Filtrate reducer for drilling fluid and preparation method thereof

A technology of fluid loss reducer and drilling fluid, applied in the field of drilling fluid, can solve problems such as reducing drilling rate and environmental pollution, and achieve the effects of reducing water loss, good water solubility, and improving filtration wall-building properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

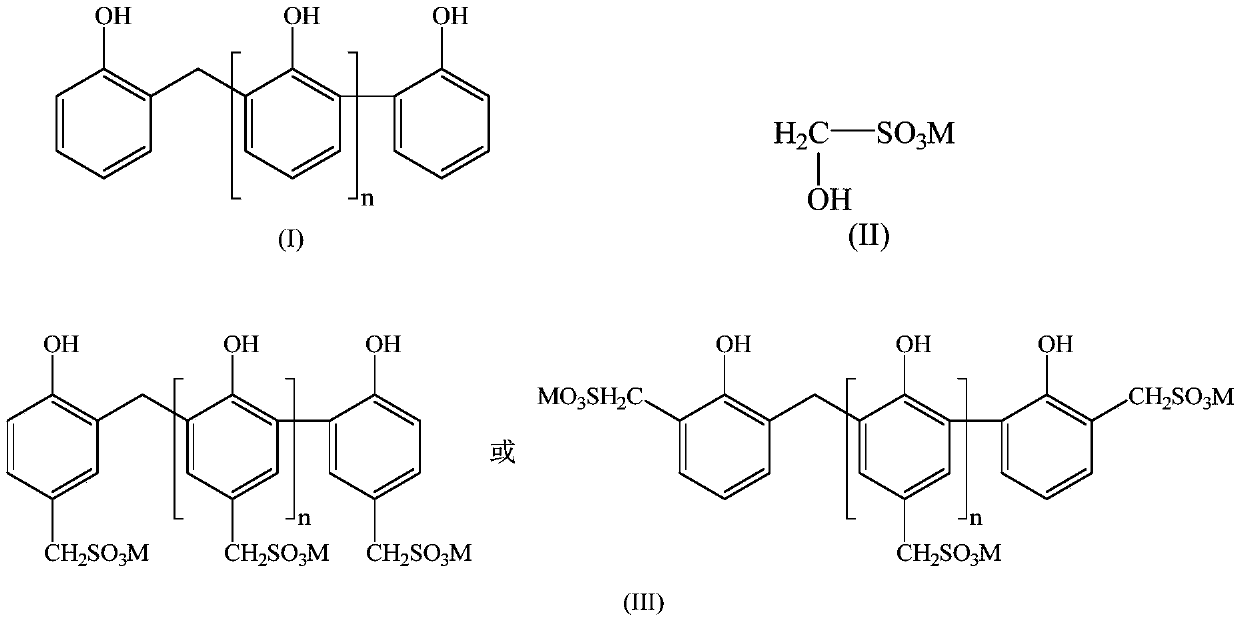

Image

Examples

Embodiment 1

[0038] Embodiment one: synthetic sulfomethyl phenolic resin

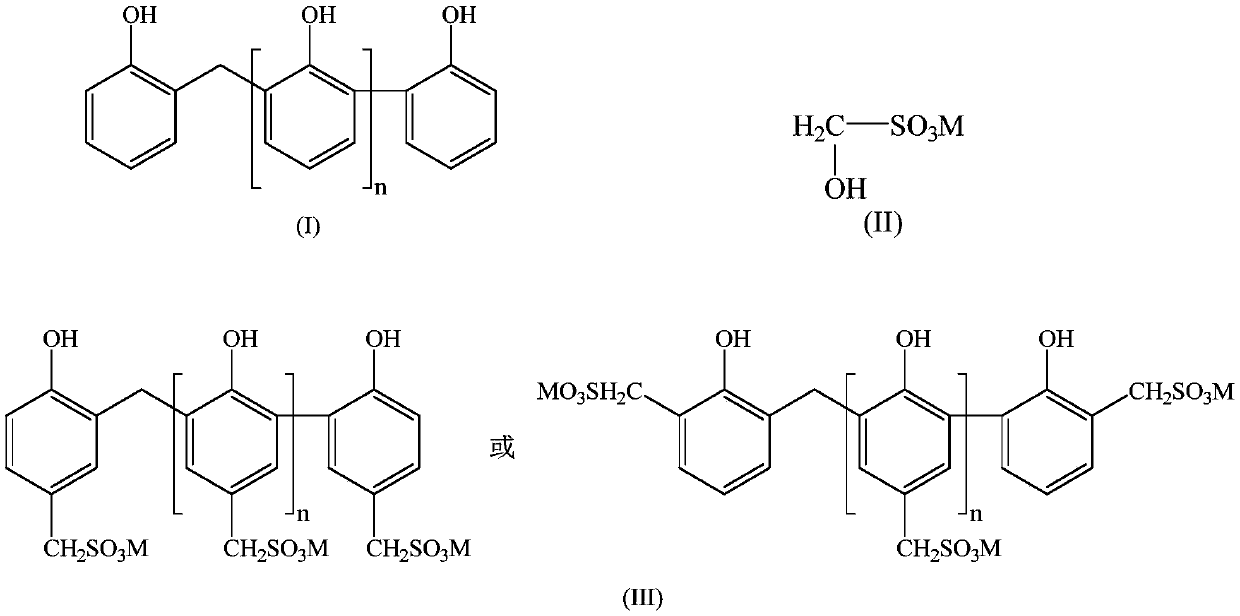

[0039] Linear resinization reaction, the reaction equation is shown in formula (IV) ~ formula (VI):

[0040]

[0041] The specific operation steps are as follows:

[0042] (1) First add 100 parts by mass of industrial phenol to the linear kettle, and then add 25 to 28 parts by mass of industrial formaldehyde under stirring conditions;

[0043](2) Stir for 3-5 minutes, after observing that there is no abnormality (including whether there are situations such as running or leaking), add hydrochloric acid with a concentration of 20% (volume concentration), and the liquid-to-solid ratio of the added hydrochloric acid solution to phenol is 0.8 × 10 -3 ~1.0×10 -3 : 1mL / g;

[0044] (3) After stirring and observing that there is no abnormality, heat up to ensure that the steam pressure is 2 to 3 kg;

[0045] (4) When stirring and heating up to the temperature in the kettle of 70°C, start the cooling water pump to carr...

Embodiment 2

[0052] Embodiment two: Synthesis of sulfomethyl compound

[0053] The sulfomethyl compound is generated by the reaction of formaldehyde with sodium bisulfite or potassium bisulfite, and the chemical reaction formula is shown in formula (VII), wherein M is Na or K:

[0054]

[0055] The specific operation steps are as follows:

[0056] Put 100 parts by mass of water and 155-160 parts by mass of sodium / potassium metabisulfite into the configuration kettle, stir and dissolve for about 30 minutes, stop stirring after the dissolution is uniform, add 29-30 parts by mass of formaldehyde in a static state, and let it stand at room temperature Soak for 30 minutes; then add 42 to 44 parts by mass of formaldehyde to the solution, and let it stand at room temperature for 1 hour; then raise the temperature to about 75°C and carry out a little stirring, and continue to stir evenly after there is no abnormality, and stop stirring when the measured pH value is 6 to 7. Complete the prepara...

Embodiment 3

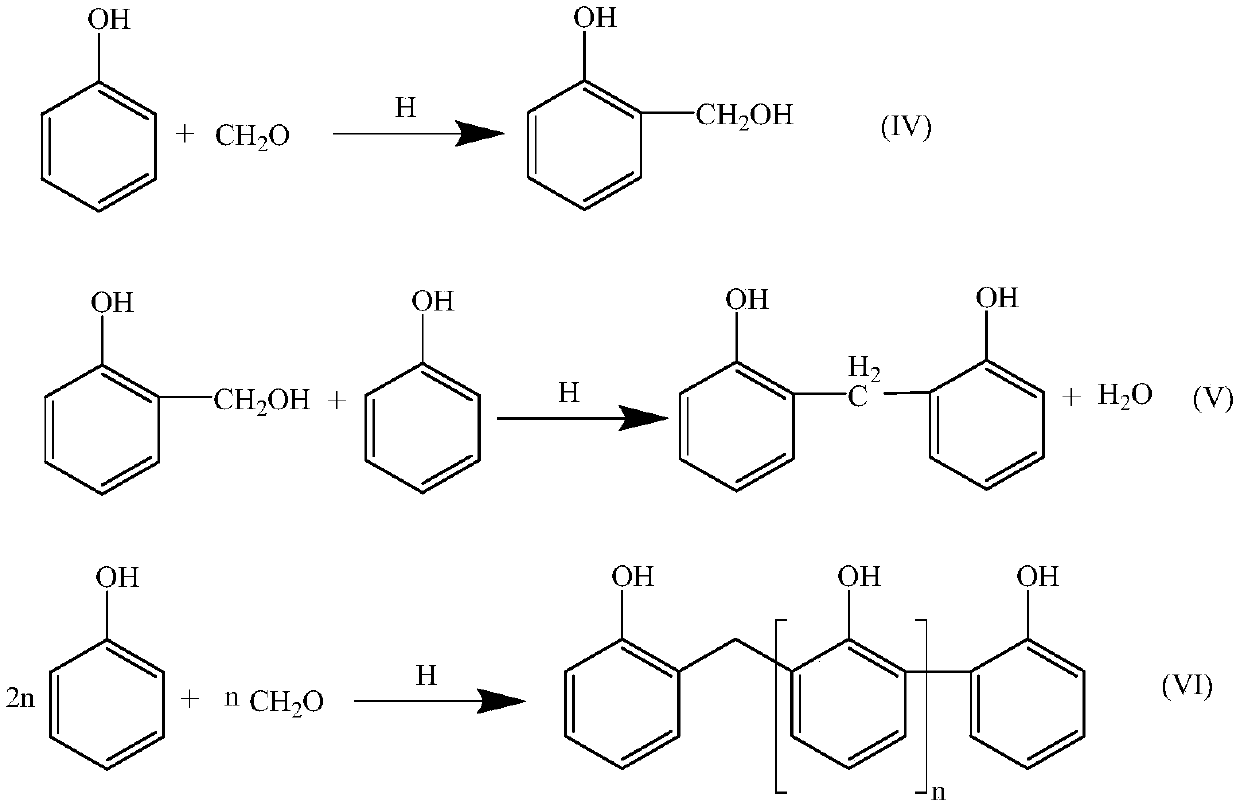

[0057] Embodiment three: synthetic sulfomethyl phenolic resin

[0058] The synthetic reaction formula of sulfomethyl phenolic resin is shown in formula (VIII):

[0059]

[0060] The specific operation steps are as follows:

[0061] 1. The first sulfomethylation reaction

[0062] (1) Novolac resin is transferred to the sulfonation kettle;

[0063] (2) When the amount of material transferred is 1 / 3 to 2 / 3, start the agitator, and add the lye with a concentration of 20% (mass concentration) according to the metered amount to carry out alkali-dissolving treatment, and the lye is sodium hydroxide solution, etc. , the mass ratio of added lye and novolak resin is 0.6~0.7:1;

[0064] (3) After adding lye, add sulfomethyl compound for the first time, the first time the addition of sulfomethyl compound accounts for 34~35% of sulfomethyl compound total amount, open steam heating up simultaneously;

[0065] (4) When the material in the kettle is observed to change from muddy to cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com