 hours to complete the reaction, through this step humic acid is grafted with lipophilic long-chain octadecyl; take 5g of oleic acid, 3g of diethanolamine and 3mL of concentrated hydrochloric acid and mix , stirred and heated at 170°C for 3 hours to obtain fatty acid amid...

Embodiment 2

[0017] Embodiment 2: fluid loss reducer for oil-based drilling fluid and its production method, humic acid is surface-modified with various surfactants, so that humic acid is grafted with an alkyl group with a long carbon chain, and the obtained product has Lipophilic emulsification properties, and then polymerized with ammonium salt, dispersed, filtered, dried, crushed to obtain the desired product. The specific operation steps are: dissolve 80kg of lignite in 15kg of caustic soda, add 200kg of water and stir for 2 hours, then filter and extract the humic acid solution; add 13kg of octadecylamine and 7kg of octadecane to the obtained humic acid solution Trimethyl ammonium chloride, heated in a water bath at 88°C for 5 hours to complete the reaction, and humic acid is grafted with lipophilic long-chain octadecyl; Take 8g of oleic acid, 6g of diethanolamine and 8mL of concentrated hydrochloric acid to mix , stirred and heated at 175°C for 4 hours to obtain fatty acid amide; mix...

Embodiment 3

[0018] Embodiment 3: oil-based drilling fluid fluid loss reducer and production method thereof, humic acid is surface-modified with various surfactants, so that humic acid is grafted with an alkyl group with a long carbon chain, and the obtained product has Lipophilic emulsification properties, and then polymerized with ammonium salt, dispersed, filtered, dried, crushed to obtain the desired product. The specific operation steps are: dissolve 100kg of lignite in 20kg of caustic soda, add 300kg of water and stir for 2 hours, then filter and extract the humic acid solution; add 15kg of octadecylamine and 10kg of octadecane to the obtained humic acid solution Trimethyl ammonium chloride, heated in a water bath at 90°C for 8 hours to complete the reaction, after this step humic acid is grafted with lipophilic long-chain octadecyl; take 10g of oleic acid, 8g of diethanolamine and 10mL of concentrated hydrochloric acid and mix , stirred and heated at 180°C for 5 hours to obtain fatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com