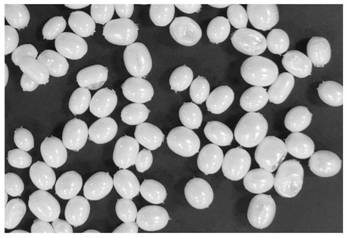

A kind of polyester foam beads and polyester foam beads molded body and preparation method thereof

A technology of foamed beads and moldings, which is applied in the field of polyester foamed beads and polyester foamed beads and their preparation, and can solve the problem of inability to obtain PET foamed beads with complete shapes and damage to PET materials, etc. problem, to achieve the effect of reducing hydrolysis and thermo-oxidative degradation, increasing the transportation radius, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

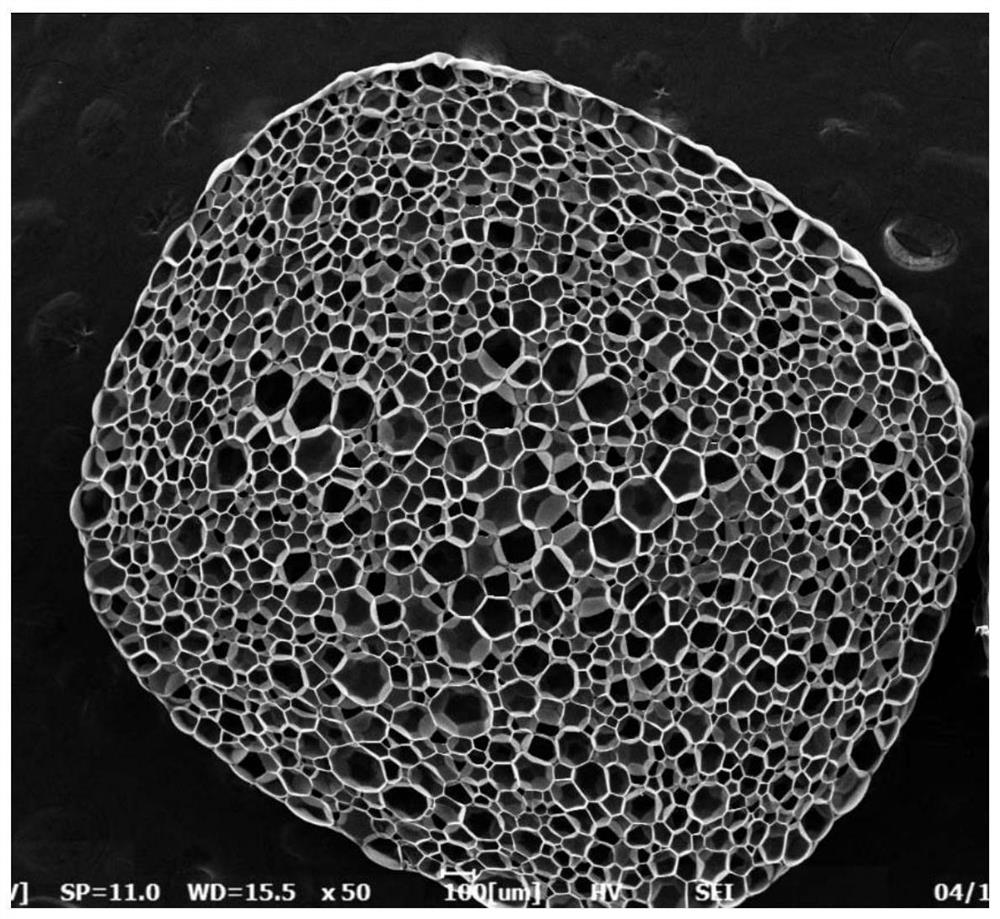

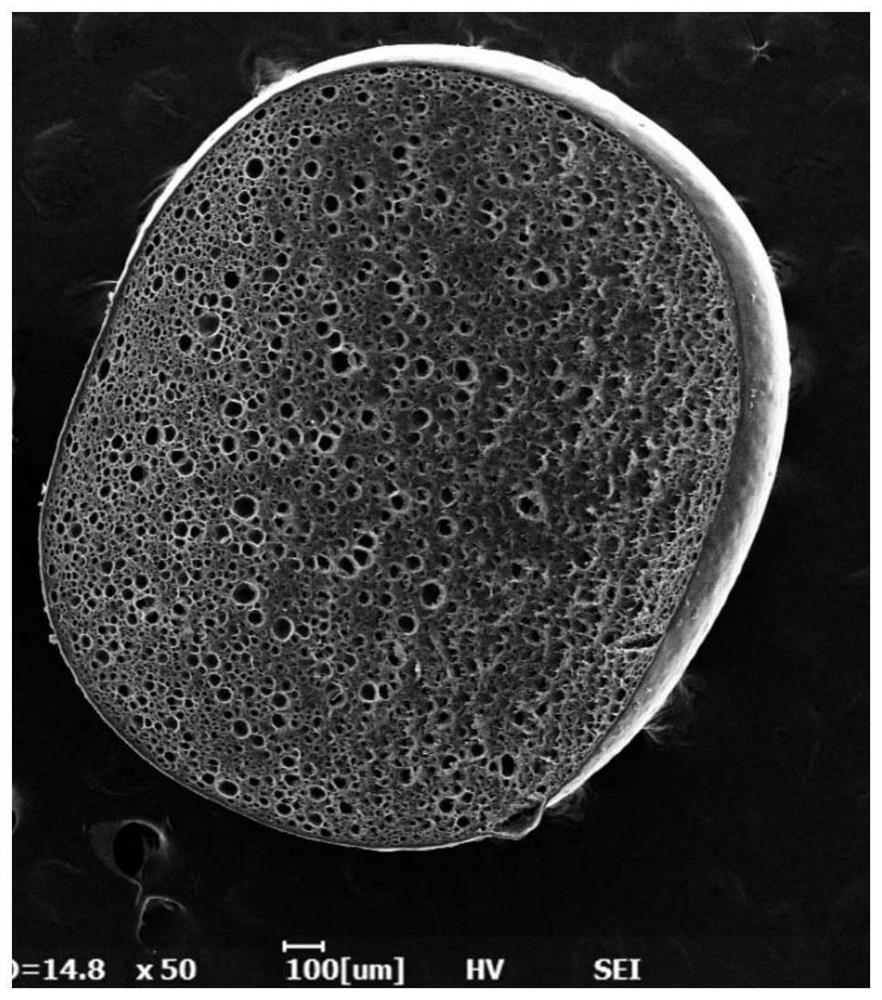

Image

Examples

Embodiment 1

[0053] The preparation method of the polyester foam beads described in this embodiment comprises the following steps:

[0054] S1. 100 parts by weight of PET particles (intrinsic viscosity is 0.9 dl / g) and 0.5 parts by weight of antioxidant are dried, premixed, and continuously extruded and diced by twin-screw to obtain polyester particles;

[0055] S2. Immerse polyester particles in anhydrous high pressure fluid with high pressure CO 2 fluid to obtain impregnated polyester particles with a high-pressure fluid content of 5.0% and a crystallinity of 0%;

[0056] S3. Use liquid nitrogen to quickly freeze the impregnated polyester particles, the temperature of the cooling cavity is minus 60 degrees, and then store the impregnated polyester particles after freezing and air locking in an environment of minus 20 degrees for 1 day to obtain a freezing lock. air-locked polyester particles; the high-pressure fluid content in the frozen air-locked polyester particles is 5.0%, and the m...

Embodiment 2

[0063] The preparation method of the polyester foam beads described in this embodiment comprises the following steps:

[0064] S1. 100 parts by weight of PET particles (intrinsic viscosity is 1.1 dl / g) and 0.5 parts by weight of antioxidant are dried, premixed, and continuously extruded and diced by twin-screw to obtain polyester particles;

[0065] S2. Immerse the polyester microparticles in anhydrous high pressure fluid with high pressure CO 2 fluid to obtain impregnated polyester particles with a high-pressure fluid content of 9.0% and a crystallinity of 5%;

[0066] S3. Use liquid nitrogen to quickly freeze the impregnated polyester particles, the temperature of the cooling cavity is minus 60 degrees, and then store the impregnated polyester particles after freezing and air locking in an environment of minus 20 degrees for 7 days to obtain a freezing lock. Air-locked polyester particles; the high-pressure fluid content in the frozen air-locked polyester particles is 8.2%,...

Embodiment 3

[0073] The preparation method of the polyester foam beads described in this embodiment comprises the following steps:

[0074] S1. 100 parts by weight of PET particles (intrinsic viscosity is 1.2 dl / g) and 0.5 parts by weight of antioxidant are dried, premixed, and continuously extruded and pelletized by twin screws to obtain polyester particles;

[0075] S2. Immerse the polyester microparticles in anhydrous high pressure fluid with high pressure CO 2 fluid to obtain impregnated polyester particles with a high-pressure fluid content of 5.0% and a crystallinity of 15%;

[0076] S3. Use liquid nitrogen to quickly freeze the impregnated polyester particles, the temperature of the cooling cavity is minus 60 degrees, and then store the impregnated polyester particles after freezing and air-locking in an environment of minus 20 degrees for 15 days to obtain a freezer lock. Air-locked polyester particles; the high-pressure fluid content in the frozen air-locked polyester particles is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com