Method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures

A nano-silica and drilling fluid technology, applied in the field of oil and gas drilling, can solve the problems of inability to build bridges and the formation of mud cakes, and achieve obvious effects and obvious effects of reducing filtration loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

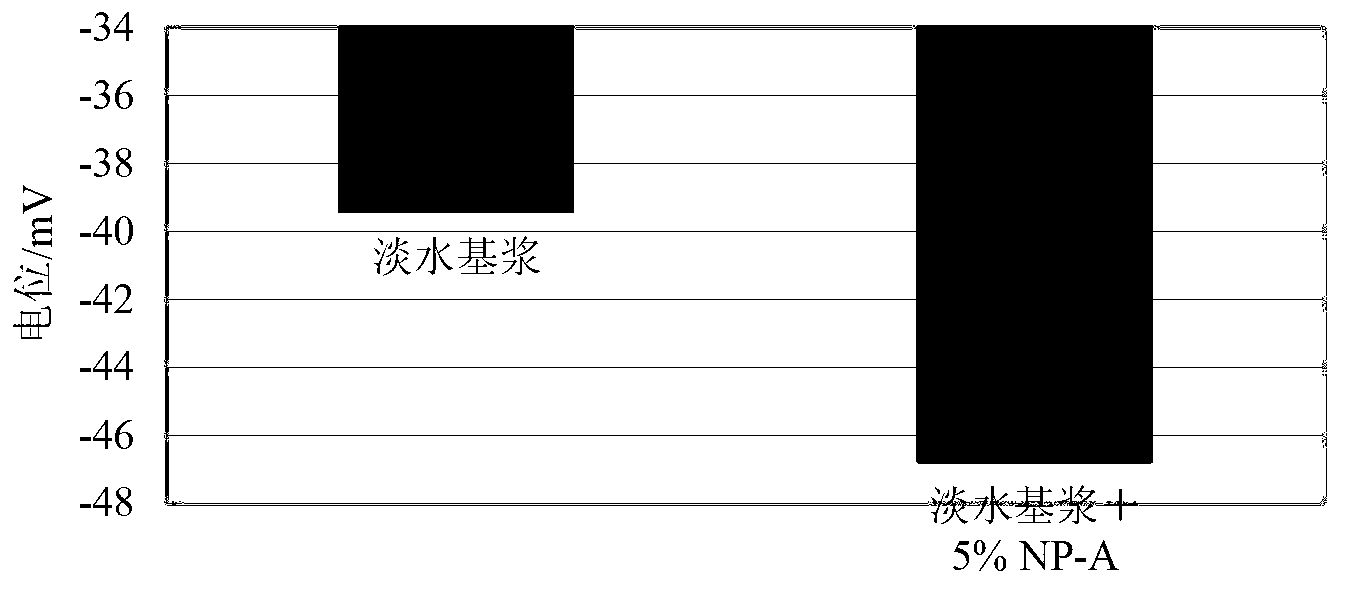

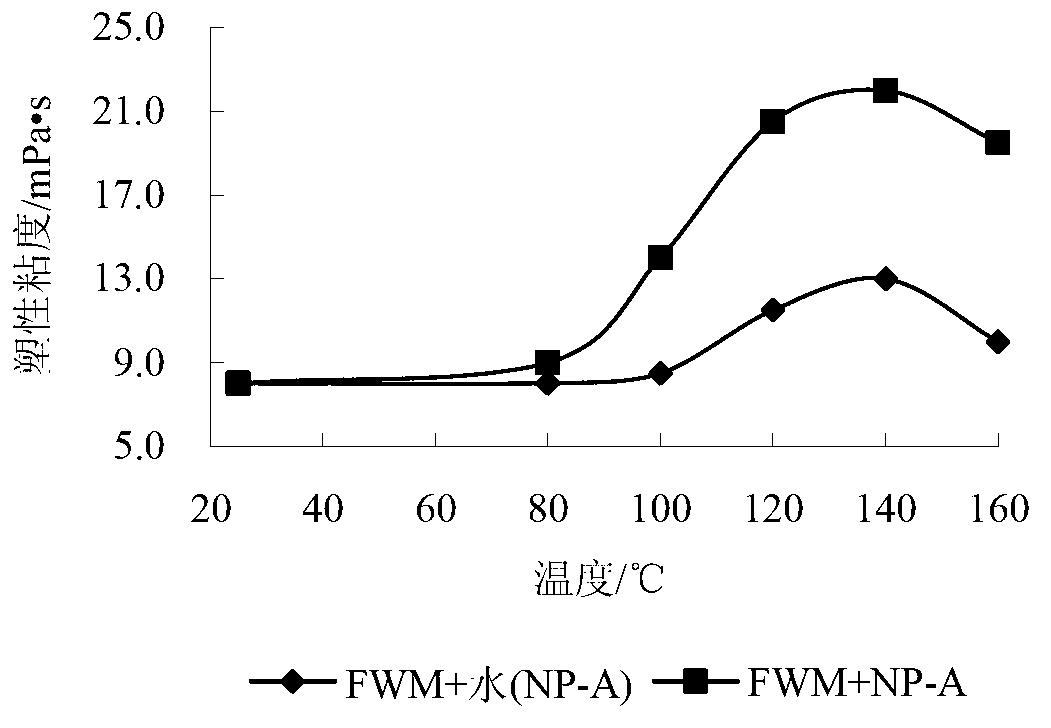

[0057] This embodiment provides a method of using nano-silica to improve the performance of water-based drilling fluid. Nano-silica is added in the base slurry in the form of dispersion liquid, and the mass of nano-silica particles accounts for the 5% of the total mass of the nano-silica dispersion.

[0058] The base pulp used in this example is fresh water mud (FWM for short), and its formula and basic performance parameters are shown in Table 1.

[0059] Table 1 Formula and basic properties of freshwater base pulp (FWM)

[0060]

[0061] The basic performance parameters of the nano-silica dispersion liquid NP-A (abbreviated as NP-A) used in this example are shown in Table 2.

[0062] Table 2 Basic performance parameters of nano-silica dispersion NP-A

[0063] code name Exterior Density / g·cm -3 Average particle size / nm Concentration / % pH NP-A Transparent liquid 1.21 10~20 30 9-11

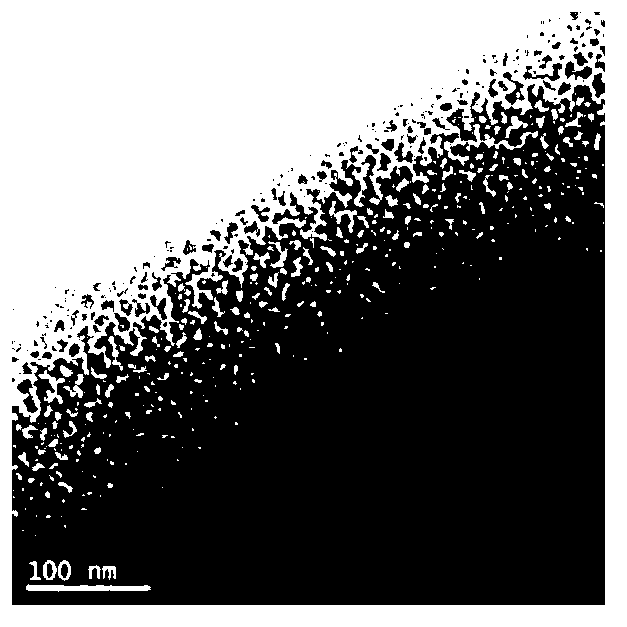

[0064] Using CM12 / STEM transmission electron microsco...

Embodiment 2

[0080] Present embodiment is roughly the same as embodiment 1, and nano-silica adds among the base slurry with the form of dispersion liquid,

[0081] The difference is that the nano-silica dispersion NP-B (abbreviated as NP-B) used in this example is different from Example 1, and its basic performance parameters are shown in Table 4.

[0082]

[0083] Table 4 Basic performance parameters of nano-silica dispersion NP-B

[0084] code name Exterior Density / g·cm -3 Average particle size / nm Concentration / % pH NP-B milky white liquid 1.20 10~20 30 9

[0085] Using CM12 / STEM transmission electron microscope to observe the morphology of nano-silica particles in nano-silica dispersion NP-B, the results are as follows Figure 6 shown.

[0086] Utilize the same method as Example 1 to carry out the test of main performance parameters (Zeta potential, average particle size, plastic viscosity of base slurry, dynamic shear force and fluid loss) to the ...

Embodiment 3

[0090] This example is roughly the same as Example 1, except that the base slurry selected in this example is bentonite mud (abbreviated as BM), and its formula and basic performance parameters are shown in Table 6.

[0091] Table 6 Bentonite base slurry (BM) formula and basic performance parameters

[0092] water / g Sodium bentonite / g Density / g·cm -3 Plastic viscosity / mPa·s Dynamic shear force / Pa Filtration / ml pH 350 30 1.04 9 15 15.5 9

[0093] Utilize the same method as Example 1 to carry out the test of main performance parameters (Zeta potential, average particle size, plastic viscosity of base slurry, dynamic shear force and fluid loss) to the bentonite base slurry after adding nano-silica NP-A, Test results such as Figure 11 , Table 7, Figure 12 to Figure 14 shown. It can be seen from Table 7 that the addition of nano-silica NP-A with a mass concentration of 5% can reduce the average particle size of bentonite base slurry.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com