Carboxyl-modified graphene graft polymer as well as preparation method and application thereof

A technique of grafting polymers and carboxyl modification, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of insufficient temperature and salt resistance, inability to have both temperature and salt resistance, and achieve excellent Salt resistance, excellent fluid loss reduction effect, excellent temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

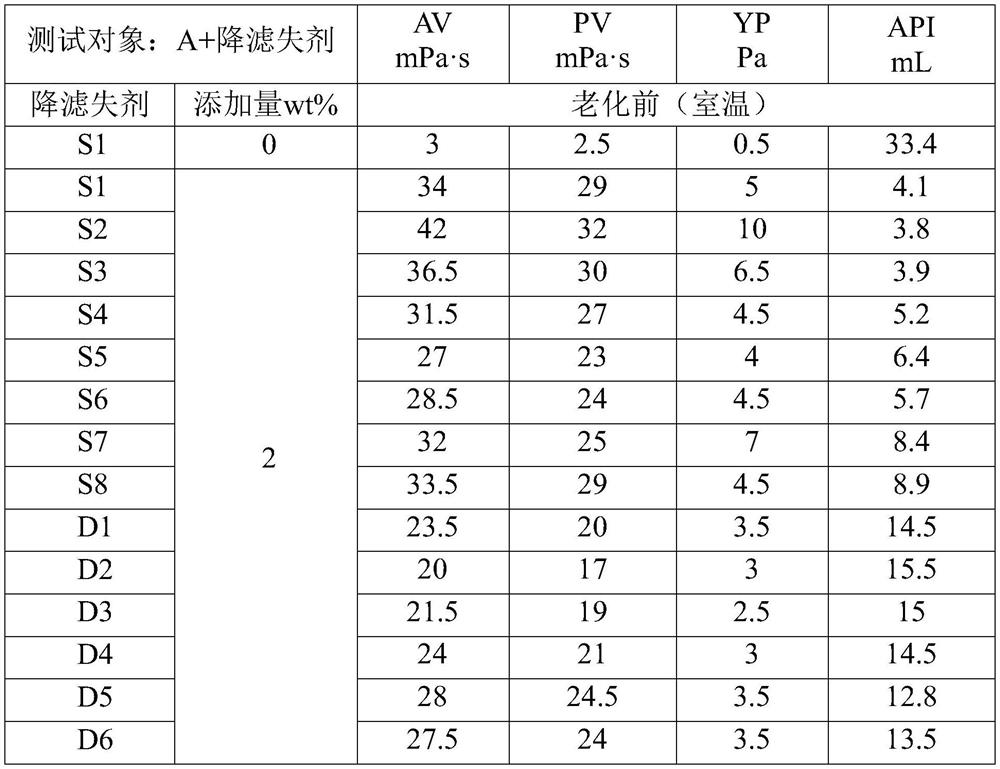

[0024] The first aspect of the present invention provides a kind of preparation method of carboxy-modified graphene graft polymer, and the method comprises:

[0025] (1) dissolving acrylamide, benzenesulfonic acid, and N-vinylpyrrolidone in water, then adding carboxy-modified graphene, and adjusting the pH value of the obtained mixture, adding the first emulsifier to obtain an aqueous phase system; The second emulsifier is dissolved in the oil phase to obtain an oil phase system;

[0026] (2) mixing the water phase system with the oil phase system to obtain an inverse emulsion system;

[0027] (3) adding the first initiator to the inverse emulsion system to carry out the first polymerization reaction to obtain an intermediate product system; adding the second initiator to the described intermediate product system to carry out the second polymerization reaction to obtain a pre-product;

[0028] (4) purifying the pre-product, drying and pulverizing to obtain carboxyl-modified g...

Embodiment 1

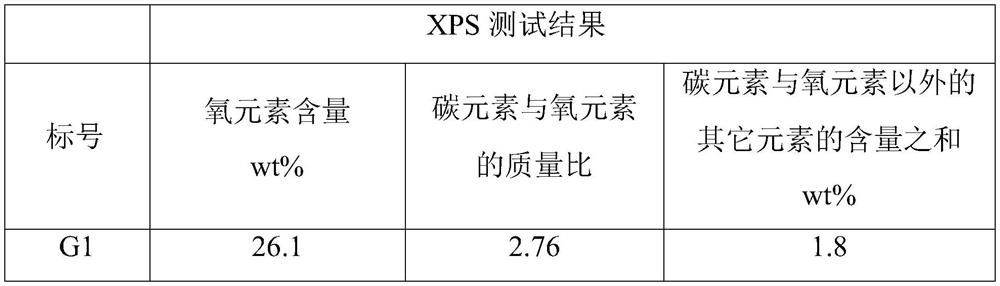

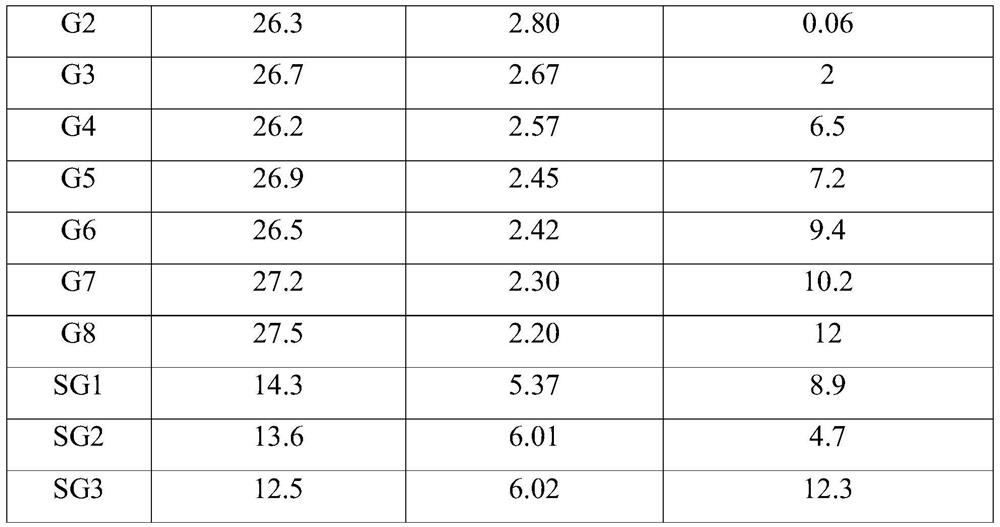

[0062] (1) Dissolve acrylamide, benzenesulfonic acid and N-vinylpyrrolidone (the total monomer concentration is 40wt%) in deionized water with a monomer mass ratio of 2:3:3, and then add the monomer Carboxyl-modified graphene G1 with a mass of 0.5 wt%, adjust the pH value of the obtained mixture to 7 with sodium hydroxide, add Triton X-100 with a monomer mass of 0.35 wt%, to obtain an aqueous phase system; Span 80 Dissolve in liquid paraffin and keep stirring to obtain an oil phase system; wherein, the mass ratio of Triton X-100:Span 80 is 0.11:1, and the volume ratio of water phase system:oil phase system is 1:1 ;

[0063] (2) Add the water phase system dropwise to the oil phase system for mixing, and at the same time use a high-speed shear emulsification mixer to stir at 6000 rpm, the mixing temperature is 25°C, and the mixing time is 0.5h to obtain a uniform and stable inverse emulsion system;

[0064] (3) Put the inverse emulsion system in the reaction bottle, continue t...

Embodiment 2

[0067] (1) Dissolve acrylamide, benzenesulfonic acid and N-vinylpyrrolidone (the total monomer concentration is 40wt%) in deionized water with a monomer mass ratio of 2:3:3, and then add the monomer Carboxyl-modified graphene G2 with a mass of 1 wt%, adjust the pH value of the obtained mixture to 7.5 with sodium hydroxide, add Triton X-100 with a monomer mass of 0.7 wt%, to obtain an aqueous phase system; put Span 80 in Dissolve in liquid paraffin, and continue to stir to obtain an oil phase system; wherein, the mass ratio of Triton X-100:Span 80 is 0.2:1, and the volume ratio of water phase system:oil phase system is 1:1;

[0068] (2) Add the water phase system dropwise to the oil phase system for mixing, and at the same time use a high-speed shear emulsification mixer to stir at 5500 rpm, the mixing temperature is 25°C, and the mixing time is 0.5h to obtain a uniform and stable inverse emulsion system;

[0069] (3) Put the inverse emulsion system in the reaction bottle, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com