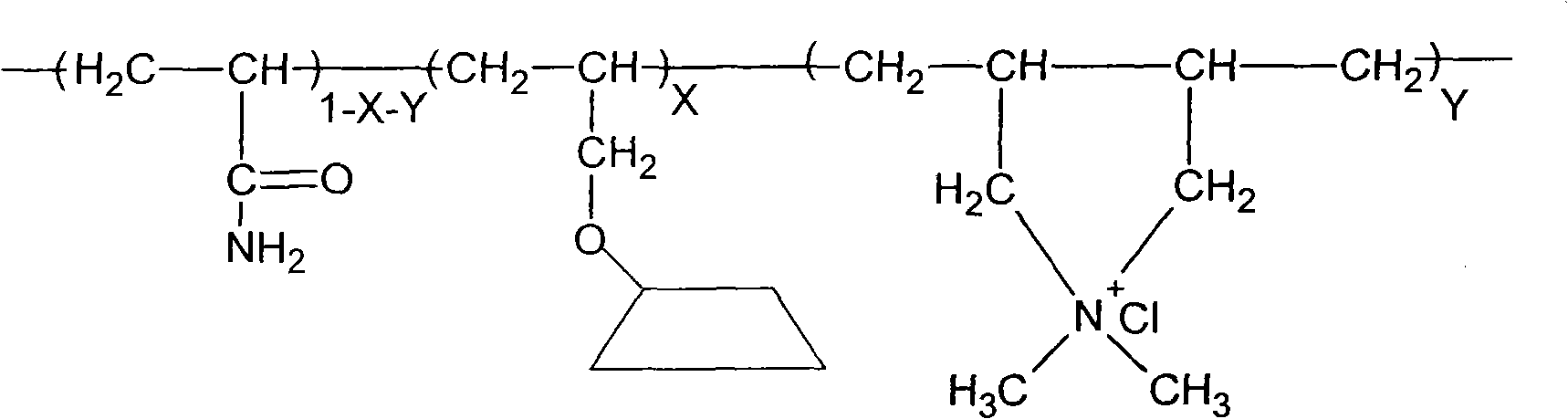

AM (Acrylamide)/DMDAAC (Dimethyl Diallyl Ammonium Chloride)/cyclodextrin polymer filtrate reducer and preparation method thereof

A technology of cyclodextrin polymer and fluid loss reducer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased water loss and instability of the well wall, and achieves mild reaction conditions and excellent water loss reduction. Filtration effect, the effect of simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1A

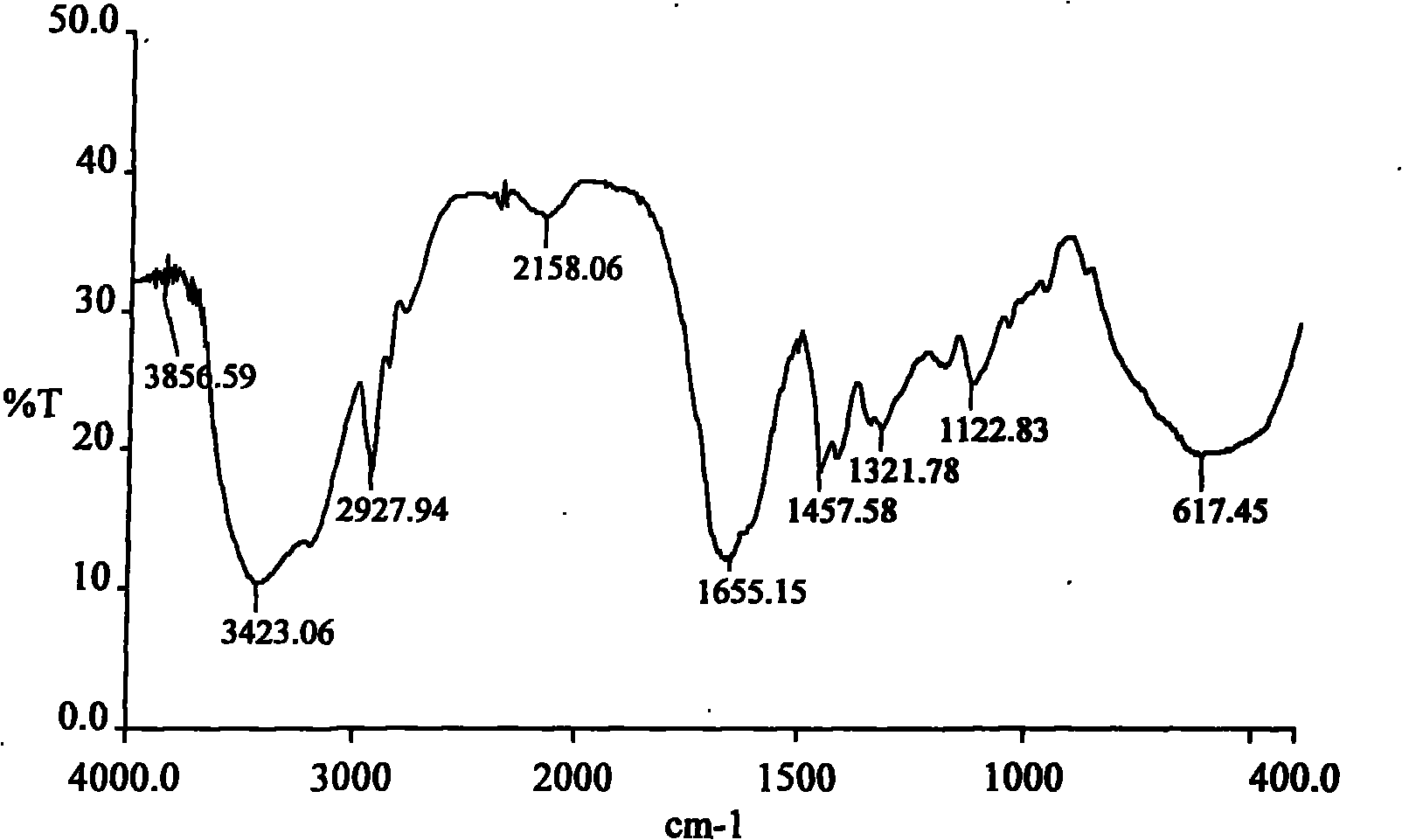

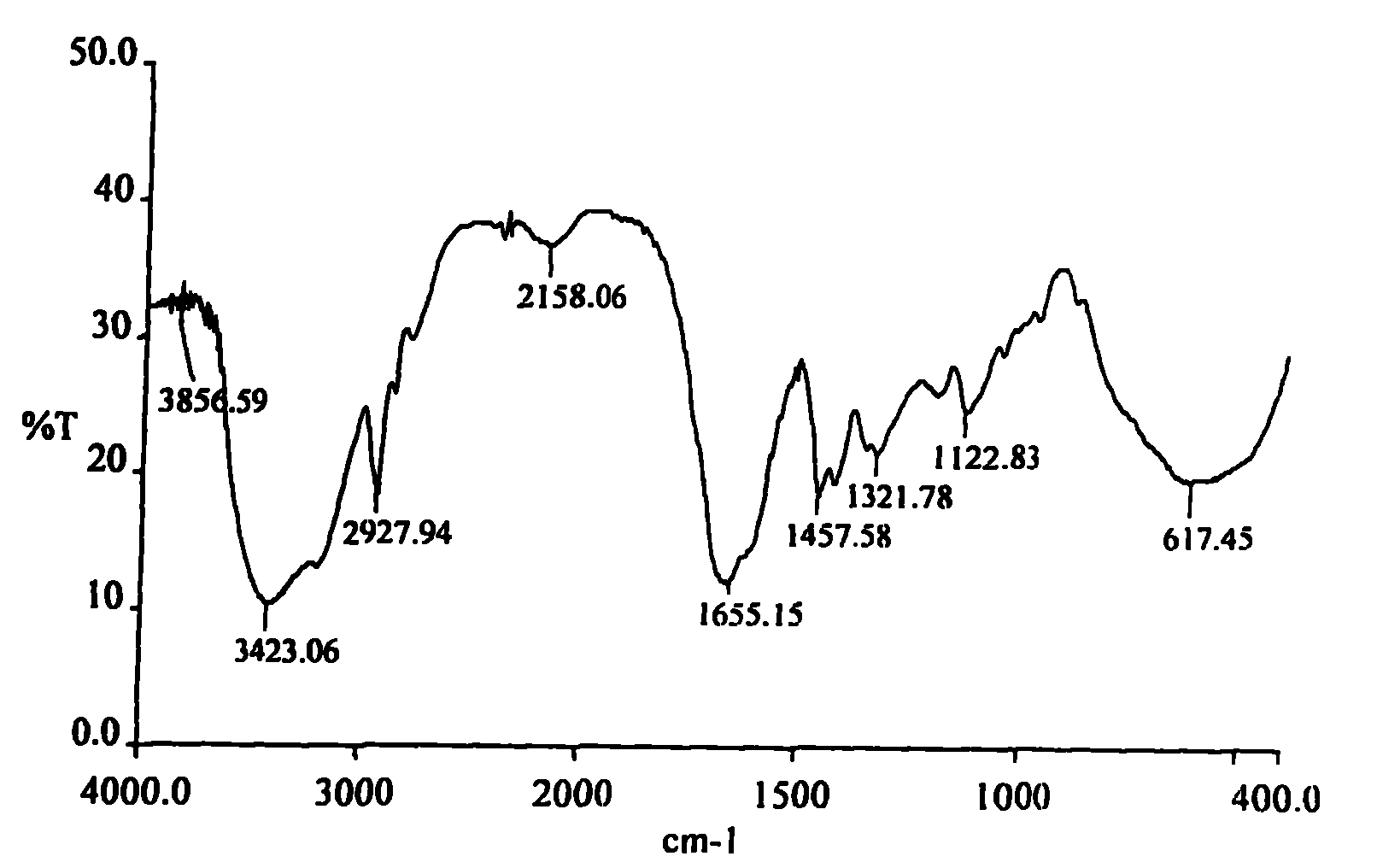

[0013] The preparation method of example 1AM / DMDAAC / cyclodextrin polymer fluid loss reducer

[0014] Add 50 mL of the prepared aqueous solution of 0.01 g / mL allyl cyclodextrin into a 150 mL beaker, then add 7 mL of the aqueous solution of 0.5 g / mL acrylamide (AM) and 0.5 g / mL of dimethyl dimethicone Allyl ammonium chloride (DMDAAC) aqueous solution 3mL. Then add 1 mL of disodium ethylenediaminetetraacetic acid (EDTA) chelating agent with a concentration of 0.5 g / mL, 1 mL of potassium persulfate oxidant with a concentration of 0.5 g / mL and sodium bisulfite reducing agent with a concentration of 0.5 g / mL. mL. Fully stir and mix evenly on a magnetic stirrer, then fill with nitrogen for 40 minutes to remove oxygen, and react at 45°C for 7 hours to obtain a transparent colloidal AM / DMDAAC / cyclodextrin polymer.

[0015] Measure the intrinsic viscosity of AM / DMDAAC / cyclodextrin polymer according to the standard described in GB12005.1-89, and then measure the molecular weight of the...

example 2A

[0016] The fluid loss effect of example 2AM / DMDAAC / cyclodextrin polymer

[0017] In order to evaluate the fluid loss reduction effect of AM / DMDAAC / cyclodextrin polymer at higher temperature, the base slurry was prepared according to the national standard GB / T16783-1997. That is, add 0.6g of anhydrous sodium carbonate, 12g of bentonite and 9g of evaluation soil to 300mL of ion-free water stirred at high speed, continue to stir for 30 minutes, and then keep it sealed for 24 hours to obtain a freshwater base slurry. Similarly, add 0.9g of anhydrous sodium carbonate, 18g of bentonite, 30g of evaluative clay and 90g of sodium chloride into 300mL of deionized water stirred at high speed, continue to stir for 30min, and then keep it sealed for 24h to obtain a saturated saline base slurry.

[0018] Table 1 shows the fluid loss control effect of AM / DMDAAC / cyclodextrin polymer. It can be seen from Table 1 that the polymer of the present invention has good temperature resistance, salt r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com